BBraun

Elbow tube adapter GA508R

27 Pages

Preview

Page 1

Aesculap®

1

2/3

Aesculap Power Systems

Instructions for use/Technical description Elbow tube adapter GA508R Gebrauchsanweisung/Technische Beschreibung Winkel-Schlauch-Adapter GA508R Mode d’emploi/Description technique Adaptateur de tuyau coudé GA508R Instrucciones de manejo/Descripción técnica Adaptador de tubo acodado GA508R Istruzioni per l’uso/Descrizione tecnica Adattatore angolare per tubi flessibili GA508R Instruções de utilização/Descrição técnica Adaptador angulado para tubo GA508R Gebruiksaanwijzing/Technische beschrijving Haakse slangadapter GA508R Bruksanvisning/Teknisk beskrivning Vinkel-slang-adapter GA508R Инструкция по примению/Техническое описание Угловой адаптер для шланга GA508R Návod k použití/Technický popis Zahnutý hadicový adaptér GA508R Instrukcja użytkowania/Opis techniczny Adapter kątowy do węży GA508R Návod na použivanie/Technický opis Adaptér pre ohyb hadice GA508R Kullanım Kılavuzu/Teknik açiklama Açılı hortum adaptörü GA508R

A 4

B

2/3

4

9

1 2/3

8

C 5

D

4 1/3

4

2

2/3

6

6

Aesculap AG | Am Aesculap-Platz | 78532 Tuttlingen | Germany Phone +49 (0) 7461 95-0 | Fax +49 (0) 7461 95-26 00 | www.aesculap.com Aesculap – a B. Braun company TA-Nr. 011268

12/13

- DIR 93/42/EEC

V6

Änd.-Nr. 48989

E

Technical alterations reserved

F

7

8

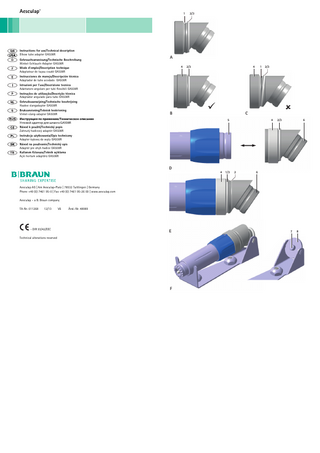

Assembly ► Ensure that lock ring 3 is positioned in the rear groove 2 and that sleeve 4 is touching lock ring 3, see Fig. B. ► Attach angled hose adapter fully onto the hose connector of the motor 5, see Fig. D. ► To lock: Push sleeve 4 in the direction of the motor. To do this, gently move the adapter to and fro axially, until

®

Aesculap Elbow tube adapter GA508R

the balls of the adapter come to rest in the groove on the hose connector of the motor 5. When the sleeve 4 is positioned correctly, the front groove 1 is visible. ► Push lock ring 3 into front groove 1, see Fig. E. The lock ring must not be positioned at a slant between the two grooves 1/2, see Fig. C. ► Pull at the elbow tube adapter to ensure that it is coupled correctly. ► Check that the elbow tube adapter can be turned smoothly.

Legend 1 2 3 4 5 6 7 8

Front groove for lock ring Rear groove for lock ring Lock ring Sleeve Motor tube connector Tube connector of the adapter Pin Adapter plate

Disassembly

WARNING

Symbols on product and packages Caution, general warning symbol Caution, see documentation supplied with the product

► Push the lock ring 3 away from the motor into the rear groove 2. ► To unlock: Push the sleeve 2 backwards, until it touches the lock ring 3, see Fig. B. ► Detach the elbow tube adapter from the motor.

5.2

Function checks

Follow the instructions for use WARNING Date of manufacture

1.

Danger to the patient! If the sleeve is pushed back too far, the balls can fall out. ► Do not push the lock ring further than the rear groove. ► Do not remove the lock ring completely from the angled hose adapter.

Applicable to

► For item-specific instructions for use and information on material compatibility, see also the Aesculap Extranet

Risk of injury if incorrectly assembled! The angled hose adapter (including compressed-air hose) can become detached from the motor on pressurization and be ejected. The user may be struck by the angled hose adapter and may injure the patient as a result of an unintentional movement due to the shock. Components of the angled hose adapter may become detached, in the worst-case scenario, over the operating site. ► Ensure that the angled hose adapter is properly assembled according to the description and figures. ► Check that it is securely fitted by pulling on the angled hose adapter or on the compressed-air hose. ► Ensure that the lock ring is fully touching the sleeve and fully positioned in the groove, see Fig. E. ► Ensure that the lock ring is not deformed.

at www.extranet.bbraun.com ► Before using the motor with the elbow tube adapter, always perform a trial run and check for proper and reliable

2.

functioning.

Safe handling

CAUTION Federal law restricts this device to sale by, or on order of a physician! ► Prior to use, check that the product is in good working order. ► To prevent damage caused by improper setup or operation, and in order not to compromise warranty and manufacturer liability: – Use the product only according to these instructions for use. – Follow the safety and maintenance instructions. – Only combine Aesculap products with each other. ► Ensure that the product and its accessories are operated and used only by persons with the requisite training, knowledge, or experience. ► Keep the instructions for use accessible for the user.

3.

Product description

3.1

Intended use

Designation

Art. no.

HiLAN motor

GA519

HiLAN hand lever motor

GA529

microLAN motor

GA553

HiLAN XS motor

GA740R

Operating principle

The elbow tube adapter serves as a coupling between the motor and the motor tube; it can be connected at any angular position on the tube connector on motor 1. The elbow tube adapter has been designed to stay on the motor.

4.

Preparation

Non-compliance with the following instructions will preclude all responsibility and liability in this respect on the part of Aesculap.

5.

Working with the elbow tube adapter GA508R

5.1

System set-up

CAUTION

5.3

Safe operation

► Always observe the instructions for use of the connected motor.

6.

Validated reprocessing procedure

► Reprocess the elbow tube adapter in the same way as the motor; see the instructions for the motor in use.

6.1

General safety instructions

Note Adhere to national statutory regulations, national and international standards and directives, and local, clinical hygiene instructions for sterile processing.

The elbow tube adapter GA508R is used as an angled interface for connecting the motor tube to one of the following motors:

3.2

► Check that the elbow tube adapter can be turned smoothly. ► Check that the elbow tube adapter is not leaking.

On pressurization, air will escape unhindered if the angled hose adapter is connected with the motor hose but not with a motor! The angled hose adapter does not have a shut-off valve. ► Leave the angled hose adapter on the motor. ► Do not leave the angled hose adapter on the hose.

The angled hose adapter has two grooves for two positions of the lock ring 3, see Fig. A: ■ Front groove 1: Lock the angled hose adapter on the motor ■ Rear groove: 2 Assembling/disassembling the angled hose adapter

Note For patients with Creutzfeldt-Jakob disease (CJD), suspected CJD or possible variants of CJD, observe the relevant national regulations concerning the reprocessing of products. Note Mechanical reprocessing should be favored over manual cleaning as it gives better and more reliable results. Note Successful processing of this medical device can only be ensured if the processing method is first validated. The operator/sterile processing technician is responsible for this. The recommended chemistry was used for validation. Note If there is no final sterilization, then a virucidal disinfectant must be used. Note For the latest information on reprocessing and material compatibility see also the Aesculap extranet at www.extranet.bbraun.com The validated steam sterilization procedure was carried out in the Aesculap sterile container system.

6.2

General information

Dried or affixed surgical residues can make cleaning more difficult or ineffective and lead to corrosion. Therefore the time interval between application and processing should not exceed 6 h; also, neither fixating pre-cleaning temperatures >45 °C nor fixating disinfecting agents (active ingredient: aldehydes/alcohols) should be used. Excessive measures of neutralizing agents or basic cleaners may result in a chemical attack and/or to fading and the laser marking becoming unreadable visually or by machine for stainless steel. Residues containing chlorine or chlorides e.g. in surgical residues, medicines, saline solutions and in the service water used for cleaning, disinfection and sterilization will cause corrosion damage (pitting, stress corrosion) and result in the destruction of stainless steel products. These must be removed by rinsing thoroughly with demineralized water and then drying. Additional drying, if necessary. Only process chemicals that have been tested and approved (e.g. VAH or FDA approval or CE mark) and which are compatible with the product’s materials according to the chemical manufacturers’ recommendations may be used for processing the product. All the chemical manufacturer's application specifications must be strictly observed. Failure to do so can result in the following problems: ■ Optical changes of materials, e.g. fading or discoloration of titanium or aluminum. For aluminum, the application/process solution only needs to be of pH >8 to cause visible surface changes. ■ Material damage such as corrosion, cracks, fracturing, premature aging or swelling. ► Do not use metal cleaning brushes or other abrasives that would damage the product surfaces and could cause corrosion. ► Further detailed advice on hygienically safe and material-/value-preserving reprocessing can be found at www.ak-i.org, link to Publications, Red Brochure – Proper maintenance of instruments.

6.3

Preparations at the place of use

► Remove any visible surgical residues to the extent possible with a damp, lint-free cloth. ► Transport the dry product in a sealed waste container for cleaning and disinfection within 6 hours.

6.4

9.

Preparation before cleaning

► For reprocessing, leave the elbow tube adapter coupled to the motor. ► Carry out non-fixating/NaCl-free pre-cleaning immediately after use.

6.5

Inspection, maintenance and checks

► Allow the product to cool down to room temperature. ► Leave the elbow tube adapter coupled to the motor. ► Inspect the product after each cleaning and disinfecting cycle to be sure it is: clean, functional, and undamaged. ► Lubricate the motor through the elbow tube adapter. ► Set aside the product if it is damaged.

6.6

Packaging

► Always follow the instructions for use of the respective packaging and storage devices (e.g. instructions for use

TA009721 for the Aesculap storage system). ► Mount the storage tray with the GB577R mounting set GB473 onto the perforated basket. ► To load, put the motor with angled hose adapter onto the pin 7 so that the hose connector of the adapter 6

touches the adapter plate 8, see Fig. F. ► To remove, hold the motor at the rear and pull it off vertically from pin 7. ► Pack trays appropriately for the sterilization process (e.g. in Aesculap sterile containers). ► Ensure that the packaging will prevent a recontamination of the product.

6.7

Accessories/Spare parts

Art. no.

Designation

GA505R

Motor tube (5 m) Aesculap Dräger system

GA506R

Motor tube (5 m) Schrader system

GA507R

Motor tube (5 m) DIN connector

GA513R

Motor tube (3 m) Aesculap Dräger system

GA523R

Motor tube (2.3 m) Aesculap Dräger system

GB473

Eccos mounting set

GB577R

Storage

10. Weight

24 g

Dimensions

∅ 20.5 mm x 25 mm

Steam sterilization

► Check to ensure that the sterilizing agent will come into contact with all external and internal surfaces (e.g. by

opening any valves and faucets). ► Validated sterilization process

– Steam sterilization using fractional vacuum process – Steam sterilizer according to DIN EN 285 and validated according to DIN EN ISO 17665 – Sterilization using fractional vacuum process at 134 °C, minimum holding time 5 min ► When sterilizing several products at the same time in a steam sterilizer, ensure that the maximum load capacity of the steam sterilizer specified by the manufacturer is not exceeded.

11.

-6

To achieve a sterility assurance level of 10 , Aesculap recommends the following parameters: Aesculap Orga Tray/Sterile container (perforated bottom) Minimum cycle parameters*

► Detailed information concerning the disposal of the product is available through your national B. Braun/Aesculap

agency, see Technical Service.

Temp.

Time

Minimum drying time

Prevacuum

270 °F/275 °F

4 min

20 min

*Aesculap has validated the above sterilization cycle and has the data on file. The validation was accomplished in an Aesculap sterile container cleared by FDA for the sterilization and storage of these products. Other sterilization cycles may also be suitable, however individuals or hospitals not using the recommended method are advised to validate any alternative method using appropriate laboratory techniques. Use an FDA cleared accessory to maintain sterility after processing, such as a wrap, pouch, etc.

Storage

► Store sterile products in germ-proof packaging, protected from dust, in a dry, dark, temperature-controlled area.

Maintenance

The elbow tube adapter GA508R is a maintenance-free product.

8.

Technical Service Risk of injury and/or malfunction! ► Do not modify the product. WARNING

► For service and repairs, please contact your national B. Braun/Aesculapagency.

Modifications carried out on medical technical equipment may result in loss of guarantee/warranty rights and forfeiture of applicable licenses. Service addresses Aesculap Technischer Service Am Aesculap-Platz 78532 Tuttlingen / Germany Phone: +49 (7461) 95 -1601 Fax: +49 (7461) 14 -939 E-Mail: [email protected] Or in the US: Aesculap Inc. Attn. Aesculap Technical Services 615 Lambert Pointe Drive Hazelwood MO, 63042 USA Aesculap Repair Hotline Phone: +1 (800) 214 -3392 Fax: +1 (314) 895 -4420 Other service addresses can be obtained from the address indicated above.

Distributor in the US/Contact in Canada for product information and complaints

Aesculap Inc. 3773 Corporate Parkway Center Valley, PA, 18034, USA TA-Nr. 011268

Sterilization method

7.

Disposal

Note The user institution is obliged to process the product before its disposal, see Validated reprocessing procedure.

12. 6.8 Sterilization for the US market ■ Aesculap advises against sterilizing the device by flash sterilization or chemical sterilization. ■ Sterilization may be accomplished by a standard prevacuum cycle in a steam autoclave.

6.9

Technical data

12/13

V6

Änd.-Nr. 48989