ConMed Linvatec

Linvatec Advantage, E9000 and PowerPro Console Instruction Manual Rev B July 2005

Instruction Manual

162 Pages

Preview

Page 1

W41-104-004.book Page 1 Tuesday, August 9, 2005 9:36 AM

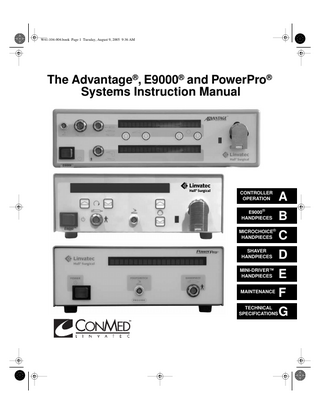

The Advantage®, E9000® and PowerPro® Systems Instruction Manual

CONTROLLER OPERATION

A

E9000® HANDPIECES

B

MICROCHOICE® HANDPIECES

C

SHAVER HANDPIECES

D

MINI-DRIVER™ HANDPIECES

E F

MAINTENANCE

TECHNICAL SPECIFICATIONS

G

W41-104-004.book Page 2 Tuesday, August 9, 2005 9:36 AM

Proprietary Information This manual contains information deemed proprietary to Linvatec Corporation. The information contained herein, including all of the designs and related materials, is the sole property of ConMed Linvatec and/or its licensors. ConMed Linvatec and/or its licensors reserve all patent, copyright and other proprietary rights to this document, including all design, manufacturing methodology and reproduction. This document, and any related materials, is confidential and is protected by copyright laws and shall not be duplicated, transmitted, transcribed, stored in a retrieval system, or translated into any human or computer language in any form or by any means, electronic, mechanical, magnetic, manual or otherwise, or disclosed to third parties, in whole or in part, without the prior express written consent of ConMed Linvatec. ConMed Linvatec reserves the right to revise this publication and to make changes from time to time in the contents hereof without obligation to notify any person of such revision or changes, unless otherwise required by law.

Linvatec, Hall, Advantage, APEX, Elite, MicroChoice, PowerPro, E9000 and Ultrapower are trademarks or registered trademarks of ConMed Linvatec Corporation.

© Linvatec Corporation 2005. All Rights Reserved. Printed in USA

Record the Model and Serial Numbers of the controller(s) and handpiece(s), and date received. Retain for future reference. Controller Model No. Controller Model No. Handpiece Model No. Handpiece Model No. Handpiece Model No. Handpiece Model No. Handpiece Model No. Handpiece Model No. Handpiece Model No. Handpiece Model No.

Serial No Serial No Serial No Serial No Serial No Serial No Serial No Serial No Serial No Serial No

Date Date Date Date Date Date Date Date Date Date

W41-104-004.book Page i Tuesday, August 9, 2005 9:36 AM

Page

Table of Contents

1.0

INTRODUCTION 1.1

Intended Use... 1

1.2

Contraindications... 1

1.3

General Warnings and Cautions... 2

1.4

Symbol Definitions... 4

1.5

System Indicators... 7

1.6

1.5.1

Advantage® Controller Front Panel (Top Portion)... 7

1.5.2

Advantage Controller Front Panel (Bottom Portion)... 8

1.5.3

Advantage Controller Back Panel... 9

1.5.4

E9000® Controller Front Panel... 10

1.5.5

E9000 Controller Back Panel... 11

1.5.6

PowerPro® Controller Front Panel... 12

1.5.7

PowerPro Controller Back Panel... 13

Handpieces... 14 1.6.1

1.6.2

1.6.3

GROUP 1 HANDPIECES... 14 1.6.1.1

Cranial Perforator Drive Handpiece (E9015)... 14

1.6.1.2

High Speed Shaver (E9005)... 14

1.6.1.3

CoolFlex® High Speed Drill (E9010)... 15

GROUP 2 HANDPIECES... 16 1.6.2.1

MicroChoice® Drills and Saws... 16

1.6.2.2

MicroChoice Modular Handpiece (5020-027)... 17

GROUP 3 HANDPIECES... 18 1.6.3.1

1.6.4

Shaver Handpieces... 18

GROUP 4 HANDPIECES... 20 1.6.4.1

Mini-Driver™ Electric Handpiece (K500)... 20

i

W41-104-004.book Page ii Tuesday, August 9, 2005 9:36 AM

Page

Table of Contents

1.0

INTRODUCTION (Continued) 1.7

Footswitches... 21 1.7.1

1.7.2

1.7.3

Footswitch, 2-Pedal (5020-053)... 21 1.7.1.1

Operation with the E9005 High Speed Shaver and Group 3 Shaver Handpieces... 21

1.7.1.2

Operation with the CoolFlex High Speed Drill and Group 2 Drills... 21

1.7.1.3

Operation with Group 2 Saws and E9015 Cranial Perforator Drive... 21

Footswitch, 3-Pedal (C9863)... 22 1.7.2.1

Operation with the E9005 High Speed Shaver and Group 3 Shaver Handpieces... 22

1.7.2.2

Operation with the CoolFlex High Speed Drill and Group 2 Drills... 22

1.7.2.3

Operation with Group 2 Saws and E9015 Cranial Perforator Drive... 22

Tubing Sets... 23 1.7.3.1

Tubing Set without Bur Irrigation (E9414) for use with the CoolFlex High Speed Drill... 23

1.7.3.2

Tubing Set with Bur Irrigation (E9415A) for use with the CoolFlex High Speed Drill... 24

1.7.3.3

Tubing Sets (E9416/E9417) for use with 3.7 mm and 4.2 mm Irrigated Shaver Blades... 25

1.7.3.4

Tubing Set (E9419) for use with 3.7 mm and 4.2 mm Irrigated Shaver Blades... 26

1.7.3.5

Tubing Set (E9418) for use with Group 2 MicroChoice Drills and Saws... 27

ii

W41-104-004.book Page iii Tuesday, August 9, 2005 9:36 AM

Page

Table of Contents

2.0

SYSTEM INSTALLATION and OPERATION 2.1

Installation and Setup... 28 2.1.1

Handpiece Cord Installation... 28

2.1.2

Footswitch and Handpiece to Controller Installation... 29

2.1.3

2.1.2.1

Connecting the Footswitch... 29

2.1.2.2

Connecting an APEX® Handpiece... 30

2.1.2.3

Connecting all Group 1 and Group 2 Handpieces... 31

2.1.2.4

Connecting the Mini-Driver (K500) Handpiece... 31

2.1.2.5

Connecting a PowerPro Handpiece... 32

Controller Options/Function Switches and Settings... 33 2.1.3.1

Controller Options/Function Switch Settings... 34

2.1.3.2

Switch 1 - “Day-to-Day” Memory Storage Operation... 36

2.1.3.3

Switch 2 - Footswitch Mode Selection... 37

2.1.3.4

Switch 3 - Audio Selection... 38

2.1.3.5

Switch 3 - Handpiece Operating Mode Selection (PowerPro Electric Two-Trigger Handpiece Only)... 38

2.1.3.6

Switch 4 - Oscillate Mode Selection (Shaver Handpieces Only) . 39

2.1.3.7

Switch 4 - Oscillate Mode Selection (Turbo™ Shaver Handpieces Only - D9920 and D9924)... 40

2.1.3.8

Switch 5 - Window Indexing... 41

2.1.3.9

Switch 5 - Display Mode Selection... 42

2.1.3.10 Switch 6 / Switch 7 - Shaver Default Speed Setting... 42 2.1.3.11 Switch 6 (Bottom Row Only) - Special Handpiece Operating Mode Selection (PowerPro Two-Trigger Handpiece Only)... 43 2.1.3.12 Switch 7 - Shaver Button Setting... 43 2.1.4

Tubing Set Cassette Installation... 44

2.1.5

Controller Operation... 45

iii

W41-104-004.book Page iv Tuesday, August 9, 2005 9:36 AM

Page

Table of Contents

2.0

SYSTEM INSTALLATION and OPERATION (Continued) 2.1.6

2.1.7

3.0

PowerPro Console Irrigation... 46 2.1.6.1

Irrigation Pump Installation... 46

2.1.6.2

Irrigation Pump Operation... 47

Footswitch Operation (Advantage Top Portion Only, PowerPro and E9000)... 52 2.1.7.1

Operation of the 2-Pedal Footswitch (5020-053)... 53

2.1.7.2

Operation of the 3-Pedal Footswitch (C9863)... 55

HANDPIECE OPERATION Group 1 Handpieces... 58 3.1

High Speed Shaver (E9005) Operation... 58

3.2

CoolFlex High Speed Drill Operation... 61

3.3

3.2.1

Preoperative Functional Test for the CoolFlex High Speed Drill... 62

3.2.2

Bur Guard Attachment... 63

3.2.3

Neuro Guard Attachment... 64

3.2.4

Tubing Set Line Attachment... 65

3.2.5

Handpiece Adjustment... 68

Cranial Perforator Drive (E9015) Operation... 68

Group 2 Handpieces... 69 3.4

MicroChoice Drills... 69 3.4.1

Tubing Set Attachment (E9418) for MicroChoice Handpieces... 69

3.4.2

Preoperative Functional Test for the MicroChoice Elite™ High Speed Drill... 70

iv

W41-104-004.book Page v Tuesday, August 9, 2005 9:36 AM

Page

Table of Contents

3.0

HANDPIECE OPERATION (Continued) 3.4.3

3.4.4 3.5

3.6

Elite High Speed (5020-025) and Medium Speed Drill (5020-021) Attachments and Accessories... 71 3.4.3.1

Medium (5020-060), Long (5020-061) and Extra-Long (5020-062) Bur Guards... 72

3.4.3.2

20° Angle (5020-063) and Extra-Long 20° Angle (5020-064) Attachments... 73

3.4.3.3

70° Contra Angle with Surgical Head (5020-065), 70° Contra Angle with Dental Head (5020-069), and 90° Angle (5020-066) Attachments... 74

3.4.3.4

Tissue Retractor Bur Guard (5020-068)... 75

3.4.3.5

Laminectomy Bur Guard (5020-067)... 76

Low Speed Drill (5020-026) Operation... 77

MicroChoice Saws... 79 3.5.1

Reciprocating Saw (5020-023) Operation... 79

3.5.2

Sagittal Saw (5022-022) Operation... 80

3.5.3

Oscillating Saw (5020-024) Operation... 82

3.5.4

Leverless Handpiece Operation... 84

MicroChoice Modular Handpiece (5020-027), Attachments and Accessories... 85 3.6.1

Connecting/Removing Attachments... 85

3.6.2

Pin and Wiredriver Attachments... 86

3.6.3

3.6.4

3.6.2.1

Wiredriver Attachment... 86

3.6.2.2

Pin Driver Attachment... 86

3.6.2.3

Pin and Wire Insertion... 86

Universal Drill Attachment (5020-029)... 87 3.6.3.1

Trinkle Shank Accessories for the Universal Drill Attachment . . 88

3.6.3.2

AO Drill Bits for the Universal Drill Attachment... 88

All Jacobs Chuck Attachments... 89

v

W41-104-004.book Page vi Tuesday, August 9, 2005 9:36 AM

Page

Table of Contents

3.0

HANDPIECE OPERATION (Continued) 3.6.5

Group 2 Handpiece Cord Button Operation... 90 3.6.5.1

Button Operation Using the Elite High Speed Drill, Medium Speed Drill, Saws and Modular Handpiece... 90

3.6.5.2

Button Operation Using the Low Speed Drill... 91

Group 3 Handpieces... 92 3.7

Preoperative Functional Test for Group 3 Shaver Handpieces... 93

3.8

Accessory Insertion and Removal... 93

3.9

3.8.1

Advantage Basic (D9820/D9920) and 2-Button (D9824/D9924) Shaver Handpieces... 93

3.8.2

Small Shaver Handpieces (MC9840, C9840)... 94

Group 3 Handpiece Operation... 95 3.9.1

3.9.2

3.9.3

Activating the Handpiece... 95 3.9.1.1

Activating the Handpiece with the Footswitch... 95

3.9.1.2

Activating the Handpiece with the Handpiece ON/OFF Button . . 95

Changing Handpiece Speeds... 96 3.9.2.1

Using the Controller Speed Buttons to Change Speed... 96

3.9.2.2

Using the Handpiece Direction Select and ON/OFF Buttons to Change Speed... 96

3.9.2.3

Using the Handpiece Speed Buttons to Change Speed... 97

3.9.2.4

Using the Handpiece Cord Button to Change Speed... 97

Changing Handpiece Operating Directions... 98 3.9.3.1

Using the Footswitch to Change Handpiece Direction (Applies only to the 2-Pedal Footswitch - 5020-053)... 98

3.9.3.2

Using the Handpiece Direction Select Button to Change Handpiece Direction... 98

vi

W41-104-004.book Page vii Tuesday, August 9, 2005 9:36 AM

Page

Table of Contents

3.0

HANDPIECE OPERATION (Continued) 3.10 Mini-Driver Handpiece, Attachments and Accessories... 99 3.10.1 Attachments and Accessories... 99 3.10.2 Connecting/Removing Attachments... 99 3.10.3 Pin and Wiredriver Attachments... 100 3.10.3.1 Pin Driver Attachment (K211)... 100 3.10.3.2 Wiredriver Attachment (K111A)... 101 3.10.3.3 Pin and Wire Insertion... 101 3.10.4 Sagittal Saw Attachment (K220)... 103 3.10.5 All Jacobs Chuck Attachments... 104 3.10.5.1 5/32” Jacobs Chuck (K110)... 104 3.10.5.2 1/4” Jacobs Chuck (K109)... 105 3.10.5.3 High-Torque Jacobs Chuck (K210)... 105 3.10.6 Trinkle Chuck Attachment (K112)... 106 3.10.6.1 Automatic Screwdrivers for the Trinkle Chuck Attachment (D520/D524)... 106 3.10.7 Hudson Chuck Attachment (K113)... 108 3.10.8 ASIF/AO Twist Drill Chuck Attachment (K114A)... 108 3.11 Handpiece Default Settings... 109

vii

W41-104-004.book Page viii Tuesday, August 9, 2005 9:36 AM

Page

Table of Contents

4.0

MAINTENANCE 4.1

Cleaning and Sterilizing... 115 4.1.1

Cleaning Precautions... 115

4.1.2

Controller and Footswitch Cleaning Instructions... 115

4.1.3

Handpiece Cleaning Instructions... 116 4.1.3.1

MicroChoice, Advantage, and APEX Shaver Handpiece Cleaning Instructions... 116

4.1.3.2

E9000 Handpiece Cleaning Instructions... 117

4.1.3.3

MicroChoice Drills, Saws, Modular Handpiece, and Mini-Driver Handpiece Cleaning Instructions... 118

4.1.4

Attachment Lubricating Instructions... 119

4.1.5

Sterilization Information... 120 4.1.5.1

Sterilization Warnings, Precautions and Notes... 120

4.2

Troubleshooting... 123

4.3

Calibration... 127

4.4

Fuse Replacement and Voltage Selection Means... 127

4.5

Bur Guard Testing Procedure... 128

4.6

Ground Continuity Test... 129

4.7

Leakage Test... 129

4.8

Theory of Operation... 130

viii

W41-104-004.book Page ix Tuesday, August 9, 2005 9:36 AM

Page

Table of Contents

5.0

TECHNICAL SPECIFICATIONS 5.1

6.0

Controller... 131 5.1.1

Advantage Controller... 131

5.1.2

E9000 Controller... 132

5.1.3

PowerPro Controller... 132

5.2

Power Cord Requirements... 133

5.3

System Environmental Requirements... 134

5.4

Footswitches (5020-053 and C9863)... 134

5.5

Handpiece Cords... 134

5.6

Tubing Sets... 135

5.7

Handpieces... 136

ACCESSORIES 6.1

Handpieces, Attachments and Accessories... 143

ix

W41-104-004.book Page x Tuesday, August 9, 2005 9:36 AM

Page

Table of Contents

x

W41-104-004.book Page 1 Tuesday, August 9, 2005 9:36 AM

1.0 INTRODUCTION

The bottom portion of the controller functions as a universal electric power source for an instrument system consisting of drills, shavers, saws and assorted modular attachments. This portion is designed for soft tissue resection, trauma procedures, total hip/knee arthroplasty, and ACLs.

t is recommended that personnel study this manual before attempting to operate, clean or sterilize the Advantage®, E9000® or PowerPro® System. The safe and effective use of this equipment requires the understanding of and compliance with all warnings, cautionary notices, and instructions marked on the product, and included in this manual.

I

1.1

he PowerPro Controller functions as a universal electric power source for an instrument system consisting of drills, shavers, saws and assorted modular attachments to perform bone cutting, reaming, drilling and driving screws, as well as soft tissue resection. The System combines the existing quality and capabilities of unprecedented control and superior reliability of the MicroChoice® System, designed for small-bone procedures, and the power and functionality of the APEX® Shaver System, designed for soft tissue resection, with the PowerPro handpieces to perform trauma procedures, total hip/knee arthroplasties, and ACLs.

T

Intended Use

he E9000 System is a combination handpiece-drive and low-flow irrigation pump. The controller operates a variety of handpieces consisting of drills, shavers, and saws, in conjunction with assorted attachments to perform bone cutting, reaming and drilling, and soft tissue resection.

T

The fields of application for the Advantage, E9000 and PowerPro Systems include Arthroscopic, Foot, Hand, Medial Sternotomy, Neurosurgical, Orthopedic, Otolaryngological, Plastic/Reconstructive and Spinal surgical procedures.

The irrigation pump and tubing sets provide a sterile fluid supply to the blades, burs and drill bits, at the surgical site, to prevent clogging and for lavage and cooling.

he Advantage Drive System combines the functionality of the APEX® Drive System, the E9000 System and the PRO2000 PowerPro System into one unit. The top portion of the controller is a combination handpiece-drive and low-flow irrigation pump that operates a variety of handpieces consisting of drills, shavers, and saws, in conjunction with assorted attachments to perform bone cutting, reaming and drilling, and soft tissue resection.

T

1.2

Contraindications

The Advantage and E9000 System’s irrigation pump and tubing sets are contraindicated for distention.

1

W41-104-004.book Page 2 Tuesday, August 9, 2005 9:36 AM

1.3

8.

Prior to each use, perform the following: • Inspect all equipment for proper operation. • Ensure all attachments and accessories are correctly and completely attached to the handpiece. • Perform the required Performance Tests for each associated handpiece prior to each use.

9.

Never operate the MicroChoice® Elite™ High Speed Drill (5020-025) Medium Speed Drill (5020-021) or the CoolFlex® High Speed Drill (E9010) without a bur and appropriate bur guard, if appropriate, in place and the collet locked. Damage will occur.

General Warnings and Cautions

1.

This equipment is designed for use by medical professionals completely familiar with the required techniques and instructions for use of the equipment. Read and follow all warning and cautionary notices and instructions marked on the product and included in this manual.

2.

Do not open the controller chassis, as this may void the warranty. There are no user-serviceable parts inside. Removing the cover may introduce an electric shock hazard by exposing you to dangerously high voltages or other risks.

3.

Do not expose the PowerPro controller to moisture, operate in wet areas, or place liquids on or above the controller.

4.

Handpieces are factory sealed. Do not disassemble or lubricate, as this may void the warranty. There are no user-serviceable parts inside.

5.

Eye protection is recommended when operating equipment.

6.

Use only associated Linvatec attachments and accessories (saw blades, bits, etc.) as defined within the descriptions of each attachment.

7.

Handle all equipment carefully. If any equipment is dropped or damaged in any way, return it immediately for service.

10. When operating shaver blades or burs in any Group 3 handpiece (reference “ Group 3 Handpieces” on page 92) the shaver handpiece suction port valve must be in the open or ON position, and the shaver blade or bur must be within the distention fluid of the joint. Otherwise, damage to the blade hub or bur hub will result. 11. Continually check all handpieces and attachments for overheating. If overheating is sensed, immediately discontinue use and return equipment for service. Overheating of the bur, bit or blade may cause damage to the bur, bit or blade and may cause thermal necrosis. 12. Do not attach, insert or remove accessories or attachments while the handpiece is operating. Place the handpiece safety switch, if equipped with one, to the appropriate safe position, prior to installation or removal of items.

2

W41-104-004.book Page 3 Tuesday, August 9, 2005 9:36 AM

13. Do not stall handpieces, damage can occur.

NOTE: Bur and neuro guards are to be returned to the factory or a Linvatec authorized service facility for routine maintenance every six (6) months.

14. Do not handle the controller, handpieces or footswitch by the cord. Do not pull on the cord to remove it from the handpiece or controller.

(a) Remove the guard from the handpiece and insert a bur into the nose of the guard.

15. Do not excessively bend or kink the instrument handpiece cord or power cord. Always inspect cords for signs of excessive wear or damage. If wear or damage is found, discontinue use and replace immediately.

(b) While holding the bur, spin the guard. The guard should spin freely around the bur shaft without resistance.

16. Tubing sets and E9000 Disposable Irrigation Tips are one-time use only. Do not resterilize or reuse. After use, dispose of properly. 17. All associated Tubing Sets are latex free.

LATEX

18. Ensure the optical cassette sensor next to the pump cassette mechanism is kept clean at all times.

(c) Attach the guard and bur to the handpiece.

19. Always inspect for bent, dull or damaged burs, blades or drill bits before each use. Do not attempt to straighten or sharpen. Do not use if damaged. After use, dispose of properly.

(d) Operate the handpiece for approximately 30 seconds. Stop the handpiece and carefully feel the end of the guard where the guard encases the shaft of the bur for overheating. If overheating is noticed, return guard for service.

20. Always use a bur of the proper length for the particular guard.

23. After each use, thoroughly clean the controller, handpieces, attachments and accessories (See “4.1 Cleaning and Sterilizing” on page 115).

21. Do not use burs for plunge cutting. Damage or injury may occur.

24. Equipment grounding is vital to ensure safe operation. Plug the power cord into a properly earthed mains supply outlet whose voltage and frequency characteristics are compatible with those listed on the unit or in this manual. Do not use plug adapters or extension cords; such devices defeat the safety ground and could cause injury.

22. Bur and neuro guards should be checked frequently. Overheating can occur if bur guard bearings are worn or not kept clean. Perform the following steps to verify guards are in good operating condition.

3

W41-104-004.book Page 4 Tuesday, August 9, 2005 9:36 AM

25. Do not use in the presence of flammable anesthetics, gases, disinfecting agents, cleaning solutions, or any material susceptible to ignition due to electrical sparking.

1.4

Symbol Definitions Controller Markings

26. The service intervals, as listed in “Table 1: Maintenance Schedule” on page 112, are required to keep the handpieces at their optimum operating performance.

Stand-by (ON/OFF)

Attention, consult accompanying documents Warning - For continued protection against risk of fire, replace only with the same type and rating fuse Mains Fuse Flammable Anesthetics Risk of explosion if used in the presence of flammable anesthetics. Type B equipment

~

Alternating Current Protective earth ground

Footswitch Connection Speed (rpm) Selection E9000 Series Handpiece Connection MicroChoice Drills and Saws Connection MicroChoice, Advantage, and APEX Shaver Handpiece Connection

4

W41-104-004.book Page 5 Tuesday, August 9, 2005 9:36 AM

PowerPro Handpiece Connection

Mini-Driver™ Handpiece Markings Indicates the safe or off position (only for a part of equipment) of the handpiece safety switch

Irrigation (Flow) Control Speed (rpm) Selection

Indicates the on or run position (only for a part of equipment) of the handpiece safety switch

Adjustment to a maximum (Increase) Adjustment to a minimum (Decrease)

F

Indicates on in the forward, or clockwise, direction of rotation

PRESET

Predetermined setting for irrigation flow using the CoolFlex High Speed Drill with the E9414 Tubing Set

R

Indicates on in the reverse, or counterclockwise, direction of rotation

RPM

Revolutions Per Minute

Max

Maximum Operating Speed

Min

Minimum Operating Speed

1 min

3 min

Duty Cycle: 1 minute on

Duty Cycle: 3 minutes off

Miscellaneous Markings

Footswitch Markings

Not to be used for plunge cutting

Shaver Handpieces Directional Selection (Forward/Reverse/Oscillate)

Single Use Only

Variable Speed, ON/OFF Latex Free

MicroChoice or Hall Handpiece

LATEX

Forward Variable Speed

Eye Protection Required

Reverse Variable Speed

No user service recommended. Refer servicing to qualified Linvatec service personnel.

Oscillate

5

W41-104-004.book Page 6 Tuesday, August 9, 2005 9:36 AM

Indicates product component should not be sterilized.

Saw operating symbol Handpiece “Aspirate Mode” symbol

Indicates product component should not be immersed in any type of fluid.

Handpiece in “safe” position

Indicates handpiece should not be immersed in any fluid.

Handpiece “Motor Overspeed” message symbol

Indicates product should not be oiled or lubricated.

Handpiece “Stalled” and “Maximum Torque” messages symbol

Lock

LOCK UN

Unlock

N

Indicates blade collet unlock position of the D9820 and D9824 Advantage Handpieces

????

Graphical Display Symbols Drill - forward direction Drill - reverse direction OscDrill - oscillate function Tap - forward direction Tap - reverse direction Screw - forward direction Screw - reverse direction Irrigation message symbol 6

S

Handpiece “Magnetic Field” message symbol Check Handpiece message

W41-104-004.book Page 7 Tuesday, August 9, 2005 9:36 AM

❶

❷

❸

❹

❺

❻

❼

❽

❾

❿

PORT 1 PORT 2

PORT 3

11

1.5

13

12

tric II Modular Handpiece, and PRO6135 Reciprocator Saw. However, with the addition of a handpiece adapter - the APEX Adapter (E9320) or the Mini-Driver Adapter (K501) - this receptacle will also accept and operate the following shaver handpieces (C9820, C9824, C9828, C9840) or the Mini-Driver Handpiece (K500).

System Indicators

1.5.1

Advantage Controller Front Panel (Top Portion)

❶ Footswitch Receptacle - Accepts the footswitch cord connector.

NOTES:

❷ APEX Handpiece Receptacle (Port 1) - Directly accepts the handpiece cord connector of any APEX handpiece (C9820, C9824, C9828, C9840).

1.

All cord receptacles and connectors are keyed to prevent incorrect insertion. Likewise, receptacles and connectors are color-coded to easily recognize where to connect each cord (footswitch receptacle and connector - yellow, handpiece receptacles and connectors - red or grey).

2.

Only one handpiece can be connected at a time in either port of the top section. If a handpiece is connected while another handpiece is already connected, “CHECK HANDPIECE” will display. BOTH handpieces must be removed to clear the fault condition.

❸ Handpiece Receptacle (Port 2) Directly accepts the handpiece cord connector of the following handpieces; all Group 1 Handpieces (E9005, E9015, and CoolFlex); all Group 2 Handpieces (5020-021, -022, -023, -024, -025, -026, -027); most Group 3 Handpieces (D9820, D9920, MC9820, D9824, D9924, MC9828, and MC9840); and the PowerPro PRO2300E and PRO6125 Oscillator Saws, PRO6100 Elec7

W41-104-004.book Page 8 Tuesday, August 9, 2005 9:36 AM

3.

The PowerPro Electric Modular (PRO2100E) and Two-Trigger (PRO2200E) handpieces will NOT operate in Port 2. If these handpieces are connected to Port 2, “INVALID HANDPIECE” will display.

1.5.2

11

Standby Power Switch - To activate the controller, place this switch to the on position. To set the controller to stand-by mode, place this switch to the off position.

12

Handpiece Receptacle (Port 3) Directly accepts all PowerPro handpieces along with several other handpieces. With the addition of a handpiece adapter - Mini-Driver Adapter (K501) or APEX Adapter (E9320) - this receptacle will also accept and operate the Mini-Driver Handpiece (K500) or two of the four APEX handpieces (C9824 and C9828).

❹ Speed Increase Button Press to increase the handpiece speed for handpieces connected to Port 1 or Port 2.

❺ Speed Decrease Button Press to decrease the handpiece speed for handpieces connected to Port 1 or Port 2.

❻ Top Display - Displays handpiece speeds, irrigation flow rates, instructions, operating modes and error messages. Displays actual speed while the handpiece is operating, and the set speed when the handpiece is inactive. Flow rate, as a percentage, displays when the pump is enabled.

Advantage Controller Front Panel (Bottom Portion)

NOTE: Even though this handpiece receptacle (Port 3) will accept the connectors of the E9000 Series handpieces (E9005, E9015, and CoolFlex), the MicroChoice Low Speed Drill (5020-026), the MicroChoice Shaver Handpieces (MC9820, MC9840), and the Advantage Basic Shaver Handpieces (D9820, D9920), they cannot be activated in this port because a footswitch is required for activation of these handpieces and there is no footswitch port for the bottom portion of the controller.

❼ Flow Increase Button - Press to increase the pump flow rate for handpieces connected to Port 1 or Port 2.

❽ Flow Decrease Button - Press to decrease the pump flow rate for handpieces connected to Port 1 or Port 2.

13

❾ Optical Sensor - Senses whether or not a tubing set is connected.

❿ Tubing Cassette Receptacle - Accepts the various tubing sets.

8

Bottom Display - Displays the following information in text or graphical format (Reference “2.1.3.9 Switch 5 - Display Mode Selection” on page 42); user/error messages, instructions, handpiece speeds, and operating modes. Displays the actual speed while the handpiece is operating and set speed when the handpiece is inactive.