Operators Manual

282 Pages

Preview

Page 1

a

Read and understand all safety information before using this product.

TABLE OF CONTENTS PREFACE ... 2 INTENDED USE... 2 INDICATIONS FOR USE ... 2 WARRANTY ... 2 SAFETY AND PRECAUTIONS ... 2 HEALTH AND SAFETY INFORMATION ... 3 SPECIFICATIONS... 4 INSTRUCTIONS FOR USE... 4 INSTRUCTIONS FOR USE – Initial Set-up ... 4 FEATURES OF THE 3M™ ATTEST™ AUTO-READER 490 ... 8 CARE AND CLEANING... 8 TROUBLESHOOTING GUIDE ... 9 OPTIONAL 3M™ ATTEST™ AUTO-READER 490 WEB APP ... 10 TROUBLESHOOTING THE 3M™ ATTEST™ AUTO-READER 490 WEB APP ... 14 REPAIR AND REPLACEMENT... 14

1

a

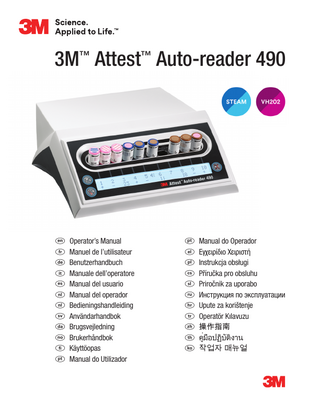

3M™ Attest™ Auto-reader 490

a

PREFACE

SAFETY AND PRECAUTIONS

Content Disclaimers

The 3M™ Attest™ Auto-reader 490 and its related devices and accessories are designed to provide safe and reliable service when used according to the instructions provided. Please read, understand, and follow all safety information contained in the instructions for use included with the 3M™ Attest™ Auto-reader 490, the 3M™ Attest™ Rapid Readout Biological Indicator 1295, and 3M™ Attest™ Super Rapid Readout Biological Indicators 1491 and 1492V devices prior to use. Use this equipment only for the purpose described in the Operator’s Manual. Retain these instructions for future reference.

Pictorial Disclaimer Sample printouts, graphics, displays and screens are for information and illustration purposes only, and shall not be used for clinical or maintenance evaluations. Data shown in sample printouts and screens do not reflect actual patient names or test results. Hardware Disclaimer The 3M™ Attest™ Auto-reader 490 hardware specifications are subject to change. The system images, hardware components and hardware specifications included in the manual may not match the system installed. Any changes or modifications to the authorized system installation have been verified as compatible with the functionality outlined in this document.

INTENDED USE The 3M™ Attest™ Super Rapid Readout Biological Indicator System provides rapid, reliable monitoring of steam sterilization processes performed in health care facilities. The system is comprised of biological indicators, challenge packs, and incubator/readers (3M™ Attest™ Auto-reader 490 and 3M™ Attest™ Auto-reader 490H having software version 4.0.0 or greater) with embedded software.

The unit is designed to be used only with the Power Supply module and Ethernet cable supplied by 3M. If this product is used in a manner not specified, the protection provided by the product may be impaired.

Explanation of Signal Word Consequences WARNING: Indicates a hazardous situation, which, if not avoided, could result in death or serious injury. CAUTION: Indicates a hazardous situation, which, if not avoided, could result in minor or moderate injury.

Warnings and Safety Precautions

The 3M™ Attest™ Auto-reader 490 having software version 4.0.0 or greater is designed to incubate and automatically read 3M™ Attest™ Super Rapid Readout Biological Indicators 1491 and 1492V at 60°C for a final negative fluorescence reading at 24 minutes. The 3M™ Attest™ Auto-reader 490 is also designed to allow for further incubation of 3M™ Attest™ Super Rapid Readout Biological Indicators, catalog numbers 1491 and 1492V, for a final negative, visual pH color change result at 24 hours and 48 hours, respectively. This further incubation is optional and not intended for routine use.

The following warnings and precautions should be followed to avoid unsafe actions that could result in personal injury or damage to the instrument.

3M™ Attest™ Auto-readers 490 having software version 4.0.0 or greater may also be used as part of the 3M™ Attest™ Rapid Readout Biological Indicator System for Vaporized Hydrogen Peroxide Sterilization to provide rapid and reliable routine monitoring of vaporized hydrogen peroxide sterilization processes in health care facilities. This system is comprised of incubator/readers (3M™ Attest™ Auto-reader 490 having software version 4.0.0 or greater and 3M™ Attest™ Auto-reader 490H) with embedded software, and a biological indicator, the 3M™ Attest™ Rapid Readout Biological Indicator 1295. The 3M™ Attest™ Auto-reader 490 having software version 4.0.0 or greater is designed to incubate and automatically read 3M™ Attest™ Rapid Readout Biological Indicators 1295 at 60°C for a final negative fluorescence reading at 24 minutes.

Do not use the equipment if it is not working properly or if it has suffered any damage.

A positive fluorescence reading or a visual pH color change indicate a sterilization process failure. However, due to the high sensitivity of the fluorescent result, there is no advantage to continuing to incubate processed 3M™ Attest™ Biological Indicators once the fluorescent result has been documented. Other biological indicators (BIs) are not compatible with this device and cannot be used.

INDICATIONS FOR USE

WARNING: To reduce the risk associated with hazardous voltage Use indoors only. Use only the power supply specified for this product and certified for the country of use.

CAUTION: To reduce the risk of injury or instrument damage Do not spill liquid onto or into the instrument. Do not immerse the unit in liquid. Always unplug the 3M™ Attest™ Auto-reader 490 and allow to cool before cleaning. Clean external surfaces using only the instructions provided by the manufacturer. Do not open the instrument housing – there are no user serviceable parts. The instrument must be returned to the manufacturer for repair. Wear safety glasses and gloves when activating the 3M™ Attest™ Rapid Readout Biological Indicator 1295.

The 3M™ Attest™ Auto reader 490 is designed to incubate and automatically read 3M™ Attest™ Rapid Readout Biological Indicators 1295 and 3M™ Attest™ Super Rapid Readout Biological Indicators, catalog numbers 1491 and 1492V, at 60°C for a final fluorescent result at 24 minutes.

Allow the 3M™ Attest™ Super Rapid Readout Biological Indicators 1491 and 1492V to cool for the recommended time period before activating. Activating or excessive handling of the biological indicator before cooling may cause the glass ampoule to burst.

WARRANTY

Wear safety glasses when activating the 3M™ Attest™ Super Rapid Readout Biological Indicators 1491 or 1492V.

In the US, the 3M™ Attest™ Auto-reader 490 has a one year limited product warranty. The US warranty, remedy and limitations are described in the Price Quote form and in the Direct Price pages. For countries outside of the US, any warranty is established by the subsidiary with responsibility for service of the 3M™ Attest™ Auto-reader 490.

Serial Number For easy identification, each 3M™ Attest™ Auto-reader 490 has a unique serial number printed on a label found on the back of the unit and displayed on the left side of the upper row of text on the LCD Display when the user depresses the

2

button.

WARNING: To reduce the risk associated with incorrect results Instrument is to be used by operators familiar with the device, device functionality, and Operator’s Manual. Do not place the instrument in environment exposed to sunlight or strong incandescent light. Do not place instrument close to any device that emits a strong electro-magnetic field. Do not use on a vibrating surface. Activate and incubate 3M™ Attest™ Rapid Readout Biological Indicators 1295 within 1 hour of the completion of the sterilization cycle. Do not incubate a 3M™ Attest™ Biological Indicator if, after processing and before BI activation, it is observed to have a broken media ampoule. Retest the sterilizer with a new biological indicator. Allow 3M™ Attest™ Super Rapid Readout Biological Indicators 1491 and 1492V to cool for the recommended time period before activating. Do not remove or change placement of 3M™ Attest™ Biological Indicator once it is placed into a well. Do not remove the 3M™ Attest™ Biological Indicator from the incubation well until the (+) or (-) symbol on the LCD panel indicates the test is complete. Do not re-incubate 3M™ Attest™ Biological Indicators for which the 3M™ Attest™ Auto-reader 490 has already determined a result.

a

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) this device may not cause harmful interference, and (2) this device must accept any interference received, including interference that may cause undesired operation. This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, and can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will be required to correct the interference at their own expense. Modifications to this device shall not be made without the written consent of 3M Company. Unauthorized modifications may void the authority granted under Federal Communication Rules permitting the operation of this device. CAN ICES-3 (A)/NMB-3(A)

EXPLANATION OF PRODUCT AND PACKAGING LABEL SYMBOLS Symbol Glossary Symbol Title

Symbol

Description and Reference

Manufacturer

Indicates the medical device manufacturer as defined in Medical Device Regulation (EU) 2017/745 formerly EU Directive 93/42/EEC. Source: ISO 15223, 5.1.1

Authorized Representative in European Community

Indicates the authorized representative in the European Community. Source: ISO 15223, 5.1.2, 2014/35/EU, and/or 2014/30/EU

Date of Manufacture

Indicates the date when the medical device was manufactured. Source: ISO 15223, 5.1.3

The 3M™ Attest™ Auto-reader 490 complies with the following standards as demonstrated by the CB Scheme Certificate and test report issued by Underwriters Laboratories (UL):

Catalogue number

Indicates the manufacturer's catalogue number so that the medical device can be identified. Source : ISO 15223, 5.1.6

• IEC 61010-1 (2010) 3rd Edition. Safety requirements for electrical equipment for measurement, control, and laboratory use - Part 1: General requirements • IEC 61010-2-010:2014 3rd Edition. Safety requirements for electrical equipment for measurement, control, and laboratory use - Part 2-010: Particular requirements for laboratory equipment for the heating of materials.

Serial number

Indicates the manufacturer's serial number so that a specific medical device can be identified. Source: ISO 15223, 5.1 .7

Caution

Indicates the need for the user to consult the instructions for use for important cautionary information such as warnings and precautions that cannot, for a variety of reasons, be presented on the medical device itself. Source: ISO 15223, 5.4.4

The 3M™ Attest™ Auto-reader 490 complies with the CE mark related to the Low Voltage Directive (LVD) 2014/35/EU as confirmed in the Declaration of Conformity.

CE Mark

Indicates conformity to all applicable European Union Medical Device Regulations and Directives.

The 3M™ Attest™ Auto-reader 490 complies with the RoHS Directive, Directive 2011/65/ EU of the European Parliament and of the Council of 8 June 2011 on the restriction of the use of certain hazardous substances in electrical and electronic equipment.

UL Listed

Indicates product was evaluated and Listed by UL for the USA and Canada.

Regulatory Compliance Mark

Indicates product complies with applicable Australian regulatory requirements. Source: AS/NZS 4417.1:2012

Direct current

To indicate on the rating plate that the equipment is suitable for direct current only or to identify relevant terminals. Source: IEC 60417-5031

CAUTION: To reduce the risk associated with incorrect results To avoid the possibility of the 3M™ Attest™ Biological Indicator vial absorbing fluorescent residue from a chemical indicator or tape, place the 3M™ Attest™ Biological Indicator vial so it does not come in direct contact with chemical indicators or tape.

HEALTH AND SAFETY INFORMATION Device Safety Compliance

The 3M™ Attest™ Auto-reader 490 is listed as Laboratory equipment and carries the UL mark with adjacent indicators “C” and “US” based on compliance to the standards UL 61010-1, CAN/CSA 22.2 No. 61010-1 and CAN/CSA 22.2 No. 61010-2-010.

The 3M™ Attest™ Auto-reader 490 complies with the WEEE Directive, Directive 2012/19/ EU of the European Parliament and of the Council of 04 July 2012 on waste electrical and electronic equipment (WEEE).

EMC Compliance The 3M™ Attest™ Auto-reader 490 complies with the following EMC standards as confirmed in the Certificate of Compliance generated by 3M: • IEC 61326-1:2012/EN 61326:2013 Electrical equipment for measurement, control and laboratory use - EMC requirements - Part 1: General requirements • EMC requirements of the CE mark EMC Directive 2014/30/EU.

DO NOT throw this unit into a municipal trash bin when this unit has reached the end of its lifetime. Please recycle. Source: Directive 2012/19/EC on waste electrical and electronic equipment (WEEE) For more information see, HCBGregulatory.3M.com Recycle electronic equipment

The 3M™ Attest™ Auto-reader 490 complies with the Australian and New Zealand electrical safety and electromagnetic compatibility requirements as confirmed in the Supplier’s Declaration of Conformity that is linked to the Australian/New Zealand RCM (Regulatory Compliance Mark). 3

a

INSTRUCTIONS FOR USE – INITIAL SET-UP

SPECIFICATIONS

Choose Location

Power Supply Specifications Power supply

Operating Condition

Units

Voltage Range

100-240

Volts AC

Frequency

50/60

Hertz

Current

0.6

Amps

Place 3M™ Attest™ Auto-reader 490 on a firm level surface away from sunlight and incandescent light. To save counter space, units may be stacked two high.

Plug In Unit Connect the power cord to the power supply. Connect the power supply to the 3M™ Attest™ Auto-reader 490 and plug the power cord into an AC grounded outlet.

Environmental Operating Conditions Environmental Condition

Operating Condition

Units

Altitude

3000 (max)

Meters

Operating Temperature

16 – 40

ºC

Storage Temperature

-10 to 50

ºC

Operating Relative Humidity

20-80 (non-condensing)

%

Voltage Range

12

Volts DC

Frequency

DC

Current

1.2

Installation/Over Voltage

Category II

Pollution Degree

2

WARNING: • Do not place the instrument in environment exposed to sunlight or strong incandescent light. • Do not place instrument close to any device that emits a strong electro-magnetic field. • Do not use on a vibrating surface.

Wait 30 Minutes Before Using Amps

Once plugged in, allow a 30 minute warm-up period before placing biological indicators into the incubation wells. The C1 caution code will disappear when proper incubation temperature is reached.

Special Considerations It is recommended that the unit be left on to eliminate warm-up periods. The unit may be turned off when it is anticipated that it will not be used for an extended period. WARNING: Use only the power supply specified for this product and certified for the country of use.

4

a

INSTRUCTIONS FOR USE – Wells, Buttons, & Display Interpretation

Please familiarize yourself with the face of the 3M™ Attest™ Auto-reader 490:

Wells

Setting the 3M™ Attest™ Auto-reader 490 Clock

1. Incubation/Reader Wells – The 3M™ Attest™ Auto-reader 490 has ten incubation wells.

The 3M™ Attest™ Auto-reader 490 date and time are displayed in this format: YYYY-MM-DD HH:MM, with the time displayed using a 24-hour clock. To change the year,

Buttons

if necessary, push the up or down buttons to set desired year, then press

2. Information / Up Arrow Button

to advance to the day. Use the to the month, adjust as necessary and press button to move to the time and set the hours and minutes.

3. Temperature / Down Arrow Button

Setting the Audible Alarm Function

4. Buzzer Alarm OFF / Enter Button

Information Display

to advance

Move across the top row of text by pushing the button. The flashing “B” in Buzzer indicates this is a changeable setting. It is recommended this be set at “Buzzer Enabled” to audibly alert the operator to a positive BI but it may be set to “Buzzer Disabled” by using either the up or down button.

5. LCD Display – Display is backlit. 6. LCD Display – Example of Error Message for well #6 7. LCD Display – Example of Remaining Incubation Time for well #10 8. LCD Display – Example of Negative (-) BI result for well #9 9. LCD Display – Example of Positive (+) BI result for well #8 10. LCD Display – Alarm Enabled Indicator

Note: If Buzzer Disabled is selected, and the change accepted, the speaker icon ( ) will disappear from the LCD panel and the alarm will be disabled for all positive 3M™ Attest™ Biological Indicators, error codes, and caution code alarm warnings.

Configuration Indicator

Press

11. Incubation well configuration sticker is black.

Setting the Optional 3M™ Attest™ Auto-reader 490 Web App Function

INSTRUCTIONS FOR USE – 3M™ Attest™ Auto-reader 490 Configuration Note: Ideally, the 3M™ Attest™ Auto-reader 490 should be empty (i.e. have no incubating BIs) when it is reconfigured. Press the and buttons on the front of the 3M™ Attest™ Auto-reader 490 simultaneously for 3 seconds to enter configuration mode. Once in configuration mode, use the Up

and Down

Note: The 3M™ Attest™ Auto-reader 490 Display backlight flashes whenever an audible alarm sounds. Disabling the audible alarm does NOT disable the LCD display backlight flashing. to select the desired option and advance to the next changeable setting.

It is recommended that the default Web Pages Enabled setting is used. If desired, however, the 3M™ Attest™ Auto-reader 490 Web App can be disabled by pressing either the up or down button. Press Accept screen.

to select the desired option and advance to the

Note: Disabling the 3M™ Attest™ Auto-reader 490 Web App will not affect connectivity to 3rd party software.

buttons to set the 3M™ Attest™ Auto-reader 490 clock,

button acts as an “Enter” key and moves audible alarm, and Web App as desired. The the flashing cursor to the next changeable setting. 5

a

Accept Screen

Follow this procedure for every 3M™ Attest™ Biological Indicator to be read:

Use the up or down buttons to toggle between Yes and No, press to accept changes (Yes selected) or retain current settings (No selected) and exit the configuration mode. The LCD panel will return to the standard display.

While wearing safety glasses (and gloves for the 1295 BI), PLACE BI in Attest™ Biological Indicator Activator.

Note: Incubation wells on 3M™ Attest™ Auto-readers 490 having software version 4.0.0 or greater are not configurable. Contact 3M for instructions on configuring incubation wells of Auto-readers having software versions less than 4.0.0.

INSTRUCTIONS FOR USE – Readout Procedure CLOSE and SQUEEZE Attest™ Biological Indicator Activator to close BI cap and crush media ampoule.

Instructions for Biological Indicator (BI) Activation and Incubation CAUTION: Allow the 3M™ Attest™ Super Rapid Readout Biological Indicator to cool for the recommended time period before activating. Activating or excessive handling of the biological indicator before cooling may cause the glass ampoule to burst. CAUTION: To avoid the possibility of the 3M™ Attest™ Biological Indicator vial absorbing fluorescent residue from a chemical indicator or tape, place the 3M™ Attest™ Biological Indicator vial so it does not come in direct contact with chemical indicators or tape.

Immediately remove BI, visually VERIFY the glass ampoule (containing growth media) has been crushed, and FLICK BI to ensure purple growth media flows to the growth chamber at the bottom of the vial.

CAUTION: Wear safety glasses when activating the 3M™ Attest™ Super Rapid Readout Biological Indicator. CAUTION: Wear safety glasses and gloves when activating the 3M™ Attest™ Rapid Readout Biological Indicator 1295.

PLACE the activated BI into any 3M™ Attest™ Auto-reader 490 well and observe 3M™ Attest™ Auto-reader 490 LCD panel to confirm correct placement of the BI. If the BI is correctly seated, the 3M™ Attest™ Auto-reader 490 LCD panel will display ***, **, * and then remaining minutes of incubation directly below the incubating BI.

WARNING: To reduce the risk associated with incorrect results Do not incubate a 3M™ Attest™ Biological Indicator if, after processing and before BI activation, it is observed to have a broken media ampoule. Retest the sterilizer with a new biological indicator. Activate and incubate 3M™ Attest™ Rapid Readout Biological Indicators 1295 within 1 hour of the completion of the sterilization cycle. Allow 3M™ Attest™ Super Rapid Readout Biological Indicators 1491 and 1492V to cool for the recommended time period before activating. Incubate the 3M™ Attest™ Rapid Readout Biological Indicator 1295 only in 3M™ Attest™ Auto-readers 490 having software versions 4.0.0 or greater.

RECORD BI result. WARNING: Do not remove the biological indicator from the incubation well until the (+) or (-) symbol on the LCD panel indicates the test is complete.

INSTRUCTIONS FOR USE – Additional Information BI Placement All incubation wells in 3M™ Attest™ Auto-readers 490 having software version 4.0.0 or greater are programmed to provide a final fluorescent result within 24 minutes of incubation and may be used to incubate both 3M™ Attest™ Super Rapid Readout Biological Indicators 1491 and 1492V and the 3M™ Attest™ Rapid Readout Biological Indicator 1295. Remaining incubation time, in minutes, will be displayed on the LCD display to indicate the 3M™ Attest™ Biological Indicator is incubating in the reader well and should not be touched. The time remaining display indicates the results are not available and incubation is in progress.

6

Note: After the first minute of incubation, if 3M™ Attest™ Biological Indicators are inadvertently removed before the incubation period is complete, an alarm will sound and a C2 Caution code will also be displayed on the LCD panel under that well. You must return the 3M™ Attest™ Biological Indicator to the reader well within 10 seconds or the results will be lost. WARNING: Do not remove or change placement of 3M™ Attest™ Biological Indicator once it is placed into a well. Doing so may result in loss of results and the biological indicator test may be invalid.

INSTRUCTIONS FOR USE – Positive Control Positive Control Activate and incubate at least one non-processed 3M™ Attest™ Biological Indicator to use as the positive control each day that a processed 3M™ Attest™ Biological Indicator is incubated and read by the unit. Write a “C” (for “control”) and the date on the label. The positive control can be placed in any incubation well. A positive control should be run for each catalog number, and have the same lot number as the processed 3M™ Attest™ Biological Indicator. It is good practice to use a positive control each day a processed 3M™ Attest™ Biological Indicator is incubated. This helps confirm: • correct incubation temperatures are met (heater block reading of 60ºC +/-2ºC). • viability of spores has not been altered due to improper storage temperature, humidity, or proximity to chemicals • capability of media to promote rapid growth, and • proper functioning of 3M™ Attest™ Auto-reader 490 components.

INSTRUCTIONS FOR USE – Interpretation of Results Fluorescent Results After placing a 3M™ Attest™ Biological Indicator into an incubation well, the 3M™ Attest™ Auto-reader 490 LCD panel will display ***, **, * and then the remaining minutes of incubation directly below the incubating BI to indicate that incubation/reading is in progress. The 3M™ Attest™ Biological Indicator should not be removed or touched when the display indicates remaining incubation time.

Optional Visual pH Color Change Result - 3M™ Attest™ Super Rapid Readout Biological Indicators 1491 and 1492V 3M™ Attest™ Super Rapid Readout Biological Indicators may be further incubated for a visual pH color change. This optional further incubation is not intended for routine use and may be used for special studies. Due to the high sensitivity of the fluorescent result, there is no advantage to incubating the 3M™ Attest™ Super Rapid Readout Biological Indicators 1491 and 1492V beyond 24 minutes. After activation and during incubation, the white Nonwoven Material in the biological indicator will absorb bromocresol purple indicator, the pH-sensitive indicator dye in the growth media, and appear blue. In the case of a positive control BI, a yellow color change of the growth media and/or Nonwoven Material will appear within 24 hours for 1491 BIs and within 48 hours for 1492V BIs. Any observation of a yellow color within the vial indicates a positive result. In the case of a processed BI, a media and/or Nonwoven material color change from purple to yellow indicates a steam sterilization process failure. A negative pH color change result, i.e. media and Nonwoven Material remain purple/blue, can be assessed at 24 hours for 1491 BIs and at 48 hours for 1492V BIs.

Optional Visual pH Color Change Result - 3M™ Attest™ Rapid Readout Biological Indicator 1295 3M™ Attest™ Rapid Readout Biological Indicators 1295 for Vaporized Hydrogen Peroxide Sterilization may be further incubated for a visual pH color change. Due to the high sensitivity of the fluorescent result, there is no advantage to continuing to incubate 3M™ Attest™ Rapid Readout Biological Indicators 1295 after the fluorescent result has been determined and documented. This optional further incubation is not intended for routine use but may be used for special studies. In the case of a positive control BI, a yellow color change of the growth media will appear within 24 hours. Any observation of a yellow color within the vial indicates a positive result. The pH color change result can be recorded and the BI discarded as soon as the yellow color is observed. For processed 3M™ Attest™ Rapid Readout Biological Indicators 1295, the use of a humidified incubator is recommended to avoid media dry out. If a visual pH color change result is desired, transfer the processed 1295 BI to a humidified incubator after the fluorescent result has been determined in the 3M™ Attest™ Auto-reader 490. A media color change from purple to yellow indicates a sterilization process failure. A negative pH color change result, i.e., media remains purple, can be assessed at 7 days.

INSTRUCTIONS FOR USE – Disposal Instrument contains a lithium battery. Dispose of instrument in accordance with federal, state, and local requirements.

A (+) will display on the LCD panel directly under the BI and an alarm will sound (if the sound feature is enabled), as soon as a positive 3M™ Attest™ Biological Indicator result is detected. At the end of the specified incubation time, if a negative 3M™ Attest™ Biological Indicator result is detected, a (-) will display on the LCD panel directly under the incubating BI. The final negative fluorescent result (-) for a processed 3M™ Attest™ Biological Indicator after 24 minutes of incubation indicates an acceptable sterilization process. After either the + or – symbol is displayed, and the result is recorded, the 3M™ Attest™ Biological Indicator can be removed from the well. The result (+ or -) is displayed on the LCD panel until the BI is removed from the incubation well. The result clears ten seconds after the BI has been removed. Do not re-incubate BIs as the result will not be valid. The positive (unprocessed) control 3M™ Attest™ Biological Indicator must provide a positive fluorescent result (+). Processed 3M™ Attest™ Biological Indicator results are not valid until the positive control reads fluorescent positive (+). With a processed 3M™ Attest™ Biological Indicator, a positive (+) result indicates a sterilization process failure. Act on any positive test results immediately. Determine the cause of the positive 3M™ Attest™ Biological Indicator and retest the sterilizer following current facility policies and procedures.

7

a

Do not remove 3M™ Attest™ Biological Indicators until the (+) or (-) symbol on the LCD panel indicates the test is complete. Once the result is determined, it is continuously displayed on the LCD panel until 10 seconds after the BI has been removed from the incubation well.

a

FEATURES OF THE 3M™ ATTEST™ AUTO-READER 490 Audible Alarm

Temperature Monitoring

An audible alarm will sound, the LCD Display backlight will flash, and a (+) symbol will be displayed on the LCD panel directly under the incubating BI when a positive result is detected. An alarm will also sound if a 3M™ Attest™ Biological Indicator is removed from the 3M™ Attest™ Auto-reader 490 well before a final result has been detected. Data will be lost if the 3M™ Attest™ Biological Indicator is not replaced in the incubation well within 10 seconds.

Easy Configuration

Alarm On/Off

The 3M™ Attest™ Auto-reader 490 may be configured using either the buttons located on the front of the unit or using the optional 3M™ Attest™ Auto-reader 490 Web App.

The audible alarm for positive results can be turned off for a particular 3M™ Attest™ Biological Indicator. This is accomplished by pressing the “Buzzer Alarm OFF” button after the alarm has sounded. This will turn off the alarm for that biological indicator only. Any positive 3M™ Attest™ Biological Indicator results subsequently detected in other wells will result in the alarm sounding. Removing the 3M™ Attest™ Biological Indicator will reactivate the alarm for that well. Pressing the “Buzzer Alarm OFF” button will not silence the alarm for error or caution code alarm warnings. To disable the alarm, see configuration section.

Stackable To save counter space, 3M™ Attest™ Auto-reader 490s may be stacked two high.

Information Button

The 3M™ Attest™ Auto-reader 490 contains an internal temperature self-diagnostic program. Should the temperature fall outside the specified range (60ºC +/-2ºC) an error code will be displayed. The heater block temperature may be checked by depressing the Temperature Button once.

Optional 3M™ Attest™ Auto-reader 490 Web App If desired, the 3M™ Attest™ Auto-reader 490 may be connected to a PC via an Ethernet connection for additional capabilities: • Remotely view current status of BIs in the 3M™ Attest™ Auto-reader 490 via PC. For full functionality, the use of an HTML5 compliant browser with JavaScript enabled is required • Remotely view and configure 3M™ Attest™ Auto-reader 490 settings • View the last 100 BI records • Print out documentation using a local or networked printer and/or save documentation as an electronic file.* * Refer to your facility’s record keeping policy and procedure.

When the Information button is pressed once the 3M™ Attest™ Auto-reader 490 displays two lines of text in the LCD display.

CARE AND CLEANING

The top row indicates (left to right):

CAUTION: Always unplug the 3M™ Attest™ Auto-reader 490 and allow to cool before cleaning.

• 3M™ Attest™ Auto-reader 490 serial number • 3M™ Attest™ Auto-reader 490 embedded software version (V X.Y.Z) • Current date and time. The bottom row indicates: • The BI type configuration for wells 1-10 (i.e., Attest) Press the information button twice and the 3M™ Attest™ Auto-reader 490 LCD panel will display: • Top row: Dynamic IP address (if unit is connected to an Ethernet jack) • Bottom row: Date (YYYY-MM-DD) and time that power was supplied to the 3M™ Attest™ Auto-reader 490. Press the information button three times and the 3M™ Attest™ Auto-reader 490 LCD display will present the unique Media Access Control (MAC) Address for the device.

8

Do not spill liquid onto or into the instrument. Do not immerse the unit in liquid. Clean external surfaces using only the instructions provided by the manufacturer. Do not open the instrument housing – there are no user serviceable parts. The instrument must be returned to the manufacturer for repair. Clean the exterior surface of the 3M™ Attest™ Auto-reader 490 by wiping it with a damp cloth moistened with a mild detergent. Do not attempt to clean interior components. If additional cleaning of the wells is required, call for repair or replacement. Note: The 3M™ Attest™ Auto-reader 490 does not contain any user serviceable parts or require any routine maintenance or calibration. Any malfunctions will be indicated by an error code. Refer to the Troubleshooting Guide section for error code explanations.

a

TROUBLESHOOTING GUIDE In the event of an error code, unplug the 3M™ Attest™ Auto-reader 490 and plug it back in to initiate the self-diagnostic test. If error code re-occurs, call for repair or replacement. The LCD Display panel will indicate detected malfunctions by displaying a caution or error code under affected BI wells. The audible alarm, if active, sounds and the LCD Display backlight flashes to alert the user to all caution (except C1) and error codes. The alarm and backlight can be silenced and extinguished, respectively, by pressing the Buzzer Alarm OFF button

. Note that disabling the audible alarm does not disable the flashing LCD Display backlight. Refer to the following:

Code

Problem

Solution

C1

Unit Warm-up Caution Incubation block not at temperature.

Allow a 30 minute warm-up after 3M™ Attest™ Auto-reader 490 is plugged in. (Note: 3M™ Attest™ BI readings are disabled until incubator block reaches 60ºC +/-2ºC).

C2

BI Removed from Well Caution 3M™ Attest™ BI has been removed before incubation is complete.

Replace 3M™ Attest™ BI in proper well within 10 seconds to prevent loss of collected data.

C4

Ambient Light Caution

Move 3M™ Attest™ Auto-reader 490 to reduced ambient light conditions.

E1

Temperature Control Error This error will occur if system is no longer able to control the temperature of the incubator block (60ºC +/-2ºC).

Unplug the unit and plug it back in to clear error. If error doesn’t clear, call for repair or replacement.

E3

Memory Error 3M™ Attest™ Auto-reader 490 unable to save/read data from memory.

Unplug the unit and plug it back in to clear error. If error doesn’t clear, call for repair or replacement.

E7

Communications Error This error will occur if internal communications have failed.

Unplug the unit and plug it back in to clear error. If error doesn’t clear, call for repair or replacement.

E8

LED Error This error occurs for a specific well if the system detects that a UV LED or Optics Detection circuit is not working.

Unplug the unit and plug it back in to clear error. If error doesn’t clear, call for repair or replacement. Do not use affected incubation well.

E11

BI Inserted Incorrectly Error Incubation time remaining will not display and fluorescent readings are not taken.

Remove BI and inspect to verify cap is fully closed, glass ampoule is crushed, and growth media is in growth chamber. If necessary, repeat BI activation steps and return BI to incubation well, ensuring it is seated properly.

E12

Power Failure Error Power to Auto-reader was off for too long to provide valid result for affected BI(s).

Ensure power supply connection to Auto-reader is secure. Retest sterilizer with a new BI.

E14

Ambient Light Error (occupied well) Fluorescent result will not display.

Rely on optional visual pH color change result for BI in affected well. Move 3M™ Attest™ Auto-reader 490 to reduced ambient light conditions to avoid future occurrences. To clear E14 error code, after visual pH color change result has been documented and BI has been removed, unplug the 3M™ Attest™ Auto-reader 490 and plug it back in.

Other

Unwanted alarm sounds when positive BI detected.

Disable alarm, refer to 3M™ Attest™ Auto-reader 490 Configuration section for instructions.

Other

Alarm Sounds 3M™ Attest™ Biological Indicator has been removed from incubation/reader well prematurely.

Replace 3M™ Attest™ Biological Indicator in incubation/reader well within 10 seconds to prevent loss of data collected.

Other

LCD Panel does not display properly.

Cycle power. If problem persists call for repair or replacement.

Other

Negative Control BI BI not properly activated. Media did not contact spore carrier. Control BI was sterilized.

Ensure BI cap is closed and glass ampoule is crushed. Flick BI until media flows to spore chamber at bottom of BI. Use a non-sterilized BI as a control. Check process indicator on BI cap.

Other

Unexplained Positive BI Adhesive residue on vial. Test vial is absorbing fluorescent residue from a chemical indicator or tape.

Do not place tape or labels on vial. Place the vial so it does not come in direct contact with chemical indicators or tape.

Other

3M™ Attest™ Auto-reader 490 will not enter Configuration mode. Pushbutton Configuration may be disabled on 3M™ Attest™ Auto-reader 490 Web App.

On 3M™ Attest™ Auto-reader 490 Web App Configuration Page, go to Pushbutton Configuration and select the Enable radio button. Save changes to begin using new setting.

9

a

OPTIONAL 3M™ ATTEST™ AUTO-READER 490 WEB APP Web Browser Requirements The Web Interface is designed to be viewed using an HTML5 compliant browser with JavaScript enabled (e.g., Google Chrome).

About the 3M™ Attest™ Auto-reader 490 Web App Pages The 3M™ Attest™ Auto-reader 490 Web App includes four pages: a) Status page

Ethernet Connection: Connection switch/router with auto-negotiation capability to identify the Auto-reader as operating at 10 Mbps and half-duplex, or able to be manually configured as 10 Mbps and half-duplex.

Connecting to the 3M™ Attest™ Auto-reader 490 Web App To use the 3M™ Attest™ Auto-reader 490 Web App, the 3M™ Attest™ 490 Auto-reader must be connected to the facility network using the supplied Ethernet cable. Consult with your facility IT personnel for assistance with network connectivity. Each 3M™ Attest™ Auto-reader 490 has a unique MAC Address which is presented on the unit’s LCD Display when the user depresses the Info button three times. The MAC Address is also provided at the bottom of the 3M™ Attest™ Auto-reader 490 Web App Configuration page. Communication occurs using the http protocol over Port 80. Users may connect to the 3M™ Attest™ Auto-reader 490 Web App using a URL based upon either the 3M™ Attest™ Auto-reader 490 serial number or the IP Address. To view the 3M™ Attest™ Auto-reader 490 Web App from a computer on a sub-net different from that to which the 3M™ Attest™ Auto-reader 490 is connected, use the IP Address URL. Note: To access the 3M™ Attest™ Auto-reader 490 Web App within a secure network, the PC must have access to the secure network; options include connecting via a network Ethernet cable, signing in to the facility’s wireless network, or connecting via a virtual private network (VPN).

A. Serial number URL 1. Connect the supplied Ethernet cable from the 3M™ Attest™ Auto-reader 490 to an Ethernet jack. button once to display the 3M™ Attest™ Auto-reader 490 6-digit 2. Depress the serial number on the left side of the top row of text on the LCD display. 3. Enter http://attestxxxxxx where xxxxxx represents the unit’s serial number (e.g. http:// attest101127) from Step 2 in PC web browser address bar and press Enter. 4. 3M™ Attest™ Auto-reader 490 Web App Status page will display on PC. For future ease of use, add this page to your web browser “Favorites”.

1. User-entered nickname (optional) 2. Well Configuration 3. Well Number 4. BI Result/Remaining Incubation Time 5. Date and Time 6. 3M™ Attest™ Auto-reader 490 Serial Number The Status page provides a real-time representation of the 3M™ Attest™ Auto-reader 490 configuration and LCD panel display. The current date and time and 3M™ Attest™ Auto-reader 490 serial number are also indicated on this page. From this page, the user may navigate to: • the History page by clicking on History on the left of the screen. • the Results Detail page by clicking on the well number of an occupied well (i.e. a well that currently has an incubating BI). Clicking on an unoccupied well takes the user to the History page. b) Results Detail page

B. IP Address URL The 3M™ Attest™ Auto-reader 490 Web App may also be accessed using either a dynamic or static IP address.

1. Dynamic IP Address A dynamic IP address is assigned when the Ethernet cable is connected from the 3M™ Attest™ Auto-reader 490 to a live Ethernet jack. Press and release the button twice to display the 3M™ Attest™ Auto-reader 490’s dynamic IP address. Enter http://IPaddress (e.g. http://xxx.xxx.xxx.xxx) in the PC’s web browser address bar and press Enter. The 3M™ Attest™ Auto-reader 490 Web App Status page will display.

2. Static IP address Some facility IT personnel may require devices connecting to the network to use a Static IP address. If this is the case at your facility, contact the IT department to request a Static IP address. Record the static IP address provided by your facility IT department here: ___________. You may wish to label the Ethernet jack with the assigned address. Enter http:// StaticIPaddress (e.g. http://xxx.xxx.xxx.xxx) in the PC’s web browser address bar and press Enter. The 3M™ Attest™ Auto-reader 490 Web App Status page will display.

This page provides an individual record for an incubated BI. For complete documentation, the user may print a hard copy and/or save the record as an electronic file. Note 1: The top four rows (highlighted in green) are populated automatically by the 3M™ Attest™ Auto-reader 490 and cannot be changed by the user. The remaining rows are completed by the user to satisfy the documentation requirements of their facility. Note 2: The Results Detail page refreshes less frequently that the Status page. Until the BI result is available, the Results Detail page displays remaining minutes of incubation in the results field.

10

a

c) History page

The 3M™ Attest™ Auto-reader 490 stores results for the last 100 incubated BIs on embedded software. The 3M™ Attest™ Auto-reader 490 Web App History page provides a summary of these last 100 results. d) Configuration page This page allows the configuration of the 3M™ Attest™ Auto-reader 490’s network and language settings from the 3M™ Attest™ Auto-reader 490 Web App.

Documenting BI Results using the 3M™ Attest™ Auto-reader 490 Web App

3. The entered information is saved automatically to temporary web browser storage on the user’s PC every 60 seconds, or by leaving the Results Details page. 4. Print/File. Once the BI result is available, print or file the Results Detail page to create a record. The page may be physically printed and/or saved as an electronic file.

Important! Data is only stored for the last 100 incubated BIs. Embedded software in the 3M™ Attest™ Auto-reader 490 saves the data from the auto-populated (i.e. green highlighted) fields. The application relies on the temporary storage in the user’s web browser to save the data in the user-populated fields. In both cases, data is only stored for the last 100 records i.e., the 101st incubated BI will erase the information saved for the 1st incubated BI. To retain the Results Detail information for future reference it is best practice to print the page as soon as the BI result is available.

1. Open the Results Detail page After inserting a new 3M™ Attest™ Super Rapid Readout BI in the 3M™ Attest™ Auto-reader 490, it is a best practice to open the 3M™ Attest™ Auto-reader 490 Web App Results Detail page for that BI by clicking on the appropriate well number from the Status page. 2. Enter the specific information for that BI (e.g. BI Type, BI Lot #, sterilizer #, load #, technician name, etc.) in the provided editable fields. Use the Notes section to capture information not prescribed in the provided row titles, for example, you may wish to use this field to record load items.

11

a

Using the BI History Page To view or print an individual record, click on the ID number of the desired record to navigate to the Results Detail page for that BI. Note 1: Column 1, “ID” is the assigned ID number with ID 1 representing the newest record and ID 100 representing the oldest record. To help find a particular record, all columns are sortable, simply click once on the column heading to sort in ascending order and click a second time to reverse the order. Note 2: The History page refreshes less frequently than the Status page. Until the BI result is available, the History page displays ••• in the Results column indicating incubation is still in-process.

Using the Configuration Page Certain set-up and configuration options are available on the password protected 3M™ Attest™ Auto-reader 490 Web App Configuration page. Ideally, the 3M™ Attest™ Auto-reader 490 should be empty (i.e. have no incubating BIs) when it is reconfigured. Navigate to the Configuration page by entering either: 1) http://attestxxxxxx/protect/config.htm (where xxxxxx is the 6-digit unit serial number), or 2) http:// xxx.xxx.xxx.xxx/protect/config.htm (where xxx.xxx.xxx.xxx is the IP address) in the web browser address bar and pressing Go or enter. A security screen will appear. Fill in the editable fields as follows: User name: manager Password: Attest and press OK.

12

a

Click on the desired radio buttons to change settings. Language

Selected setting indicates language in which text on 3M™ Attest™ Auto-reader 490 Web App pages will appear on the computer screen.

Pushbutton Configuration

Selecting Enable

allows the user to configure the 3M™ Attest™ Auto-reader 490 from the buttons on the unit itself.

Selecting Disable

prevents the user from being able to configure the 3M™ Attest™ Auto-reader 490 from the buttons on the unit itself.

Selecting Enable

enables the audible alarm. The speaker icon will appear on the LCD panel.

Selecting Disable

disables the audible alarm. The speaker icon will disappear from the 3M™ Attest™ Auto-reader 490 LCD panel.

Buzzer Configuration Attest Auto-reader 490 Nickname

Naming the 3M™ Attest™ Auto-reader 490 may be useful in facilities with multiple units. The assigned nickname will appear on the 3M™ Attest™ Auto-reader 490 Web App Status page.

Enable DHCP

Default: setting is checked indicating the Web App will use the Dynamic IP address automatically assigned when the 3M™ Attest™ Auto-reader 490 is connected to the network. Remove the check if you wish to use a Static IP address assigned by your facility IT.

IP Address

Enter Static IP address assigned by IT

Gateway

Enter Gateway

Subnet Mask

Enter Subnet Mask

Primary DNS

Enter Primary DNS

Secondary DNS

Enter Secondary DNS.

MAC Address

XX:XX:XX:XX:XX:XX (Unique MAC address assigned to device. This value cannot be changed.)

Use Computer Time

Check this box if you wish to set the clock on-board the 3M™ Attest™ Auto-reader 490 using the computer’s clock.

Attest Auto-reader 490 Time

Alternatively, leave the Use Computer Time box unchecked and complete the date and time boxes to set the 3M™ Attest™ Auto-reader 490 clock.

After changing desired settings, click on Save Config button to save your changes. A new screen confirming the settings were successfully changed appears.

13

a

TROUBLESHOOTING THE 3M™ ATTEST™ AUTO-READER 490 WEB APP Issue

Problem

Solution

Unable to access 3M™ Attest™ Auto-reader 490 Web App on networked computer

Web Pages have been disabled.

Enable Web Pages using push buttons on unit (see 3M™ Attest™ Auto-reader 490 Configuration section)

Unable to access 3M™ Attest™ Auto-reader 490 Web App on networked computer

3M™ Attest™ Auto-reader 490 and/or computer not connected to network.

Ensure 3M™ Attest™ Auto-reader 490 Ethernet cable is connected to a live jack and that connection to 3M™ Attest™ Auto-reader 490 is secure. Ensure computer is connected to network. If failure is with connection attempted using 3M™ Attest™ Auto-reader 490 serial number URL, try connecting using IP address URL.

Auto-negotiation issue between the 3M™ Attest™ Auto-reader 490 and facility network switch.

Switch port setting must be set at 10 Mbps and half-duplex. Contact facility IT or 3M if problem persists.

Data entered by user on Results Detail page disappears

User entered data is written to temporary web browser storage. Browser may have cleared data.

Set web browser to accept (allow or enable) cookies.

BI result displayed on 3M™ Attest™ Auto-reader 490 LCD panel does not appear on Results Detail page

The Results Detail page has not refreshed yet.

Use your browser to refresh the Results Detail page, or wait up to 60 seconds for the page to automatically refresh.

Results Detail page will not open from the Status page

The Results Detail page only opens from the Status page for occupied 3M™ Attest™ Auto-reader 490 wells.

Do not attempt to navigate to the Results Detail page from unoccupied wells on the Status page.

REPAIR AND REPLACEMENT In the USA, 3M™ Attest™ Auto-reader 490s must be repaired at: 3M Health Care Service Center Suite 200, Bldg. 502 3350 Granada Avenue North Oakdale, MN 55128 1-800-228-3957 Outside of the USA, contact your local 3M Subsidiary. If you have questions, call our Customer Service number: 1-800-228-3957.

14

As a best practice, print or save Results Detail record as soon as BI result is final.