CooperSurgical Inc

Electrosurgical Systems

Euro-Med Stainless Steel Instruments Cleaning & Sterilization Instructions Rev A May 2010

Cleaning & Sterilization Instructions

2 Pages

Preview

Page 1

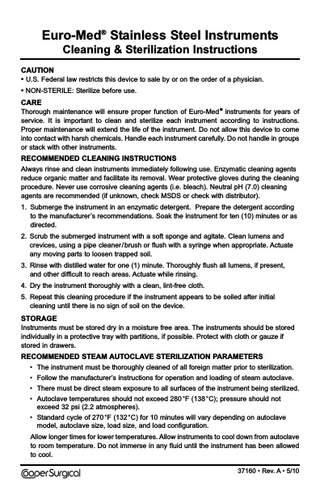

Euro-Med® Stainless Steel Instruments Cleaning & Sterilization Instructions CAUTION • U.S. Federal law restricts this device to sale by or on the order of a physician. • NON-STERILE: Sterilize before use. CARE Thorough maintenance will ensure proper function of Euro-Med ® instruments for years of service. It is important to clean and sterilize each instrument according to instructions. Proper maintenance will extend the life of the instrument. Do not allow this device to come into contact with harsh chemicals. Handle each instrument carefully. Do not handle in groups or stack with other instruments.

RECOMMENDED CLEANING INSTRUCTIONS Always rinse and clean instruments immediately following use. Enzymatic cleaning agents reduce organic matter and facilitate its removal. Wear protective gloves during the cleaning procedure. Never use corrosive cleaning agents (i.e. bleach). Neutral pH (7.0) cleaning agents are recommended (if unknown, check MSDS or check with distributor). 1. Submerge the instrument in an enzymatic detergent. Prepare the detergent according to the manufacturer’s recommendations. Soak the instrument for ten (10) minutes or as directed. 2. Scrub the submerged instrument with a soft sponge and agitate. Clean lumens and crevices, using a pipe cleaner / brush or flush with a syringe when appropriate. Actuate any moving parts to loosen trapped soil. 3. Rinse with distilled water for one (1) minute. Thoroughly flush all lumens, if present, and other difficult to reach areas. Actuate while rinsing. 4. Dry the instrument thoroughly with a clean, lint-free cloth. 5. Repeat this cleaning procedure if the instrument appears to be soiled after initial cleaning until there is no sign of soil on the device.

STORAGE Instruments must be stored dry in a moisture free area. The instruments should be stored individually in a protective tray with partitions, if possible. Protect with cloth or gauze if stored in drawers.

RECOMMENDED STEAM AUTOCLAVE STERILIZATION PARAMETERS • The instrument must be thoroughly cleaned of all foreign matter prior to sterilization. • Follow the manufacturer’s instructions for operation and loading of steam autoclave. • There must be direct steam exposure to all surfaces of the instrument being sterilized. • Autoclave temperatures should not exceed 280 °F (138 °C); pressure should not exceed 32 psi (2.2 atmospheres). • Standard cycle of 270 °F (132 °C) for 10 minutes will vary depending on autoclave model, autoclave size, load size, and load configuration. Allow longer times for lower temperatures. Allow instruments to cool down from autoclave to room temperature. Do not immerse in any fluid until the instrument has been allowed to cool. 37160 • Rev. A • 5/10

(Cleaning & Sterilization Instructions, continued ) Pre-vacuum Cycle Preconditioning Pulses: 4 Exposure temperature: 270 °F– 273 °F (132 °C –134 °C) Exposure time: 4 minutes

Gravity Displacement Cycles Exposure temperature: 270 °F – 275 °F (132 °C –135 °C) Exposure time: 15 minutes Exposure temperature: 250 °F – 253 °F (121 °C –123 °C) Exposure time: 40 minutes

RECOMMENDED HOSPITAL ETHYLENE OXIDE STERILIZATION PARAMETERS • Items must be thoroughly cleaned of all foreign matter prior to sterilization. • Follow the manufacturer’s instructions for operation and loading of sterilizer. • There must be direct exposure to all surfaces of the instruments being sterilized. • Instruments should be sterilized in their “open” position. • Contact of plastic to bare metal should be avoided.

Ethylene Oxide Cycle Temperature

125 °F–130 °F (52 °C – 54 °C)

50% RH (pre-humidity)

60 minutes -0/+10 minutes

Pre-vacuum

24” Hg ± 2” Hg (61 cm Hg ± 5 cm Hg)

Gas Pressure

6 – 8 psig (550-660 mg/L EO)

Exposure Time

4 hours minimum

Post Vacuum

24” Hg 2X ± 2” Hg (61 cm Hg 2X ± 5 cm Hg)

Aeration

12 -0/+1 hour at 120 °F (49 °C)

NOTE: The particular EO cycle must be validated per the equipment manufacturer’s requirements. It is recommended that each institution employ procedures, which include the use of biological indicators in order to determine the effectiveness of the ethylene oxide process.

95 Corporate Drive • Trumbull, CT 06611 USA Phone: (800) 243-2974 • Fax: (800) 262-0105 37160 • Rev. A • 5/10

International Phone: (203) 601-9818 • Fax: (203) 601-4747