1 Page

Preview

Page 1

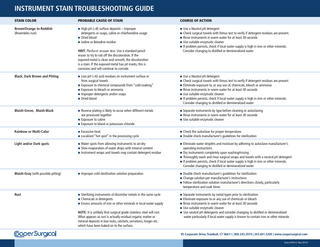

INSTRUMENT STAIN TROUBLESHOOTING GUIDE STAIN COLOR Brown/Orange to Reddish (Resembles rust)

PROBABLE CAUSE OF STAIN

COURSE OF ACTION

n High pH (>8) surface deposits – improper

n Use a Neutral pH detergent

detergents or soaps, saline or chlorhexidine usage n Dried blood n Iodine or Betadine residue

n Rinse instruments in warm water for at least 30 seconds

HINT: Perform eraser test. Use a standard pencil eraser to try to rub off the discoloration. If the exposed metal is clean and smooth, the discoloration is a stain. If the exposed metal has pit marks, this is corrosion and will continue to corrode. Black, Dark Brown and Pitting

n Low pH (<6) acid residues on instrument surface or

from surgical towels n Exposure to chemical compounds from “cold soaking” n Exposure to bleach or ammonia n Improper detergents and/or soaps n Dried blood

n Check surgical towels with litmus test to verify if detergent residues are present. n Use suitable enzymatic cleaner

n If problem persists, check if local water supply is high in iron or other minerals.

Consider changing to distilled or demineralized water

n Use a Neutral pH detergent

n Check surgical towels with litmus test to verify if detergent residues are present n Eliminate exposure to, or any use of, chemicals, bleach or ammonia n Rinse instruments in warm water for at least 30 seconds n Use suitable enzymatic cleaner

n If problem persists, check if local water supply is high in iron or other minerals.

Consider changing to distilled or demineralized water Bluish-Green, Bluish-Black

n Reverse plating is likely to occur when different metals

n Separate instruments by type before cleaning or autoclaving

are processed together n Exposure to saline n Exposure to blood or potassium chloride

n Use suitable enzymatic cleaner

n Rinse instruments in warm water for at least 30 seconds

Rainbow or Multi-Color

n Excessive heat

n Check the autoclave for proper temperature

Light and/or Dark spots

n Water spots from allowing instruments to air-dry

n Eliminate water droplets and moisture by adhering to autoclave manufacturer’s

n Instrument wraps and towels may contain detergent residue

n Dry instruments completely upon washing/rinsing

n Localized “hot spot” in the processing cycle n Slow evaporation of water drops with mineral content

n Double check manufacturer’s guidelines for sterilization

operating instructions

n Thoroughly wash and rinse surgical wraps and towels with a neutral pH detergent n If problem persists, check if local water supply is high in iron or other minerals.

Consider changing to distilled or demineralized water Bluish-Gray (with possible pitting)

n Improper cold sterilization solution preparation

n Double check manufacturer’s guidelines for sterilization n Change solution per manufacturer’s instructions

n Follow sterilization solution manufacturer’s directions closely, particularly

temperature and soak times Rust

n Sterilizing instruments of dissimilar metals in the same cycle

n Separate instruments by metal types prior to sterilization

n Excess amounts of iron or other minerals in local water supply

n Rinse instruments in warm water for at least 30 seconds

n Chemicals in detergents

NOTE: It is unlikely that surgical grade stainless steel will rust. What appears as rust is actually residual organic matter or mineral deposits in box locks, ratchets, serrations, hinges etc. which have been baked on to the surface.

n Eliminate exposure to or any use of chemicals or bleach n Use suitable enzymatic cleaner

n Use neutral pH detergents and consider changing to distilled or demineralized

water particularly if local water supply is known to contain iron or other minerals

95 Corporate Drive, Trumbull, CT 06611 | 800.243.2974 | 203.601.5200 | www.coopersurgical.com Form # 81613 Rev. 03/14