Users Guide

82 Pages

Preview

Page 1

Reader

User’s Guide AB11321031

© ASP 2021. All rights reserved.

AB11321031-50 January 2021.

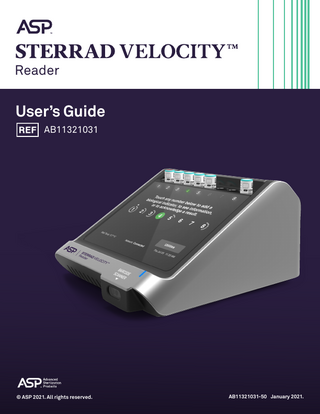

STERRAD VELOCITY™ Reader

User’s Guide AB11321031

ADVANCED STERILIZATION PRODUCTS, INC. 33 Technology Drive, Irvine, CA 92618, USA

ASP, The Netherlands BV BIC 1, 5657 BX, Eindhoven, The Netherlands

1-888-STERRAD (USA only) or 949-581-5799 ASP Professional Services ASP International Customer Support (Call your local ASP Customer Support Representative) www.asp.com For warranty information, please visit our website or contact ASP Professional Services.

© ASP 2021. All rights reserved. STERRAD VELOCITY™, ASP ACCESS™ and ALLClear™ are trademarks of Advanced Sterilization Products, Inc. (ASP). STERRAD™ and STERRAD NX™ are registered trademarks of Advanced Sterilization Products, Inc. (ASP). Other products mentioned in this publication are trademarked by their respective owners. Reproduction, adaptation, or translation of this publication without prior written permission is prohibited. Printed in the U.S.A.

Contents Chapter 1. Introduction... 1 How to Use This Guide...1 Intended Use...1 Indications for Use...2 Product Description...2 If You Have Questions...2

Chapter 2. Safety Information... 3 Symbols...3 Warnings, Cautions, and Notes...5

Chapter 3. Overview...9 The STERRAD VELOCITY Reader and Features...9 Before You Start...10 Start and Warm-up...10 The Status Screen...11 System Status Indicator...12 Biological Indicators...12 Biological Indicator Wells...13 Sleep Mode...14 Touch Screen...14 Barcode Scanner...14 Power Adapter...14

Chapter 4. Operation... 15 Instructions for Use...15 Process Description...15 Warm-up...15 Adding a Positive Control BI...15 Adding a Test BI...19 Manual Entry of Cycle Information...21 In-Progress Summary...22 Interpretation of Results...23 Chemical Indicator Result...23 Negative Test Result...24 Positive Test Result...24 Positive Result on a Positive Control...26

STERRAD VELOCITY Reader User’s Guide

iii

First Negative Result on a Positive Control...26 Second Negative Result on a Positive Control...27 Optional Visual Interpretation of Results...28

Chapter 5. Files... 31 System Information Files...31 History Files...32 Notes...32 Reader Log...33

Chapter 6. Maintenance... 35 Care and Cleaning...35 Biological Indicator Disposal...35 Reader Disposal...36

Chapter 7. Access Levels and Administrator Tasks... 37 Access Levels...37 Utilities Menu...38 Admin Login...38 Manage Administrators...39 Add New Account...39 Edit or Delete Existing Account...39 Manage Sterilizers...39 Add New Sterilizer...40 Edit or Delete Existing Sterilizer...40 History...40 View Details...40 Add Note...40 System Configuration...41 Language Selection...41 Backlight Conservation...41 Volume...41 Display Brightness...42 Alert Sounds...42 Barcode Scanner in Use...42 Reader Settings...42 Printer Settings...42 Date and Time...43 Calibrate Insertion Sensor...43 Network Settings...43 ASP ACCESS Configuration...44

iv

STERRAD VELOCITY Reader User’s Guide

Control Alerts...44 File Management...45 Update Software...45 System Information...45 Reader Log...45

Chapter 8. Troubleshooting... 47 User Error Messages...47 System Error Messages...58 Call Your ASP Representative...58

Appendix A. Accessories and Additional Parts...59 Appendix B. Reader Specifications... 61 Appendix C. User’s Network Connection Information...63 Appendix D. Compliance and Regulatory Standards...65 Appendix E. First Time Setup... 67 Network Setup...67 ASP ACCESS Setup...68 Date and Time Setup...69 Administrator Setup...70 STERRAD Sterilizer Setup...71 Reader Setup...71 Control Chemical Indicator Color Change Configuration Setup...72 Printer Setup...72 Setup Complete...72

Appendix F. Software License Agreement... 73

STERRAD VELOCITY Reader User’s Guide

v

Introduction

1

Chapter 1.

Introduction This Guide will instruct the user in the proper care and operation of the STERRAD VELOCITY™ Reader (reader). The reader provides a fast and reliable way of testing the STERRAD VELOCITY™ Biological Indicator / Process Challenge Device (biological indicator or BI). The BI is designed to test the effectiveness of the STERRAD™ 100NX with and without ALLClear™ Technology, STERRAD NX™ with and without ALLClear Technology, and STERRAD™ 100S Sterilization Systems. Failure to follow the instructions provided in this guide may result in inaccurate results or impairment of the safety features of the reader.

How to Use This Guide If you are a reader operator, you must read the “Introduction” (Chapter 1), “Safety Information” (Chapter 2), “Operation” (Chapter 4), and “Maintenance” (Chapter 6) chapters prior to operating the reader. This “Introduction” explains the features and parts of the reader. “Safety Information” explains personal safety as well as device safety information. “Operation” explains how to operate the reader and obtain optimal results. “Maintenance” explains how to clean and care for the reader. If you are an administrator overseeing the reader, you should read the entire User’s Guide and pay particular attention to the chapter featuring “Access Levels and Administrator Tasks” (Chapter 7). This chapter describes tasks and options that are only available through “Administrator-level” access.

Intended Use The STERRAD VELOCITY Reader is used to incubate and automatically read the STERRAD VELOCITY Biological Indicator / Process Challenge Device at 57°C (134.6°F) for a final fluorescent result within 15 minutes. The BI is a rapid biological indicator designed for frequent monitoring and periodic testing of STERRAD™ Sterilization Cycles which use hydrogen peroxide as the sterilant. The BI used in conjunction with the reader provides a fast and reliable way to verify the effectiveness of the STERRAD Sterilization Cycle. The STERRAD VELOCITY Biological Indicator / Process Challenge Device is for use in STERRAD™ Sterilizers only.

STERRAD VELOCITY Reader User’s Guide

1

1

Introduction

Indications for Use The STERRAD VELOCITY Reader, in conjunction with the STERRAD VELOCITY Biological Indicator / Process Challenge Device, is intended to be used as a standard method for frequent monitoring and periodic testing of the following STERRAD™ Sterilization Systems: •

STERRAD 100NX (STANDARD, FLEX, EXPRESS, and DUO Cycles) with and without ALLClear Technology

•

STERRAD NX (STANDARD and ADVANCED Cycles) with and without ALLClear Technology

•

STERRAD 100S

Product Description The reader is an integral part of a monitoring system which tests the BI for the presence of an indicator organism. The reader incubates the BI at 57°C (134.6°F) and provides final fluorescent results within 15 minutes. The presence or absence of the viable indicator organism, indicated by fluorescence, in the BI determines the effectiveness of the sterilization cycle. The BI and reader system is used for frequent monitoring and periodic testing of the STERRAD NX with and without ALLClear Technology, STERRAD 100NX with and without ALLClear Technology, and the STERRAD 100S Sterilization Systems in hospitals and healthcare facilities.

If You Have Questions If you are located in the United States and have questions about the STERRAD VELOCITY Reader, please call ASP Professional Services at 1-888-STERRAD (1-888-783-7723). Internationally, call your local ASP Customer Support Representative. You may also wish to visit our website at www.asp.com.

2

STERRAD VELOCITY Reader User’s Guide

der Artwork

Safety Information

2

Front Color: PMS 325 C, PMS 426 C, Solid 100% White Ink = Front Graphic Size: 140.4 mm x 17.4 mm Chapter 2. 426 (Black) Rear Color: PMS Rear Graphic Size: 62.54 mm x 12.6 mm GTIN: 10705037048915

Safety Information

Your safety is important to Advanced Sterilization Products, Inc. (ASP). The following sections provide information on safely using the STERRAD VELOCITY Reader. You must read and understand the safety information before operating the reader. Always pay attention to the warnings, cautions, and notes throughout this User’s Guide. This information is for your safety and to ensure that you receive the most benefit from the safe operation of your reader.

Symbols Emits laser radiation. Avoid direct eye exposure. Warning. Caution. Ethernet. Ethernet Connection Port. USB. Universal serial bus connector port. Electric shock hazard. Electric shock hazard. Ultraviolet (UV) light hazard. Avoid direct eye exposure. Direct current.

STERRAD VELOCITY Reader User’s Guide

3

2

Safety Information

Waste Electrical and Electronic Equipment (WEEE) and EU Battery Directive. This device contains circuit boards and a rechargeable battery which need to be disposed of properly. Catalogue number. Indicates the manufacturer’s catalogue number so that the medical device can be identified. Serial number. Indicates the manufacturer’s serial number so that a specific medical device can be identified. RCM. Indicates compliance with applicable ACMA regulatory requirements. Manufacturer. Indicates the medical device manufacturer. Date of Manufacture. Indicates the date when the medical device was manufactured. Hot Surfaces. Authorized representative in the European Community. This symbol is

ASP, The Netherlands BV accompanied by the name and address of the authorized representative BIC 1, 5657 BX, Eindhoven, The Netherlands

in the European Community.

eifu.asp.com

Consult instructions for use. Indicates the need for the user to consult the instructions for use. Fragile, Handle with Care. Indicates a medical device that can be broken or damaged if not handled carefully. This Side Up. Indicates the orientation the package should remain in during shipping and storage. For indoor use only. Keep away from sunlight. Indicates a medical device that needs protection from light sources.

4

STERRAD VELOCITY Reader User’s Guide

Safety Information

2

Keep dry. Indicates a medical device that needs to be protected from moisture. CE mark. Indicates the product conforms to all legal requirements to be sold within the European Union/European Economic Area (EU/EEA). Recyclable. The packaging materials in which the device is shipped are recyclable.

Warnings, Cautions, and Notes Warnings and cautions are accompanied by symbols surrounded by a triangle and are printed in boldface text. Warnings indicate events or conditions that can result in serious injury or death. Cautions indicate events or conditions that can result in damage to the reader or data loss. IMPORTANT! The photos and graphics of the reader screens are for reference only. Your reader may look different or present different screens and/or messages. WARNING! A situation potentially causing personal injury or death. CAUTION! A situation potentially causing instrument damage or data loss. Notes appear in italics and highlight specific information about the proper use and maintenance of the reader. 9 Note: Specific information about proper use and maintenance.

STERRAD VELOCITY Reader User’s Guide

5

2

Safety Information

WARNING! RISK OF ELECTRIC SHOCK. Do not use a damaged or non-functional reader. Only use a power supply certified for the country of use and rated for this product. Unplug and allow the device to cool before cleaning. Do not attempt to open the device housing. The interior of the device contains no user serviceable parts and requires no routine maintenance.

WARNING! HEATED INTERIOR SURFACES. The interior of the instrument well may be hot. Do not touch the interior of the well with your bare or gloved hand, or insert any non-BI item in the instrument wells.

WARNING! AVOID EXPOSURE TO ULTRAVIOLET LIGHT. The fluorescence detection system uses an ultraviolet light source located inside the reader wells. To avoid eye injury, do not stare directly at the ultraviolet light source for an extended period of time.

CAUTION! KEEP AWAY FROM SUNLIGHT. The instrument needs protection from light sources. Do not place the instrument in an environment where it is exposed to excessive sunlight or artificial light.

CAUTION! KEEP DRY. The instrument needs to be protected from moisture. Do not immerse the instrument in liquid, or spill liquid onto or into the instrument housing.

CAUTION! FOR INDOOR USE ONLY. The instrument is designed primarily for indoor use.

6

STERRAD VELOCITY Reader User’s Guide

Safety Information

2

CAUTION! RISK OF INSTRUMENT DAMAGE OR INCORRECT RESULTS. Operators using the instrument must have an understanding of the device, its functionality, and the User’s Guide. The hospital or healthcare facility is responsible for the security of the reader. Do not drop the reader. Place the reader on a flat, level surface free from vibration. Do not store near any sterilizer, sources of ethylene oxide, hydrogen peroxide, acids, alkalis or volatile antimicrobials such as glutaraldehyde or formaldehyde, STERRAD™ Cassettes, or any other oxidizers. Clean only the external surfaces of the reader following the manufacturer’s instructions. After plugging in the reader, allow the instrument to complete its warm-up sequence before placing a BI in a well. Ensure that the time is synchronized between the reader, the Sterilizer and the ASP ACCESS™ to prevent errors occurring during manual entry. Process the BI according to the directions provided in the BI IFU. Do not process a BI from a canceled or aborted sterilization cycle. The accuracy of the BI result has been verified up to two hours post sterilization processing. Activate and incubate the biological indicator within two hours of the completion of the sterilization cycle. Failure to do so may generate misleading results or cause system lockout. Handle BIs one at a time. Check the expiration date of the BI prior to use, and only use non-expired BIs. Select a well before scanning the BI barcode. Scan and activate the BI before inserting into the reader well. Do not activate the BI while it is in the instrument well. Do not remove the biological indicator from the reader until the reader display indicates the test is complete. Do not use a damaged or non-functional reader well as identified by the reader. Changes or modifications not expressly approved by the party responsible for compliance could void the user’s authority to operate the equipment.

STERRAD VELOCITY Reader User’s Guide

7

THIS PAGE INTENTIONALLY LEFT BLANK

8

STERRAD VELOCITY Reader User’s Guide

Overview

3

Chapter 3.

Overview The STERRAD VELOCITY Reader and Features The reader features a 1024 x 500 pixel touch screen. It also features eight individual STERRAD VELOCITY Biological Indicator / Process Challenge Device test wells which can be used for test samples or positive controls. The thermoplastic exterior makes the instrument easy to clean and maintain. The built-in barcode scanner coupled with network connectivity makes maintaining sterilization records easy.

Biological Indicator

Biological Indicator Well Well Status Indicator

Touch Screen Interface

System Status Indicator

Figure 1. The STERRAD VELOCITY Reader

STERRAD VELOCITY Reader User’s Guide

9

3

Overview

USB Ports

Ethernet Adapter

Power Adapter

Figure 2. The STERRAD VELOCITY Reader (Back) The back panel of the reader has four connector ports. The RJ45 connector port supports a 10/100/1000 Base-T Ethernet connection. The two USB 2.0 ports in the center allow the user to attach a USB barcode scanner, a printer, or an external hard drive. The final port is for connecting the power adapter.

Before You Start To start, remove the device from its packaging and ensure that all of the following items are included. The package will include the reader, an AC power adapter, and four sets of interchangeable prongs which fit plug types A, C, G, and I. Attach the set of prongs which fit the plug socket to the AC power adapter. Place the reader on a nonvibrating level surface which is not exposed to excessive sunlight or artificial light. Attach the power adapter to the back of the reader and then connect it to a power outlet. Position the reader so that the power connection is accessible. Access is needed to power the device on and off.

Start and Warm-up When the reader is first powered on, it will display a splash screen with a progress bar as it goes through a diagnostic and warm-up sequence. Warm up time can take up to 15 minutes. After completing the warm-up sequence, the reader will display the Status Screen.

10

STERRAD VELOCITY Reader User’s Guide

Overview

3

The Status Screen The Status Screen is the default home screen for the reader. It displays the current status of the wells, the current well temperature, the network connection status, the date, and the time. It also provides access to the Utilities Menu, which is explained in the “Utilities Menu” section (Chapter 7). The Status Screen will also display important alert messages and helpful hints about the next steps to take. When a BI is added to a well an audible tone plays and a teal circle briefly appears on the well number to indicate success. After a BI is added to a well and the reading process has begun, a series of small tick marks will appear around the well number. The small tick marks indicate the elapsed time since the BI began the incubation process and give a visual representation of the remaining time. A green circle on a well number indicates either a positive control BI result or a negative test BI result. A red circle on a well number indicates either a positive result on a test BI or a negative result for a positive control BI. A yellow well number and caution symbol indicate the reader has detected a problem and locked the well. A small circular dot above a well number indicates that a positive control BI is currently in the well.

Figure 3. The Status Screen with Alert Message

STERRAD VELOCITY Reader User’s Guide

11

3

Overview

System Status Indicator The System Status indicator light indicates when the device is powered on by displaying a blue light. When scanning the BI barcode, the blue light flashes brighter to indicate a successful scan. If the system detects an error the status indicator changes to red. The system status indicator will blink red when a system status error is detected, and it will remain solid red when a fatal error is detected. The indicator would display a red light for issues such as: the device is unable to read from the internal storage, the internal clock returns an erroneous reading, or the device detects a voltage or temperature outside of a specific range. Refer to the “Troubleshooting” section of this guide (Chapter 8) if a red system status indicator is displayed.

System Status Indicator Light Indicator State Meaning Solid Blue

System Status: OK

Bright Blue Flash

Visual affirmation that biological indicator barcode has been scanned successfully.

Blinking Red

System Status: System Failure

Solid Red

System Status: General System Error Table 1. System Status Indicator

Biological Indicators The BI is a single-use testing device used to monitor the effectiveness of hydrogen peroxide sterilization. STERRAD VELOCITY Biological Indicator / Process Challenge Devices are for use in STERRAD Sterilizers only. The BI is designed to monitor all cycles of the STERRAD NX with and without ALLClear Technology, STERRAD 100NX with and without ALLClear Technology, and STERRAD 100S Sterilization Systems. Each biological indicator includes a chemical indicator on the top of the cap which changes color from red/pink to yellow, or yellow with some red/orange/brown dots, when exposed to hydrogen peroxide (refer to the “Chemical Indicator Result” section (Chapter 4) for more detailed instructions). During the sterilization cycle hydrogen peroxide passes into the interior of the BI through the sterilant ingress windows and kills the indicator organism. Once the sterilization cycle is complete the BI is placed in one of eight biological indicator wells, on the top of the reader, for incubation and reading. The BI wells detect the presence of the BI and begin the incubation and interrogation process. 12

STERRAD VELOCITY Reader User’s Guide

Overview

3

Chemical Indicator BI Cap with Label

Vial

Sterilant Ingress Window Medium Ampoule Insert

Growth Reservoir

Spore Disc

Figure 4. STERRAD VELOCITY Biological Indicator / Process Challenge Device

Biological Indicator Wells There are eight individual biological indicator incubation wells at the top along the back of the device. Positioned in the bottom of the wells is a heater block which maintains a constant temperature range to promote the growth of the indicator organism. If any of the indicator organisms survive the sterilization cycle they will produce an enzyme which reacts with the growth medium causing it to fluoresce under ultraviolet light. Each well contains an ultraviolet light source to excite fluorescence in the growth medium, and a photodetector to detect that fluorescence. Directly under each well is a well number illuminated by a well status indicator light. The light can shift between three colors (white, green, and red). The colors and states are explained in the table below.

Well Status Indicator Light Indicator State Meaning Off

Well Open

Solid White

Adding BI to Well

Solid Green

Passed Result

Solid Red

Failed Result

Table 2. Well Status Indicator STERRAD VELOCITY Reader User’s Guide

13

3

Overview

Sleep Mode After a user configurable idle time (default 15 minutes), the reader will go into a sleep mode which dims the touch screen backlight while continuing to incubate BIs. The reader enters sleep mode to preserve energy and prolong the life of the touch screen backlight. The length of idle time which activates sleep mode can be adjusted in the Utilities Menu under System Configuration. Refer to “Access Levels and Administrator Tasks” (Chapter 7) for information on how to change these settings. The reader will wake from sleep mode by touch screen input, USB device input, inserting or removing a BI, and on detection of an error.

Touch Screen The full color 1024 x 500 pixel resolution capacitive touch display can be used with bare hands or while wearing latex, nitrile, vinyl, and polyisoprene medical gloves.

Barcode Scanner The barcode scanning mechanism makes entering BI information quick and simple. It is located on the right front of the reader. It uses two LEDs for illumination and aiming, making it possible to scan a barcode in a wide variety of lighting conditions. In order to scan a BI barcode, hold the BI approximately 10 cm (4 in.) from the scanner with the barcode facing the scanner. Align the barcode on the cap label with the center of the red light produced by the barcode scanner. Slowly rotate the BI back and forth until an audible beep is heard. If the barcode cannot be read, the device will beep five times. The reader can also be equipped with a handheld USB barcode scanner. Attach the handheld barcode scanner to a USB port in the rear of the device. To activate the attached scanner, go to Utilities > System Config, and under Barcode Scanner In Use select USB. Once the external barcode scanner is activated, the internal barcode scanner is disabled.

Power Adapter The reader comes with an AC power adapter with an input of 100V to 240V at 50–60Hz and an output of 12V DC at 5A maximum. It has four sets of interchangeable prongs making it easy to switch between plug types A, C, G, and I. Simply remove the blanking plate and attach the prongs which fit the wall outlet at the install location and then connect the adapter to the wall and the back of the reader.

14

STERRAD VELOCITY Reader User’s Guide

Operation

4

Chapter 4.

Operation Instructions for Use This chapter gives instructions on how to use the STERRAD VELOCITY Reader to test the STERRAD VELOCITY Biological Indicator / Process Challenge Device and obtain positive or negative results.

Process Description Remove the test BI from the sterilization chamber, or select a positive control BI from the shelf carton. When adding a positive control BI, make sure it has the same lot number as the test BI. Select the incubation well on the reader’s touch screen before scanning the BI barcode. When prompted, select Test or Control, scan the barcode on the cap of BI, and enter the operator’s name. Activate the BI and insert it in the well. The reader will provide the results within 15 minutes.

Warm-up When initially powered on, the reader will display a splash screen and then go through a diagnostic and warm-up sequence which takes up to 15 minutes. After completing the warm-up sequence, the reader will display the Status Screen.

Adding a Positive Control BI A positive control is an unprocessed BI which is activated then read in the reader. The positive control ensures the system is functioning properly. Always inspect the positive control BI prior to processing in the reader to ensure that the expiration date on BI cap is current, the growth medium ampoule is intact, the growth medium is purple, the spore disc is lying horizontally in the bottom of the growth reservoir, and the chemical indicator on the top of the cap is red/pink. Touch an available well number on the screen or place the BI in an open well. The selected well will then be used for reading. These steps can be repeated for any open well. Touch Control to add a positive control BI to the well.

STERRAD VELOCITY Reader User’s Guide

15