BBraun

Head extractor Instructions for Use

47 Pages

Preview

Page 1

Aesculap® 5

4 Aesculap Orthopaedics

en USA

de fr es it pt nl da sv fi lv lt ru cs pl sk hu sl hr ro bg tr el

Instructions for use/Technical description Head extractor Note for U.S. users This Instructions for Use is NOT intended for United States users. Please discard. The Instructions for Use for United States users can be obtained by visiting our website at www.aesculapImplantsystems.com. If you wish to obtain a paper copy of the Instructions for Use, you may request one by contacting your local Aesculap representative or Aesculap's customer service at 1-866-229-3002. A paper copy will be provided to you upon request at no additional cost. Gebrauchsanweisung/Technische Beschreibung Kopfabziehinstrument Mode d’emploi/Description technique Instrument de retrait de tête Instrucciones de manejo/Descripción técnica Instrumento para retirar cabeza de cadera Istruzioni per l’uso/Descrizione tecnica Strumento di estrazione testa Instruções de utilização/Descrição técnica Instrumento de remoção de cabeça Gebruiksaanwijzing/Technische beschrijving Het instrument om de prothesekop los te trekken Brugsanvisning/Teknisk beskrivelse Aftræksinstrument Bruksanvisning/Teknisk beskrivning Huvudavdragningsinstrument Käyttöohje/Tekninen kuvaus Poistoinstrumentti Lietošanas instrukcijas/tehniskais apraksts Galvas novilkšanas instruments Naudojimo instrukcija/techninis aprašas Galvutės ištraukimo instrumentas Инструкция по примению/Техническое описание Инструмент для удаления головки Návod k použití/Technický popis Nástroj na obtažení hlavy Instrukcja użytkowania/Opis techniczny Ściągacz do główek Návod na použitie/Technický opis Nástroj na stiahnutie hlavy Használati útmutató/Műszaki leírás Fejlehúzó eszköz Navodila za uporabo/Tehnični opis Instrument za izvlek glave Upute za uporabu/Tehnički opis Instrument za uklanjanje glave Manual de utilizare/Descriere tehnică Instrument de extragere a capului Упътване за употреба/Техническо описание Инструмент за отстраняване главата на протезата Kullanım Kılavuzu/Teknik açiklama Başlık çıkarma ekipmanı Οδηγίες χρήσης/Τεχνική περιγραφή Όργανο έλξης κεφαλής

Aesculap AG | Am Aesculap-Platz | 78532 Tuttlingen | Germany Phone +49 (0) 7461 95-0 | Fax +49 (0) 7461 95-26 00 | www.aesculap.com Aesculap® – a B. Braun brand TA009392

0482

2020-11

V6

Change No. 63662

3

B

1

A

2

C

6

1

2

en ®

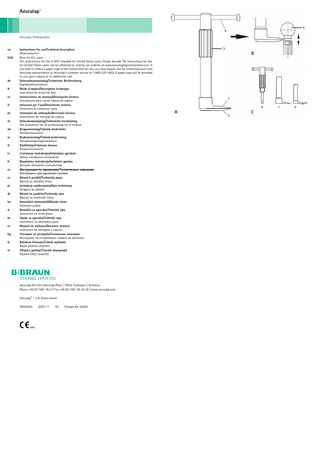

Aesculap Head extractor Legend 1 2 3 4 5 6

Upper distraction forceps Lower distraction forceps Positioning wheel Turn release handle Implant with prosthesis head Control piece

1.

About this document

Note General risk factors associated with surgical procedures are not described in these instructions for use.

1.1

Scope

These instructions for use apply to the head extractor ND382R. ► For article specific instructions for use and material compatibility and lifetime information, see B. Braun eIFU at eifu.bbraun.com

1.2

Safety messages

Safety messages make clear the dangers to patient, user and/or product that could arise during the use of the product. Safety messages are labeled as follows: WARNING Indicates a possible threat of danger. If not avoided, minor or moderate injury may result. CAUTION Indicates a possible threat of material damage. If not avoided, the product may be damaged.

2.

Clinical use

2.1

Areas of use and limitations of use

2.1.1

Intended use

The head extractor is used to extract a prosthesis head from a BiCONTACT or Centrament hip endoprosthesis stem with cone 8/10 or 12/14.

2.1.2

Indications

Note The manufacturer is not responsible for any use of the product against the specified indications and/or the described applications. The indications correspond to those of the implant system used.

3.

Validated reprocessing procedure

3.1

General safety information

Note Adhere to national statutory regulations, national and international standards and directives, and local, clinical hygiene instructions for sterile processing. Note For patients with Creutzfeldt-Jakob disease (CJD), suspected CJD or possible variants of CJD, observe the relevant national regulations concerning the reprocessing of products. Note Mechanical reprocessing should be favored over manual cleaning as it gives better and more reliable results. Note Successful processing of this medical device can only be ensured if the processing method is first validated. The operator/sterile processing technician is responsible for this. Note If there is no final sterilization, then a virucidal disinfectant must be used. Note For up-to-date information about reprocessing and material compatibility, see B. Braun eIFU at eifu.bbraun.com The validated steam sterilization procedure was carried out in the Aesculap sterile container system.

3.2

General information

Dried or affixed surgical residues can make cleaning more difficult or ineffective and lead to corrosion. Therefore the time interval between application and processing should not exceed 6 h; also, neither fixating pre-cleaning temperatures >45 °C nor fixating disinfecting agents (active ingredient: aldehydes/alcohols) should be used. Excessive measures of neutralizing agents or basic cleaners may result in a chemical attack and/or to fading and the laser marking becoming unreadable visually or by machine for stainless steel. Residues containing chlorine or chlorides e.g. in surgical residues, medicines, saline solutions and in the service water used for cleaning, disinfection and sterilization will cause corrosion damage (pitting, stress corrosion) and result in the destruction of stainless steel products. These must be removed by rinsing thoroughly with demineralized water and then drying. Additional drying, if necessary. Only process chemicals that have been tested and approved (e.g. VAH or FDA approval or CE mark) and which are compatible with the product’s materials according to the chemical manufacturers’ recommendations may be used for processing the product. All the chemical manufacturer's application specifications must be strictly observed. Failure to do so can result in the following problems: ■ Optical changes of materials, e.g. fading or discoloration of titanium or aluminum. For aluminum, the application/process solution only needs to be of pH >8 to cause visible surface changes. ■ Material damage such as corrosion, cracks, fracturing, premature aging or swelling. ► Do not use metal cleaning brushes or other abrasives that would damage the product surfaces and could cause corrosion. ► Further detailed advice on hygienically safe and material-/value-preserving reprocessing can be found at www.a-k-i.org, link to "AKI-Brochures", "Red brochure".

3.3

Reusable products

The absolute contraindications correspond to those of the implant system used.

Influences of the reprocessing which lead to damage to the product are not known. A careful visual and functional inspection before the next use is the best opportunity to recognize a product that is no longer functional, see Inspection.

2.1.4

3.4

2.1.3

Absolute contraindications Relative contraindications

The relative contraindications correspond to those of the implant system used. In the presence of relative contraindications, the user decides individually regarding the use of the product.

2.2

Safety information

2.2.1

Clinical user

General safety information To prevent damage caused by improper setup or operation, and to not compromise the manufacturer warranty and liability: ► Use the product only according to these instructions for use. ► Follow the safety and maintenance instructions. ► Ensure that the product and its accessories are operated and used only by persons with the requisite training, knowledge and experience. ► Store any new or unused products in a dry, clean, and safe place. ► Prior to use, check that the product is in good working order. ► Keep the instructions for use accessible for the user. Note The user is obligated to report all severe events in connection with the product to the manufacturer and the responsible authorities of the state in which the user is located. Notes on surgical procedures It is the user's responsibility to ensure that the surgical procedure is performed correctly. Appropriate clinical training as well as a theoretical and practical proficiency of all the required operating techniques, including the use of this product, are prerequisites for the successful use of this product. The user is required to obtain information from the manufacturer if there is an unclear preoperative situation regarding the use of the product.

2.2.2

Product-specific safety information

► Only use the product under vision.

2.2.3

Sterility

Preparations at the place of use

► If applicable, rinse non-visible surfaces preferably with deionized water, with a disposable syringe for example. ► Remove any visible surgical residues to the extent possible with a damp, lint-free cloth. ► Transport the dry product in a sealed waste container for cleaning and disinfection within 6 hours.

3.5

Preparing for cleaning

► Disassemble the product prior to cleaning, see Disassembly.

3.6

Disassembly

► Remove lower distraction forceps 2 by turning release handle 4 clockwise. ► Unscrew upper distraction forceps 1 from control piece 6 by turning the positioning wheel 3 counterclockwise.

3.7

Cleaning/Disinfection

3.7.1

Product-specific safety information on the reprocessing method

Danger to the patient! The product must not be manually reprocessed. ► Reprocess the product only by manually pre-cleaning followed by cleaning in a mechanical washer/disinfector. Damage to or destruction of the product due to inappropriate cleaning/disinfecting agents and/or excessive temperatures! ► Following the manufacturer's instructions, use cleaning and disinfecting agents – that are approved for high-grade steel. – that do not attack softeners (e.g., in silicone). ► Observe specifications regarding concentration, temperature and exposure time. ► Do not exceed the maximum allowable disinfection temperature of 95 °C. In products with plasma layers (e.g. Noir instruments), the layer is attacked or removed when applying special cleaning methods with the addition of oxidizing chemicals (e.g. hydrogen peroxide H2O2). ► Do not use oxidizing chemicals for cleaning. ► Use suitable cleaning/disinfecting agents if the product is disposed of in a wet condition. To prevent foaming and

degradation of the efficacy of the process chemicals: prior to mechanical cleaning and disinfection, rinse the product thoroughly with running water.

The product is delivered in an unsterile condition. ► Clean the new product after removing its transport packaging and prior to its initial sterilization.

3.7.2

2.3

Validated procedure

Specific requirements

Reference

Manual pre-cleaning with ultrasound and brush, and subsequent mechanical alkaline cleaning and thermal disinfection

■ Single use syringe 20 ml ■ Place the product on a tray that

Chapter Mechanical cleaning/disinfection with manual pre-cleaning and subsection:

Application

WARNING Risk of injury and/or malfunction! ► Prior to each use, inspect the product for loose, bent, broken, cracked, worn, or fractured components. ► Always carry out a function test prior to each use of the product. ► Make certain that the distraction forceps 1/2 are fully closed. ► Push the head extraction instrument in the direction of the arrow as far as it will go onto the prosthesis neck,

see Fig B. ► Turn positioning wheel 3 clockwise to distract the distraction forceps 1/2 as far as possible, until they are posi-

tioned firmly between the prosthesis head and prosthesis stem. ► Gently hold down with the hand to prevent the prosthesis head from jumping off. ► Turn release handle 4 clockwise. ► Extract prosthesis head.

Validated cleaning and disinfection procedure

is suitable for cleaning (avoid rinsing blind spots).

■ Chapter Manual pre-cleaning with ultrasound and brush

■ Chapter Mechanical alkaline cleaning and thermal disinfecting

3.8

Mechanical cleaning/disinfection with manual pre-cleaning

Note The cleaning and disinfection device must be of tested and approved effectiveness (e.g. FDA approval or CE mark according to DIN EN ISO 15883). Note The cleaning and disinfection device used for processing must be serviced and checked at regular intervals.

3.12 Steam sterilization Note The product can be sterilized either in disassembled or in assembled condition. ► Make certain that all external and internal surfaces of the product will be exposed to the sterilizing agent. To do

this, slightly open the distraction forceps 1/2. ► Validated sterilization process

– Steam sterilization using fractional vacuum process – Steam sterilizer according to DIN EN 285 and validated according to DIN EN ISO 17665 – Sterilization using fractionated vacuum process at 134 °C/holding time 5 min ► If several devices are sterilized at the same time in the same steam sterilizer: Ensure that the maximum permitted load according to the manufacturers’ specifications is not exceeded.

3.8.1

Manual pre-cleaning with ultrasound and brush

Phase

Step

T [°C/°F]

t [min]

Conc. [%]

Water quality

Chemical

I

Ultrasonic cleaning

RT (cold)

>15

2

D–W

Aldehyde-free, phenol-free, and QUAT-free concentrate, pH ~ 9*

3.13 Storage

RT (cold)

1

-

4.

II

Rinsing

-

D–W

Technical service

CAUTION Modifications to medical technology equipment result in loss of approval and can result in forfeiture of guarantee/warranty claims. ► Do not modify the product. ► For service and repairs, please contact your national B. Braun/Aesculap agency.

D–W: Drinking water RT: Room temperature *Recommended: BBraun Stabimed fresh ► Note the information on appropriate cleaning brushes and disposable syringes, see Validated cleaning and dis-

infection procedure. Phase I ► Clean the product in an ultrasonic cleaning bath (frequency 35 kHz) for at least 15 min. Ensure that all accessible surfaces are immersed and acoustic shadows are avoided. ► Clean the product with a suitable cleaning brush in the solution until all discernible residues have been removed from the surface. ► If applicable, brush through non-visible surfaces with an appropriate cleaning brush for at least 1 min. ► Mobilize non-rigid components, such as set screws, links, etc. during cleaning. ► Thoroughly rinse through these components with the cleaning disinfectant solution (at least five times), using a disposable syringe. Phase II ► Rinse/flush the product thoroughly (all accessible surfaces) under running water. ► Mobilize non-rigid components, such as set screws, joints, etc. during rinsing.

3.8.2

► Store sterile products in germ-proof packaging, protected from dust, in a dry, dark, temperature-controlled area

Service addresses Aesculap Technischer Service Am Aesculap-Platz 78532 Tuttlingen / Germany Phone: +49 7461 95-1601 Fax: +49 7461 16-2887 E-Mail: [email protected] Other service addresses can be obtained from the address indicated above.

5.

Disposal

WARNING Risk of infection due to contaminated products! ► Adhere to national regulations when disposing of or recycling the product, its components and its packaging.

Mechanical alkaline cleaning and thermal disinfecting

Machine type: single-chamber cleaning/disinfection device without ultrasound Phase

Step

T [°C/°F]

t [min]

Water quality

Chemical

WARNING Risk of injury due to sharp-edged and/or pointed products! ► When disposing of or recycling the product, ensure that the packaging prevents injury by the product.

I

Prerinse

<25/77

3

D–W

-

Note The user institution is obliged to reprocess the product before its disposal, see Validated reprocessing procedure.

II

Cleaning

55/131

10

FD-W

■ Concentrate, alkaline: – pH ~ 13 – <5 % anionic surfactant

■ working solution 0.5% – pH = 11* III

Intermediate rinse

>10/50

1

FD-W

-

IV

Thermal disinfecting

90/194

5

FD-W

-

V

Drying

-

-

-

In accordance with the program for the cleaning and disinfecting machine

D–W: FD–W:

Drinking water Fully desalinated water (demineralized, low microbiological contamination: drinking water quality at least) *Recommended: BBraun Helimatic Cleaner alkaline ► Check visible surfaces for residues after mechanical cleaning/disinfecting.

3.9

Inspection

► Allow the product to cool down to room temperature. ► Dry the product if it is wet or damp.

3.9.1

Visual inspection

► Ensure that all soiling has been removed. In particular, pay attention to mating surfaces, hinges, shafts, recessed

areas, drill grooves and the sides of the teeth on rasps. ► If the product is dirty: repeat the cleaning and disinfection process. ► Check the product for damage, e.g. insulation or corroded, loose, bent, broken, cracked, worn or severely scratched and fractured components. ► Check the product for missing or faded labels. ► Check the surfaces for rough spots. ► Check the product for burrs that could damage tissue or surgical gloves. ► Check the product for loose or missing parts. ► Immediately put aside damaged or inoperative products and send them to Aesculap Technical Service, see Technical service.

3.9.2

Functional test

CAUTION Damage (metal cold welding/friction corrosion) to the product caused by insufficient lubrication! ► Prior to function checks, lubricate moving parts (e.g. joints, pusher components and threaded rods) with maintenance oil suitable for the respective sterilization process (e.g. for steam sterilization: STERILIT® I oil spray JG600 or STERILIT® I drip lubricator JG598). ► Assemble disassembled products, see Assembly. ► Check that the product functions correctly. ► Check that all moving parts are working property (e.g. hinges, locks/latches, sliding parts etc.). ► Check for compatibility with associated products. ► Immediately put aside inoperative products and send them to Aesculap Technical Service, see Technical service.

3.10 Assembly ► Attach upper distraction forceps 1 onto control piece 6. ► Screw on upper distraction forceps 1 by turning the positioning wheel 3 clockwise as far as the marking. ► Insert lower distraction forceps 2 into channel of upper distraction forceps 1. ► Tighten lower distraction forceps 2 by turning release handle 4 counterclockwise.

3.11 Packaging ► Place the product in its holder or on a suitable tray. Ensure that sharp edges are covered. ► Package trays appropriately for the sterilization process (e.g. in Aesculap sterile containers). ► Ensure that the packaging provides sufficient protection against contamination of the product during storage.

TA009392

2020-11

V6

Change No. 63662