BBraun

Rinsing Units GB694R GB695R GB696R

27 Pages

Preview

Page 1

en ®

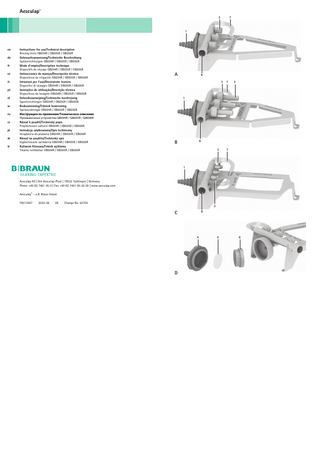

Aesculap Rinsing Units GB694R / GB695R / GB696R Legend 1 2 3 4 5 6 7 8

Connector for irrigation tube Applied part adapter Control button/lever Filter lid Filter Silicon washer Rinsing tube Connection for water/compressed air gun

Symbols on product and packages Caution Observe important safety information such as warnings and precautions in the instructions for use.

Connector for water/compressed-air gun

5.

Manual pre-cleaning/mechanical cleaning with rinsing device

5.1

Changing the filter of the rinsing device (Fig. D)

Note The quality of cleaning is dependent on the pore size and flow rate of the filter. Successful cleaning is only guaranteed with the GB693 filter. Note The filter must be changed at least once a week. ► Unscrew the filter cover 4. ► Remove silicone washer 6 from filter lid 4. ► Remove the filter 5 from the filter cover 4 and dispose of the filter 5. ► Clean inside of filter lid 4. ► Insert a new filter 5 in filter lid 4. ► Insert the silicone washer 6 in the correct position in the filter lid 4. ► Screw filter lid 4 on tight.

5.2

Assembling the rinsing device

5.2.1

Assemble the rinsing device GB694R (Fig. A)

Note Rinsing device GB694R may only be equipped with Hi-Line or Hi-Line-XS series. ► Take the applied part out of the ECCOS holder. ► Turn the screw ring on the applied part in the direction of the arrow . ► Attach hand piece to the connector 2. ► Turn the screw ring on the applied part in the direction of the arrow . ► Make certain that the applied part is securely seated. When doing this, ensure that the opening points down-

wards.

5.2.2 Turn “right” to unlock the applied part

Turn “left” to lock the applied part

► Take the applied part out of the ECCOS holder. ► Slide the hand piece to connector 2 up to the stop. ► Make certain that the applied part is securely seated. When doing this, ensure that the opening points down-

wards.

5.2.3

1.

Applicable to

► For item-specific instructions for use and information on material compatibility, see also the Aesculap Extranet

at https://extranet.bbraun.com

2.

Intended use

Note Hi-Line hand pieces, Hi-Line XS hand pieces, Hi-Line XXS shafts and micro-Line hand pieces are summarized below with the term “applied parts”. Note Applied parts must be prepared in accordance with the validated preparation procedures. This instruction manual describes only the use of the rinsing device. Detailed information on the preparation of the applied parts are described in the relevant instruction manuals. The rinsing devices with water filters are used to attach the applied parts for mechanical cleaning and disinfection. They are used specially for interior cleaning of the applied parts. Note The rinsing devices are not suitable as storage for the sterilization of the applied parts.

3.

Safe handling

CAUTION Federal law restricts this device to sale by, or on order of a physician! ► Remove the transport packaging and clean the new product, either manually or mechanically, prior to its initial use. ► Prior to use, check that the product is in good working order. ► To prevent damage caused by improper setup or operation, and in order not to compromise warranty and manufacturer liability: – Use the product only according to these instructions for use. – Follow the safety and maintenance instructions. – Only combine Aesculap products with each other. ► Ensure that the product and its accessories are operated and used only by persons with the requisite training, knowledge, or experience. ► Keep the instructions for use accessible for the user.

Assembling the rinsing device GB695R (Fig. B)

Note Only use the rinsing device GB695R with applied parts from the micro-Line series.

Assembling rinsing device GB696R (Fig C)

Note Only equip rinsing device GB696R with shafts of the Hi-Line XXS series. ► Remove shaft from ECCOS holder. ► Press and hold actuation button 3. ► Slide the applied part onto the attachment 2 up to the stop. ► Release control button 3. ► Check that the shaft is secure. When doing this, ensure that the opening points downwards.

5.3

Manual Pre-Cleaning

5.3.1

Pre-cleaning with rinsing device

► Connect the rinsing hose 7 to the connection for the rinsing hose 1 and connect to the water line. ► Flush through for 5 minutes.

Water must emerge from the tip of the applied part/shaft. The empty applied parts attachments 2 and the connection for the compressed air gun 8 must be sealed off. ► Remove the rinsing hose 7 from the rinsing device.

5.3.2

Pre-cleaning with water gun

► Attach the water gun to the connection to the water/compressed air gun 8. ► Seal the connection for rinsing hose 1 with cellulose or similar material. ► Flush the assembly 3 times for 5 seconds.

Water must emerge from the tip of the applied part/shaft. Any connectors 2 which are not connected to equipment must be sealed. ► Remove water gun from the connection for the water/compressed air gun 8.

5.4

Mechanical cleaning/disinfecting

CAUTION

Insufficient quantity of rinsing water will result in incomplete cleaning of the applied parts! ► Connect the irrigation tube directly and without branching to the rinsing bracket in the cleaning and disinfecting machine. ► Close any unused rinsing ports on the rinsing bracket of the cleaning and disinfecting machine. ► Ensure a rinsing pressure of at least 0.4 bar. ► Rinse for at least 10 minutes with the cleaner.

► Attach the rinsing hose 7 to the connection for the rinsing hose 1 and to the rinsing channel in the cleaning and

4.

Product description

4.1

Package includes

Art. no.

Designation

GB694R

GB696R

Rinsing device for Hi-Line / Hi-Line XS hand pieces - or Rinsing device for micro-Line hand pieces - or Rinsing device for Hi-Line XXS hand piece shafts

GB693

Filter (10 pcs.)

TA013567

Instructions for use for rinsing device GB694R / GB695R / GB696R

GB695R

disinfection device. ► Start the cleaning and disinfection device.

Note The adapter and hoses needed for the connection to the rinsing channel are not included in the delivery.

5.5

Remove the rinse water

CAUTION

4.2

Operating principle

The rinsing devices are used for interior and exterior cleaning of applied parts. The rinsing device prevents components becoming damaged during the cleaning process and ensures that the detergent reaches all necessary areas in the interior of components. The integrated filter of the rinsing device prevents dirt particles from the rinsing agent getting into the components.

Residual rinsing water in applied part! ► Ensure that the compressed air gun is flush with the compressed air gun connection. ► Ensure that any existing openings to the compressed-air gun are completely enclosed.

► Remove the rinsing hose 7 from the connector for the rinsing hose 1. ► Seal the connection for rinsing hose 1 with cellulose or similar material. ► Attach the compressed air gun directly to the connector for the compressed air gun 8 of the rinsing device. ► Briefly blow compressed air through rinsing device.

5.6

Removing applied parts from rinsing device

5.6.1

Remove the applied part from the rinsing device GB694R (Fig. A)

► Turn the screw ring on the applied part in the direction of the arrow ► Remove the applied part.

5.6.2

.

Remove the applied part from the rinsing device GB695R (Fig. B)

► Press the activation button 3 and pull the applied part from the rinsing device.

5.6.3

Remove the applied part from the rinsing device GB696R (Fig. C)

► Press the activation button 3 and pull the applied part from the rinsing device.

5.7

10.

Cleaning the filter in the rinsing device

Disposal

► Adhere to national regulations when disposing of or recycling the product, its components and its packaging!

Incomplete cleaning due to a dirty filter! ► Blow air through filter after each wash cycle without applied parts. ► Change the filter weekly. ► Do not reuse the filter after disassembly.

CAUTION

Dirty filter due to incorrect use of the compressed-air gun! ► Ensure that the compressed-air gun is in close contact with the connector for water/compressed-air gun. ► Ensure that any existing openings to the compressed-air gun are completely enclosed.

CAUTION

► Cover connector for flushing tube 1 with absorbent cellulose wadding or similar material. ► Attach the compressed air gun directly to the compressed air gun connector 8. ► Forcefully blow compressed air through filter 5 in the rinsing device for at least 3 seconds.

6.

Inspection, maintenance and checks

The rinsing devices are not suitable for use as storage for the sterilization of the applied parts. ► After unintentional sterilization of the rinsing device: change the filter, see Changing the filter of the rinsing device (Fig. D). ► Allow the product to cool down to room temperature. ► Inspect the product after each cleaning and disinfecting cycle to be sure it is clean, functional and undamaged. ► Set aside the product if it is damaged.

Care of the applied parts Failure of applied parts in surgical use through lack of maintenance! ► Oil the applied parts after each cleaning procedure. WARNING ► Spray the applied parts with Aesculap-STERILIT oil spray GB600 with the proper adapter, see instructions for use

of the relevant applied part. – Spray through micro-Line applied part for about 1 s with Aesculap-STERILIT oil spray GB600 with adapter GB600830. – Spray through Hi-Line, Hi-Line XS and Hi-Line XXS applied parts with Aesculap-STERILIT oil spray GB600 with adapter GB600820 until clear oil emerges from the tip. ► Check the applied parts for damage, abnormal operation noises, excessive heat or strong vibrations. ► Immediately removed applied parts that are damaged. ► Lay the applied parts in the proper ECCOS holder and insert into sterilizer.

7.

Troubleshooting list

Malfunction

Detection

Cause

Remedy

Defective applied part adapter

Applied parts cannot be coupled

Adapter damaged

Have rinsing device repaired at Aesculap Technical Service

Dirty filter

Applied parts are not clean inside

Filter has not been replaced

Change filter at least once per week.

Air not blown through filter

Blow air through filter after every wash cycle.

Filter is not inserted

Applied parts are not clean

Particles of the cleaning solution can get into the applied part

Insert a new filter. Clean applied part repeatedly.

Silicon washer is not inserted

Applied parts are not clean

Particles of the cleaning solution can get into the applied part

Insert silicone washer. Clean applied parts repeatedly.

8.

Technical Service Risk of injury and/or malfunction! ► Do not modify the product. WARNING

► For service and repairs, please contact your national B. Braun/Aesculap agency.

Modifications carried out on medical technical equipment may result in loss of guarantee/warranty rights and forfeiture of applicable licenses. Service addresses Aesculap Technischer Service Am Aesculap-Platz 78532 Tuttlingen / Germany Phone: +49 (7461) 95 -1601 Fax: +49 (7461) 14 -939 E-Mail: [email protected] Or in the US: Attn. Aesculap Technical Services 615 Lambert Pointe Drive Hazelwood MO, 63042 USA Aesculap Repair Hotline Phone: +1 (800) 214 -3392 Fax: +1 (314) 895 -4420 Other service addresses can be obtained from the address indicated above.

9.

Accessories/Spare parts

Art. no.

Designation

GB693

Filter (10 pcs.)

GB600

Aesculap-STERILIT oil spray

GB600820

Adapter for oil spray for Hi-Line, Hi-Line XS and Hi-Line XXS applied parts

GB600830

Adapter for oil spray for micro-Line applied parts

TA013567

Instructions for use for rinsing devices GB694R, GB695R and GB696R

11.

Distributor in the US/Contact in Canada for product information and complaints

Aesculap Inc. 3773 Corporate Parkway Center Valley, PA, 18034, USA TA013567

2020-06

V6

Change No. 62705