BBraun

Endoscopic myoma screw

40 Pages

Preview

Page 1

Aesculap® A

Aesculap Endoscopic Technology

Instructions for use/Technical description Endoscopic myoma screw Gebrauchsanweisung/Technische Beschreibung Endo-Myomheber Mode d’emploi/Description technique Système de traction pour myome Instrucciones de manejo/Descripción técnica Endotirabuzón para miomas Istruzioni per l’uso/Descrizione tecnica Endo-tiramiomi Instruções de utilização/Descrição técnica Alavanca de endomioma Gebruiksaanwijzing/Technische beschrijving Endo myoomhaak Bruksanvisning/Teknisk beskrivning Endo-myomlyft Инструкция по примению/Техническое описание Эндоскопический винт миомный Návod k použití/Technický popis Endoskopický zdvihač myomu Instrukcja użytkowania/Opis techniczny Endoskopowa śruba do mięśniaków Návod na použivanie/Technický opis Myómový endozdvíhač Kullanım Kılavuzu/Teknik açiklama Endo ur kaldırıcısı

A1 6

A2

B 6

B1

Aesculap AG | Am Aesculap-Platz | 78532 Tuttlingen | Germany Phone +49 (0) 7461 95-0 | Fax +49 (0) 7461 95-26 00 | www.aesculap.com

B2

Aesculap – a B. Braun company

11 TA-Nr. 014006

08/13

6

7

8

1

V6

- DIR 93/42/EEC Technical alterations reserved

6

7

10

8

9

3 2

4 5

I

II

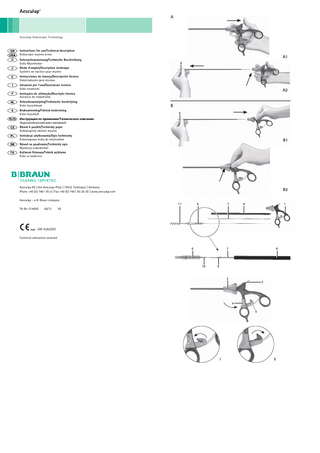

Assembling Aesculap® Endoscopic myoma screw Legend 1 Handle (complete) 2 HF pin 3 Star wheel 4 Actuating lever 5 Switch (lubrication point) 6 Jaw insert (lubrication point) 7 Inner tube 8 Outer tube 9 Leaf springs 10 Nib 11 Myoma screw

Symbols on product and packages

Note For assembling the product, also see additional series of illustrations B. Star wheel 3 must be arrested in such a way that the red colored ring is visible. ► Deactivate the ratchet mechanism on the handle with lock: Position switch 5, see I. ► Assemble the shaft:

– Push inner tube 7 with the four flexible tongues 9 onto the jaw insert 6 in the direction of the working end as far as it will go, so that the two nibs 10 are guided into the flexible tongues 9. – Slide outer tube 8 over inner tube 7 onto jaw insert 6 as far as it will go. ► Hold the assembled shaft at jaw insert 6 with one hand. ► With the other hand, hold handle 1 behind star wheel 3 at the fixed handle part. The moveable part of the handle must still be freely moveable. ► Push the shaft into the handle. The moveable part of the handle will move down. When the stop is reached, star wheel 3 automatically clicks into place at the distal end. The red colored ring is not visible anymore. ► Check to make sure that the instrument is working properly by opening and closing the jaws. ► Grasp the myoma screw 11 with the holding instrument.

Validated reprocessing procedure General safety instructions

Caution, general warning symbol Caution, see documentation supplied with the product

Note Adhere to national statutory regulations, national and international standards and directives, and local, clinical hygiene instructions for sterile processing.

Date of manufacture

Note For patients with Creutzfeldt-Jakob disease (CJD), suspected CJD or possible variants of CJD, observe the relevant national regulations concerning the reprocessing of products. Note Mechanical reprocessing should be favored over manual cleaning as it gives better and more reliable results.

Intended use The endoscopic myoma screw is used to manipulate myomas. Unlike conventional myoma drills, the drill can be separated from the instrument for easier manipulation of the myoma. The drill then remains in the myoma. To manipulate the myoma, the drill can be picked up again via a different approach.

Safe handling and preparation CAUTION Federal law restricts this device to sale by, or on order of a physician! ► Ensure that the product and its accessories are operated and used only by persons with the requisite training, knowledge, or experience. ► Read, follow, and keep the instructions for use. ► Use the product only in accordance with its intended use, see Intended use. ► Remove the transport packaging and clean the new product, either manually or mechanically, prior to its initial sterilization. ► Store any new or unused products in a dry, clean, and safe place. ► Prior to each use, inspect the product for loose, bent, broken, cracked, worn, or fractured components. ► Do not use the product if it is damaged or defective. Set aside the product if it is damaged. ► Replace any damaged components immediately with original spare parts. ► To avoid damage to the working tip and to the trocar: Carefully insert the product through the working channel (e.g. trocar).

Safe operation Risk of injury and/or malfunction! ► Always carry out a function check prior to using the product. WARNING Risk of injury when using the product beyond the field of view! ► Apply the product only under visual control.

Note Successful processing of this medical device can only be ensured if the processing method is first validated. The operator/sterile processing technician is responsible for this. The recommended chemistry was used for validation. Note If there is no final sterilization, then a virucidal disinfectant must be used. Note For the latest information on reprocessing and material compatibility see also the Aesculap extranet at www.extranet.bbraun.com The validated steam sterilization procedure was carried out in the Aesculap sterile container system.

General information Dried or affixed surgical residues can make cleaning more difficult or ineffective and lead to corrosion. Therefore the time interval between application and processing should not exceed 6 h; also, neither fixating pre-cleaning temperatures >45 °C nor fixating disinfecting agents (active ingredient: aldehydes/alcohols) should be used. Excessive measures of neutralizing agents or basic cleaners may result in a chemical attack and/or to fading and the laser marking becoming unreadable visually or by machine for stainless steel. Residues containing chlorine or chlorides e.g. in surgical residues, medicines, saline solutions and in the service water used for cleaning, disinfection and sterilization will cause corrosion damage (pitting, stress corrosion) and result in the destruction of stainless steel products. These must be removed by rinsing thoroughly with demineralized water and then drying. Additional drying, if necessary. Only process chemicals that have been tested and approved (e.g. VAH or FDA approval or CE mark) and which are compatible with the product’s materials according to the chemical manufacturers’ recommendations may be used for processing the product. All the chemical manufacturer's application specifications must be strictly observed. Failure to do so can result in the following problems: ■ Optical changes of materials, e.g. fading or discoloration of titanium or aluminum. For aluminum, the application/process solution only needs to be of pH >8 to cause visible surface changes. ■ Material damage such as corrosion, cracks, fracturing, premature aging or swelling. ► Do not use metal cleaning brushes or other abrasives that would damage the product surfaces and could cause corrosion. ► Further detailed advice on hygienically safe and material-/value-preserving reprocessing can be found at www.ak-i.org, link to Publications, Red Brochure – Proper maintenance of instruments.

Disassembling the product before carrying out the reprocessing procedure ► Disassemble the product immediately after use, as described in the respective instructions for use. ► Open up instruments with hinges.

WARNING Risk of injury if the product is used with HF current! The product is not intended for use with HF current. ► Do not use the product with HF current. WARNING ► To open and close the distal end of the jaws: open and close the moveable part of the handle. ► Grasp the myoma screw P0183R 11 with the jaw parts of the jaw insert 6.

Preparations at the place of use ► If applicable, rinse non-visible surfaces preferably with deionized water, with a disposable syringe for example. ► Remove any visible surgical residues to the extent possible with a damp, lint-free cloth. ► Transport the dry product in a sealed waste container for cleaning and disinfection within 6 hours.

Preparation before cleaning ► Dismantle the product prior to cleaning, see Disassembling.

Handle with lock ► Press actuating lever 4 to release the ratchet mechanism. ► To activate the ratchet mechanism, release actuating lever 4.

Cleaning/disinfection

Switch 5 can be used for permanently deactivating the ratchet mechanism. ► To deactivate the ratchet mechanism on the handle: Position switch 5, see I. The switch clicks into the front position. ► To activate the ratchet mechanism on the handle: Position switch 5, see II. The switch clicks into the back position.

Product-specific safety notes on the reprocessing procedure

CAUTION

Disassembling Note For disassembling the product, also see additional series of illustrations A. ► Deactivate the ratchet mechanism on the handle with lock: Position switch 5, see I. ► Turn star wheel 3 proximally until it clicks into place. A red colored ring becomes visible. ► Detach the shaft from the handle: Hold the jaw insert 6 at the tip and together with inner tube 7 and outer

tube 8 pull it out of the handle 1. Do not hold the moveable part of the handle. The moveable part of the handle will move up. ► Disassemble the shaft: Remove outer tube 8 and inner tube 7 from jaw insert 6.

Damage to the product due to inappropriate cleaning/disinfecting agents and/or excessive temperatures! ► Use cleaning and disinfecting agents approved for plastics and high-grade steel according to manufacturer’s instructions. ► Observe specifications regarding concentration, temperature and exposure time. ► Do not exceed the maximum allowable temperature of 96 °C.

► Use suitable cleaning/disinfecting agents if the product is put away in a wet condition. To prevent foam forma-

tion and reduced effectiveness of the process chemicals: Prior to mechanical cleaning and disinfection, rinse the product thoroughly with running water. ► Carry out ultrasound cleaning: – as an effective mechanical supplement to manual cleaning/disinfection. – as a pre-cleaning procedure for products with encrusted residues, in preparation for mechanical cleaning/ disinfection. – as an integrated mechanical support measure for mechanical cleaning/disinfection. – for additional cleaning of products with residues left after mechanical cleaning/disinfection.

Validated procedure

Specific requirements

Reference

Phase V ► Dry the product in the drying phase with suitable equipment (e.g. cloth, compressed air), see Validated cleaning and disinfection procedure.

Manual cleaning with ultrasound and immersion disinfection

■ Cleaning brush, e.g., PM995R

Chapter Manual cleaning/disinfection and sub-chapter:

Mechanical cleaning/disinfecting

■ Chapter Manual cleaning with

Note The cleaning and disinfection device must be of tested and approved effectiveness (e.g. FDA approval or CE mark according to DIN EN ISO 15883).

Validated cleaning and disinfection procedure

■ Shaft ■ Handle

or GK469R

■ 20 ml disposable syringe ■ Keep working ends open for

ultrasound and immersion disinfection

cleaning.

Note The cleaning and disinfection device used for processing must be serviced and checked at regular intervals.

■ When cleaning instruments with movable hinges, ensure that these are in an open position and, if applicable, move the hinge while cleaning.

Mechanical alkaline cleaning and thermal disinfecting Machine type: single-chamber cleaning/disinfection device without ultrasound

■ Drying phase: Use a lint-free

Phase

Step

T [°C/°F]

t [min]

Water quality

Chemical/Note

Chapter Mechanical cleaning/disinfecting and sub-chapter:

I

Prerinse

<25/77

3

D–W

-

■ Chapter Mechanical alkaline

II

Cleaning

55/131

10

FD-W

■ Concentrate, alkaline:

cloth or medical compressed air Mechanical alkaline cleaning and thermal disinfection

■ Place the instrument in a tray that is suitable for cleaning (avoiding rinsing blind spots).

■ Handle only

■ Connect components with

cleaning and thermal disinfecting

lumens and channels directly to the rinsing port of the injector carriage.

– pH = 13 – <5 % anionic surfactant

■ 0.5 % working solution – pH = 11*

■ Keep working ends open for cleaning.

■ Place instruments in the tray

III

Intermediate rinse

>10/50

1

FD-W

-

IV

Thermal disinfecting

90/194

5

FD-W

-

V

Drying

-

-

-

According to the program for cleaning and disinfection device

with their hinges open. Manual pre-cleaning with brush and subsequent mechanical alkaline cleaning and thermal disinfection

■ Shaft only

■ Cleaning brush, e.g., PM995R or GK469R

■ 20 ml disposable syringe ■ Place the instrument in a tray that is suitable for cleaning (avoiding rinsing blind spots).

Chapter Mechanical cleaning/disinfection with manual pre-cleaning and sub-chapter:

■ Chapter Manual pre-cleaning with a brush

■ Chapter Mechanical alkaline

■ Connect components with lumens and channels directly to the rinsing port of the injector carriage.

cleaning and thermal disinfecting

D–W: FD–W:

Drinking water Fully desalinated water (demineralized, low microbiological contamination: drinking water quality at least) *Recommended: BBraun Helimatic Cleaner alkaline ► Check visible surfaces for residues after mechanical cleaning/disinfecting.

■ Keep working ends open for

Mechanical cleaning/disinfection with manual pre-cleaning

cleaning.

■ Place instruments in the tray

Note The cleaning and disinfection device must be of tested and approved effectiveness (e.g. FDA approval or CE mark according to DIN EN ISO 15883).

with their hinges open.

Note The cleaning and disinfection device used for processing must be serviced and checked at regular intervals.

Manual cleaning/disinfection ► Prior to manual disinfecting, allow water to drip off for a sufficient length of time to prevent dilution of the dis-

infecting solution.

Manual pre-cleaning with a brush

► After manual cleaning/disinfection, check visible surfaces visually for residues. ► Repeat the cleaning /disinfection process if necessary.

Manual cleaning with ultrasound and immersion disinfection Phase

Step

T [°C/°F]

t [min]

Conc. [%]

Water quality

Chemical

I

Ultrasonic cleaning

RT (cold)

>15

2

D–W

Aldehyde-free, phenol-free, and QUAT-free concentrate, pH ~ 9*

II

Intermediate rinse

RT (cold)

1

-

D–W

-

III

Disinfection

RT (cold)

15

2

D–W

Aldehyde-free, phenol-free, and QUAT-free concentrate, pH ~ 9*

Phase

Step

T [°C/°F]

t [min]

Conc. [%]

Water quality

Chemical

I

Disinfectant cleaning

RT (cold)

>15

2

D–W

Aldehyde-free, phenol-free, and QUAT-free concentrate, pH ~ 9*

II

Rinsing

RT (cold)

1

-

D–W

-

D–W: Drinking water RT: Room temperature *Recommended: BBraun Stabimed ► Note the information on appropriate cleaning brushes and disposable syringes, see Validated cleaning and dis-

IV

Final rinse

RT (cold)

1

-

FD-W

-

V

Drying

RT

-

-

-

-

D–W: FD–W:

Drinking water Fully desalinated water (demineralized, low microbiological contamination: drinking water quality at least) RT: Room temperature *Recommended: BBraun Stabimed ► Note the information on appropriate cleaning brushes and disposable syringes, see Validated cleaning and dis-

infection procedure. Phase I ► Fully immerse the product in the cleaning/disinfectant for at least 15 min. Ensure that all accessible surfaces are moistened. ► Clean the product with a suitable cleaning brush in the solution until all discernible residues have been removed from the surface. ► If applicable, brush through non-visible surfaces with an appropriate cleaning brush for at least 1 min. ► Mobilize non-rigid components, such as set screws, links, etc. during cleaning. ► Thoroughly rinse through these components with the cleaning disinfectant solution (at least five times), using a disposable syringe. Phase II ► Rinse/flush the product thoroughly (all accessible surfaces) under running water. ► Mobilize non-rigid components, such as set screws, joints, etc. during rinsing.

infection procedure. Phase I ► Clean the product in an ultrasonic cleaning bath (frequency 35 kHz) for at least 15 min. Ensure that all accessible surfaces are immersed and acoustic shadows are avoided. ► Clean the product with a suitable cleaning brush in the solution until all discernible residues have been removed from the surface. ► If applicable, brush through non-visible surfaces with an appropriate cleaning brush for at least 1 min. ► Mobilize non-rigid components, such as set screws, links, etc. during cleaning. ► Thoroughly rinse through these components with the cleaning disinfectant solution (at least five times), using a disposable syringe.

Mechanical alkaline cleaning and thermal disinfecting Machine type: single-chamber cleaning/disinfection device without ultrasound Phase

Step

T [°C/°F]

t [min]

Water quality

Chemical

I

Prerinse

<25/77

3

D–W

-

II

Cleaning

55/131

10

FD-W

■ Concentrate, alkaline: – pH = 13 – <5 % anionic surfactant

Phase II ► Rinse/flush the product thoroughly (all accessible surfaces) under running water. ► Mobilize non-rigid components, such as set screws, joints, etc. during rinsing. ► Drain any remaining water fully.

■ 0.5 % working solution – pH = 11* III

Intermediate rinse

>10/50

1

FD-W

-

Phase III ► Fully immerse the product in the disinfectant solution. ► Mobilize non-rigid components, such as set screws, joints, etc. during rinsing. ► Rinse lumens at least five times at the beginning of the exposure time with an appropriate disposable syringe. Ensure that all accessible surfaces are moistened.

IV

Thermal disinfecting

90/194

5

FD-W

-

V

Drying

-

-

-

Phase IV ► Rinse/flush the product thoroughly (all accessible surfaces) under running water. ► Mobilize non-rigid components, such as set screws, joints, etc. during final rinse. ► Rinse lumens with an appropriate disposable syringe at least five times. ► Drain any remaining water fully.

According to the program for cleaning and disinfection device

D–W: FD–W:

Drinking water Fully desalinated water (demineralized, low microbiological contamination: drinking water quality at least) *Recommended: BBraun Helimatic Cleaner alkaline

► Check visible surfaces for residues after mechanical cleaning/disinfecting.

Disposal ► Adhere to national regulations when disposing of or recycling the product, its components and its packaging!

Inspection, maintenance and checks

CAUTION

Damage (metal seizure/friction corrosion) to the product caused by insufficient lubrication! ► Prior to function checks, lubricate moving parts (e.g. joints, pusher components) at the marked lubrication points, using maintenance oil suitable for the respective sterilization process (e.g. for steam sterilization: STERILIT® I oil spray JG600 or STERILIT® I drip lubricator JG598).

► Allow the product to cool down to room temperature. ► After each complete cleaning, disinfecting and drying cycle, check that the instrument is dry, clean, operational,

and free of damage (e.g. broken insulation or corroded, loose, bent, broken, cracked, worn, or fractured components). ► Dry the product if it is wet or damp. ► Repeat cleaning and disinfection of products that still show impurities or contamination. ► Check that the product functions correctly. ► Immediately put aside damaged or inoperative products and send them to Aesculap Technical Service, see Technical Service. ► Assemble dismountable products, see Assembling. ► Check for compatibility with associated products.

Packaging ► Store products with ratchet locks fully opened or locked no further than in the first notch. ► Place the product in its holder or on a suitable tray. ► Pack trays appropriately for the intended sterilization process (e.g. in sterile Aesculap containers). ► Ensure that the packaging provides sufficient protection against recontamination of the product during storage.

Steam sterilization Note The product can be sterilized either in disassembled or in assembled condition. Note To avoid breakage due to stress crack corrosion, sterilize the instruments with the lock fully open or locked no further than on the first ratchet tooth. ► Check to ensure that the sterilizing agent will come into contact with all external and internal surfaces (e.g. by

opening any valves and faucets). ► Validated sterilization process

– Steam sterilization using fractionated vacuum process – Steam sterilizer according to DIN EN 285 and validated according to DIN EN ISO 17665 – Sterilization using fractionated vacuum process at 134 °C/holding time 5 min ► When sterilizing several instruments at the same time in a steam sterilizer, ensure that the maximum load capacity of the steam sterilizer specified by the manufacturer is not exceeded.

Sterilization for the US market ■ Aesculap advises against sterilizing the device by flash sterilization or chemical sterilization. ■ Sterilization may be accomplished by a standard prevacuum cycle in a steam autoclave. To achieve a sterility assurance level of 10-6, Aesculap recommends the following parameters: Aesculap Orga Tray/Sterile container (perforated bottom) Minimum cycle parameters* Sterilization method

Temp.

Time

Minimum drying time

Prevacuum

270 °F/275 °F

4 min

20 min

*Aesculap has validated the above sterilization cycle and has the data on file. The validation was accomplished in an Aesculap sterile container cleared by FDA for the sterilization and storage of these products. Other sterilization cycles may also be suitable, however individuals or hospitals not using the recommended method are advised to validate any alternative method using appropriate laboratory techniques. Use an FDA cleared accessory to maintain sterility after processing, such as a wrap, pouch, etc.

Storage ► Store sterile products in germ-proof packaging, protected from dust, in a dry, dark, temperature-controlled area.

Technical Service Risk of injury and/or malfunction! ► Do not modify the product. WARNING ► For service and repairs, please contact your national B. Braun/Aesculap agency.

Modifications carried out on medical technical equipment may result in loss of guarantee/warranty rights and forfeiture of applicable licenses. Service addresses Aesculap Technischer Service Am Aesculap-Platz 78532 Tuttlingen / Germany Phone: +49 (7461) 95-1602 Fax: +49 (7461) 16-5621 E-Mail: [email protected] Or in the US: Aesculap Inc. Attn. Aesculap Technical Services 615 Lambert Pointe Drive Hazelwood MO, 63042 Aesculap Repair Hotline Phone: +1 (800) 214-3392 Fax: +1 (314) 895-4420 Other service addresses can be obtained from the address indicated above.

Accessories/Spare parts For accessories and spare parts, see brochure C766 or visit http://www.endoscopy-catalog.com

Distributor in the US/Contact in Canada for product information and complaints Aesculap Inc. 3773 Corporate Parkway Center Valley, PA, 18034, USA TA-Nr. 014006

08/13

V6