3M ESPE

3M Pentamix Lite Operating Instructions Sept 2019

Operating Instructions

90 Pages

Preview

Page 1

UMSCHLAG AUSSEN - 627 x 297 mm - 3100016478/01 - CYAN • MAGENTA • GELB • SCHWARZ - 19-187 (kn)

Pentamix Lite

en de fr it es pt nl el sv fi da no ko zh th

3M, ESPE, Penta and Pentamix are trademarks of 3M or 3M Deutschland GmbH. Used under license in Canada. © 2019, 3M. All rights reserved. 3M, ESPE, Penta et Pentamix sont des marques de commerce de 3M ou 3M Deutschland GmbH. Utilisées sous licence au Canada. © 2019, 3M. Tous droits réservés

3100016478/01

3M Deutschland GmbH Health Care Business Carl-Schurz-Str. 1 41453 Neuss - Germany

Automatic Mixing Unit Automatisches Mischgerät Mélangeur automatique Mescolatore automatico Mezcladora automática de materiales de impresión Misturador automático Automatisch mengapparaat Συσκευή αυτόµατης ανάµιξης Automatisk blandningsapparat Automaattinen sekoituslaite Automatisk blandeapparat Automatisk blandeapparat 자동 믹스 유니트

เครื่องผสมวัสดุพิมพ์ปากอัตโนมัต

Operating Instructions Betriebsanleitung Mode d’emploi Istruzioni per l’uso Instrucciones de uso Manual de instruções Bedieningshandleiding Οδηγίες χρήσεως

Driftsanvisning Käyttöohjeet Betjeningsvejledning Driftsveiledning 사용설명서

ข้อแนะนำในการใช้งาน

쏴쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿

™

™

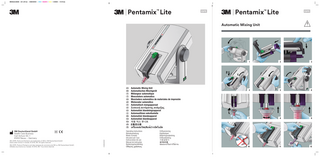

Pentamix Lite Automatic Mixing Unit

1

2

3

4

5

6

7

8

9

10

11

12

UMSCHLAG INNEN - 627 x 297 mm - 3100016478/01 - CYAN • MAGENTA • GELB • SCHWARZ - 19-187 (kn)

3M Deutschland GmbH Health Care Business Carl-Schurz-Str. 1 41453 Neuss - Germany 3M, ESPE, Penta and Pentamix are trademarks of 3M or 3M Deutschland GmbH. Used under license in Canada. © 2019, 3M. All rights reserved. 3M, ESPE, Penta et Pentamix sont des marques de commerce de 3M ou 3M Deutschland GmbH. Utilisées sous licence au Canada. © 2019, 3M. Tous droits réservés

ENGLISH

DEUTSCH

FRANÇAIS

ITALIANO

it

ESPAÑOL

es

Automatic Mixing Unit Operating Instructions

Automatisches Mischgerät Betriebsanleitung

Mélangeur automatique Mode d’emploi

Mescolatore automatico Istruzioni per l’uso Mezcladora automática de materiales de impresión

PORTUGUÊS

Misturador automático

NEDERLANDS

Instrucciones de uso

Automatisch mengapparaat

ΕΛΛΗΝΙΚΑ

pt

Συσκευή αυτόµατης ανάµιξης

nl

el

SVENSKA

sv

fi SUOMI

21

fr

da DANSK

20

18

de

no NORSK

19

17

15

Pentamix™ Lite

ko

Manual de instruções

Bedieningshandleiding

Οδηγίες χρήσεως

Automatisk blandningsapparat Driftsanvisning

Automaattinen sekoituslaite Käyttöohjeet

Automatisk blandeapparat Betjeningsvejledning

Automatisk blandeapparat Driftsveiledning

자동 믹스 유니트 사용설명서

zh

th

ภาษาไทย

16

14

쏴쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿쏿

13

en

เครื่องผสมวัสดุพิมพ์ปากอัตโนมัต ข้อแนะนำในการใช้งาน

Seite 5 - 210 x 297 mm - 3100016478/01 - SCHWARZ - 19-187 (kn)

ENGLISH

en

1. Safety Instructions

en ENGLISH

Pentamix Lite

ATTENTION! Read these Operating Instructions carefully before plugging in and operating the unit! As with all technical units, the trouble-free function and safe operation of this unit can be assured only if standard safety procedures and the special safety instructions in these Operating Instructions are observed.

Automatic Mixing Unit Operating Instructions

3M Deutschland GmbH guarantees trouble-free operation of the Pentamix system only if 3M system components are used exclusively.

™

1. The unit may be used only in strict accordance with the following instructions. We accept no liability for any damage arising from any other or improper use of this unit. 2. If the unit is moved from a cold into a warm environment, condensation can result in a hazardous situation. Never begin operating the unit until it has reached the ambient temperature. 3. The power plug must be connected to a suitably grounded socket before the unit is operated. If an extension cable is used, make sure that it also provides a ground wire. 4. Position the unit so that the power plug is accessible at all times. 5. The unit must be placed on a non-slip, level surface to insure stable placement. 6. Always turn off the unit and disconnect the plug from the power source before changing the plunger discs. 7. When changing the plunger discs, position the smooth side of the new discs towards the foil bag (the opposite side of the discs with the fan-shaped depressions must face away). Otherwise, the foil bag might be damaged.

Table of Contents

8. To avoid electrical shock, do not insert any objects into the unit. Page

1. Safety Instructions

5

2. Product Description

5

3. Technical Data

6

4. Installation

6

5. Operation 6 5.1 Swiveling the Unit into Working Position 6 5.2 Loading the Cartridge 6 5.3 Inserting the Cartridge 6 5.4 Attaching the Mixing Tip 6 5.5 Starting a New Cartridge 6 5.6 Loading the Impression Tray and Penta Elastomer Syringe 6 5.7 Removing the Cartridge 7 5.8 Re-starting a Partly Empty Cartridge 7 5.9 Replacing a Cartridge 7 5.10 Storage of Partially Used Cartridges 7 5.11 Fill Level Gauge 7 5.12 Parking the Unit 7 5.13 Transporting the Unit 7 5.14 Disposal of Consumable Materials 7 5.15 Return of Old Electric and Electronic Equipment for Disposal 7 5.16 Notes 7 6. Malfunctions and Error Messages

8

7. Maintenance and Care 7.1 Replacement of the Plunger Discs 7.2 Care 7.3 Maintenance and Repair

8 8 8 8

8. Customer Information 8.1 Warranty 8.2 Limitation of Liability

8 8 8

Symbol Glossary

9

9. Use only genuine 3M parts when replacing defective components as directed in these Operating Instructions. We assume no liability for any damage caused by the use of non-3M parts. 10. If, for any reason, it is possible that the safety of a unit has been compromised, that unit must be removed from operation and identified in such a way that it is not inadvertently operated again by a third party. Safety may have been compromised, for example, if the unit does not work as specified or is visibly damaged. 11. Keep solvents, flammable liquids, and powerful heat sources away from the unit as they may damage the plastic housing. 12. Do not allow any cleaning agents to enter the unit during cleaning as they could cause an electrical short or a dangerous malfunction. 13. Only a properly trained, authorized technician may open the unit housing and repair the unit. Please report a serious incident occurring in relation to the device to 3M and the local competent authority (EU) or local regulatory authority.

2. Product Description Pentamix™ Lite is an automatic mixing unit for the preparation of Penta™ impression materials. 3M Penta impression materials have been specifically designed for this unit and are supplied in special foil bags. This is the only form of packaging which can be used in the Pentamix Lite units. Every Penta™ foil bag is sealed with a PentaMatic sealing cap. The external geometry of the sealing cap insures its proper positioning on the cartridge. When the Pentamix unit is turned on, a special internal device opens the foil bag automatically once sufficient pressure has been built up by the plunger. The connection pieces located on the PentaMatic sealing caps serve for proper attachment of the mixing tip. The cartridges and the PentaMatic sealing caps act together as a stable unit for the preparation of pastes in the Pentamix unit and allow a change of products without intermediate cleaning of the device and

5

Seite 6 - 210 x 297 mm - 3100016478/01 - SCHWARZ - 19-187 (kn)

with no loss of paste. Do not operate the Pentamix Lite unit using any elements other than Penta™ cartridges for Pentamix Lite and Penta™ Mixing Tips - Red.

왘 With one hand, slowly tip the mixing apparatus of the Pentamix Lite

Thanks to the integrated swivel mechanism and carrying handle, the Pentamix Lite mixing unit can be folded into a compact bundle for simple transport.

왘 Do not push the unit beyond the final position as this could lead to

These Instructions for Use should be kept for the duration of product use. The product may only be used when the product labeling is clearly readable. For details on all additionally mentioned products please refer to the corresponding Instructions for Use.

5.2 Loading the Cartridge

Intended Purpose Intended users: educated dental professionals, e.g. general dentists, dental assistants, dental hygienists, who have theoretical and practical knowledge on usage of dental products.

mixing unit forward from the horizontal park position until it audibly snaps into the working position (Fig.1). technical problems.

Please carry out the steps in the following sequence exactly. 왘 Have ready one foil bag of base paste and one of catalyst paste as

well as a matching 3M Penta cartridge for Pentamix Lite. 왘 Insert the foil bags into the unlocked cartridge (Fig. 2). 왘 The locating lugs make sure they are correctly seated. 왘 Press down on the cartridge locking lever (Fig. 3) until it audibly clicks

into place.

3. Technical Data

5.3 Inserting the Cartridge

Operating mode:

Short term operation - max.1.5 min. on, min.10 min. off

왘 Take the cartridge in your left hand.

Cartridges:

Suitable for use with Penta foil bags Dimensions: 60 x 130 mm, 26.8 x 130 mm

Housing:

All parts of the housing are made of impactresistant plastic

Power supply: Frequency: Power input:

100-120 V / 230 V (see rating plate) 60 Hz / 50 Hz (see rating plate) 2.5 A / 1.5 A

왘 Turn the plunger adjustment knob clockwise with your right hand until

it stops and hold it in place. The plungers are now in the uppermost position. 왘 Place the cartridge into the unit. 왘 Rotate the plunger adjustment knob anticlockwise until the plungers

markedly touch the foil bags (Fig. 5).

Ambient temperatures: 18° C/64° F... 40° C/104° F

!

Rel. humidity:

20%...80%

왘 Attach a mixing tip prior to begin mixing (see Section 5.4).

Classification:

Hazard Class I

Dimensions:

L 395 mm x W 265 mm x H 305 mm

Weight:

approx. 6.7 kg

Storage and transport: -20° C to +60° C/-4° F to 140° F Maximum rel. humidity 80%. Emission sound pressure level:

approx. 65 dB(A).

4. Installation

! !

Prior to installing the unit, make sure the power supply corresponds to the supply quoted on the rating plate of the unit. In order to work with the unit, the power plug must be connected into a suitably grounded socket. In case of using an extension cable, make sure that the ground line is not interrupted.

쐌 Pentamix Lite can be placed on any non-skid flat surface.The unit is

ready for operation as soon as the power cable has been plugged into an electrical outlet and the power switch has been turned on. 쐌 The Pentamix Lite mixing unit can be permanently left in operational

mode. Power consumption in the standby mode is extremely low (<1 W).

5. Operation

The unit cannot be activated until the plungers touch the foil bags.

5.4 Attaching the Mixing Tip. Always Attach a Mixing Tip Before Use! Foil bags equipped with a PentaMatic sealing cap may be used exclusively with 3M Penta mixing tips. 왘 Release the lock (Fig. 6). 왘 First, place the mixing tip only on the tip of the mixing shaft (Fig. 7).

Turn slightly to align the mixing tip with the corresponding outflow openings of the foil bags (Fig. 8). Attach the mixing tip and press down firmly to insure that the mixing tip is seated tightly on the outflow openings (Fig. 9). 왘 Press the locking lever down until it audibly clicks into place (Fig.10).

5.5 Starting a New Cartridge 왘 Press the green “Start” button on the cartridge (Fig.11). 왘 When a new pair of foil bags is started, you must wait 15-25 sec.

until pressure has built up in the cartridge; the foil bags will then open automatically. Once the bags are open, one of the two pastes, which are of different colors, may flow out first, producing an uneven mixture. For this reason, observe the flow of the two pastes, discard any uneven mixture, and do not apply the paste until the mixture shows a homogeneous color (Fig.12). 왘 After mixing, leave the mixing tip on the cartridge as a seal!

5.6 Loading the Impression Tray and Penta Elastomer Syringe 왘 Press the green “Start” button on the cartridge.

5.1 Swiveling the Unit into Working Position

! 6

Safe and correct operation of the Pentamix Lite is assured only when it is in working position. When swiveling the unit, use caution to avoid the possibility of injury from jamming or crushing your fingers.

Please note: A few seconds pass before the paste becomes visible in the mixing tip. The unit only functions as long as the “Start” button is held down. As soon as the button is released, the paste does not flow any more.

Seite 7 - 210 x 297 mm - 3100016478/01 - SCHWARZ - 19-187 (kn)

When the “Start” button is released, the Pentamix Lite unit automatically relieves the tension on the foil bags by withdrawing the plungers, which is indicated audibly by the sound of the drive motor.

When the foil bags are completely empty, the red fill gauge marker disappears, and the unit shuts off automatically.

왘 Tilt the tray to load it. Fill the tray bottom continually from one end

5.12 Parking the Unit

to the other, keeping the opening of the mixing tip immersed in the impression material (Fig.13). If necessary, smooth the impression material with a spatula. A mixing tip may only be used as long as the mixing shaft inside the mixer rotates smoothly. If the mixing procedure is interrupted for more than 30 sec, the material inside the mixing tip begins to harden and a new mixing tip must be assembled (refer to 5.4 “Attaching the Mixing Tip”). If the mixer is operated while containing hardened material, the catalyst nipple of the sealing cap can be damaged or may break away. 왘 Put the Penta Elastomer Syringe (after removing the plunger) with its

rear opening directly onto the mixing tip and press the “Start” button (Fig.14).

!

CAUTION: Not all Penta impression materials can be syringed. Please refer to the instructions for use of the respective product.

왘 Cleaning the Penta Elastomer Syringe

Please refer to the pertinent Instructions for Use for information about cleaning and disinfecting the Penta Elastomer Syringe.

5.7 Removing the Cartridge

!

Do not press the “Start” button while removing the cartridge!

왘 Turn the plunger adjustment knob anticlockwise with your right hand

until it stops and hold it in place. The plungers are now in the uppermost position. 왘 Using your left hand, remove the cartridge from the device (Fig.15).

5.8 Re-starting a Partly Empty Cartridge 왘 After prolonged storage (especially for silicones), use an instrument to

remove any plugs that may have formed from the outflow openings of the foil bags. 왘 It may be necessary to start the unit without a mixer to check the

paste flow.

ENGLISH

en

The Pentamix Lite unit can easily be folded into a compact park position when its operation is temporarily not required.

!

When swiveling the unit, use caution to avoid the possibility of injury from jamming or crushing your fingers.

왘 Before tipping the mixing apparatus of the unit containing a cartridge,

always be sure that the plunger discs are in the cartridge and that the mixing tip which has been used is still in place. The cartridge may otherwise fall out of the unit and be damaged. 왘 With one hand, slowly tip the mixing apparatus of the Pentamix Lite

mixing unit backward from the working position until it audibly snaps into the park position (Fig.18). 왘 Do not push the unit beyond the final position as this could lead to

technical problems.

5.13 Transporting the Unit When in the park position, the Pentamix Lite unit can be easily transported and stored.

!

When transporting the unit, use caution to avoid the possibility of injury from jamming or crushing your fingers.

왘 Move the unit into the park position before transport; see 5.12. 왘 Turn off the power switch on the Pentamix Lite unit and remove the

power cable from the unit. 왘 Grasp the unit from the side with one hand (Fig. 20) and carry it using

the carrying handle in the housing (Fig.19).

5.14 Disposal of Consumable Materials Dispose of used mixing tips and empty foil bags in residual waste. Be sure to comply with local waste disposal regulations. The used-off-packaging of the Penta base paste is subject to the EU Waste Electrical and Electronic Equipment Directive (WEEE) and must be collected and disposed in the EU separately from other waste in accordance with the local regulations for electric or electronic waste.

왘 Attach a new mixer and start the mixing procedure.

5.9 Replacing a Cartridge If a cartridge is nearly empty, we recommend that you have a second cartridge ready for use at hand so that you will be able to replace the exhausted cartridge quickly. This cartridge should be prepared as described under 5.5 “Starting a New Cartridge”. Do not forget to move the plungers into contact with the bags! Lifetime of the mixing tip: see 5.6.

5.10 Storage of Partially Used Cartridges 왘 Foil bags which have been started and partially emptied must be

stored only in the cartridge and with attached and filled mixer. 왘 Store any cartridges with partially used foil bags either horizontally

or with the mixers pointing down (Fig.16). If stored improperly, the impression material may flow backwards, which would prolong the restarting time or cause the base and catalyst pastes to mix. 왘 When there is a partially used cartridge in the unit and it is in park

position, the plunger discs hold the foil bags in the cartridge. It is not necessary to remove the cartridge before parking the unit.

5.15 Return of Old Electric and Electronic Equipment for Disposal 1. Collection Users of electric and electronic equipment are required to collect their old equipment separately from other waste in accordance with the regulations of the specific country. Old electric and electronic equipment must not be disposed of with unsorted household waste. This separate collection is a prerequisite for recycling and reprocessing as an important method for preserving environmental resources. 2. Return and Collection Systems When your Pentamix Lite is no longer usable, do not dispose of the device with household waste. 3M Deutschland GmbH has set up special disposal facilities to handle the equipment. Details about the procedure for the specific country can be obtained from the pertinent 3M subsidiary.

5.16 Notes Before using the foil bag, record the batch data printed on the bag (batch code, use-by date, 14-digit GTIN) for the office’s own documentation or for questions to the manufacturer and archive the data so that they can later be accessed at any time.

5.11 Fill Level Gauge

Penta Mixing Tips - Red are single-use devices and would be damaged when removing set impression material.

The fill level gauge shows how much material remains in the foil bags (Fig.17).

Please keep the single-use accessory in the original bag to guarantee the traceability of the batch.

7

Seite 8 - 210 x 297 mm - 3100016478/01 - SCHWARZ - 19-187 (kn)

6. Malfunctions and Error Messages Malfunction

Cause

Remedy

The unit does not start

The plungers are either fully advanced or retracted

Turn the plunger adjustment knob to move the plungers from their upper or lower limit

Material has set in the mixing tip

Attach a new mixing tip

The plungers are jammed

Turn the plunger adjustment knob to check for smooth movement

The pastes are too cold, or sealing cap of the base paste is defective

Allow the pastes to attain room temperature (at least 18° C). Replace defective foil bag

The paste is extruded The drive shaft has but the rotor in the tip not engaged the does not rotate mixing tip, it is stuck in its top position

Remove the mixing tip. Turn the plungers several times up to their upper limit, thus regaining axial moveability. Attach new mixing tip

Unit starts, but no paste is extruded

The paste flows too slowly or not at all

The cartridge will not fit into the unit

The plungers are not fully retracted

Turn the plungers up to their limit by turning the adjustment knob clockwise and arresting it. Check the plunger discs for damage

The cartridge receptacle is dirty

Clean the cartridge receptacle

The unit does not switch off

The “Start” button is stuck

Press the “Start” button again or unplug the unit and release the “Start” button

The plungers are difficult to retract

Foil of a bag is wedged between the cartridge and the plunger

Retract plunger against the resistance, but avoid damage of plunger discs

7. Maintenance and Care 7.1 Replacement of the Plunger Discs If damaged, the plunger discs must be replaced. Only original parts may be used as replacements to insure safe operation. 왘 Turn off the unit and disconnect the plug from the power source. Use

an Allen wrench to remove the screw in the center of the plunger disc. Remove the disc and screw a new one into place (Fig. 21). When changing the plunger discs, make sure you position them with the correct alignment (see Fig. 21) to prevent damage to the foil bags.

8

7.2 Care Clean all components with a soft cloth and, if necessary, a mild cleaning agent (e.g., dish-washing detergent). Solvents or abrasive cleaners may not be used in any case, as they can damage the plastic components! - Cleaning agents must not enter the unit! To disinfect all components, spray the disinfectant on a towel and use it to disinfect the unit. Do not spray the disinfectant directly on the device. - Disinfectant agents must not enter the unit! - Dry residual disinfectants on the device with a soft and fluff-free cloth, as they damage the plastic components. If necessary, ask the manufacturer of the disinfectant if its constant use will damage plastic surfaces.

7.3 Maintenance and Repair No components inside the unit require servicing or repair by the user. 3M Deutschland GmbH will accept responsibility for the safety, reliability, and correct function of the unit only if: - Any modifications or repairs are carried out only by personnel authorized to do so by 3M Deutschland GmbH; - The electrical fittings in the room comply with all regulatory requirements; - The unit is operated according to these Operating Instructions. Plastic cartridges are subject to wear depending on the material and frequency of use and are therefore not covered by the warranty for this unit. They should be regularly checked for signs of wear (e.g., fissures) and replaced with new Penta cartridges for Pentamix Lite two years after initial operation at the very latest. The use of worn or defective cartridges can have adverse effects on the evenness of the mixture, reducing the quality of the impression.

8. Customer Information No person is authorized to provide any information that deviates from the information provided in this instruction sheet.

8.1 Warranty 3M Deutschland GmbH warrants this product to be free from defects in material and manufacture. 3M Deutschland GmbH MAKES NO OTHER WARRANTIES, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. User is responsible for determining the suitability of the product for user’s application. If this product is defective within the warranty period, your exclusive remedy and 3M Deutschland GmbH’s sole obligation shall be repair or replacement of the 3M Deutschland GmbH product.

8.2 Limitation of Liability Except where prohibited by law, 3M Deutschland GmbH will not be liable for any loss or damage arising from this product, whether direct, indirect, special, incidental or consequential, regardless of the theory asserted, including warranty, contract, negligence or strict liability.

Seite 9 - 210 x 297 mm - 3100016478/01 - SCHWARZ - 19-187 (kn)

ENGLISH

en

Symbol Glossary Reference Number and Symbol Title

Symbol

Description of Symbol

ISO 15223-1 5.1.1 Manufacturer

Indicates the medical device manufacturer as defined in EU Directives 90/385/EEC, 93/42/EEC and 98/79/EC.

ISO 15223-1 5.1.3 Date of Manufacture

Indicates the date when the medical device was manufactured.

ISO 15223-1 5.1.5 Batch code

Indicates the manufacturer's batch code so that the batch or lot can be identified.

ISO 15223-1 5.1.6 Catalogue number

Indicates the manufacturer's catalogue number so that the medical device can be identified.

ISO 15223-1 5.1.7 Serial number

Indicates the manufacturer's serial number so that a specific medical device can be identified.

ISO 15223-1 5.3.1 Fragile, handle with care

Indicates a medical device that can be broken or damaged if not handled carefully.

ISO 15223-1 5.3.4 Keep dry

Indicates a medical device that needs to be protected from moisture.

ISO 15223-1 5.4.4 Caution

Indicates the need for the user to consult the instructions for use for important cautionary information such as warnings and precautions that cannot, for a variety of reasons, be presented on the medical device itself.

ISO 7000-0623 This way up

Indicates to orientation to store and handle product.

CE Mark

Indicates conformity to European Union Medical Device Regulation or Directive.

Medical Device

Indicates the item is a medical device.

Rx Only

Indicates that U.S. Federal Law restricts this device to sale by or on the order of a dental professional. 21 Code of Federal Regulations (CFR) sec. 801.109(b)(1).

PAP 20

Indicates paper material is recyclable.

Low-density polyethylene

Indicates plastic component made of low-density polyethylene is recyclable.

Recycle electronic equipment

DO NOT throw this unit into a municipal trash bin when this unit has reached the end of its lifetime. Please recycle.

Green Dot

Indicates a financial contribution to national packaging recovery company per European Directive No. 94/62 and corresponding national law. Packaging Recovery Organization Europe.

Information valid as of September 2019

9