Atherton

Washing Systems

Duck Automatic Bedpan and Bottle Flusher Sanitizer Equipment Manual Rev 4 Sept 2011

Equipment Manual

28 Pages

Preview

Page 1

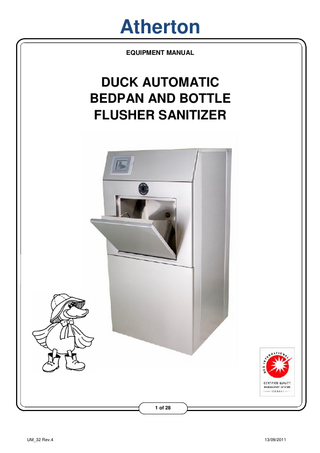

Atherton EQUIPMENT MANUAL

DUCK AUTOMATIC BEDPAN AND BOTTLE FLUSHER SANITIZER

1 of 28

UM_32 Rev.4

13/09/2011

Atherton A WORD FROM ATHERTON This manual contains important information on the proper use and maintenance of the Atherton Duck automatic door series Bedpan and Bottle Flusher Sanitizer range. All operators and Departmental Heads are urged to carefully read this manual and become familiar with the warnings, cautions and instructions contained within it. A thorough Scheduled Maintenance Programme is essential for safe and reliable sterilization. You are urged to contact the ATHERTON SERVICE MANAGER in your State to arrange a maintenance programme for your equipment. The Atherton range of equipment is designed and manufactured in general accordance with applicable Standards Association of Australia codes and relevant statutory requirements in all states. Due to the continuous programme of research and development conducted by ATHERTON, all design details are subject to change without notice. IMPORTANT: For warranty to be valid, complete, sign, and return the "INSTALLATION AND COMMISSIONING” form to: A. E. Atherton & Sons Pty. Ltd. P.O. Box 111, Salisbury Qld 4107 Australia

Warning Must be followed carefully to avoid endangering human life and/or damage to equipment

Caution Should be followed to ensure proper operation of equipment

ADELAIDE UNIT 22, 11-31 PORT WAKEFIELD ROAD GEPPS CROSS, S.A. 5094

PERTH UNIT 3 1914 BEACH ROAD MALAGA, W.A. 6062

Note & Important Contains important information and useful tips on operation of equipment

BRISBANE MELBOURNE COMPANY HEAD OFFICE A.E. ATHERTON & SONS PTY. LTD 364 DAREBIN ROAD, THORNBURY VICTORIA, 3071, AUSTRALIA ACN 004 104 607 TEL.+61 1300 580 870 FAX +61 3 9497 1190 National Service 1300 580 870 www.atherton.net Email: [email protected]

66 RAYNHAM STREET SALISBURY, QLD, 4107

SYDNEY UNIT 6 9 KILTO CRESCENT GLENDENNING NSW 2761

2 of 28

UM_32 Rev.4

13/09/2011

Atherton Section

Topic

Page

1

INSTALLATION 1.1 SERVICE REQUIREMENTS

5 5

2

TECHNICAL DETAILS

6

3

OPERATING INSTRUCTIONS 3.1 FAST START INSTRUCTIONS 3.2 DOOR CONTROL 3.2.1 Door Major Fault - Reset 3.3 SYSTEM ADMINISTRATION 3.4 SYSTEM MENU 3.4.1 Cycle Parameters 3.4.2 Eco/Water Save Cycle Parameters 3.4.3 Alarms 3.4.4 Cycle Charts 3.4.5 System Options 3.4.6 Analog Inputs 3.4.7 The Commission Unit Button 3.4.8 Changing The Administrator Password 3.5 STEAMER RESET

7 7 7 9 10 11 12 13 13 15 15 15 16 16 18

4

CYCLE OPERATION & ABORT SEQUENCE 4.1 SEQUENCE OF OPERATION 4.1.1 Operating Screens – Detailed Mode Turned OFF 4.1.2 Operating Screen – Detailed Mode Turned ON 4.2 ABORT SEQUENCE

19 19 19 20 20

5

ROUTINE MAINTENANCE

22

6

FAULT STATUS 6.1 AUTOMATIC DOOR FAULT 6.2 SYSTEM LOW BATTERY

23 24 24

7

WIRING DIAGRAMS

25

8

SPARE PARTS LISTING

26

9

TROUBLE SHOOTING

27

10 INSTALLATION AND COMMISSIONING REFERENCE FORM

28

3 of 28

UM_32 Rev.4

13/09/2011

Atherton YOUR WARRANTY COVER All equipment manufactured and work performed by the Company is warranted to be of good material throughout, and of good careful workmanship. The Company undertakes to correct and make good any defect or defects, which may develop under normal and proper use within the warranty period which are due to workmanship, provided that the Company is notified immediately after the defect is discovered. The warranty period is twelve months and shall be from the date delivery is made, or notification to the client that delivery can be made. The Company’s liability is limited as provided in these conditions and does not extend to consequential damage, either direct or indirect, that may be caused by any malfunction of the equipment, or to any expense for repair or replacement otherwise paid or incurred without the authority of the Company. The Company does not accept liability or responsibility for the defects or depreciation caused by wear and tear, accidents, lightning, corrosion, neglect, misuse, incorrect installation not carried out by the Company’s personnel or nominees of the Company, incorrectly maintained, incorrect operation or other abnormal conditions. Should field service be required, costs incurred in travelling to and from location of equipment, including travelling time, transportation and accommodation costs, and freight charges of sending replacement parts to and from a nominated Atherton office, are borne by the buyer. All field service will be carried out during normal working hours. If warranty service is requested outside normal working hours such work will be charged at the ruling overtime rates. Requests for replacement parts or components under warranty must be accompanied with a purchase order for the replacement part or component at the ruling spare parts price cost. The defective part or component must be returned to the Atherton office handling the warranty claim complete with details of serial number, catalogue or model number or some means of verifying the unit and its delivery date. After receipt and inspection of the defective part or component the Company shall decide at its sole discretion whether a warranty claim applies. If the claim is granted a credit will be issued for the replacement amount previously charged. Material and equipment not manufactured by the Company are sold under such warranty only as the makers give the Company and the Company is able, without legal expense to enforce, but are not guaranteed by the Company in any way. The warranty and warranty period does not cover such articles which are considered to be expendable, including but not limited to gaskets, filters, bellows, globes, gauges, electrical components.

4 of 28

UM_32 Rev.4

13/09/2011

Atherton 1

INSTALLATION Installation should only be attempted by experienced and qualified personnel fully acquainted with this equipment. Use of inexperienced or unqualified persons could cause personal injury or death. Damage to the equipment may also result in the voiding of your warranty.

1.1

SERVICE REQUIREMENTS Cold Water:

½” B.S.P. Connection

Power:

10 amp GPO

Waste:

To local sewerage authorities Code AS3500.2 100mm PVC DWV connection

Vent:

All units fitted with water plate condensor Vent to atmosphere not required

Water discharge temperature Maximum 40°C

Before using the panflusher ensure that the cold tap is on and that the cold water tank is full. Ensure that there are no leaks. Turn panflusher on at main isolating switch. Refer to Fast Start Instructions, Section 3.1 (page 7) If panflusher faults out during initial run refer to Section 6, Fault Status and Section 9, Troubleshooting.

5 of 28

UM_32 Rev.4

13/09/2011

Atherton 2

TECHNICAL DETAILS

Atherton

6 of 28

UM_32 Rev.4

13/09/2011

Atherton 3

OPERATING INSTRUCTIONS

3.1

FAST START INSTRUCTIONS

3.2

Step 1:

Ensure power is on at isolating switch; immediately the system will start a test cycle – this cycle clears the last cycle and resets the door operation. When completed the unit is ready to start work.

Step 2:

Open washer door - Hold bedpan in front of sensor located approximately 100mm above door opening for hands free operation, or press DOOR CONTROL button on control panel.

Step 3:

Load machine with bedpan or bottles.

Step 4:

Select Go. The Door will automatically close and cycle will start. The display will display cycle stages and operating parameters.

Step 5:

On completion of cycle, open door as detailed in Step 2 and remove sanitized articles.

DOOR CONTROL The Duck is fitted with an automatic door which if set to auto-open after a cycle may never need to be manually activated. If however you require to manually control the door, there are 2 ways to open the door; either simply wave your hand past the electronic eye on the front of the unit, or select the Door button from the home screen:

7 of 28

UM_32 Rev.4

13/09/2011

Atherton

The state of the door is the reverse of what is displayed beneath the Operate Door button. In the case above, the door is currently closed so the Operate Door button will open the door. Hence to open the door, simply press the Operate Door button. The screen will then change to the following:

If the door is obstructed while operating the following screen will appear:

8 of 28

UM_32 Rev.4

13/09/2011

Atherton Once the obstruction has been removed simply touch the Error Fixed Continue button. The door will then attempt to complete the operation it was previously undertaking. 3.2.1 Door Major Fault - Reset If the door operation times out after an obstruction and the user has not acknowledged the error the following Major Fault Screen will appear:

If however you are certain that the obstruction has been removed and that the error does not relate to the door actuator; the procedure then to reset the door is to navigate to the System Menu as described below, and select the Reset Door button.

Reset door button must be pressed on and off; it is NOT momentary i.e. it requires turning off after being turned on. FAILURE TO RESET THE DOOR RESET BUTTON WILL CAUSE DAMAGE.

9 of 28

UM_32 Rev.4

13/09/2011

Atherton 3.3

SYSTEM ADMINISTRATION When the unit is initially powered the control system will go through an initialisation stage. During this stage the touchscreen will display the unit’s IP address, the controller communications and the MAC address of the touchscreen. These parameters are only relevant if the Duck has been configured to operate on the hospital or facilities’ internal data network. Once the duck has gone through its pre-operation initialisation which entails running a cycle, the system will display a cycle passed message with a button for the user to open the door :

This is your indication that the system is ready for operation. Touch anywhere on the button and the door will open after which the screen will return to the home page:

As described above, the process for starting a cycle from here is as simple as waving your hand past the electronic eye on the front of the panel. Once the door has closed select either the GO button for a NORMAL cycle or for a more economical water saver cycle, select the MENU button which will navigate you to the cycle selection screen then select the SAVER cycle button. The unit will then begin the cleaning process. 10 of 28

UM_32 Rev.4

13/09/2011

Atherton To customise the unit select the MENU button from the cycle selection screen. If you are on the home screen you will need to select MENU first then MENU again. To recognise the home screen, it does not have any option to select the SAVER CYCLE. The correct screen from which you can proceed to customise the unit is shown below. Select the MENU button from this screen to proceed to the system menu screen; From there the system can be customised.

3.4

SYSTEM MENU The System Menu screen will display the following menu:

When you select any of the options you will be required to login to Administrator Level. This is done automatically by selecting a button and entering your password: (The default password is ‘333’)

11 of 28

UM_32 Rev.4

13/09/2011

Atherton Once you are logged in select any of the options on the screen, with the exception of the Commission Unit button, the display will change allowing you to enter new operating parameters. We will now discuss each option in detail.

3.4.1 Cycle Parameters The Cycle Parameters button allows you change the operating parameters for the Normal Cycle. This is the cycle that is started by selecting the GO button from the home screen. The following parameters can be altered: 1. Rinse Time 2. Sanitising Temperature 3. Sanitising Time 4. Final Rinse Time The screen below shows the complete list of adjustable cycle parameters:

To adjust a parameter simply touch the raised grey button and enter the new value in the pop-up; then select the return button from the pop-up. The screen will now display the new parameter. IT SHOULD BE NOTED THAT THE AUSTRALIAN STANDARD DICTATES THAT SANITISING SHOULD BE CARRIED OUT AT NO LESS THAN 85°C FOR NO LESS THAN 60sec

To return to the System Menu select the MENU button at the bottom of the screen. 12 of 28

UM_32 Rev.4

13/09/2011

Atherton 3.4.2 Eco/Water Save Cycle Parameters The process of altering the parameters for the SAVER Cycle is identical to the procedure described above.

The Eco/Water Save cycle is the cycle that is started by selecting the SAVER CYCLE button from the home screen. The same precautions regarding the setting of sanitising temperature and sanitising time apply, however it is envisaged that the user may opt for a shorter Rinse Time and shorter Final Rinse Time. 3.4.3 Alarms The Duck has a sophisticated alarm management system, with the user being alerted to an alarm condition by a flashing bell, which appears in the top right hand corner of the screen:

Alarm indicator

13 of 28

UM_32 Rev.4

13/09/2011

Atherton To view the alarm text, the user must log in with an Administrator password, as described in the System Menu section, and then select Alarms from the System Menu:

Here we can see there are two alarms active: -The Steamer Over temp. - Low Sanitising Temperature. To acknowledge an alarm select the line on the screen by touching it; a black outline box will indicate the selected alarm. Then touch the “tick” button from the right hand menu. This will cause the text for the alarm to change colour; this indicates that the alarm is still active but has been acknowledged. When the alarm condition has reset, the text indicating the alarm will change to a grey background colour. When all alarm states have cleared, the ringing bell in the top right hand corner will disappear. To view the time and date of the alarm, select the wristwatch icon from the right hand menu. If the alarm has an associated reset screen, select the “i” icon; this will force the system to change to the reset screen. If however the alarm cannot be reset, the system will immediately indicate that the alarm is still active. The system will retain 1024 alarms; once this number has been reached the earliest alarm is over written as newer alarms occur.

14 of 28

UM_32 Rev.4

13/09/2011

Atherton 3.4.4 Cycle Charts While the system is operating a cycle the following chart is active: The chart records the steamer temperature and the chamber temperature. The chart has an update time of 2 seconds and will retain 500 samples before the earliest sample is over written. To exit out of the chart simply select the RETURN button and the screen will change to the previously displayed screen. 3.4.5 System Options The Duck can be customised in the following ways: 1. The operating screen can be customised to display more detail about the operating cycle. 2. The door can be set to open automatically after a passed cycle. The system options screen is shown below:

3.4.6 Analog Inputs By selecting the Analog Inputs button the system will display the current, chamber and steamer temperatures: 15 of 28

UM_32 Rev.4

13/09/2011

Atherton

To return to the main menu select the Menu button at the bottom of the screen. 3.4.7 The Commission Unit Button The commission unit button is not available to the user. It is to be accessed by Atherton or your designated service personnel. The parameters, which are set by accessing this area of the system directly, effect the performance of the unit. In most cases the parameters are factory set values that should never need changing. 3.4.8 Changing The Administrator Password Before we discuss the process of changing the administrator password it is important to understand what access the Administrator level is required for. The Administrator level of access is required to: 1. Acknowledge a failed cycle, and proceed to open the door. 2. Reset the steamer over temperature alarm. 3. Access the system menu. 4. Customise the operating screen. 5. Set the system options. To remove Administrator protection simply delete the password. To change the Administrator password, select the Passwords button from the system menu. This will display the passwords pop-up. The Administrator password is the Level 3 value; in this case it is set to the default “333”. 16 of 28

UM_32 Rev.4

13/09/2011

Atherton To change the password, select the value next to the text Level 3 (Levels 1 & 2 are reserved for future system features, they are not used in this version of the Duck). In this case select 333. The screen will now display the standard input pop-up:

I can now enter the new password – I am entering the value “123”. When complete I then select the return button. To commit the new password use the scroll down arrows until the OK button on the passwords screen is available, then select OK:

I have now changed the Administrator password from “333” to “123”.

17 of 28

UM_32 Rev.4

13/09/2011

Atherton 3.5

STEAMER RESET If the temperature in the steamer has been greater than 110°C for more than 2 seconds, the system will go into alarm and alert the user that the steamer requires resetting. If this condition occurs during a cycle, the cycle will abort. There are two ways to reset the steamer. 1. From the System Menu:

2.Via the steamer alarm page:

Steamer Reset

18 of 28

UM_32 Rev.4

13/09/2011

Atherton 4

CYCLE OPERATION & ABORT SEQUENCE The previous section details the procedure for operating and customising your Duck Sanitiser. In this section we will discuss the sequence of operation for a cycle, and we will also look at what to do when the Duck aborts a cycle.

4.1

SEQUENCE OF OPERATION NOTE: This sequence applies to both the Saver Cycle and the Normal Cycle. After you have selected a cycle from the home screen, the system will either close the door, or if the door is closed, start the cycle. The cycle sequence is as follows: 1. Rinse Stage – cold water is sprayed into the chamber to rinse the contents. 2. Sanitising Stage - the steamer is enabled and once cycle setpoint is achieved by monitoring the chamber temperature, the cycle holding time is counted down to zero. 3. Final Rinse Stage - cold water is sprayed into the chamber to rinse and cool down the contents.

4.1.1 Operating Screens – Detailed Mode Turned OFF During the cycle the system will display the following screen: Remaining sanitizing time Chamber temperature

When the unit is sanitizing the text SANITIZING appears here.

19 of 28

UM_32 Rev.4

13/09/2011

Atherton 4.1.2 Operating Screen – Detailed Mode Turned ON With the system operating in detailed mode – set in the systems option screen - while a cycle is running the following screen is displayed:

4.2

ABORT SEQUENCE At any stage during a cycle the cycle can be aborted by touching the ABORT CYCLE button. The user will be forced to log in with the Administrator password and then touch the button again. This will cause the cycle to be aborted and the system will proceed with the following abort sequence: 1. Display the Cycle Aborting Screen:

2. If the steamer is active it will be shut-off. 3. The final rinse stage will be initiated. 4. If the chamber temperature is below 85°C and the hi-level indicator is off, the system will display the following Cycle Finished - Fail Screen: 20 of 28

UM_32 Rev.4

13/09/2011