Addendum

8 Pages

Preview

Page 1

Addendum for DINAMAP® PRO 100-400V2 Operation and Service Manuals

Addendum for DINAMAP® PRO 100-400V2 Operation and Service Manuals This addendum contains updated information for the DINAMAP® PRO 100-400V2 Monitor and the accompanying Operation and Service Manuals.

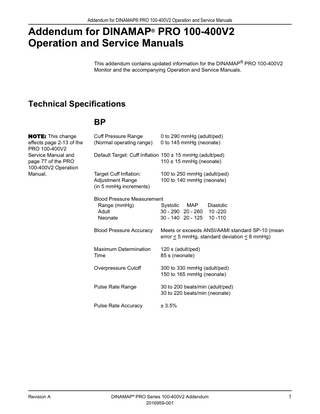

Technical Specifications BP NOTE: This change effects page 2-13 of the PRO 100-400V2 Service Manual and page 77 of the PRO 100-400V2 Operation Manual.

Cuff Pressure Range (Normal operating range)

0 to 290 mmHg (adult/ped) 0 to 145 mmHg (neonate)

Default Target: Cuff Inflation 150 ± 15 mmHg (adult/ped) 110 ± 15 mmHg (neonate) Target Cuff Inflation: Adjustment Range (in 5 mmHg increments)

100 to 250 mmHg (adult/ped) 100 to 140 mmHg (neonate)

Blood Pressure Measurement Range (mmHg) Systolic MAP Diastolic Adult 30 - 290 20 - 260 10 -220 Neonate 30 - 140 20 - 125 10 -110

Revision A

Blood Pressure Accuracy

Meets or exceeds ANSI/AAMI standard SP-10 (mean error < 5 mmHg, standard deviation < 8 mmHg)

Maximum Determination Time

120 s (adult/ped) 85 s (neonate)

Overpressure Cutoff

300 to 330 mmHg (adult/ped) 150 to 165 mmHg (neonate)

Pulse Rate Range

30 to 200 beats/min (adult/ped) 30 to 220 beats/min (neonate)

Pulse Rate Accuracy

± 3.5%

DINAMAP® PRO Series 100-400V2 Addendum 2016959-001

1

Addendum for DINAMAP® PRO 100-400V2 Operation and Service Manuals

Alarm Limits NOTE: This change effects page 4-11 of the PRO 100-400V2 Service Manual and page 62 of the PRO 100-400V2 Operation Manual.

Alarm Limits Table Parameter

2

Range

Default

Systolic High

35 - 290

180

Systolic Low

30 - 285

30

Diastolic High

15 - 220

130

Diastolic Low

10 - 215

15

MAP High

25 - 260

140

MAP Low

20 - 255

50

BPM High

35 - 250

150

BPM Low

30 - 245

50

SpO2 High

21 - 100

Off

SpO2 Low

20 - 99

90

DINAMAP® PRO Series 100-400V2 Addendum 2016959-001

Revision A

Addendum for DINAMAP® PRO 100-400V2 Operation and Service Manuals

Leak Test NOTE: This change effects the Leak Test on page 4-17 of the PRO 100-400V2 Service Manual.

This test performs a leak test of the pneumatic system. Equipment required:

CRITIKON® Adult Blood Pressure Cuff (P/N 2774)

12 foot Gray, Adult/Pediatric Air Hose (P/N 107365)

Figure 4-1 1. Secure the Adult-size cuff to the 12-foot air hose. Attach to the PRO Monitor as shown in Figure 4-1. Secure the BP cuff around a rigid, unbreakable object that measures at least 2 inches in diameter. 2. Ensure the index-line of the CRITIKON® Blood Pressure Cuff is properly aligned within the range-markers on the opposite end of the cuff. 3. Power on the PRO Monitor and select More... 4. Select the Service option and input 8 3 7 8. 5. From the Super Service menu, select the NIBP option. 6. From the NIBP menu, select the LEAK option. The leak-test sequence closes both valves and turns on the pump. The PRO Monitor will self-pressurize the pneumatic test setup to approximately 200 mmHg. After settling for 45 seconds, the test pressure value will be displayed in mmHg on the LCD. After 30 seconds, the system displays the final pressure. Confirm that the pressure has fallen no more than 5 mmHg.

Revision A

DINAMAP® PRO Series 100-400V2 Addendum 2016959-001

3

Addendum for DINAMAP® PRO 100-400V2 Operation and Service Manuals

Overpressure Adjustment of a Two-Pot System This procedure describes how to set the overpressure thresholds. See NOTE: This change effects the Figure 4-2 for adjustment locations. Overpressure Adjustment on page 4-22 of the PRO 100-400V2 Service Manual.

Figure 4-2 Adjusting the overpressure requires opening the PRO 100-400 Monitor and adjusting the overpressure potentiometers on the Main board. 1. Enable Service Mode. a. Power on the Monitor. b. Select the More... button from the Main menu. c. Select the Service button. d. Enter the Service Mode access code 2 2 1 3. e. Select NIBP. 2. Select the Check button. This button sets the overpressure point to the adult value and closes the pneumatic valves. 3. Adjust potentiometer VR1 fully counter-clockwise. 4. Manually inflate the system pressure to 315 mmHg (the optimal default Adult Overpressure setting). 5. Once the manometer displays 315 mmHg, adjust VR1 clockwise until the valves release the pressurized system. 6. Select the Check button again, and verify that the overpressure trips at 315 mmHg ±10 mmHg. 7. Power the Monitor off.

4

DINAMAP® PRO Series 100-400V2 Addendum 2016959-001

Revision A

Addendum for DINAMAP® PRO 100-400V2 Operation and Service Manuals 8. Enable Service Mode. a. Power on the Monitor. b. Select the More button from the Main menu. c. Select the Service button. d. Enter the Service Mode access code 2 2 1 3. e. Select NIBP. 9. Select the Pop off button. This button sets the overpressure point to the neonatal value and closes the pneumatic valves. 10. The unit will display three zeros in the systolic and diastolic windows. 11. Adjust VR2 (more to the middle of board) fully counter-clockwise. 12. Set the cuff pressure to 157 mmHg ±2 mmHg using your connected NIBP test setup. 13. The air pressure within the system may fluctuate initially. Verify pressure with your external manometer. 14. Adjust VR2 clockwise until the pressure is released and the Monitor displays Systolic: 000 & Diastolic: 000. 15. Verify the overpressure setting by performing the Neonate Overpressure Check 4.6.4. 16. Power the Monitor off. NOTE: A transducer calibration must be performed after changing the overpressure thresholds to save the levels into the EEPROM. These levels are used for a self test during normal operation.

Revision A

DINAMAP® PRO Series 100-400V2 Addendum 2016959-001

5

Addendum for DINAMAP® PRO 100-400V2 Operation and Service Manuals

New Menu Options There are several new menu options that have been added to the PRO 100400V2 Monitor. These options are available in the Service Mode and can be found under two new buttons:

Cycle Button Selection of the Cycle button activates a menu that allows the user to activate the Preventative Maintenance (PM) reminder notice. The Cycle button is available in the password-protected Service Mode under the NIBP menu. Using this menu, the user can specify the number of days desired between monitor maintenance checks. During a maintenance check, the current date set on the Monitor will be stored in the eeprom as the last PM date when: 1. An NIBP calibration completes successfully. 2. The Check button under the NIBP button in the Service Mode Menu is selected. 3. The Pop Off button under the NIBP button in the Service Mode Menu. If the dates captured by the Check or Pop Off buttons would ever precede the calibration date, the PM date would default to the calibration date. When the number of days since the last PM exceeds the specified Cycle number of days, a full-screen warning page will be displayed after the powerup screen, informing the user that preventative maintenance is due. This screen can be dismissed by pressing any front panel key, and normal operation will begin. The date of the last PM and Calibration can be found by selecting the Info button in the Service Mode Menu or by selecting the Info button in Clinician Mode Menu.

Preventative Maintenance Reminder Screen

6

DINAMAP® PRO Series 100-400V2 Addendum 2016959-001

Revision A

Addendum for DINAMAP® PRO 100-400V2 Operation and Service Manuals Cycle Button Selection of this button displays a menu that allows the user to select the number of days that elapse between the last NIBP PM date and the activation of the Preventative Maintenance reminder screen. Cycle times range from 30 to 365 days in 5-day increments and OFF. If you choose OFF as your cycle time, the Preventative Maintenance Reminder screen is disabled.

Cancel Button Selection of this button takes the user back to the Service Mode NIBP Menu. Changes to the Cycle time will not be retained if the Save button has not been selected before leaving the menu. Save Button Selection of this button stores the currently displayed Cycle time in the eeprom. The Cycle time is retrieved for analysis on power-up to determine whether the Preventative Maintenance Reminder screen should be shown.

ID Tag Button ID Tag Button The ID Tag button is available in the password-protected Service Menu in the System menu. Selection of the ID Tag button opens a menu that allows the user to enter a 12-digit Monitor Asset Tag for their own use. If the Asset ID Tag is not equal to zero, the ID tag number will be displayed at the top of the screen upon power-up, before the Monitor displays the Main Menu. If the value is equal to zero, the ID Tag option is disabled and not shown on the start-up screen upon power-up. Input Asset Tag Digits Selection of the individual digit buttons (0 to 9) in this menu allows the user to input an Asset ID Tag. Use the SelectKnob to choose the digits of the tag for the Monitor. You must select Save to permanently change the Asset ID Tag. The choice of digits range from 0 to 9.

Revision A

DINAMAP® PRO Series 100-400V2 Addendum 2016959-001

7

Addendum for DINAMAP® PRO 100-400V2 Operation and Service Manuals Back Selection of this button erases the last digit chosen for the Asset ID tag. The Save button must then be selected for this to be a permanent change. Clear Selection of this button resets the Asset ID tag number being created back to zero, allowing a new number to be input or to turn the feature off. The Save button must then be selected for this to be a permanent change. Cancel Selection of this button takes the user back to the Service Mode System Menu. Changes to the Asset ID tag will not be retained if the Save button has not been selected before leaving the menu. Save Selection of this button enters the Asset ID Tag number being created in eeprom. None of the operations of the Digit, Clear, or Back buttons are permanent until the Save button is selected. On power-up, this saved number will be displayed on start-up screen.

8

DINAMAP® PRO Series 100-400V2 Addendum 2016959-001

Revision A