Acumed

10mm X 260mm Long Trial Stem

Reusable Surgical Instruments and Accessories Instructions for Use

106 Pages

Preview

Page 1

Reusable Surgical Instruments and Accessories

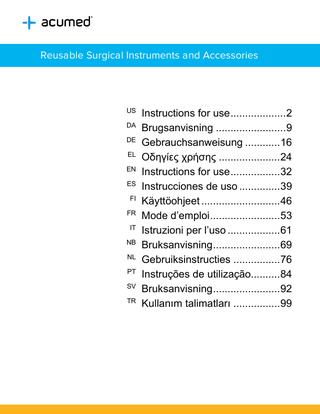

Instructions for use ... 2 DA Brugsanvisning ... 9 DE Gebrauchsanweisung ... 16 EL Οδηγίες χρήσης ... 24 EN Instructions for use ... 32 ES Instrucciones de uso ... 39 FI Käyttöohjeet ... 46 FR Mode d’emploi ... 53 IT Istruzioni per l’uso ... 61 NB Bruksanvisning ... 69 NL Gebruiksinstructies ... 76 PT Instruções de utilização... 84 SV Bruksanvisning ... 92 TR Kullanım talimatları ... 99 US

US

U.S. English – US / PAGE 2

Instructions for use Reusable Surgical Instruments and Accessories US

These instructions are intended for the Operating Surgeon and supporting Healthcare Professionals. The US instructions are intended for users in the United States and its territories.

Rx only

DESCRIPTION Acumed Reusable Surgical Instruments and Accessories are available for a wide variety of surgical techniques and implant systems. Proper care and inspection after each use is critical. WARNINGS & PRECAUTIONS Warning: • Instrument breakage or damage, as well as tissue damage, may occur when an instrument is subjected to excessive loads, excessive speeds, dense bone, improper use or unintended use. Caution: • The instruments are intended only for professional use by a licensed physician. • Do not use the sterile product past the use-by date. Refer to the device label. • Do not reuse single use surgical instruments. The instrument may suddenly fail as a result of previous stresses. • Do not resharpen drill bits or reamers as these devices have critical dimensions and geometries that cannot be restored once the instrument has been consumed. • Do not use chemical disinfection methods as chemical residues may affect steam sterilization. • Do not block holes in the case or trays, for example with labels, as this may adversely affect steam penetration and sterilization. • Screws, tacks, Kirschner wires, guidewires, cutting instruments, and similar devices may be sharp. Observe hospital procedures, practice guidelines, and/or government regulations for the proper handling and disposal of sharps. SURGICAL TECHNIQUE Acumed offers one or more Surgical Techniques to promote the safe and effective use of this system. Consult our Surgical Techniques at www.acumed.net. Important: Surgical techniques may contain important safety information.

US

Instructions for use

U.S. English – US / PAGE 3

Important: The instruments in this system are intended to be used by suitably trained and qualified surgeons in a hospital operating room setting. Before treatment, the surgeon is advised to read and fully understand all instructions and communicate to the patient any relevant medical information provided therein, including the use, limitations, risks (safety communications), and possible adverse effects of the proposed treatment. Consult the most recent versions of the Instructions for Use and Surgical Techniques as they are subject to change. Contact Acumed or an authorized agent to request any additional information. LIFETIME • Multiple-use instruments have a lifetime that is affected by usage, handling, and processing. Assess multiple-use instruments for fitness during the pre-sterilization inspection. STERILITY • Instruments may be provided either sterile or non-sterile as indicated on the label. • Non-sterile devices are intended to be sterilized before use. • Devices purchased and received sterile were exposed to a minimum dose of 25.0 kGy gamma radiation to obtain a minimum sterility assurance level of 10-6.

INSTRUMENTS MATERIALS The instruments are manufactured from various grades of titanium, stainless steel, aluminum, silicone, and other polymers. MULTIPLE USE and SINGLE USE • Instruments are intended for multiple use unless identified on the label for single use only. • Single use instruments are intended to be disposed after use on a single patient during a single procedure. • Do not reuse single use instruments as this may increase the risks of failure and cross-contamination. • Multiple use instruments are only intended for use on a single patient and a single procedure before requiring processing. • Multiple (limited) use instruments, such as drills and reamers, have a limited lifespan. Immediately replace any multiple use instrument if performance becomes inadequate. • Multiple use instruments potentially contaminated with transmissible spongiform encephalopathy (TSE) agents shall not be processed for reuse.

US

Instructions for use

U.S. English – US / PAGE 4

IMPORTANT • To replace the jaws of Plate Cutters (80-1143), use a T15 hexalobe driver to remove the screws attaching the jaw pieces to the plate cutters, noting original alignment of the jaw components. Replace the cutters using Plate Cutter Jaw Replacement Assembly (80-1247). Cutting Jaw 01 (80-1246) and Cutting Jaw 02 (80-1248) should be inserted into the plate cutters such that the mating surfaces of the jaws fit within one another when the handle of the plate cutters is fully compressed. Insert replacement screws (80-1244) and hand tighten with a T15 hexalobe driver. • Protect instruments against scratching and nicking to prevent stress concentrations, which can lead to instrument failure. • Near the point of use: Wipe excess contamination from instruments and prevent any soil from drying. Instruments with substantial or dried soil are particularly difficult to reliably process. Transport contaminated instruments for processing as soon as possible after use. • Avoid prolonged instrument contact with iodine and saline. • Handle and transport soiled instruments in a manner that avoids contamination of any unused implants.

PROCESSING

Important: Processing personnel must be qualified with suitable training and experience. Use proper personal protective equipment (PPE) when working with contaminated devices. IMPORTANT • Promptly perform the processing steps to limit microbial growth and maximize the effectiveness of sterilization. • Prevent instrument corrosion by minimizing contact with solutions containing iodine, chlorine, and saline or other metal salts. • Prevent damage to the protective anodization layer on aluminum instruments by avoiding contact with solutions < 4 pH and > 9 pH, especially if they contain sodium carbonate or sodium hydroxide. • Repeated processing of anodized metals may cause colors to fade but this does not affect the function of the device. • Avoid cleaning agents containing aldehydes since they can denature and coagulate proteins (fixation). • Enzymatic detergents are well suited for loosening protein-based contamination. - Use a neutral pH enzymatic detergent. - Use a low foaming solution to allow visibility of the device during cleaning. • Closely follow the manufacturer’s instructions for the safety, storage, mixing, water quality, exposure time, temperature, replacement, and disposal of cleaning agents. • Devices potentially contaminated with transmissible spongiform encephalopathy (TSE) agents shall not be processed or reused. These processing instructions are not suitable for inactivation of TSE agents. Observe hospital procedures, practice guidelines, and/or government regulations for the proper handling and disposal of devices potentially contaminated with TSE agents. • Utility water: Refer to AAMI TIR34* when instructed to use utility water. Utility water is typically municipal or tap water but may require additional treatment to be suitable for use.

US

Instructions for use

U.S. English – US / PAGE 5

• Critical water: Refer to AAMI TIR34* when instructed to use critical water. Critical water is highly treated and has very low organic and inorganic content with an endotoxin level under 10 EU/mL. Suitable water may also be specified in national pharmacopeias, national standards, and hospital protocols. * Association for the Advancement of Medical Instrumentation (AAMI). Water for the reprocessing of medical devices. AAMI TIR34:2014/(R)2017. Arlington, VA. MANUAL CLEANING 1. 2. 3. 4. 5. 6. 7.

Rinse the contaminated instruments under running cold utility water to reduce heavy surface contamination. Dispose of any used instruments intended for single use only. Place the contaminated instruments in enzymatic solution* until completely submerged to minimize the spraying of solution. Actuate all moveable parts to allow detergent to contact all surfaces. Soak for a minimum of ten (10) minutes. Scrub the instruments using a soft-bristled brush to remove all visible debris. Do not use stainless steel or other abrasives as these may damage the surface. - When possible, scrub the instruments when totally submerged to minimize the spraying of fluid. Some instruments may require special consideration: - Clean the instruments with all parts loosened. Clean the instruments disassembled if they are designed to be taken apart. - Use a water jet to flood cleaning solution into challenging areas, such as mating surfaces, springs, coils, cannulations, blind holes, flutes, cutting teeth, and flexible parts to flush out any trapped soil. - Operate movable parts and rotate (as necessary) while scrubbing to ensure that all crevices are accessible. - Carefully clean cannulated parts and challenging areas using an appropriately sized brush. - Optionally sonicate for 10 to 15 minutes using a fresh, neutral pH ultrasonic cleaning solution. Follow the ultrasonic cleaner and detergent manufacturer’s instructions. Important: Any previous surface damage may increase due to ultrasonic cleaning.

8. Perform an initial rinse for at least 3 minutes using clean, soft, utility water in the temperature range of 25°C to 35°C (77°F to 95°F) to remove all signs of contamination and cleaning agent. - Actuate all movable parts. - Flush out cannulations and complex mechanisms. 9. Repeat the previous processing steps if visible residue remains present. 10. Perform a final rinse for at least 1 minute using critical water to displace minerals and other impurities found in utility water. Do not use saline solutions for final rinsing because they may interfere with disinfection and sterilization. - Actuate all moving parts - Pay particular attention to cannulations and blind holes as well as hinges and joints between mating surfaces. - Rinse cannulations at least three times with a syringe (volume 1-50ml). 11. Remove excess moisture from the instruments using a clean, absorbent, non-shedding wipe. 12. Allow the instruments to thoroughly dry. Any moisture may affect sterilization and devices may remain wet after the drying period. * Manual cleaning was validated using STERIS Prolystica 2X Concentrate Enzymatic Presoak and Cleaner.

US

Instructions for use

U.S. English – US / PAGE 6

PRE-STERILIZATION INSPECTION • Visually inspect all devices under normal lighting to ensure that cleaning was effective. Pay close attention to all challenging areas. - Re-process an instrument that is not clean. - Replace an instrument that cannot be cleaned. • Inspect the instruments for surface damage, such as nicks, scratches, and cracks. Replace any device that is affected. • Assess the instruments for proper use. Operate all parts and connecting mechanisms. Give careful attention to drivers, drill bits and reamers, and instruments used for cutting or implant insertion. Critically assess them for wear, sharpness, straightness, and corrosion. Replace any instrument that does not perform as intended. • Inspect all cutting edges under magnification. - Replace an instrument if a cutting edge is dull, chipped, cracked, rolled, or otherwise deformed. - Running a cotton cloth over the edge may help detect chipping and cracking. • Verify the legibility of all markings and reference scales. Replace any device that is unreadable. • Repair, replace, and/or repeat the cleaning of instruments as needed to ensure proper operation before proceeding with sterilization. • Lubrication (“instrument milk”) may increase the useful life of surgical instruments. Do not use siliconebased lubricants, oil, or grease, as these will interfere with steam sterilization. Only use a water-based lubricant intended for use on surgical instruments and with steam sterilization. Use the lubricant as directed by the manufacturer. Use critical water if dilution is required. • Fully replenish the system trays and caddies. STERILIZATION • Perform sterilization using a dynamic-air-removal (prevacuum) autoclave. - Gravity displacement sterilization is not recommended. - Immediate use (flash) sterilization is not recommended. • Ensure the sterilizer’s maximum load limit is not exceeded when sterilizing multiple sets or devices. • Do not stack containers as this might prevent the penetration of steam and inhibit drying. • Refer to the sterilizer manufacturer's instructions and ensure proper installation, calibration, use, and ongoing maintenance. • The sterilized items should be allowed to cool to room temperature before handling. This allows for safe handling and preventing condensation. • Follow current industry best practice guidelines such as ANSI/AAMI ST79:2017*. * Association for the Advancement of Medical Instrumentation (AAMI). Comprehensive guide to steam sterilization and sterility assurance in health care facilities. AAMI ST79:2017. Arlington, VA. • The following table shows the minimum parameters validated* to achieve a required Sterility Assurance Level (SAL) of 10-6 for the system. Important: -

Sterilization parameters are only valid for devices that have been cleaned per these instructions and are thoroughly dry. Sterilization parameters are only valid when the devices are properly housed in the Acumed storage case part numbers identified in the table.

US

Instructions for use

U.S. English – US / PAGE 7

Prevacuum Steam Sterilizer Parameters Condition1:

Wrapped

Exposure Temperature:

270°F (132°C)

Exposure Time:

4 minutes

Dry Time:

30 minutes

1 US customers must use FDA-cleared sterilization packaging/wrap and other accessories appropriate for the cycle

parameters recommended in these instructions. Refer to PKGI-76 at www.acumed.net/ifu for sterilization in Aesculap® rigid sterilization containers.

* Sterilization was validated using a STERIS Amsco 3023 Vacamatic Prevacuum sterilizer and KimGuard KC600 One-Step wrap. POST-STERILIZATION INSPECTION • Do not store or use sterile devices if they are not dry. - Moisture supports the survival of microorganisms. - Moisture remaining on wrapped or contained products after sterilization could compromise the sterile barrier. - Moisture can corrode metal and dull sharp edges. • Inspect the sterile barrier for signs of damage. Do not use the product if the sterile barrier has been compromised.

US

Instructions for use

U.S. English – US / PAGE 8

Symbols Glossary

Symbol

Rx Only

Description

ISO 15223-1

Consult the electronic instructions for use (eIFU) at www.acumed.net/ifu

5.4.3

Caution

5.4.4

Sterilized using irradiation

5.2.4

Double sterile barrier system

5.2.12

Non-sterile

5.2.7

Use-by date

5.1.4

Catalogue number

5.1.6

Batch code

5.1.5

Authorized representative in the European Community / European Union

5.1.2

Medical device

5.7.7

Manufacturer

5.1.1

Date of manufacture

5.1.3

Do not resterilize

5.2.6

Do not re-use

5.4.2

Do not use if package is damaged and consult instructions for use / do not use if the product sterile barrier system or its packaging is compromised

5.2.8

Caution: U.S. federal law restricts this device to sale by or on the order of a physician.

U.S. 21 CFR 801.109

The reticle is a registered trademark of Acumed. It may appear alone or with the Acumed name. CE marking of conformity, Article 17 of EU Directive 93/42/EEC. CE marking may be accompanied by the identification number of the notified body responsible for conformity assessment.

EN

English (non-U.S.) – EN / PAGE 32

Instructions for use Reusable Surgical Instruments And Accessories EN

These instructions are intended for the Operating Surgeon and supporting Healthcare Professionals. The EN instructions are intended for users in English speaking countries outside the United States and its territories.

DESCRIPTION Acumed Reusable Surgical Instruments and Accessories are available for a wide variety of surgical techniques and implant systems. Proper care and inspection after each use is critical. WARNINGS & PRECAUTIONS Warning: • Instrument breakage or damage, as well as tissue damage, may occur when an instrument is subjected to excessive loads, excessive speeds, dense bone, improper use or unintended use.

Caution: • The instruments are intended only for professional use by a licensed physician. • Do not use the sterile product past the use-by date. Refer to the device label. • Do not reuse single use surgical instruments. The instrument may suddenly fail as a result of previous stresses. • Do not resharpen drill bits or reamers as these devices have critical dimensions and geometries that cannot be restored once the instrument has been consumed. • Do not use chemical disinfection methods as chemical residues may affect steam sterilization. • Do not block holes in the case or trays, for example with labels, as this may adversely affect steam penetration and sterilization. • Screws, tacks, Kirschner wires, guidewires, cutting instruments, and similar devices may be sharp. Observe hospital procedures, practice guidelines, and/or government regulations for the proper handling and disposal of sharps. SURGICAL TECHNIQUE Acumed offers one or more Surgical Techniques to promote the safe and effective use of this system. Consult our Surgical Techniques at www.acumed.net. Important: Surgical techniques may contain important safety information.

EN

Instructions for use

English (non-U.S.) – EN / PAGE 33

Important: The instruments in this system are intended to be used by suitably trained and qualified surgeons in a hospital operating room setting. Before treatment, the surgeon is advised to read and fully understand all instructions and communicate to the patient any relevant medical information provided therein, including the use, limitations, risks (safety communications), and possible adverse effects of the proposed treatment. Consult the most recent versions of the Instructions for Use and Surgical Techniques as they are subject to change. Contact Acumed or an authorized agent to request any additional information. LIFETIME • Multiple-use instruments have a lifetime that is affected by usage, handling, and processing. Assess multiple-use instruments for fitness during the pre-sterilization inspection.

STERILITY • Instruments may be provided either sterile or non-sterile as indicated on the label. • Non-sterile devices are intended to be sterilized before use. • Devices purchased and received sterile were exposed to a minimum dose of 25.0 kGy gamma radiation to obtain a minimum sterility assurance level of 10-6.

INSTRUMENTS MATERIALS The instruments are manufactured from various grades of titanium, stainless steel, aluminum, silicone, and other polymers. MULTIPLE USE and SINGLE USE • Instruments are intended for multiple use unless identified on the label for single use only. • Single use instruments are intended to be disposed after use on a single patient during a single procedure. • Do not reuse single use instruments as this may increase the risks of failure and cross-contamination. • Multiple use instruments are only intended for use on a single patient and a single procedure before requiring processing. • Multiple (limited) use instruments, such as drills and reamers, have a limited lifespan. Immediately replace any multiple use instrument if performance becomes inadequate. • Multiple use instruments potentially contaminated with transmissible spongiform encephalopathy (TSE) agents shall not be processed for reuse.

EN

Instructions for use

English (non-U.S.) – EN / PAGE 34

IMPORTANT • To replace the jaws of Plate Cutters (80-1143), use a T15 hexalobe driver to remove the screws attaching the jaw pieces to the plate cutters, noting original alignment of the jaw components. Replace the cutters using Plate Cutter Jaw Replacement Assembly (80-1247). Cutting Jaw 01 (80-1246) and Cutting Jaw 02 (80-1248) should be inserted into the plate cutters such that the mating surfaces of the jaws fit within one another when the handle of the plate cutters is fully compressed. Insert replacement screws (80-1244) and hand tighten with a T15 hexalobe driver. • Protect instruments against scratching and nicking to prevent stress concentrations, which can lead to instrument failure. • Near the point of use: Wipe excess contamination from instruments and prevent any soil from drying. Instruments with substantial or dried soil are particularly difficult to reliably process. Transport contaminated instruments for processing as soon as possible after use. • Avoid prolonged instrument contact with iodine and saline. • Handle and transport soiled instruments in a manner that avoids contamination of any unused implants.

PROCESSING

Important: Processing personnel must be qualified with suitable training and experience. Use proper personal protective equipment (PPE) when working with contaminated devices. IMPORTANT • Promptly perform the processing steps to limit microbial growth and maximize the effectiveness of sterilization. • Prevent instrument corrosion by minimizing contact with solutions containing iodine, chlorine, and saline or other metal salts. • Prevent damage to the protective anodization layer on aluminum instruments by avoiding contact with solutions < 4 pH and > 9 pH, especially if they contain sodium carbonate or sodium hydroxide. • Repeated processing of anodized metals may cause colors to fade but this does not affect the function of the device. • Avoid cleaning agents containing aldehydes since they can denature and coagulate proteins (fixation). • Enzymatic detergents are well suited for loosening protein-based contamination. - Use a neutral pH enzymatic detergent. - Use a low foaming solution to allow visibility of the device during cleaning. • Closely follow the manufacturer’s instructions for the safety, storage, mixing, water quality, exposure time, temperature, replacement, and disposal of cleaning agents. • Devices potentially contaminated with transmissible spongiform encephalopathy (TSE) agents shall not be processed or reused. These processing instructions are not suitable for inactivation of TSE agents. Observe hospital procedures, practice guidelines, and/or government regulations for the proper handling and disposal of devices potentially contaminated with TSE agents. • Utility water: Refer to AAMI TIR34* when instructed to use utility water. Utility water is typically municipal or tap water but may require additional treatment to be suitable for use.

EN

Instructions for use

English (non-U.S.) – EN / PAGE 35

• Critical water: Refer to AAMI TIR34* when instructed to use critical water. Critical water is highly treated and has very low organic and inorganic content with an endotoxin level under 10 EU/mL. Suitable water may also be specified in national pharmacopeias, national standards, and hospital protocols. * Association for the Advancement of Medical Instrumentation (AAMI). Water for the reprocessing of medical devices. AAMI TIR34:2014/(R)2017. Arlington, VA. MANUAL CLEANING 1. 2. 3. 4. 5. 6. 7.

Rinse the contaminated instruments under running cold utility water to reduce heavy surface contamination. Dispose of any used instruments intended for single use only. Place the contaminated instruments in enzymatic solution* until completely submerged to minimize the spraying of solution. Actuate all moveable parts to allow detergent to contact all surfaces. Soak for a minimum of ten (10) minutes. Scrub the instruments using a soft-bristled brush to remove all visible debris. Do not use stainless steel or other abrasives as these may damage the surface. - When possible, scrub the instruments when totally submerged to minimize the spraying of fluid. Some instruments may require special consideration: - Clean the instruments with all parts loosened. Clean the instruments disassembled if they are designed to be taken apart. - Use a water jet to flood cleaning solution into challenging areas, such as mating surfaces, springs, coils, cannulations, blind holes, flutes, cutting teeth, and flexible parts to flush out any trapped soil. - Operate movable parts and rotate (as necessary) while scrubbing to ensure that all crevices are accessible. - Carefully clean cannulated parts and challenging areas using an appropriately sized brush. - Optionally sonicate for 10 to 15 minutes using a fresh, neutral pH ultrasonic cleaning solution. Follow the ultrasonic cleaner and detergent manufacturer’s instructions. Important: Any previous surface damage may increase due to ultrasonic cleaning.

8. Perform an initial rinse for at least 3 minutes using clean, soft, utility water in the temperature range of 25°C to 35°C (77°F to 95°F) to remove all signs of contamination and cleaning agent. - Actuate all movable parts. - Flush out cannulations and complex mechanisms. 9. Repeat the previous processing steps if visible residue remains present. 10. Perform a final rinse for at least 1 minute using critical water to displace minerals and other impurities found in utility water. Do not use saline solutions for final rinsing because they may interfere with disinfection and sterilization. - Actuate all moving parts - Pay particular attention to cannulations and blind holes as well as hinges and joints between mating surfaces. - Rinse cannulations at least three times with a syringe (volume 1-50ml). 11. Remove excess moisture from the instruments using a clean, absorbent, non-shedding wipe. 12. Allow the instruments to thoroughly dry. Any moisture may affect sterilization and devices may remain wet after the drying period. * Manual cleaning was validated using STERIS Prolystica 2X Concentrate Enzymatic Presoak and Cleaner.

EN

Instructions for use

English (non-U.S.) – EN / PAGE 36

PRE-STERILIZATION INSPECTION • Visually inspect all devices under normal lighting to ensure that cleaning was effective. Pay close attention to all challenging areas. - Re-process an instrument that is not clean. - Replace an instrument that cannot be cleaned. • Inspect the instruments for surface damage, such as nicks, scratches, and cracks. Replace any device that is affected. • Assess the instruments for proper use. Operate all parts and connecting mechanisms. Give careful attention to drivers, drill bits and reamers, and instruments used for cutting or implant insertion. Critically assess them for wear, sharpness, straightness, and corrosion. Replace any instrument that does not perform as intended. • Inspect all cutting edges under magnification. - Replace an instrument if a cutting edge is dull, chipped, cracked, rolled, or otherwise deformed. - Running a cotton cloth over the edge may help detect chipping and cracking. • Verify the legibility of all markings and reference scales. Replace any device that is unreadable. • Repair, replace, and/or repeat the cleaning of instruments as needed to ensure proper operation before proceeding with sterilization. • Lubrication (“instrument milk”) may increase the useful life of surgical instruments. Do not use siliconebased lubricants, oil, or grease, as these will interfere with steam sterilization. Only use a water-based lubricant intended for use on surgical instruments and with steam sterilization. Use the lubricant as directed by the manufacturer. Use critical water if dilution is required. • Fully replenish the system trays and caddies. STERILIZATION • Perform sterilization using a dynamic-air-removal (prevacuum) autoclave. - Gravity displacement sterilization is not recommended. - Immediate use (flash) sterilization is not recommended. • Ensure the sterilizer’s maximum load limit is not exceeded when sterilizing multiple sets or devices. • Do not stack containers as this might prevent the penetration of steam and inhibit drying. • Refer to the sterilizer manufacturer's instructions and ensure proper installation, calibration, use, and ongoing maintenance. • The sterilized items should be allowed to cool to room temperature before handling. This allows for safe handling and preventing condensation. • Follow current industry best practice guidelines such as ANSI/AAMI ST79:2017*. * Association for the Advancement of Medical Instrumentation (AAMI). Comprehensive guide to steam sterilization and sterility assurance in health care facilities. AAMI ST79:2017. Arlington, VA. • The following table shows the minimum parameters validated* to achieve a required Sterility Assurance Level (SAL) of 10-6 for the system. Important: -

Sterilization parameters are only valid for devices that have been cleaned per these instructions and are thoroughly dry. Sterilization parameters are only valid when the devices are properly housed in the Acumed storage case part numbers identified in the table.

EN

Instructions for use

English (non-U.S.) – EN / PAGE 37

Prevacuum Steam Sterilizer Parameters Condition1:

Wrapped

Exposure Temperature:

270°F (132°C)

Exposure Time:

4 minutes

Dry Time:

30 minutes

1 Use sterilization packaging/wrap and other accessories appropriate for the cycle parameters recommended in these

instructions and in accordance with national regulations. Refer to PKGI-76 at www.acumed.net/ifu for sterilization in Aesculap® rigid sterilization containers.

* Sterilization was validated using a STERIS Amsco 3023 Vacamatic Prevacuum sterilizer and KimGuard KC600 One-Step wrap. POST-STERILIZATION INSPECTION • Do not store or use sterile devices if they are not dry. - Moisture supports the survival of microorganisms. - Moisture remaining on wrapped or contained products after sterilization could compromise the sterile barrier. - Moisture can corrode metal and dull sharp edges. • Inspect the sterile barrier for signs of damage. Do not use the product if the sterile barrier has been compromised.

EN

Instructions for use

English (non-U.S.) – EN / PAGE 38

Symbols Glossary

Symbol

Rx Only

Description

EN ISO 15223-1

Consult the electronic instructions for use (eIFU) at www.acumed.net/ifu

5.4.3

Caution

5.4.4

Sterilized using irradiation

5.2.4

Double sterile barrier system

5.2.12

Non-sterile

5.2.7

Use-by date

5.1.4

Catalogue number

5.1.6

Batch code

5.1.5

Authorized representative in the European Community / European Union

5.1.2

Medical device

5.7.7

Manufacturer

5.1.1

Date of manufacture

5.1.3

Do not resterilize

5.2.6

Do not re-use

5.4.2

Do not use if package is damaged and consult instructions for use / do not use if the product sterile barrier system or its packaging is compromised

5.2.8

Caution: U.S. federal law restricts this device to sale by or on the order of a physician.

U.S. 21 CFR 801.109

The reticle is a registered trademark of Acumed. It may appear alone or with the Acumed name. CE marking of conformity, Article 17 of EU Directive 93/42/EEC. CE marking may be accompanied by the identification number of the notified body responsible for conformity assessment.

Acumed Headquarters 5885 NE Cornelius Pass Road Hillsboro, OR 97124 USA Office: +1.888.627.9957 Office: +1.503.627.9957 Fax: +1.503.520.9618 www.acumed.net

These materials contain information about products that may or may not be available in any particular country or may be available under different trademarks in different countries. The products may be approved or cleared by governmental regulatory organizations for sale or use with different indications or restrictions in different countries. Products may not be approved for use in all countries. Nothing contained in these materials should be construed as a promotion or solicitation for any product or for the use of any product in a particular way that is not authorized under the laws and regulations of the country where the reader is located. Nothing in these materials should be construed as a representation or warranty as to the efficacy or quality of any product, nor the appropriateness of any product to treat any specific condition. Physicians may direct questions about the availability and use of the products described in these materials to their authorized Acumed distributor. Specific questions patients may have about the use of the products described in these materials or the appropriateness for their own conditions should be directed to their own physician.

PKGI-56-P | Effective 10-2020 | © 2020 Acumed® LLC

Acumed® is a registered trademark of Acumed, LLC.

Subsidiaries: Acumed Ltd Huebner House The Fairground Andover Hampshire UK SP11 0QN Tel: +44 1264 774450

Acumed Iberica C/ Álvaro Caballero, 14 28023 Madrid, Spain Tel: +34 913516357

Acumed Beijing Room A1206, Horizon International Tower No. 6, Zhichun Road Haidian District 100088 Beijing, China Tel: +86 10 82001303

Acumed GmbH Fuhlsbüttler Strasse 300 22307 Hamburg Deutschland Tel: + 49-40 947 82 093

Emergo Europe Prinsessegracht 20 2514 AP The Hague The Netherlands

2797