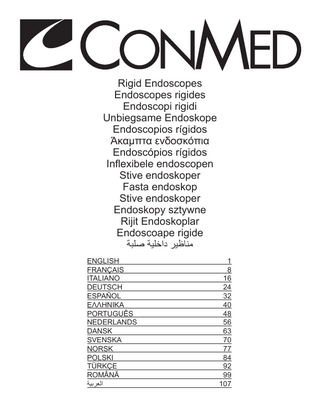

ConMed

Rigid Endoscopes Instructions for Use

115 Pages

Preview

Page 1

ENGLISH/INSTRUCTIONS FOR USE

Device Description

The CONMED rigid endoscope is an instrument that is inserted into body spaces and includes an optical system for conveying an image either directly to the user’s eye or to an accessory video system so that an image may be viewed upon a video monitor.

Components

Your CONMED endoscope comes complete with the following endoscope fiber-optic adapters: ACMI, WOLF DYONICS and LINVATEC/STORZ. 1. Objective lens (distal lens) 6 2. Rod lens tubular shaft 5 3. Ocular lens (proximal lens) with eyepiece 4. Fiber-optic post (ACMI style) 4 2 5. Fiber-optic post adapter (WOLF, DYONICS style) 1 6. Fiber-optic post adapter (LINVATEC/STORZ style)

3

Color Coding

The viewing direction of the endoscope is indicated by the color at the fiber-optic connection. Color

Viewing Direction

Green

0°

Red

30°

Orange

45°

Intended Use/Indication For Use

CONMED endoscopes are used when access, illumination, and/or observation of body cavities, hollow organs, and/or canals are necessary during minimally invasive surgical procedures.

Contraindications None known.

Warnings and Precautions

Do not bypass this section. It contains warnings and precautions that must be thoroughly understood before operating any of the products. Lack of understanding or adherence to the warnings and precautions may result in injury or even death to the patient. The words WARNING, PRECAUTIONS, and NOTE carry special meanings and they must be read carefully. WARNING: A warning contains critical information regarding serious adverse reactions and potential safety hazards that can occur during proper use or misuse of the equipment. Failure to observe the information or procedures presented in the Warning may result in injury, death or other serious adverse reactions to the patient and/or surgical staff. PRECAUTIONS: A precaution contains instructions for any special care to be exercised by the practitioner for the safe and effective use of the equipment. Failure to observe the information or procedures presented in a Precaution may result in damage to the device. NOTE: A note is added to provide additional information. This information has no critical effect on the patient or device.

Warnings

1. Read this manual carefully before you begin work. Follow instructions specifically, giving special attention to warnings, contraindications, controls, features and user specifications. You must be thoroughly familiar with the assembly, use, and care of this device and in all applicable surgical procedures. 2. Before every procedure, carefully inspect the device to ensure it has been properly maintained, is cleaned and sterilized, and is fully functional. Do not use this device if an inspection reveals damage. 3. Due to the high energy from the illumination fiber, the fiber-optic connection area of the endoscope and the distal end of the endoscope (within a distance of 10 mm from the tip) may reach temperature above 106°F (41°C). 4. To avoid burns to the patient tissue, do not leave the tip of the endoscope or the fiber-optic connection junction in 1

ENGLISH/INSTRUCTIONS FOR USE

direct contact with the patient. Avoid direct contact of the distal end with body tissue or flammable materials as it can cause burns. Reduce the light intensity of the light source when working near body tissue or flammable materials. 5. If High Frequency (HF) electro surgical instruments are used, keep the working element always within the field of view to prevent accidental burns. Always ensure a sufficient distance from the tip of the endoscope with conductive accessories before activating the HF output. Only medical electrical equipment, which complies with IEC 60601-1, is allowed to be used with this endoscope. 6. Endoscopes are fragile opto-mechanical devices, which need to be handled with caution. To avoid damages caused from Laser burns it is necessary to keep the Laser delivery fiber away from all parts of the scope. 7. To avoid potential eye damage when using the endoscope with Laser equipment, always wear protective filtering spectacles or insert a suitable filter in the eyepiece. Refer to Laser equipment manual for proper protective means. 8. Remove the endoscope before defibrillating the patient. 9. Risk of infection to the patient or medical professionals. • The endoscopes are delivered non-sterile as reusable products. • The state of the art and national laws require the observance of validated processes. • In general, users are responsible for the validation of their processes. • Ensure that the processing, material and personnel are suitable for achieving the results necessary. • Observe any valid local operator regulations for all manual cleaning and drying processes. • Clean/disinfect and sterilize the endoscope prior to initial use as well as each subsequent use of the endoscope. • Bring the endoscope to the decontamination area after use. Observe valid protective measures to prevent contaminating the environment. 10. In the event of functional loss or damage, always have a backup sterile endoscope available ready for use during surgical procedure. 11. Ensure that the endoscopes are used with fiber-optic and light sources compliant with Type F applied part per IEC 60601-1 and IEC 60601-2-18 standards. 12. To avoid risk of injury due to improper configuration, ensure that the applied parts from other suppliers of electromedical devices, or any accessories used for endoscopic application in this configuration, are of Type BF or Type CF. 13. Do not use equipment in the presence of flammable anesthetics, gases, disinfecting agents, cleaning solutions, or any material susceptible to ignition due to electrical sparking. 14. When energized endoscopes are used with energized endotherapy devices, including IEC 60601-1 approved devices, patient leakage currents may be additive.

Precautions

1. Caution: Federal (USA) law restricts this device to sale by or on the order of a licensed healthcare practitioner. 2. Use the endoscope only as intended, see “Intended Use/Indication for Use.” 3. This manual must be available to the surgical team during every procedure. 4. If you are using other manufacturer’s equipment in conjunction with this device, follow the instructions in the operating manuals for using that equipment. 5. Handle all equipment carefully. If any equipment is dropped or damaged in any way, return it immediately for service. 6. The warranty becomes void and the manufacturer is not liable for direct or resulting damage if: • The device or the accessories are improperly used, prepared or maintained; • The instructions in the manual are not adhered to. 7. No modification of this equipment is allowed.

2

ENGLISH/INSTRUCTIONS FOR USE

Symbol Definitions

QTY

Manufacturer

Caution, General Warning Symbol

Prescription Only

Authorized Representative

EC REP MDSS GmbHKeep Dry Quantity Schiffgraben 41 D-30175 Hannover, Germany Consult Instructions For Non Sterile Use

Do Not Use If Package Is Damaged

No User Service Recommended

CE Mark

Atmospheric Pressure

Humidity Limitation

Temperature Limit

This Side Up

Fragile

2797

Proper Handling and Maintenance

Endoscopes are precision medical instruments, and handling them requires great care. 8. Do not subject the endoscope to impact. 9. Do not bend the shaft. 10. Do not bend the shaft after inserting the endoscope into the body. A piece broken off the endoscope can become lodged in the soft tissue or no longer appear in the endoscope’s field of vision and thus remain in the body. 11. Inspect the endoscope for damage prior to and after each use. If the endoscope is damaged, discontinue use and contact the manufacturer. 12. Put the endoscope down carefully. 13. Hold endoscope only by the ocular funnel/main part and not by the shaft. 14. Transport endoscopes individually and store them safely by using a tray container. 15. Clean/disinfect and sterilize the endoscope prior to initial use as well as each additional use of the endoscope. 16. Residual contaminants on the irradiation surface of the illumination fibers can burn in during use, which impacts image quality. Ensure surface is free of contaminants before use.

Removing Deposits From Optical End Surfaces (distal end, proximal end and fiber-optic post) If deposits are found when checking the image quality, they can be removed with the provided polishing powder as follows: • Only clean with polishing powder if the image which you see through the endoscope is cloudy and blurry. • Disconnect all fiber-optic post adapters; see “Components” section of this document. • Moisten a cotton-tipped swab with distilled water. Dip the moistened swab in the aluminum oxide powder. • For large optical end surfaces: press cotton swab lightly on the end surface to be cleaned and rub it over the glass. • For small end surfaces: place cotton swab lightly on the end surface to be cleaned and turn it.

3

ENGLISH/INSTRUCTIONS FOR USE

• • • • • •

Clean all optical end surfaces with warm water and mild detergent to remove all polishing powder residue. Rinse optical end surfaces with distilled water. Clean with a cotton swab using isopropyl alcohol. Dry optical end surfaces with a soft cloth. Clean/disinfect and sterilize the endoscope. Carry out visual inspection. If the deposits were not removed send the endoscope for repair.

NOTE: The aluminum oxide powder can be ordered separately under catalog T0001, Replacement Aluminum Oxide Powder (Al2O3).

Function Checks

Warnings: Risk of injury due to faulty endoscopes. 1. Carry out a visual inspection and function check prior to initial use as well as each additional use. 2. Only use endoscopes which are in fully functional condition. 3. Ensure that the proximal end of the endoscope is dry to prevent the endoscope from fogging during the examination/ procedure. 4. Ensure that no parts are missing or loose. 5. Ensure that there are no residual cleaning agents or disinfectants on the endoscope. 6. Inspect the entire endoscope, particularly the shaft, for contaminants and damage of any type, such as dents, scratches, cracks, bending and sharp edges. 7. Inspect Endoscopes with locking devices for contaminants and damage. 8. Inspect distal end, proximal end and surface of the illumination fibers for contamination and scratches. Check for contaminants and scratches by holding the connection of the optical fibers against the light and inspect whether the optical fibers illuminate evenly at the distal end. 9. Check image quality: The image shall not be blurry, clouded or dark. If necessary, remove deposits on the optical end surface using polishing powder provided, see “Removing Deposits From Optical End Surfaces” section of this document. 10. Make sure the endoscope fiber-optic post adapter matches mating fiber-optic cable.

Cleaning, Disinfection & Sterilization Information

1. It is recommended to reprocess endoscopes immediately after use. They can be cleaned manually or in an automatic cleaning unit using a cleaning agent. 2. Do not clean endoscope in an ultrasonic bath. 3. Do not scratch contaminants off with hard objects as this can cause damage to the optical end surfaces. 4. The endoscope can be damaged if the manufacturer’s specifications are not observed. 5. Always store endoscope securely and transport it to processing in a closed container to prevent damage to the endoscope and contamination of the environment. 6. Repeated processing has only minimal effect on the endoscopes. The service life of the units is usually determined by wear and damage. 7. The following materials and machines were used for the validation: • Cleaning agent: - Alkaline: Neodisher FA; Dr. Weigert; Hamburg - Enzymatic: Endozime, Ruhof • Neutraliser: - Neodisher Z; Dr. Weigert, Hamburg • Cleaning and disinfecting unit: - Miele G 7736 CD

4

ENGLISH/INSTRUCTIONS FOR USE

Manual Cleaning Process

Pre-Rinsing: 1. Disassemble all components from the endoscope including fiber-optic post adapter; see “Components” section of this document. 2. Soak for 3 minutes in warm water and a neutral pH enzymatic pre-wash solution to soften and remove biological debris (prolonged soaking may be detrimental to components). 3. Use a tray designed for endoscopes. Avoid contact with dissimilar equipment to avoid damage to optical surfaces. Washing: 1. Instruments should be submerged in warm water with an appropriate neutral pH detergent. 2. Carefully clean with a soft bristled brush or sponge only. Take care not to damage optical surfaces.

3. Do not place endoscopes in an ultrasonic cleaner or washer-sterilizer. Rinsing: 1. Rinse instrument in tap water at a minimum of 25°C, using a minimum of 2 liters and rinsing for a minimum of 30 seconds. 2. Rinse instrument in de-ionized water at a minimum of 25°C, using a minimum of 2 liters and rinsing for a minimum of 30 seconds. 3. Carefully dry endoscope with soft cloth to ensure clean lenses. 4. Carry out visual inspection, function check and servicing; see “Function Checks” section of this document.

Automated Cleaning Process (Pre-cleaning + Automated Wash and Disinfection)

Pre-Cleaning 1. Disassemble all components from the endoscope including fiber-optic post adapters; see “Components” section of this document. 2. Immerse the instrument in cold water for 5 minutes. 3. Brush instrument under cold water until visible contamination is removed. 4. Clean all cavities, threads, and bores with a water jet gun or pistol for 10 seconds and brush again. 5. Place disassembled instrument and components in an instrument automated washer and follow instructions below. Automated Washer (Automated Wash and Disinfection) 1. Run 1 minute pre-cleaning with cold water and drain. 2. Run 3 minutes pre-cleaning with cold water and drain again. 3. Run 5 minutes cleaning with cleaner agent and temperature (see recommended cleaner agent and temperature below) and drain. 4. Run 3 minutes neutralization with warm water (>40°C) and drain. 5. Run 2 minutes intermediate rinsing with warm water (>40°C) and drain. 6. Remove from washer and carefully dry instruments (endoscopes) with soft cloth to ensure clean lenses. 7. Carry out visual inspection and function check, see “Function Checks” section of this document. Sterilization (Autoclaving) method 1. Disassemble all components from the endoscope including fiber-optic post adapters. 2. Autoclavable endoscopes have “AUTOCLAV” clearly marked on the body of the endoscope. Only endoscopes marked “AUTOCLAV” are suitable for steam sterilization. 3. After the recommended cleaning procedure is completed, sterilize using the following parameters. 5

ENGLISH/INSTRUCTIONS FOR USE

Method

Minimum Exposure Temperature

Minimum Exposure Time

Minimum Dry Time

Configuration

Pre-vacuum

132°C (270°F)

3 minutes

10 minutes

Double Wrapped using FDA cleared sterilization wrap

Gravity

132°C (270°F)

10 minutes

15 minutes

Double Wrapped using FDA cleared sterilization wrap

4. Prepare endoscopes such that all surfaces have direct contact with steam. 5. Do not suddenly expose hot endoscopes to cold temperature after autoclaving. Let all components cool before use. NOTE: Endoscopes have been tested for survivability at 273°F (134°C) for 18 minutes 3.1 bar (absolute). NOTE: In the practice of Immediate Use Steam Sterilization (IUSS), wrapped or unwrapped without a Dry Cycle, the time and temperature parameters of exposure, as stated above for wrapped devices, assure sterilization in chamber. Post-cycle sterility maintenance for a device processed by IUSS wrapped or unwrapped is dependent on handling and aseptic delivery to the sterile field. Hydrogen Peroxide Sterilization (STERRAD® method) Disconnect all fiber-optic post adapters before applying the STERRAD® sterilization process. Endoscopes can be sterilized with the following STERRAD® systems: STERRAD® Systems

Cycle

STERRAD® 100S

Short

STERRAD® NX®

Standard

STERRAD® 100NX™

Express, Standard

Observe specifications of the manufacturer (ASP) regarding the corresponding method. STERIS® Method Disconnect all fiber-optic post adapters before applying the STERIS® sterilization process. Endoscopes can be sterilized with the following STERIS® systems: STERIS® Systems

Cycle

V-PRO® 1 Sterilization System

Standard

V-PRO® 1 Plus Sterilization System

Lumen and Non Lumen

V-PRO® maX Sterilization System

Lumen, Non Lumen and Flexible

V-PRO® maX 2 Sterilization System

Lumen, Fast Non Lumen and Flexible

V-PRO® 60 Sterilization System

Lumen and Non Lumen

Observe specifications of STERIS® regard the corresponding method. Ethylene Oxide (EtO) Sterilization Method Disconnect all light post adapters before applying the EtO sterilization process. The following process has been validated: Preconditioning parameters. Temperature

53 - 57°C (126 - 136 °F)

Relative Humidity

≥35%

Vacuum

21 ± 1 In Hg

Preconditioning

1 hour

6

ENGLISH/INSTRUCTIONS FOR USE

Sterilization parameters: Temperature

53 - 57°C (126 - 136°F)

Relative Humidity

≥35%

Pressure (PSIG Start)

19 ± 1 PSIG

Ethylene Oxide Concentration

736 mg/L

Gas Exposure Time (Full cycle)

4 hours

Aeration

11 hours at 54°C (129°F) minimum

Special Precautions: Pathogens of Transmissible Spongiform Encephalopathy

A comprehensive explanation of the necessary preventative measures regarding agents of Transmissible Spongiform Encephalopathy (TSE) would go beyond the scope of this document. It is assumed that pathogens of the Creutzfeldt Jakob Disease cannot be killed using normal disinfection and sterilization processes. Therefore, the standard methods for decontamination and sterilization are not sufficient if there is a risk of transferring Creutzfeldt Jakob Disease. In general, only tissue with a low potential of TSE infection encounters surgical instruments. Despite this, special preventative measures must be taken for instruments which are used to treat patients with a known or suspected infection of TSE, as well as for patients at risk.

Storage

Unsterile endoscope must be stored in a clean, dry environment. As long as endoscopes are stored unsterile in the original packaging or in a screen tray/container, the following storage conditions apply: • Temperature: -20°C to +60°C • Humidity: 10% to 90% Ensure that the endoscope is stored securely.

Packaging and Labeling

Product should be accepted only if the original packaging and labeling arrive intact and not damaged. If packaging has been opened or altered, contact your local CONMED sales representative, or in the U.S. contact the Customer Service Department.

Warranty

CONMED will repair or replace any endoscope found to have manufacturing or material defects within the first year after purchase by the initial purchaser. CONMED will repair or replace, at our discretion, endoscopes which fail during normal use for a period of one year following purchase. The warranty does not apply to altered products, products previously repaired by unauthorized entities (entities other than CONMED) and products damaged through customer misuse. CONMED will only accept for repair or replacement, products that are clean and safe to handle.

Contact Information

For more information or a product demonstration, contact your regional CONMED sales representative, or call 1-866-426-6633 in the U.S.

Accessories/Spare Parts Description

Catalog

Replacement Aluminum Oxide Powder (Al2O3)

T0001

Replacement Scope Fiber Post Adapters Wolf/Storz

7513

Dispose

Observe country-specific regulations and laws for the disposal of medical products.

7

2797

EC REP MDSS GmbH Schiffgraben 41 D-30175 Hannover, Germany

CONMED Corporation 525 French Road Utica, NY 13502-5994 USA Customer Service: 1-866-426-6633 USA FAX: (727) 399-5256 International FAX: +1 (727) 397-4540 email: CustomerExperience@conmed.com www.conmed.com

P000018962

Rev C

07/2021