Alger

ALGERBRUSH II Operating Instructions Rev 3 April 2012

Operating Instructions

2 Pages

Preview

Page 1

ALGERBRUSH II ALGERBRUSH II Operating Instructions *** Please read the following before operating the ALGERBRUSH II ***

ALGERBRUSH II Operating Instructions

x

The ALGERBRUSH II burr must be sterilized prior to its initial use and following each use thereafter (for sterilization information, refer to section entitled “Sterilization” )

x

The chuck and burr on the ALGERBRUSH II are held together by friction and may become loose during shipment. Prior to each use of the ALGERBRUSH II, check the following:

*** Please read the following before operating the ALGERBRUSH II ***

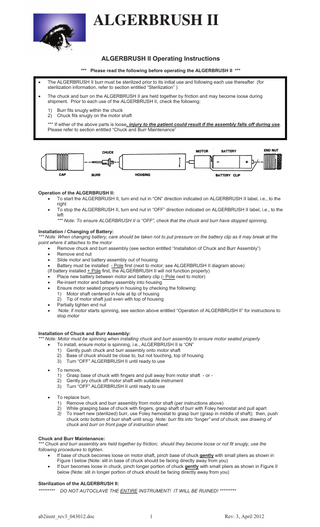

• The ALGERBRUSH II burr must be sterilized prior to its initial use and following each use thereafter 1) Burr fits snugly within the chuck (for sterilization information, refer to section entitled “Sterilization” ) 2) Chuck fits snugly on the motor shaft *** Ifchuck either of theburr above is loose, injury to II theare patient could result if the assembly off during • The and onparts the ALGERBRUSH held together by friction and mayfalls become looseuse. during Please refer to section entitled “Chuck and Burr Maintenance” shipment. Prior to each use of the ALGERBRUSH II, check the following:

1) 2)

Burr fits snugly within the chuck Chuck fits snugly on the motor shaft

*** If either of the above parts is loose, injury to the patient could result if the assembly falls off during use. Please refer to section entitled “Chuck and Burr Maintenance” Operation of the ALGERBRUSH II: x To start the ALGERBRUSH II, turn end nut in “ON” direction indicated on ALGERBRUSH II label, i.e., to the right x To stop the ALGERBRUSH II, turn end nut in “OFF” direction indicated on ALGERBRUSH II label, i.e., to the left *** Note: To ensure ALGERBRUSH II is “OFF”, check that the chuck and burr have stopped spinning.

Operation of the ALGERBRUSH II: Installation / Changing of Battery: • Note: To start thechanging ALGERBRUSH II,should turn end nut innot “ON” on ALGERBRUSH *** When battery, care be taken to putdirection pressureindicated on the battery clip as it may breakIIatlabel, the to the right to the motor pointi.e., where it attaches x stop Remove chuck and burr assembly entitled “Installation of Chuck on andALGERBRUSH Burr Assembly”) II label, • To the ALGERBRUSH II, turn(see end section nut in “OFF” direction indicated x Remove end nut i.e., to the left x Slide motor and battery assembly out of housing *** Note: To ensure ALGERBRUSH II is “OFF”, check that the chuck and burr have stopped spinning. x Battery must be installed - Pole first (next to motor; see ALGERBRUSH II diagram above) (If battery installed + Pole first, the ALGERBRUSH II will not function properly)

Installation / Changing of Battery: x Place new battery between motor and battery clip (- Pole next to motor) x Re-insert motor and battery assembly housing *** Note: When changing battery, care should into be taken not to put pressure on the battery clip as it may break at the x Ensure motor seated properly in housing by checking the following: point where it attaches to the motor 1) Motor shaft centered in hole at tip of housing • Remove chuck and burr assembly (see section entitled “Installation of Chuck and Burr Assembly”) 2) Tip of motor shaft just even with top of housing • Remove endtighten nut end nut x Partially • Slide motorif motor and battery assemblysee outsection of housing x Note: starts spinning, above entitled “Operation of ALGERBRUSH II” for instructions to stopmust motorbe installed - Pole first (next to motor; see ALGERBRUSH II diagram above) • Battery (If battery installed + Pole first, the ALGERBRUSH II will not function properly) • Place new battery between motor and battery clip (- Pole next to motor) Installation of Chuck and Burr Assembly: • Note: Re-insert and batterywhen assembly into housing *** Motormotor must be spinning installing chuck and burr assembly to ensure motor seated properly • Ensure motor ensure seated motor properly in housing by checking the following: x To install, is spinning, i.e., ALGERBRUSH II is “ON” Gently push and in burr assembly onto motor shaft 1) 1) Motor shaft chuck centered hole at tip of housing Baseofofmotor chuck shaft shouldjust be even close with to, buttop notof touching, 2) 2) Tip housingtop of housing 3) Turn “OFF” ALGERBRUSH II until ready to use • Partially tighten end nut Toifremove, • xNote: motor starts spinning, see section above entitled “Operation of ALGERBRUSH II” for 1) Grasp base of chuck with fingers and pull away from motor shaft - or instructions to stop motor 2) Gently pry chuck off motor shaft with suitable instrument 3)

x

Turn “OFF” ALGERBRUSH II until ready to use 1

Rev: 2, Oct 2009

To replace burr, 1) Remove chuck and burr assembly from motor shaft (per instructions above) 2) While grasping base of chuck with fingers, grasp shaft of burr with Foley hemostat and pull apart 3) To insert new (sterilized) burr, use Foley hemostat to grasp burr (grasp in middle of shaft); then, push chuck onto bottom of burr shaft until snug Note: burr fits into “longer” end of chuck; see drawing of chuck and burr on front page of instruction sheet.

Chuck and Burr Maintenance: *** Chuck and burr assembly are held together by friction; should they become loose or not fit snugly, use the following procedures to tighten. x If base of chuck becomes loose on motor shaft, pinch base of chuck gently with small pliers as shown in Figure I below (Note: slit in base of chuck should be facing directly away from you) x If burr becomes loose in chuck, pinch longer portion of chuck gently with small pliers as shown in Figure II below (Note: slit in longer portion of chuck should be facing directly away from you) Sterilization of the ALGERBRUSH II: ********* DO NOT AUTOCLAVE THE ENTIRE INSTRUMENT! IT WILL BE RUINED! *********

ab2instr_rev3_043012.doc

1

Rev: 3, April 2012

Remove chuck and burr assembly from ALGERBRUSH II (per instructions above); Separating burr by itself is fine, but burrs are small and hard to handle; therefore, it is easier to keep chuck and burr assembly together Housing can be cleaned by wiping with alcohol Refer to Appendix 1 for validated sterilization and cleaning procedures FIG. I

FIG. II

Appendix 1: Cleaning and Sterilization Instructions Scope: The following is applicable before initial use and after each subsequent use. Carbide burrs are provided mechanically clean, but are not sterile (unless labeled “STERILE”). Therefore, carbide burrs should be sterilized before first use. Warnings: Do not use chemical or dry heat to sterilize carbide burrs, as these processes have not been validated for use Cleaning agents with chlorine or chloride as the active ingredient are corrosive to stainless steel and must not be used. Cleaning agents with neutral pH are recommended. Do not use Cold Sterilizing Methods for the sterilization of burrs. These agents often contain strong oxidizing chemicals that may dull or weaken burrs. Do not use enzymatic solutions for cleaning or debriding burrs. Reprocessing Limitations: The end of life is determined by wear and damage in use. Carbide burrs should be inspected for defects (i.e. broken tips, broken sections on flutes, etc.) during the cleaning process. Point of Use: Delay in reprocessing must be kept to a minimum to avoid contaminants drying thereby making cleaning more difficult. Containment/Transportation: Carbide burrs can be transported wet or dry and should be protected from damage. If transported wet there is an increased chance of staining or corrosion. Prolonged storage in disinfectant solutions may result in degradation of the product and must be avoided. Ultrasonic Cleaning Procedure: Prepare a fresh pH-neutral cleaning solution; place the carbide burr in the dedicated instrument block (if applicable) and then place in a sonication unit. Follow the agent manufacturers' instructions for correct concentration, exposure time, temperature, and water quality. Completely submerge the device in the cleaning solution and sonicate for at least fifteen (15) minutes. Perform a final thorough rinse of the device and instrument block (if applicable) under running warm tap water for at least (1) minute. Visually inspect to confirm the removal of debris. Repeat the cycle if needed. Dry the device using a non-shedding wipe or clean compressed air. Inspection Testing: Carefully inspect each device to ensure that all debris has been removed. Visually inspect the device for damage/ wear that would prevent proper operation: o Do not use if the tip is broken. o Do not use if there is a broken section of a flute. o Do not use if there is evidence of corrosion. Packaging: Singly: Pack the carbide burr in pouches validated for sterilization In Sets: Place the carbide burr in the dedicated instrument block. Sterilization: Use the following cycle for steam sterilization Cycle Type Minimum Sterilization Exposure Time (minutes) Gravity 10 Pre-vacuum (4 Pulses) 3

Minimum Sterilization Exposure Temperature 135°C (275°F) 134°C (273°F)

Minimum Dry Time (minutes) 30 30

Ensure that the sterilizer manufacturer’s maximum load is not exceeded. Storage: The carbide burr should be stored in the sterilization pouch (or instrument block) until required. Additional Information: These processes have been validated as being capable of preparing carbide burrs for reuse. Any deviation from these instructions should be properly validated for effectiveness and potential adverse results.

ab2instr_rev3_043012.doc

2

Rev: 3, April 2012