British Oxygen Company

ENTONOX Data

ENTONOX Integral valve cylinders ED and EX Instructions for Use May 2013

Instructions for Use

3 Pages

Preview

Page 1

→ BOC: Living healthcare

ENTONOX® (50% nitrous oxide/50% oxygen). Integral valve cylinders (ED, EX).

Best-in-class cylinder packages BOC Healthcare pioneers the medical gas products and services that will deliver tomorrow’s patient care today. Our unrivalled commitment to improving medical gas technology, reduces costs, and optimises patient treatment. All BOC Healthcare gas cylinders are designed to be robust, reliable, convenient to use and safe to handle. To provide the highest quality, all cylinders are tested at every fill to ensure patient safety.

Integral valve cylinders BOC was the first UK company to introduce integral valve cylinders to the healthcare sector. These simple, ready to use cylinders require no additional equipment. The lightweight packages in the range are more convenient to use and hold more gas than conventional cylinders.

The benefits and features of these cylinders are: • constantly live gauge indicates gas levels, even when the cylinder is not turned on • higher gas capacity for less cylinder changes • lightweight small cylinders for less lifting effort, ideal for portable use • improved manual handling, minimising the risk of injury • easier to store and handle due to its flat stable base and carry handle • clear product labelling to avoid selecting the wrong gas • eliminates the costs of buying and maintaining separate regulators • tamper-evident covers to ensure the gas is kept uncontaminated and safe for the patient up to the time of use • no need for a cylinder key • simple push fit connection to save time. With BOC as your provider, you can be sure to benefit from leadingedge technology.

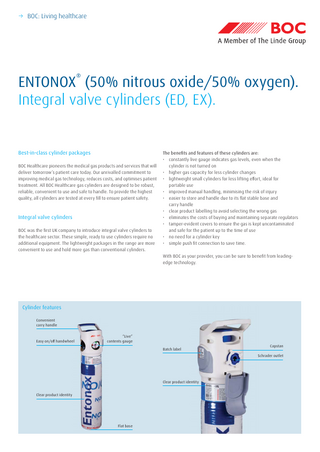

Cylinder features Convenient carry handle

Easy on/off handwheel

“Live” contents gauge Batch label

Capstan Schrader outlet

Clear product identity Clear product identity

Flat base

02

Cylinder instructions

Cylinder instructions

Instructions for use.

03

Note: (1)

If you suspect that you have a leak, turn off the cylinder and check the equipment is properly connected. Turn on the cylinder and re-check for leaks. If the leak continues, turn off and quarantine the cylinder and contact BOC Healthcare.

1. Initial safety checks Before handling cylinders ensure your hands are clean. If you have been using alcohol based gel or liquids to decontaminate your hands make sure the alcohol has totally evaporated.

When selecting the cylinder for use, check that the cylinder is free from oil and grease, particularly around the Schrader outlet. Check that the cylinder is not damaged in any way, if it is contact BOC.

2. Preparing a new cylinder for use

2.1 Ensure you have the correct medical gas by checking the cylinder label.

2.2 Check the expiry date on the batch label. Use cylinders with the nearest expiry date.

3.5 Check the demand valve is operating by pushing the “test button”. Ensure you can hear the gas flowing.

3.6 Check for leaks which maybe indicated by a hissing sound.(1)

4. Monitoring during use

2.3 Make sure the contents gauge is in the green zone. This indicates that the cylinder is FULL.

If the cylinder has been used before make sure you have suffi cient gas for treatment by inspecting the contents gauge. If the needle is in the red zone there is limited capacity and you may need to change the cylinder (see nominal duration chart overleaf).

2.4 Remove the tamper evident handwheel cover by pulling the tear ring. Discard the cover into the recycle bin. If the cylinder has been used before this cover will not be present.

Note:

4.1 Instruct the patient on how to use the demand valve correctly before commencing therapy. The gas should be inhaled for at least 2 minutes prior to starting any procedure for optimum pain relief.

4.2 Use scavenging equipment whenever possible, to avoid a build up of nitrous oxide in the environment. If scavenging is not possible, use in a well ventilated area.

4.3 Ensure the clinical condition of the patient remains satisfactory throughout the therapy. If the patient experiences complications ask them to stop inhaling the gas.

4.4 Check the contents gauge at regular intervals (as described in 2.3), to make sure there is enough gas to continue the therapy.

5.2 Turn off the cylinder by rotating the hand wheel clockwise until it comes to a stop. Do not use excessive force.

5.3 Vent any residual gas in the hose by pressing test button on the demand valve. Wait for the gas to stop venting.

5.4 Disconnect the probe from the cylinder outlet. Holding the probe twist the capstan and withdraw it from the outlet.

5. After use

Ideally the cylinder should not be placed on the bed next to the patient.

2.5 Open the valve outlet cover. The hinged grey cover is pulled down. Do not remove the grey cover and refit after use.

2.6 Place the cylinder in a safe location, preferably in an appropriately designed cylinder holder fitted to the patient‘s bed.

If there is no alternative; before placing on the patient‘s bed make sure that: • the equipment is connected • the cylinder is turned on and not leaking (see 3.1 to 3.6) • check there is a gas flow by pressing the test button. 5.1 Remove the demand valve from the patient. If the treatment is finished safely dispose of the filter and mouthpiece or mask.

3. Connecting a demand valve to the Schrader outlet

In the event of an emergency, or if you suspect your cylinder is leaking, contact BOC Healthcare on 0800 111 333.

3.1 Ensure the demand valve is clean and ready for use. You will need a single patient use mouthpiece or face mask.

3.2 Fit a new microbial filter to the demand valve. Fit a new filter/ mouthpiece for each patient to prevent cross contamination.

3.3 Insert the probe on the hose connected to the demand valve into the Schrader outlet. Push firmly to ensure the probe clicks securely into place.

3.4 Slowly turn on the cylinder by rotating the hand wheel anti-clockwise until it comes to a stop. Do not use excessive force.

5.5 Replace the outlet cover by pulling up the hinged grey cover.

5.6 Check the cylinder gauge, for content level (refer to nominal duration chart). Return the cylinder to a designated ‘in use’ or empty storage area.

04

Cylinder instructions

Cylinder range and specifications Cylinder code Cylinder order code Nominal contents (litres) Nominal cylinder pressure (bar) Nominal outlet pressure (bar) Valve outlet pressure connection Valve operation Maximum flow-rate (litres/min) Dimensions (inc. valve) L x D (mm) Water capacity (litres) Nominal weight full (kg)

ED 211-ED 700 217 4 ENTONOX BS 5682 Schrader Handwheel Schrader: 40 (nominal) 520 x 100 2.0 4.5

EX 211-EX 3500 217 4 ENTONOX BS 5682 Schrader Handwheel Schrader: 40 (nominal) 940 x 140 10.0 19.8

Nominal cylinder duration Estimated usage time, based on an average 6 litres per minute consumption rate for an adult person.

Size ED ENTONOX (700 ltrs) EX ENTONOX (3500 ltrs)

Full (100%) (hrs. min) 1.56 9.43

Gauge contents Half (50%) (hrs. min) (mins) 0.58 58 4.51 292

(mins) 116 583

Low (25%) (hrs. min) 0.29 2.25

(mins) 29 146

Storage and use If ENTONOX cylinders are allowed to get too cold (below -6ºC) the nitrous oxide component of the gas will start to separate out of the gas mixture, changing the concentration of the gas delivered to the patient. To prevent this it is recommended that cylinders should be stored above 10ºC for at least 24 hours before use. If a cylinder is allowed to get too cold, it will automatically be remixed for use by storing it above 10ºC for at least 24 hours. Alternatively, for small ED size cylinders, the cylinder can be remixed by inverting it three times just prior to use, once it has been warmed to 10ºC.

Safety information and precautions

• • •

• •

ENTONOX is a non-flammable gas, but strongly supports combustion. Do not store or use medical gas cylinders near naked flames, sources of ignition or combustible materials. Ensure the ENTONOX cylinders are stored in a safe and secure area where they cannot fall over and cause injury. Clearly identify the storage areas with appropriate signage. Ensure separation of full and empty cylinders. Store medical gas cylinders separately from industrial and other non medical cylinders in a well-ventilated area that is clean and dry, preferably inside. Smoking should not be permitted in the vicinity where cylinders are used or stored. Ensure labels remain clearly visible at all times and not removed or covered. Unauthorised labels/tags must not be fitted.

•

• • • • • •

Use a suitable trolley to transport large cylinders. Any stationary cylinder trolley in a ward area should be fixed in place to prevent it falling over. Where available, always use an appropriately designed cylinder support to hold the cylinder whilst in use adjacent to the patient. Ensure the cylinder is set up and tested before placing near the patient. Do not place the cylinder on the patient‘s bed unless there is no suitable alternative for retaining the cylinder. Do not use oil or grease (or any oil-based products which includes hand creams) in the vicinity of an ENTONOX cylinder. If you need to clean the cylinder do not use any materials which contain ammonium or chlorine compounds. Do not refill or tamper with the cylinder package.

If you require a replacement or have concerns about your cylinder package please contact our Customer Service Centre on 0800 111 333 quoting your account number. This number should also be used in the unlikely event of an emergency or if you suspect your cylinder is leaking (our Customer Service Centre is open 365 days a year, 24 hours a day). BOC Healthcare Customer Service Centre, Priestley Road, Worsley, Manchester M28 2UT Phone 0800 111 333, Fax 0800 111 555, Email bochealthcare-uk@boc.com, www.bochealthcare.co.uk The stripe symbol and the letters BOC are registered trade marks of The BOC Group Limited. Both BOC Limited and The BOC Group Limited are members of The Linde Group, the parent company of which is Linde AG. Reproduction without permission is strictly prohibited. © Copyright 2013

HLC/504365/UKS/BAMC/0513

• •