BPR Medical

OASIS System Instructions For Use Sept 2020

Instructions For Use

16 Pages

Preview

Page 1

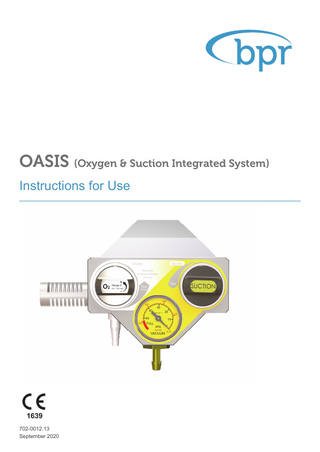

OASIS (Oxygen & Suction Integrated System) Instructions for Use

702-0012.13 September 2020

Contents 1.

Symbols... 2

2.

Warnings and Cautions ... 2

3.

4.

5.

6.

2.1.

Warnings! ... 2

2.2.

Cautions! ... 3

Functional Description ... 4 3.1.

Intended Use ... 4

3.2.

Technical Description ... 4

Operating Instructions ... 4 4.1.

Pre-use Checks ... 4

4.2.

Connection of the Gas Pressure Regulator to a Cylinder ... 5

4.3.

Oxygen Delivery ... 5

4.4.

Suction Delivery ... 5

4.5.

Removing the Regulator from the Cylinder ... 5

4.6.

Suction Jar Systems... 6

4.7.

Suction Jar Compatibility ... 6

4.8.

Suction Jar Compatibility ... 7

Cleaning and Disinfection ... 8 5.1.

After Every Use ... 8

5.2.

Suspected Contamination ... 8

Maintenance ... 8 6.1.

User Maintenance and Inspection ... 8

7.

Specification ... 9

8.

Parts and Spares... 11

1.

Symbols Warning!

Indicates a potentially hazardous situation which, if not avoided, could result in personal injury to the user or others

Caution!

Indicates a potentially hazardous situation which, if not avoided, could result in damage to the equipment or property

Note

Highlights points that might allow more convenient or efficient operation of the equipment Use no oil Service due date

2.

Warnings and Cautions Warnings! There is no flow between the indicated settings provided on the oxygen flowmeter. Do not attempt to set it between settings.

Read through this entire instruction manual before using or showing others how to use this OASIS. As with all medical equipment, attempting to use this device without a thorough understanding of its operation may result in patient or user injury.

OASIS is not suitable for use in an MRI environment. Oxygen therapy may be a critical treatment. A flowmeter should be used in strict accordance with the prescription and instructions of a qualified clinician. The effectiveness of supplemental oxygen therapy can only be determined by continuous monitoring of blood oxygen levels.

Ensure that the oxygen cylinder is securely fastened to the trolley base. When the flowmeter is turned off, isolate the patient from the equipment by disconnecting the delivery tube from either the patient or the flowmeter.

Only appropriately trained service personnel working in controlled conditions must perform disassembly, assembly and testing of this equipment.

Do not submerge in water or allow any fluid to enter the equipment. If you have reason to suspect that fluid or other ingress has occurred remove the device from use and contact the manufacturer.

Check the cylinder contents before use and at regular intervals during use as low cylinder pressure may result in poor or non-performance of the equipment. Always change the oxygen cylinder when the oxygen cylinder contents gauge is showing red.

OASIS has been tested with the suction jar systems indicated in this manual. The use of suction jar systems other than those listed and/or approved by the manufacturer may result in poor or nonperformance of the equipment.

The accuracy of the flowmeter and suction device may be affected if the input pressure is other than that stated in the specifications.

Oxygen is not flammable, but the presence of oxygen will drastically increase the rate and severity of combustion. Hydrocarbons such as oil or grease become highly combustible in the presence of oxygen. Oxygen must never be allowed to contact oil, grease or other petroleum-based substances. 2

Many hand creams and moisturisers contain paraffin and petroleum bases which are highly flammable and must never be allowed to contact the OASIS. Ensure hands are clean and dry before operating the equipment.

Never administer oxygen while smoking or when near an open flame. Oxygen cylinders have fill pressures up to 20,000 kPa (200 bar). Never use medical oxygen from a cylinder without first reducing the pressure to a safe level through a suitable pressure regulator.

Ensure that the threaded fittings or indexing pins on the regulator are properly mated and tightened before opening the cylinder valve.

Never install a pin index regulator with more than one Yoke Seal between the cylinder and the regulator. Before attaching the regulator verify that the post valve is not already fitted with a Yoke Seal. Never add a second Yoke Seal to the regulator inlet while one is in place.

Make sure that the pin-indexed or threaded fittings on the regulator inlet are compatible with the gas cylinder on which it is to be fitted. Never attempt to force an incompatible connection.

The threaded bullnose connection on a UK medical oxygen cylinder may be the same as that for a UK medical air cylinder. Ensure that you have the correct cylinder for the application. OASIS and its regulator are intended for use with oxygen only and must not be connected to an air cylinder.

Before removing a regulator from a cylinder fully close the cylinder valve and release all gas from the regulator.

Never permit compressed medical gases to enter a regulator suddenly. Always open the cylinder valve slowly. Do not stand in front of a regulator outlet when opening the cylinder valve.

Do not use or store oxygen equipment near excessive heat (>50 °C or 125 °F) or an open flame. Use only lubricants recommended by the manufacturer when servicing the OASIS. The use of lubricants other than those recommended by the manufacturer may result in fire or explosion.

OASIS must always be used in an upright position. When fitting OASIS to a patient trolley ensure that the front membrane panel is vertical.

Never attempt to disassemble this device while it is connected to a gas source. Do not attempt to remove or replace the connectors supplied with this device. The inlet connector is gas specific.

The oxygen flowmeter provided does not provide an indication that gas is flowing, it only provides an indication that an orifice has been selected for that flow rate.

Cautions! The performance of the OASIS may be affected if it is stored or transported in temperatures outside of the range -20 °C to 60 °C (-4 °F to 140 °F).

The device is not suitable for autoclaving.

3

3.

Functional Description Intended Use OASIS is an oxygen flowmeter and a suction regulator integrated into one device, driven by a single oxygen cylinder. It is designed to provide controllable delivery of supplemental oxygen and suction in emergency situations or when patients are being moved on patient trolleys. The suction delivery meets the requirements of high suction/high flow and pharyngeal suction in EN ISO 10079-3:2014 Medical Suction Equipment. Suction equipment powered from a vacuum or pressure source. OASIS is intended to be fitted to the head end of patient trolleys to provide easy access to both oxygen and suction where and when it is needed most. The integrated and sturdy design provides protection from damage in a harsh environment. The oxygen flowmeter is of fixed orifice type, providing eleven pre-set flow rates selectable by turning the control knob to the required position. The flow rate at each position is shown through a window in the body of the flowmeter and is given in units of litres per minute (l/min). The patient or outlet connection barb is situated underneath the OASIS directly below the flowmeter control knob.

Technical Description OASIS comprises a fixed orifice Dialflow Meter (range 0-15 l/min) and a venturi vacuum generator mounted in a common manifold and driven by pressurised oxygen supplied from an oxygen cylinder via a suitable pressure regulator. OASIS can be supplied complete with the optional pressure regulator either permanently attached or provided with a probe (quick connector). The suction and oxygen system includes a valve for suction control, a gauge to monitor the suction level and a check valve to prevent positive pressure from exhausting the contents of the suction jar or tube in a hazardous manner. A Dialflow Meter can be set to deliver eleven different flow rates or turned off as detailed in section 7. The flow rate is indicated through a window at the top of the oxygen control dial. A detent system resident in the control dial assembly ensures a positive tactile setting and inadvertent adjustment. The flowmeter is permanently fitted to the OASIS module. OASIS has an intended life of 12 years.

4.

Operating Instructions Pre-use Checks Check the device is securely attached or mounted. Check the oxygen supply is connected and that sufficient oxygen is available. Check that suction is available by occluding suction wand and observing the vacuum gauge. Turn the flow selection dial to its highest setting and check that gas flow can be felt at the patient end of the supply tubing.

4

Connection of the Gas Pressure Regulator to a Cylinder Check that the cylinder type and regulator inlet connector are compatible. Check the presence and condition of the input connector seal on the regulator. Note: For pin-index regulators this is a washer type seal (yoke seal), for bull-nose regulators an Oring. Fit the regulator to the cylinder ensuring that it is properly mated and the connectors are done up. Hand tight is sufficient. Open the cylinder valve with a suitable cylinder key. Check the regulator cylinder contents gauge to verify that there is sufficient gas available.

Oxygen Delivery Connect a sufficient length of oxygen tubing (not supplied) to the outlet barb. Connect the other end of the oxygen tubing to the patient or patient enclosure using the appropriate connector (not supplied). Determine the appropriate oxygen flow rate in l/min required for the patient. Turn the control knob anticlockwise until the required rate is visible in the viewing window. Continue to monitor the patient as advised by the clinician. Continue to check the cylinder contents gauge on the regulator. Upon completion of the therapy turn the control knob to zero and disconnect the delivery hose from the patient.

Suction Delivery Prepare the suction jar system in accordance with the manufacturer’s instructions. If you are intending to use an autoclavable suction jar system ensure that a hydrophobic filter and overflow protection device is fitted. Note: Autoclavable suction jar systems have single use hydrophobic filter/overflow protection devices, which should be replaced with each new use/patient. The disposable liner systems recommended for OASIS (refer to ‘Suction Jar Systems’ table) have an integral hydrophobic filter and overflow protection device. Connect the suction hose (supplied) between the suction barb on the OASIS manifold and the barb on the suction jar marked ‘Vacuum’. Connect suction hosing and wand (not supplied) to the barb on the suction jar marked ‘Patient’. This tubing is used for removing fluids from the patient and depositing them in the suction jar. Note: If these hoses are reversed the suction device will not operate correctly. Fit the suction jar into the cradle provided on the bottom of the trolley. To activate the suction unit, turn the control knob anticlockwise.

Removing the Regulator from the Cylinder To remove the regulator from the cylinder, first ensure the cylinder valve is closed. Bleed off any residual gas pressure in the system by turning on either the oxygen or suction delivery systems until flow ceases. Undo and remove the regulator from the cylinder.

5

Suction Jar Systems Suction jar systems can generally be broken down into autoclavable and disposable types. Autoclavable systems have a rigid suction jar with a sealable lid. Following cleaning and sterilisation they may be reused. A disposable hydrophobic filter is fitted to such systems and should be replaced after every use. Disposable systems comprise either a rigid suction jar into which a disposable liner is fitted (the rigid jar being reusable) or a rigid or semi-rigid canister requiring no other components and being wholly disposable. The disposable systems recommended for use with the OASIS (refer appropriate table) have integrated hydrophobic filters and overflow protection devices and no other provision need be made in this regard. Components from single use or disposable systems should never be re-used and no attempt should be made to clean or sterilise them.

Suction Jar Compatibility OASIS has been tested and found to be compatible with the suction jar systems detailed in the table provided. Some 2 litre size jars shown in the table, whilst compatible with the OASIS suction regulator, are too tall and are liable to be broken should the trolley be lowered or put into the Trendelenberg position. These suction jar systems are therefore considered incompatible with OASIS and are shown with the manufacturer’s part number crossed out (e.g. XXX XXXX). For the same reason all 3 litres and larger suction jar systems are incompatible with OASIS.

6

Monokit Disposable

Flowmeter Spa Monokit Autoclavable

VacSax

Tyco Sep-T-Vac

Medi-Vac CRD

Medi-Vac Flex Advantage

Allegiance Medi-Vac Guardian

Abbott Receptal

Manufacturer/Model

Autoclavable suction jar OASIS cradle type Re-usable suction jar for disposable liner Disposable liner OASIS Cradle Type

Re-usable suction jar for disposable liner Disposable liner OASIS Cradle Type

Disposable canister OASIS Cradle Type Re-usable suction jar for disposable liner Disposable liner OASIS Cradle Type

Disposable canister OASIS Cradle Type Re-usable suction jar for disposable liner Disposable liner OASIS Cradle Type Re-usable suction jar for disposable liner Disposable liner OASIS Cradle Type

Re-usable suction jar for disposable liner Disposable liner OASIS Cradle Type

Description

Suction Jar Compatibility

7

5113080 B

MAK1000 A

3833-132 9910-340 B

8888-310003 B

65652-611 65651-910 B 65652-511 1510CE

W064 L212 A

0.8/1.0 Litre

8888-310052 B 8888-310839 8888-310821 B

1212CE B 65652-616 65651-920 B 65652-516 1515CE

E124 F807 A

1.2/1.5 Litre

3833-090 9910-208 B

8888-310813 8888-310995

8888-310151

1230CE

E123 F806

2.0 Litre

5.

Cleaning and Disinfection

Ensure the OASIS is disconnected from the gas supply before attempting to clean it. Caution! This device is not suitable for autoclaving.

After Every Use Use a mild disinfectant soap solution and hot water to clean external parts in accordance with hospital procedures. There is no limit to the number of time OASIS can be cleaned.

Suspected Contamination If you suspect that the OASIS is contaminated remove it from use and refer to the OASIS Service Manual. If liquid or solid contaminants are accidentally drawn into the device, it must be removed from service – seek advice from BPR Medical Ltd. Never immerse the device in any fluid or attempt to clean internal parts whilst fully assembled.

6.

Maintenance User Maintenance and Inspection OASIS and its oxygen pressure regulator require servicing every 4 years. A Service Due date is given on both device labels as a reminder. Servicing must be carried out by a suitably qualified person working in a controlled environment. The Service Manual can be obtained from BPR Medical, details can be found at www.bprmedical.com. A valid decontamination certificate must accompany equipment returned for servicing. For reasons of Health & Safety, equipment returned for service without a valid decontamination certificate will be returned without further processing. When serviced by BPR Medical and where the time to end of life is less than the normal service interval, the Service Due date will be replaced by the End of Life date and preceded by a symbol ( ). In these cases, the date now indicates when the device reaches end of life.

6.1.1.

Visual Inspection All devices should be inspected every 6 months or when there is reason to believe it has sustained damage or may not be working at full performance. Regulator Checklist:

Input seal integrity (O-ring or bonded seal) Cylinder contents gauge in good condition. Needle registers in the green area of the gauge on a full cylinder and zero when not connected to a cylinder

Sintered bronze filter in place and not blocked by debris Labels are intact and legible OASIS Manifold Checklist:

The vacuum gauge is in good condition The low pressure hose assembly is in good condition OASIS is securely fixed to the trolley or bed 8

6.1.2.

Leak Test Flowmeter Leak Through: Connect and charge the system to a full cylinder in accordance with Section 4.2. Check that the oxygen and suction control knobs are at zero (fully clockwise). Connect one end of a length of hose to the flowmeter outlet barb and place the other end into a container of water. Check that there are no bubbles coming from the end of the tube, which would indicate leak through. External Leak – Following on from the test above, with the device still pressurised, check each joint for leaks using a proprietary leak detector spray and observe for leaks.

6.1.3.

Flow Rate Verification Verify flow rates at all flow settings against those given in the Device Specification in section 6. Mass flow meters with appropriate full-scale ranges for the flow rates are particularly suitable for this. Alternatively, where flow measuring equipment is not available, a qualitative check can be performed by confirming that gas flow can be sensed to be increasing with each step increase in flow across the full flow range. For higher flow rates, this can be sensed audibly or by holding a hand close to the flow outlet; moistening the skin can increase the cooling sensation and therefore sensitivity to the flow. For very low flow rates, this may better be achieved by placing the end of a connected tube in a glass of water to observe the bubbles.

6.1.4.

Suction Test Verify maximum suction capability by occluding the suction outlet, turning the control knob fully anticlockwise and checking the suction gauge enters the red “FULL” zone.

6.1.5.

Troubleshooting For fault finding and corrections for any problem encountered, contact BPR Medical Ltd.

7.

Specification

Specification

Value

Oxygen Dialflow Meter Nominal Flow Rates

0, 0.5, 1, 1.5, 2, 3, 4, 5, 6, 8, 10, 15

Flow Accuracy

±10% of setting at 1 l/min and above, ±20% of setting below 1 l/min at 400 kPa

Inlet Pressure Range

350 to 450 kPa

Delivery Hose

6.0 mm inside diameter

Environmental Regulatory

Transport and Storage Temperature: -20°C to 60°C (-4°F to 140°F) Operating Temperature: -20 °C to 60 °C (-4 °F to 140°F) CE: Medical Device Directive 93/42/EEC – Active Medical Device – Class IIa

Effect on accuracy as a result of: i) varying inlet pressure

Typically less than 10% change across the input pressure range

ii) varying outlet resistance

Less than 1% of reading up to 5kPa (50cmH2O) back pressure

iii) varying temperature

Less than 0.2% of reading per degree Celsius

Suction Controller 9

EN ISO 10079-3 Performance

High Suction/High Flow and Pharyngeal Suction

Vacuum Range

0 - 60 kPa with 400 kPa driving pressure

Vacuum Flow

~26 l/min with 400 kPa driving pressure

Driving Pressure Range

350 – 600 kPa (required to power the injector suction)

Gas Consumption

45 l/min at maximum suction with 400 kPa driving pressure

Recommended Suction Hose

7.5 mm inside diameter

Pressure Regulator P1 Maximum Input Pressure

20,000 kPa

P3 Minimum Input Pressure

900 kPa

Q1 Standard Discharge

40 l/min

P2 Outlet Pressure Stated at Input Pressure P3 and Flow Q1

400 kPa

Applied Standards ISO 15002

Flowmetering devices for connection to terminal units of medical gas pipeline systems.

BS EN ISO 5359

Low-pressure hose assemblies for use with medical gases

BS EN ISO 10079-3

Medical suction equipment. Suction equipment powered from a vacuum or pressure source

10

8.

Parts and Spares

Part Number

Description

Hose (m)

Mount

Inlet Connection

812-0044

OASIS - Medirail - 1.1 m hose - BS 5682

1.1

Medirail

BS 5682

812-0047

OASIS - Medirail - 0.8 m hose - BS 5682

0.8

Medirail

BS 5682

812-0051

OASIS - Medirail - 0.6 m hose - BS 5682

0.6

Medirail

BS 5682

812-0052

OASIS - Medirail - 0.45 m hose - BS 5682

0.45

Medirail

BS 5682

812-0053

OASIS - Medirail - 2.5 m hose - BS 5682

2.5

Medirail

BS 5682

812-0054

OASIS - Medirail - 3 m hose - BS 5682

3

Medirail

BS 5682

812-0055

OASIS - Bedrail - 0.45 m hose - BS 5682

0.45

Bedrail

BS 5682

812-0056

OASIS - Bedrail - 0.6 m hose - BS 5682

0.6

Bedrail

BS 5682

812-0057

OASIS - Bedrail - 0.8 m hose - BS 5682

0.8

Bedrail

BS 5682

812-0058

OASIS - Bedrail - 1.1 m hose - BS 5682

1.1

Bedrail

BS 5682

812-0059

OASIS - Bedrail - 2.5 m hose - BS 5682

25

Bedrail

BS 5682

812-0060

OASIS - Bedrail - 3 m hose - BS 5682

3

Bedrail

BS 5682

Spare Parts and Servicing 602-0132

Cradle - Size A

602-0133

Cradle - Size B

504-0008

Exhaust Silencer

812-0027

Cradle Securing Kit

999-0004

OASIS Service – Pin Index Pressure Regulator

999-0005

OASIS Service – Bull-nose Pressure Regulator

999-0006

OASIS Service – No Pressure Regulator

11

BPR Medical Limited

+44 (0)1623 628 281

Qarad EC-REP BV

22 Hamilton Way, Mansfield, Notts.

Pas 257, 2440 Geel

NG18 5BU, United Kingdom

www.bprmedical.com

Belgium