BBraun

Micro reciprocating saw GB129

53 Pages

Preview

Page 1

Aesculap®

Aesculap Power Systems

Instructions for use/Technical description Micro reciprocating saw GB129 Gebrauchsanweisung/Technische Beschreibung Mikro-Pendelsäge GB129 Mode d’emploi/Description technique Micro-scie pendulaire GB129 Instrucciones de manejo/Descripción técnica Microsierra pendular GB129 Istruzioni per l’uso/Descrizione tecnica Microsega oscillante GB129 Instruções de utilização/Descrição técnica Micro serra pendular GB129 Gebruiksaanwijzing/Technische beschrijving Micro-oscillerende zaag GB129 Bruksanvisning/Teknisk beskrivning Mikro-pendelsåg GB129 Инструкция по примению/Техническое описание Сагиттальная микропила GB129 Návod k použití/Technický popis Mikro oscilační pila GB129 Instrukcja użytkowania/Opis techniczny Mikro-piła oscylacyjna, strzałkowa GB129 Návod na použivanie/Technický opis Kyvadlová mikropíla GB129 Kullanım Kılavuzu/Teknik açiklama Mikro sarkaçlı testere GB129

1

2

1

3

2

4

5

3

6

4

11

5

7

5

9

8 10

Aesculap AG | Am Aesculap-Platz | 78532 Tuttlingen | Germany Phone +49 (0) 7461 95-0 | Fax +49 (0) 7461 95-26 00 | www.aesculap.com

6

Aesculap – a B. Braun company TA-Nr. 005320

06/14

V6

7

Änd.-Nr. 50518 14

- DIR 93/42/EEC Technical alterations reserved

8

12

13

Aesculap® Micro reciprocating saw GB129

5.

Working with the micro pendulum saw GB129

5.1

System set-up

Note Products marked as unsterile must be sterilized, prior to use, according to respective instructions, see Steam sterilization.

Legend

Risk of injury due to accidental activation of motor unit! ► Change tools only with the motor unit uncoupled.

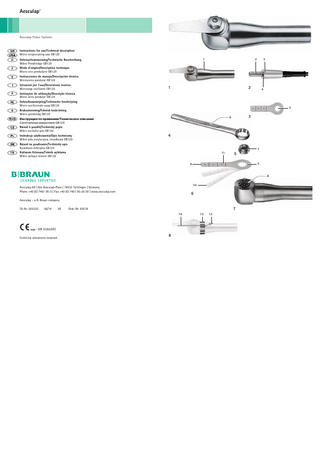

1 Collar 2 Centering lug 3 Release 4 Cover plate 5 Ten-tooth adapter 6 Box wrench SW14 7 Lock nut 8 Ten-tooth shaft 9 Possible position 10 Possible position 11 Saw blade 12 Spray nozzle 13 Tube olive 14 Nozzle

WARNING

WARNING

Risk of contamination and infection caused by unsterile components in the sterile area! ► Use only sterile or sterilized parts in the sterile area. WARNING

Symbols on product and packages Caution, general warning symbol Caution, see documentation supplied with the product

1.

Risk of burns to the patient, caused by blunt saw blades or lack/inadequacy of maintenance of handpieces! ► Prior to each use and before clamping in a saw blade, check the saw blades for any wear or damage.

WARNING

Risk of contamination and infection if surgical gloves are damaged by a sharp tool! ► Do not touch the cutting edges of the tool, neither when changing tools nor during use.

WARNING

Damage to the product due to incorrect handling or operation! ► Couple the product only while the motor is inactive. ► Make certain that the maximum speed of 18 000 rpm is correctly set on the motor unit.

Applicable to

► For item-specific instructions for use and information on material compatibility, see also the Aesculap Extranet

at www.extranet.bbraun.com

Connecting the accessories

2.

Safe handling

CAUTION Federal law restricts this device to sale by, or on order of a physician! ► Remove the transport packaging and clean the new product, either manually or mechanically, prior to its initial sterilization. ► Prior to use, check that the product is in good working order. ► To prevent damage caused by improper setup or operation, and in order not to compromise warranty and manufacturer liability: – Use the product only according to these instructions for use. – Follow the safety and maintenance instructions. – Only combine Aesculap products with each other. ► Ensure that the product and its accessories are operated and used only by persons with the requisite training, knowledge, or experience. ► Keep the instructions for use accessible for the user.

3.

Product description

3.1

Scope of supply

Combinations of accessories that are not mentioned in the present instructions for use may only be employed if they are specifically intended for the respective application, and if they do not compromise the performance and safety characteristics of the products. Also note that any equipment connected at the interfaces must demonstrably meet the respective IEC standards (e.g. IEC 60950 for data processing equipment, IEC/DIN EN 60601-1 for electromedical devices). All configurations must comply with basic standard IEC/DIN EN 60601-1. Any individual connecting devices with one another is responsible for such configuration and must ensure compliance with basic standard IEC/DIN EN 60601-1 or applicable national standards. ► Please address your B. Braun/Aesculap partner or Aesculap Technical Service with any inquiries in this respect; for a contact address, see Technical Service.

Attaching the tool ► Undo lock nut 7 with box wrench SW14 6 and remove. ► Attach saw blade 11 in the required position 9 or 10 onto the ten-tooth shaft 8. ► Screw on nut 7 and tighten it with box wrench SW14 6.

Mounting the spray nozzle ► Push spray nozzle 12 onto collar 1. ► Attach the silicon tube onto the tube olive 13. ► Bend nozzle 14 in the required direction.

Designation

Art. no.

Micro pendulum saw

GB129

Box wrench SW14

TA010100

Instructions for use GB129

TA005320

Coupling a motor unit The motor unit must be switched off. ► Insert the centering lug 2 of the motor unit into the micro pendulum saw. You will feel the motor unit click into place when the cover plate 4 of the motor unit touches the ring-shaped connection surface of the micro pendulum saw.

5.2 3.2 Components required for operation ■ Micro pendulum saw GB129 ■ Saw blades with ten-tooth adapter - or ■ Files with ten-tooth adapter ■ Box wrench SW14 ■ Flexible shaft GA173 with Elan-E, Elan-EC - or ■ Micro motor GD622 with Microton-EC, Integral-EC 3.3

Intended use

The micro reciprocating saw GB129 is used to dissect bone or ablate bone material in osteosynthesis procedures and small bone surgery (hand and foot surgery, craniofacial and maxillofacial surgery, plastic surgery, spinal surgery). Cooling/irrigation The spray nozzle 12 is used for cooling and clearing the operating field with a sterile irrigation solution. This reduces the risk of necrosis and enables the surgeon to work more precisely, more quickly and more gently on the tissue.

3.4

Operating principle

The bone is dissected or ablated by the to-and-fro movement of the saw blade at an oscillating angle of 4.8°. Any soft tissue parts touched by the saw blade remain unharmed. Cooling/irrigation The sterile irrigation solution is sprayed through the spray nozzle 12 into the operating field. This cools down the bone, tissue and tool and washes away the saw chippings, preventing the tool in direct contact with the bone from getting too hot.

4.

Preparation

Function checks

Note The following function checks must be carried out prior to every surgical application of the product!

WARNING

Risk of burns to soft tissue due to heated handpiece as a result of defective bearings! ► Make certain that there is no visible abrasion or similar at the site where the ten-tooth shaft leaves the housing. ► Do not use a handpiece with defective bearings; have it repaired.

Check that the tool is seated properly ► Hold the micro pendulum saw with one hand. ► Hold the back of the micro pendulum saw with the thumb and index finger of the other hand. ► Check that the micro reciprocating saw is firmly seated by pulling on it. When doing so, ensure that no relative

motion occurs between the saw blade and chuck adapter.

Performing a test run ► Briefly switch on the micro reciprocating saw with a maximum speed of between 15,000 and 18,000 rpm. ► Press the foot control switch for approx. 5 seconds. ► Switch on the pump and activate the foot control switch until irrigation solution is sprayed out of the nozzle 12. ► Check for proper and reliable functioning.

5.3

Safe operation Risk of burns to patient and user due to hot motor/hot tool! ► Put down the motor/hot tool beyond reach of the patient. ► Use a cloth to protect against burns when changing the motor or tool. WARNING

Non-compliance with the following instructions will preclude all responsibility and liability in this respect on the part of Aesculap. ► Prior to use, inspect the product and its accessories for any visible damage. ► Use the products and their accessories only if they are in perfect condition. WARNING

Risk of injury and material damage due to inappropriate use of handpieces or motors! ► Always follow the safety advice and information given in the instructions for use of the handpieces and motors. ► Do not exceed the specified maximum motor speed.

Risk of injury and/or malfunction! ► Always carry out a function check prior to using the product. WARNING Injuries to tissue if the tool is unintentionally released or moved! ► Make certain that the tool is correctly tightened in the chuck adapter with the lock nut on the ten-tooth shaft and that the tool is seated tightly. WARNING Risk of injury when using the product beyond the field of view! ► Apply the product only under visual control. WARNING Risk of infection and contamination due to aerosol formation! ► Take appropriate protective measures, e.g. watertight protective clothing, face mask, protective goggles and a suction extraction system. WARNING

WARNING

Impaired healing process! ► Use the saw blade with the smallest possible cutting width to – complete the saw incision in the shortest possible time. – This facilitates the healing process due to low bone loss and low thermal stress of the bone and tissue. Risk of contamination and infection caused by unsterile parts! ► Use only sterile or sterilized parts in the sterile area.

WARNING

Risk of injury from a broken saw blade! ► Do not twist, cant or bend the saw blade. WARNING Risk of injury from cracks and cuts from high-speed saws and sharp tool! ► Hold the micro reciprocating saw tightly in the hand. WARNING

WARNING

Risk of injury from metal chippings! Damage to the tool! ► Dissect and ablate bone only! Ensure that no instruments are sawed into in the operating field.

6.

Validated reprocessing procedure

6.1

General safety instructions

Note Adhere to national statutory regulations, national and international standards and directives, and local, clinical hygiene instructions for sterile processing. Note For patients with Creutzfeldt-Jakob disease (CJD), suspected CJD or possible variants of CJD, observe the relevant national regulations concerning the reprocessing of products. Note Mechanical reprocessing should be favored over manual cleaning as it gives better and more reliable results. Note Successful processing of this medical device can only be ensured if the processing method is first validated. The operator/sterile processing technician is responsible for this. The recommended chemistry was used for validation. Note If there is no final sterilization, then a virucidal disinfectant must be used. Note For the latest information on reprocessing and material compatibility see also the Aesculap extranet at www.extranet.bbraun.com The validated steam sterilization procedure was carried out in the Aesculap sterile container system.

6.2

6.3

Damage to the motor unit due to incorrect coupling of the saw! ► Couple the compass saw with the motor unit only while the motor is inactive.

► Activate the foot control switch for the motor unit and if applicable the foot control switch for the pump. ► Begin at a low speed. ► Once the saw blade is inserted in the bone gap, continue at a higher speed.

Note The micro pendulum saw achieves the best cutting performance at a high speed.

Preparation before cleaning

► Carry out non-fixating/NaCl-free pre-cleaning immediately after use. ► Prior to the first mechanical cleaning/disinfection process, mount the Eccos holder GB682R in a suitable tray (e.g.

JF214R).

6.6

CAUTION

Preparations at the place of use

► Remove any visible surgical residues to the extent possible with a damp, lint-free cloth. ► Transport the dry product in a sealed waste container for cleaning and disinfection within 6 hours.

6.5

WARNING

Dismantling prior to carrying out the reprocessing procedure

► Disassemble the product immediately after use, as described in the respective instructions for use.

6.4 Risk of burns from a hot tool! A blunt tool can cause heat to develop quickly. ► Use only sharp tools in new condition.

General information

Dried or affixed surgical residues can make cleaning more difficult or ineffective and lead to corrosion. Therefore the time interval between application and processing should not exceed 6 h; also, neither fixating pre-cleaning temperatures >45 °C nor fixating disinfecting agents (active ingredient: aldehydes/alcohols) should be used. Excessive measures of neutralizing agents or basic cleaners may result in a chemical attack and/or to fading and the laser marking becoming unreadable visually or by machine for stainless steel. Residues containing chlorine or chlorides e.g. in surgical residues, medicines, saline solutions and in the service water used for cleaning, disinfection and sterilization will cause corrosion damage (pitting, stress corrosion) and result in the destruction of stainless steel products. These must be removed by rinsing thoroughly with demineralized water and then drying. Additional drying, if necessary. Only process chemicals that have been tested and approved (e.g. VAH or FDA approval or CE mark) and which are compatible with the product’s materials according to the chemical manufacturers’ recommendations may be used for processing the product. All the chemical manufacturer's application specifications must be strictly observed. Failure to do so can result in the following problems: ■ Optical changes of materials, e.g. fading or discoloration of titanium or aluminum. For aluminum, the application/process solution only needs to be of pH >8 to cause visible surface changes. ■ Material damage such as corrosion, cracks, fracturing, premature aging or swelling. ► Do not use metal cleaning brushes or other abrasives that would damage the product surfaces and could cause corrosion. ► Further detailed advice on hygienically safe and material-/value-preserving reprocessing can be found at www.ak-i.org, link to Publications, Red Brochure – Proper maintenance of instruments.

Cleaning/disinfection

Product-specific safety instructions for the reprocessing procedure

CAUTION

► Move the micro pendulum saw forwards in the bone using mild pressure and, potentially, slow, wave-like move-

ments. Avoid jerky movements. ► Ensure the tool only applies mild pressure on the bone. ► Do not cant the tool so that the saw blade does not break. ► Avoid resonances in the saw blade when the saw is idle. ► If resonances do occur, continue working at a different speed.

Damage to the product due to inappropriate cleaning/disinfecting agents and/or excessive temperatures! ► Use cleaning and disinfecting agents according to the manufacturer’s instructions which – are approved for plastic material and high-grade steel, – do not attack softeners (e.g. in silicone). ► Observe specifications regarding concentration, temperature and exposure time. ► Do not exceed the maximum allowable temperature of 6 °C.

► Dry the product for at least 10 minutes at a maximum of 120 °C.

Changing the tool during the operation Risk of injury from the tool due to accidental activation of the motor! ► Change tools only with the motor unit uncoupled. WARNING

Note The indicated drying temperature is a guide temperature only. It must be checked taking into account the specific conditions (e.g. load) and adjusted if applicable. ► Do not clean motors/handpieces by ultrasonic treatment and do not immerse them in any liquids. To avoid the

risk of corrosion/malfunctioning, allow any fluid that has entered the product to drain out immediately.

Validated cleaning and disinfection procedure Uncoupling the micro reciprocating saw from the motor unit ► Switch off the motor unit. ► Press release 3. ► Remove the micro reciprocating saw.

Tool change ► Undo lock nut 7 with box wrench SW14 6. ► Remove the tool. ► Attach the new saw blade 11 in the required position 9 or 10 onto the ten-tooth shaft 8. ► Tighten lock nut 7 with box wrench SW14 6.

Check the tool is firmly seated ► Hold the micro reciprocating saw with one hand. ► Hold the back of the micro reciprocating saw with the thumb and index finger of the other hand. ► Check that the micro reciprocating saw is firmly seated by pulling on it. When doing so, ensure that no relative

motion occurs between the saw blade and chuck adapter.

Coupling a motor unit ► Couple the motor unit, see Coupling a motor unit.

Validated procedure

Special features

Reference

Manual cleaning and wipe disinfection

■ When cleaning products with

Chapter Manual cleaning/disinfecting and subchapter:

movable hinges, ensure that these are in an open position and, if applicable, move the joint while cleaning.

■ Drying phase: Use a lint-free cloth or compressed air for medical purposes

■ Ensure that the product is positioned in such a way that water will not enter the product e.g. through coupling interfaces. (Immediately remove any fluid that entered the product inadvertently.)

■ Chapter Manual cleaning and wipe disinfecting

Validated procedure Mechanical neutral or mild alkaline cleaning and thermal disinfecting

Special features

■ Insert the product in its proper position in the Eccos holder.

■ Follow the instructions for use of

Reference

6.9

Chapter Mechanical cleaning/disinfecting and subchapter:

► Allow the product to cool down to room temperature. ► Inspect the product after each cleaning and disinfecting cycle to be sure it is: clean, functional, and undamaged. ► Prior to sterilization, spray through the product with Aesculap STERILIT oil spray GB600 with adapter GB600810

■ Chapter Mechanical neutral or mild alkaline cleaning and thermal disinfecting

the Eccos holder.

6.7

Manual cleaning/disinfecting

Inspection, maintenance and checks

for approx. 1 second. ► Check the product for any damage, abnormal running noise, overheating or excessive vibration. ► Inspect tools for broken, damaged or blunt edges. ► Set aside the product if it is damaged. ► Prior to an extended period of non-use, always store attachments cleaned and dried according to the instruc-

tions.

► Prior to manual disinfecting, allow water to drip off for a sufficient length of time to prevent dilution of the dis-

infecting solution.

6.10 Packaging

► After manual cleaning/disinfection, check visible surfaces visually for residues. ► Repeat the cleaning/disinfection process if necessary.

► Follow the instructions for use for the applied packaging and storage systems (e.g. instructions for use TA009721

for Aesculap Eccos storage system). ► Insert the product in its proper position in the Eccos holder, or put it on a tray in such a way that the product is

Manual cleaning and wipe disinfecting Phase

protected against damage. Ensure that all cutting edges are protected.

D–W

-

6.11 Steam sterilization

-

-

► Check to ensure that the sterilizing agent will come into contact with all external and internal surfaces (e.g. by

I

Cleaning

RT (cold)

-

-

II

Drying

RT

-

-

III

Wipe disinfection

-

>1

-

-

Meliseptol HBV wipes 50 % Propan-1-ol

IV

Final rinse

RT (cold)

0.5

-

FD-W

-

V

Drying

RT

-

-

-

-

RT:

Conc. [%]

► Pack trays appropriately for the sterilization process (e.g. in Aesculap sterile containers). ► Ensure that the packaging will prevent a recontamination of the product.

T [°C/°F]

D–W: FD–W:

t [min]

Chemical

Step

Water quality

Drinking water Fully desalinated water (demineralized, low microbiological contamination: drinking water quality at least) Room temperature

opening any valves and faucets). ► Validated sterilization process

– Disassemble the instrument – Steam sterilization using fractionated vacuum process – Steam sterilizer according to DIN EN 285 and validated according to DIN EN ISO 17665 – Sterilization using fractionated vacuum process at 134 °C/holding time 5 min ► When sterilizing several products at the same time in a steam sterilizer, ensure that the maximum load capacity of the steam sterilizer specified by the manufacturer is not exceeded.

6.12 Sterilization for the US market ■ Aesculap advises against sterilizing the device by flash sterilization or chemical sterilization. ■ Sterilization may be accomplished by a standard prevacuum cycle in a steam autoclave.

Phase I ► Clean the product under running faucet water, using a suitable cleaning brush until all visible residues have been removed from the surfaces. ► Mobilize non-rigid components, such as set screws, links, etc. during cleaning.

To achieve a sterility assurance level of 10-6 , Aesculap recommends the following parameters:

Phase II ► Dry the product in the drying phase with suitable equipment (e.g. cloth, compressed air), see Validated cleaning and disinfection procedure.

Sterilization method

Temp.

Time

Minimum drying time

Prevacuum

270 °F/275 °F

4 min

20 min

Phase III ► Wipe all surfaces of the product with a single-use disinfectant wipe. Phase IV ► After the specified exposure time (at least 1 min), rinse the disinfected surfaces under running FD water. ► Drain any remaining water fully.

Aesculap Orga Tray/Sterile container (perforated bottom) Minimum cycle parameters*

*Aesculap has validated the above sterilization cycle and has the data on file. The validation was accomplished in an Aesculap sterile container cleared by FDA for the sterilization and storage of these products. Other sterilization cycles may also be suitable, however individuals or hospitals not using the recommended method are advised to validate any alternative method using appropriate laboratory techniques. Use an FDA cleared accessory to maintain sterility after processing, such as a wrap, pouch, etc.

Phase V ► Dry the product in the drying phase with suitable equipment (e.g. cloth, compressed air), see Validated cleaning and disinfection procedure.

6.13 Storage

6.8

7.

Mechanical cleaning/disinfecting

Note The cleaning and disinfection device must be of tested and approved effectiveness (e.g. FDA approval or CE mark according to DIN EN ISO 15883). Note The cleaning and disinfection device used for processing must be serviced and checked at regular intervals.

Mechanical neutral or mild alkaline cleaning and thermal disinfecting Machine type: single-chamber cleaning/disinfection device without ultrasound Phase

Step

T [°C/°F]

t [min]

Water quality

Chemical

I

Prerinse

<25/77

3

D–W

-

II

Cleaning

55/131

10

FD-W

Neutral:

► Store sterile products in germ-proof packaging, protected from dust, in a dry, dark, temperature-controlled area.

Maintenance

To ensure reliable operation, the product must be maintained at least once a year. The grease for the gears and ball bearing should always be changed during this maintenance procedure. Blunt or damaged tools must be replaced. For technical service, please contact your national B. Braun/Aesculap agency, see Technical Service.

8.

Troubleshooting list

Malfunction

Cause

Detection

Remedy

Excessive noise

Hot micro reciprocating saw

Worn gearing

Have repaired by Aesculap Service

Excessive play between the lock nut 7 and the housing

■ Concentrate: – pH neutral – <5 % anionic surfactant

■ 0.5 %* working solution

Overheating micro reciprocating saw

Hot micro reciprocating saw

Worn gearing

Have repaired by Aesculap Service

Tool not moving

Gap between micro reciprocating saw and motor unit

Motor unit not coupled

Coupling a motor unit

Motor running, but not driving the attachment or tool

Defective gearings

Have repaired by Aesculap Service

Worn cutting edges

Blunt tool

Install a new tool

See instructions for use of the motor unit

Insufficient power or speed of the motor unit

See instructions for use of the motor unit

Saw blade hot

Inadequate chip removal

Back and forth movement during sawing

Deformed clamping elements

Deformation

Have repaired by Aesculap Service

Mildly alkaline:

■ Concentrate: – pH = 9.5 – <5 % anionic surfactant

■ 0.5 % solution III

Intermediate rinse

>10/50

1

FD-W

-

IV

Thermal disinfecting

90/194

5

FD-W

-

Drying

-

Insufficient power

V

-

-

According to the program for cleaning and disinfection device

D–W: FD–W:

Drinking water Fully desalinated water (demineralized, low microbiological contamination: drinking water quality at least) *Recommended: BBraun Helimatic Cleaner neutral ► Check visible surfaces for residues after mechanical cleaning/disinfecting. ► Repeat the cleaning/disinfecting process if necessary.

Tool cannot be coupled

Coupling between micro reciprocating saw and motor unit defective

Deformed tool Tool is not part of current product range

Install a new tool Wrong tool

Insert appropriate tool

9.

Technical Service Risk of injury and/or malfunction! ► Do not modify the product. WARNING

► For service and repairs, please contact your national B. Braun/Aesculapagency.

Modifications carried out on medical technical equipment may result in loss of guarantee/warranty rights and forfeiture of applicable licenses. Service addresses Aesculap Technischer Service Am Aesculap-Platz 78532 Tuttlingen / Germany Phone: +49 (7461) 95 -1601 Fax: +49 (7461) 14 -939 E-Mail: [email protected] Or in the US: Attn. Aesculap Technical Services 615 Lambert Pointe Drive Hazelwood MO, 63042 USA Aesculap Repair Hotline Phone: +1 (800) 214 -3392 Fax: +1 (314) 895 -4420 Other service addresses can be obtained from the address indicated above.

10.

Accessories/Spare parts

Art. no.

Designation

GA222R

Spray nozzle

GB125804

Lock nut

GB682R

Eccos holder

GB459R

Eccos mounting set for holders

JG693R

Tray clamp

TA010100

Box wrench SW14

GB600

Aesculap STERILIT oil spray

GB600810

STERILIT adapter

TA005320

Instructions for use GB129

11.

Technical data

Classification acc. to Directive 93/42/EEC Art. no.

Designation

Class

GB129

Micro reciprocating saw

IIa

Weight

345 g

Dimensions

(L x W x H) 120 mm x 28 mm x 45 mm

Saw blade adapter

Ten-tooth adapter

Max. motor speed

18,000 1/min

Conversion of rotation into oscillations

1:1

11.1 Ambient conditions Operation

Storage and transport

Temperature

Relative humidity

Atmospheric pressure

12.

Disposal

Note The user institution is obliged to process the product before its disposal, see Validated reprocessing procedure. ► Detailed information concerning the disposal of the product is available through your national B. Braun/Aesculap

agency, see Technical Service.

13.

Distributor in the US/Contact in Canada for product information and complaints

Aesculap Inc. 3773 Corporate Parkway Center Valley, PA, 18034, USA TA-Nr. 005320

06/14

V6

Änd.-Nr. 50518