Fujifilm Medical Systems

Intraoperative Probes (CDA) Reprocessing Instructions

9 Pages

Preview

Page 1

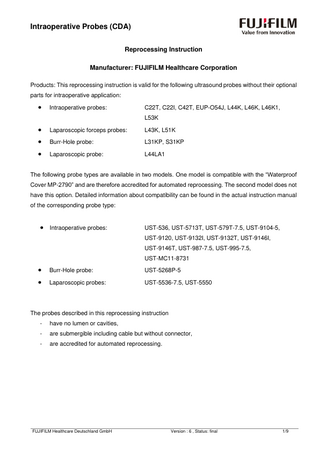

Intraoperative Probes (CDA) Reprocessing Instruction Manufacturer: FUJIFILM Healthcare Corporation Products: This reprocessing instruction is valid for the following ultrasound probes without their optional parts for intraoperative application:

•

Intraoperative probes:

C22T, C22I, C42T, EUP-O54J, L44K, L46K, L46K1, L53K

•

Laparoscopic forceps probes:

L43K, L51K

•

Burr-Hole probe:

L31KP, S31KP

•

Laparoscopic probe:

L44LA1

The following probe types are available in two models. One model is compatible with the “Waterproof Cover MP-2790” and are therefore accredited for automated reprocessing. The second model does not have this option. Detailed information about compatibility can be found in the actual instruction manual of the corresponding probe type:

•

Intraoperative probes:

UST-536, UST-5713T, UST-579T-7.5, UST-9104-5, UST-9120, UST-9132I, UST-9132T, UST-9146I, UST-9146T, UST-987-7.5, UST-995-7.5, UST-MC11-8731

•

Burr-Hole probe:

UST-5268P-5

•

Laparoscopic probes:

UST-5536-7.5, UST-5550

The probes described in this reprocessing instruction -

have no lumen or cavities,

-

are submergible including cable but without connector,

-

are accredited for automated reprocessing.

FUJIFILM Healthcare Deutschland GmbH

Version : 6 , Status: final

1/9

Intraoperative Probes (CDA) - Probes are delivered unsterile. Prior to the first use the probes have to be reprocessed depending on the type of application and with regard to the risk evaluation. - Probe connector has no water resistance.

WARNINGS

- If the entire length of the cable is wiped at once, a part of the cable may be wrinkled. Always wipe the cable in 20 cm intervals. - Do not exceed 60°C. Limitations on reprocessing

These probes are not completely submergible. Parts which are not submergible can only be disinfected by wipe disinfection.

Sterile pouch or container should be kept between transportation from Transportation before Central Sterile Supply Department (CSSD) to operating room. Be careful that using no damages are applied to the pouch or container for transportation.

Levels of reprocessing requirements Depending on the application of the product and with regard to risk evaluation the user has to classify the medical device according to the current Medical Device Directive for processing of medical devices as non-critical, semi-critical or critical. Supporting information concerning this topic is listed in the following Table 1. The user is responsible for correct classification of the medical device.

Classification Non-critical

Semi-critical

Critical

Definition

Processing

Application part only contacts intact, not pathological altered skin

Cleaning Disinfection Cleaning

Application part contacts mucosa

Disinfection (disinfectant with bactericidal, fungicidal and virucidal effect)

(intracavitary application) Application part contacts intracorporeal tissue directly

Cleaning

(operative application)

Sterilization

Disinfection

Table 1: Classification prior reprocessing

Additional information The Instructions provided above have been validated by the medical device manufacturer as being capable of preparing a medical device for re-use. It remains the responsibility of the processor to ensure that the processing as actually performed using equipment, material and personnel in the processing facility achieve the desired result. This requires validation and routine monitoring of the process. Likewise any deviation by the processor from the instructions provided should be properly evaluated for effectiveness and potential adverse consequences.

FUJIFILM Healthcare Deutschland GmbH

Version : 6 , Status: final

2/9

Intraoperative Probes (CDA) Containment and transportation Put the contaminated probe into exclusive shock and damage proof container for transportation. Instruments should be reprocessed as soon as possible, but not later than 4 hours after usage. INSTRUCTIONS

Manual reprocessing by immersion procedure Pre-cleaning in the examination room (point of use) after application of the probe: Initially remove used optional parts like protective covers and puncture adapters from the probe. The reprocessing of the puncture adapters is described in separate reprocessing instruction. Flush patient’s blood or fluid by tap water directly after use until the surface looks visually clean. Wipe the surfaces of the probe with patient contact by gauze pad and remove superficial visible impurities.

Prepare following items before manual cleaning and disinfection: a)

Detergent: Cidezyme®/ENZOL® (Johnson & Johnson, # 2258) or another cleaning agent with approved material compatibility for this medical device

b)

Disinfectant: Cidex® OPA (Johnson & Johnson, # 20391) or another disinfectant with approved material compatibility for this medical device

c)

2 tanks, 1 for cleaning and 1 for disinfection - optional: 1 additional tank for rinsing with deionized/tap water (sufficient size for immersion of the submergible part of the probe at full length)

d)

Soft, fluff free cloth or single use towel

e)

Personal protective equipment (gloves, water repellent protective skirt, face protection mask or protective glasses, see also instructions of the manufacturer for the detergent and the disinfectant)

Cleaning: 1)

The temperature of the detergent solution should be between 15-30°C, concentration is 1.6%. Please note the minimum contact time of the detergent in the manufacturer’s instruction. If a differing detergent is used, please also note the approved material compatibility for the medical device.

2)

Immerge the submergible part of the probe (see Figure) into the diluted detergent.

3)

Wipe the submergible part of the probe under the surface of the detergent solution with a single-use fluff free soft cloth to remove all visible soil. Be sure that all grooves of the probe are implemented during the cleaning process. If necessary use an appropriate cleaning brush for this purpose.

FUJIFILM Healthcare Deutschland GmbH

Version : 6 , Status: final

3/9

Intraoperative Probes (CDA) 4)

Rinse the submergible part of the probe with running water (minimum tap water quality) for 1 minute. (alternatively: suspend the submergible part of the probe in a tray filled with water (minimum tap water quality, see Figure) for 5 min.)

5)

Visually check the outer surface of the probe for cleanness. If necessary, use magnifying glass for visually check. If there is still soil visible, repeat all above steps.

Figure: Immerge the submergible part of the probe into water, detergent or disinfectant solution

Disinfection: 1)

It is recommended to test the concentration of disinfectant solution before each usage. The solution Cidex® OPA is ready for use and does not need to be diluted. Test strips to verify that the appropriate concentration of Cidex® OPA is correct are available by manufacturer. Test strips will indicate a concentration above the Minimum Effective Concentration (MEC). Please also note the expiration date of the test stripes. Temperature of disinfectant solution should be minimum 20°C. The minimum contact time is 5 minutes. If a different disinfectant is used, follow the manufacturer’s instructions. Please also consider the material compatibility for the medical device.

2)

Immerge the submergible part of the probe into the disinfectant (see Figure). Set a clock to insure the recommended contact time is observed.

3)

Rinse the submergible part of the probe with running deionized water for 1 minute. (alternatively: suspend the submergible part of the probe in a tray filled with deionized water (see Figure) for 5 min.)

4)

Visually check the surface of the probe that there are no leavings of the disinfectant. If necessary, repeat the rinsing.

FUJIFILM Healthcare Deutschland GmbH

Version : 6 , Status: final

4/9

Intraoperative Probes (CDA) Drying: 1)

Wipe the probe with a single use, fluff free wipe or towel for removing moisture on the surface of the probe. Dry until no visible moisture is left.

2)

If using drying heater for medical equipment, the temperature limit is a maximum of 60°C. Dry until no visible moisture is left.

3)

If using natural drying, temperature range should be between 15-30°C for a minimum time of 4 hours.

Cable and connector Wipe the cable in 20 cm intervals with gauze dipped in ethyl alcohol or water, and dry it after wiping. If the entire length of the cable is wiped at once, a part of the cable may be wrinkled. Always wipe the cable in 20 cm intervals. Clean the connector with gauze dipped in ethyl alcohol, and dry it after cleaning.

Automated reprocessing: The following items must be provided prior to automated cleaning and disinfection: a)

Washer disinfector according to DIN EN ISO 15883 with chemo-thermal program (Temperature max. 60°C)

b)

Detergent: Korsolex® Endo-Cleaner (BODE Chemie; # 972020) or another cleaning agent with approved material compatibility for this medical device

c)

Disinfectant: Korsolex® Endo-Disinfectant (BODE Chemie; # 972030) or another disinfectant with approved material compatibility for this medical device

d)

Waterproof box EZU-WB1, waterproof case WP-001 or waterproof cover MP-2790 for the probe connector (see Table 2) and an appropriate air leak tester. Probe type

EZU-WB1 WP-001

C22I

x

C22T

x

C42T

x

EUP-O54J

x

L43K

x

L44K

x

L51K

x

L44LA1

x

L46K

x

L46K1

x

L53K

x

FUJIFILM Healthcare Deutschland GmbH

MP-2790

Version : 6 , Status: final

5/9

Intraoperative Probes (CDA) L31KP

x

S31KP

x

UST-536

x

UST-579T-7.5

x

UST-987-7.5

x

UST-995-7.5

x

UST-5268P-5

x

UST-5536-7.5

x

UST-5550

x

UST-5713T

x

UST-9104-5

x

UST-9120

x

UST-9132I

x

UST-9132T

x

UST-9146I

x

UST-9146T

x

UST-MC11-8731

x

Table 2: Selection of waterproof case

1)

The parameters of the cleaning and disinfection of the device are as follows: Program step

Water (40l)

Pre-Rinse

Cold water

Cleaning

Deionized water

Rinse

Deionized water

Disinfection

Deionized water

Rinse

Deionized water

Rinse

Deionized water

Dosage (ml/l) Temp. (°C) Time (min) 5 5 (0,5%)

50

5 1

10 (1%)

55

5 1

Drying

55

1

55

15

Table 3: Parameters for automated process

2)

Remove used optional parts from the probe and proceed as described under pre-cleaning in the examination room.

3)

Connect the waterproof box EZU-WB1, waterproof case WP-001 or waterproof cover MP-2790 to the probe connector and confirm there is no air leak by the tester. About detail information, refer to the instruction manual of the waterproof box EZU-WB1 waterproof case WP-001 or waterproof cover MP-2790.

4)

After closing the door, start the chemo-thermal program.

5)

After the end of the program, open the door.

FUJIFILM Healthcare Deutschland GmbH

Version : 6 , Status: final

6/9

Intraoperative Probes (CDA) 6)

Remove the probe and check whether it is dry. If not, proceed as described under drying.

Inspection, maintenance and testing Confirm following items: 1)

The correct function of mechanical moving parts.

2)

An efficient image performance of the monitor when the probe is connected to the ultrasound system.

3)

Look for cracks, scratches or deformations on the surface of the probe tip, cable and connector. Don’t use the probe in case of existing damage. Contact your local manufacturer’s service immediately.

Packaging Store the disinfected probe in a dustproof environment until next application. Before sterilization it is necessary to pack the cleaned and disinfected probe in a sterile barrier system for plasma sterilization (for example Polypropylene fleece or transparent package out of Polyethylene film and Tyvek®). Additionally the probe can be placed on plastic mesh wires sufficient for plasma sterilization supplied by the manufacturer and packed in the material mentioned above afterwards. The probe can be packed in a simple or double packing. The probe should be packed either in Polypropylene fleece or transparent package. The package has to be large enough to avoid tension to the sealing seam. Check the sealing seam after hot sealing for any defects. The sealing machine should be designed for sealing transparent package out of Polypropylene film or Tyvek®. In case of processing mistakes or defects the package has to be opened again and the device has to be packed and sealed again.

Sterilization Sterilization methods of ethylene oxide gas and plasma are available. Follow the instructions of the sterilizer manufacturer regarding usage, temperature and sterilizationtime etc. Handling and maximum input to the chamber of the sterilizer should be according to the operation manual of the sterilizer. Ethylene oxide (EtO) gas sterilization: Gas Type

10% EO/ 90% HCFC

Temperature

50 - 60°C

Exposure Time

Minimum 120 minutes

Pressurization

162 - 200kPa

Depressurization

13 - 8kPa

Relative humidity

40 - 90%

Aeration

Minimum 12 hours

FUJIFILM Healthcare Deutschland GmbH

Version : 6 , Status: final

7/9

Intraoperative Probes (CDA) Perform full aeration after gas sterilization. Residual gas can cause an adverse reaction to the operator or patient. STERRAD® sterilization: Refer to Table 4, which method is applicable for each probe. Probe type

STERRAD® 50, 100S, 200

STERRAD® NX, 100NX

C22I

x

x

C22T

x

x

C42T

x

x

EUP-O54J

x

L43K

x

x

L44K

x

x

L51K

x

x

L44LA1

x

x

L46K

x

x

L46K1

x

x

L53K

x

x

L31KP

x

x

S31KP

x

x

UST-536

x

x

UST-579T-7.5

x

x

UST-987-7.5

x

x

UST-995-7.5

x

x

UST-5268P-5

x

x

UST-5536-7.5

x

x

UST-5550

x

x

UST-5713T

x

x

UST-9104-5

x

x

UST-9120

x

x

UST-9132I

x

x

UST-9132T

x

x

UST-9146I

x

x

UST-9146T

x

x

UST-MC11-8731

x

x

Table 4: Selection of sterilization method

FUJIFILM Healthcare Deutschland GmbH

Version : 6 , Status: final

8/9

Intraoperative Probes (CDA) Storage Store the probe in a cool, dust free and dry space to avoid high temperature, humidity and direct sunlight. Limitations for the time for sterilized probe belong to package.

Manufacturer contact Find your local contact under: https://www.fujifilm.com/hce

Manufacturer

European Representative

Importer

FUJIFILM Healthcare Corporation

FUJIFILM Healthcare Deutschland GmbH Otto-von-Guericke-Ring 3 65205 Wiesbaden, Germany

FUJIFILM Healthcare Europe Holding AG Sumpfstrasse 13 6312 Steinhausen, Switzerland

FUJIFILM Healthcare Deutschland GmbH

Version : 6 , Status: final

9/9