GE Healthcare

Flow Sensor Instructions

371 Pages

Preview

Page 1

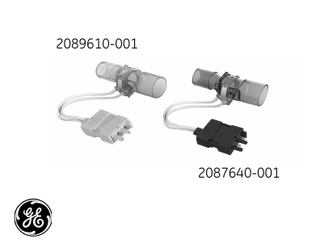

English Only use these instructions for flow sensors 2087640-001 and 2089610-001. Keep these instructions with the anesthesia system User's Reference Manual. Refer to the anesthesia system User’s Reference Manual for additional information regarding flow sensor use and installation. Replace flow sensor as necessary (dispose of safely if damaged, checkout fails, or visual check continually fails). Under typical use the flow sensor meets specifications for a minimum of 1 year. CAUTION Do not use different instructions for flow sensors 2087640-001 and 2089610-001. Damage to the flow sensors or ineffective cleaning, disinfection, and sterilization could occur. CAUTION Flow sensor errors could occur due to cuts or punctures in the flow sensor tubes. Over or under delivery of ventilation and possible over pressure of the patient circuit could occur due to excessive flow. Handle flow sensors carefully to prevent damage to the packaging and to the flow sensor. Do not use a sharp tool to open the flow sensor packaging. Inspect the flow sensor and flow sensor 2095125-MULTI Rev. C (2022 03)

1

tubing for damage after opening the package, before installing, and when handling the flow sensors. CAUTION Only parts marked 134°C are autoclavable. CAUTION Do not insert any objects into the flow sensor. Damage to the flow sensor can occur. Do not touch the internal flow sensor flap as it may affect flow sensing performance. CAUTION Do not allow sensors to dry between soaking, agitation, and rinsing steps to prevent residue as it may affect flow sensing performance. WARNING Use personal protective equipment recommended by the chemical and autoclave manufacturers. Part number 2087640-001 2

Symbol

Cleaning X

Disinfection

Sterilization X

2095125-MULTI Rev. C (2022 03)

Part number

Symbol

2089610-001

Cleaning

Disinfection

X

X

Sterilization

MRI compatibility information Flow sensors marked with the MR Conditional symbol may be used with appropriate General Electric MR (Magnetic Resonance) compatible anesthesia devices. Refer to anesthesia device user documentation for conditions of use. Symbols on the equipment .

BCG - Breathing Circuit Gas

MR conditional

Not autoclavable

Autoclavable

2095125-MULTI Rev. C (2022 03)

3

AB.82.144

Flow sensor cleaning Note This cleaning procedure is applicable to 2087640-001 and 2089610-001 flow sensors. For all soaking, agitation, and rinsing steps, use a minimum of 500 ml of liquid per sensor. Make sure that all surfaces of the flow sensor (except the connector) are submerged in the liquid and there are no visible air bubbles. Do not allow sensors to dry between steps. A Flow Sensor Cleaning Kit M1086468 is available for soaking. Soak only 6 sensors maximum using the cleaning kit as shown.

CAUTION Do not submerge or get the flow sensor connector wet. Damage to the flow sensor will occur. 4

2095125-MULTI Rev. C (2022 03)

1.

2. 3.

AC.27.001

4.

Mix a mild detergent solution in a clean soaking tray: • Use Prolystica 2x Neutral detergent concentration of 1 ml per liter of 20°C to 40°C distilled water. Thoroughly mix the solution. Soak the sensor in the detergent solution for a minimum of 20 minutes. Agitate the flow sensor in the detergent solution sliding it through the solution lengthwise 30 times in a 10 cm path for 30 seconds. Remove the sensor from the solution. Using a syringe, flush each tube with approximately 10 ml of clean detergent solution through the flow sensor connector.

5.

Visually inspect internal and external surfaces of the sensor for soil contaminant. • If loose contaminant remains, repeat steps 3 and 4 in clean detergent solution until removed.

2095125-MULTI Rev. C (2022 03)

5

•

If contaminant remains adhered to surfaces, repeat steps 1 through 4 in clean detergent solution until removed. 6. Using a syringe, flush each tube with approximately 10 ml of distilled water through the flow sensor connector. 7. Soak the sensor in fresh distilled water for a minimum of 30 minutes at room temperature. 8. Using a syringe, flush each tube with approximately 10 ml of fresh distilled water through the flow sensor connector. 9. Rinse the sensor by agitating it in room temperature distilled water. Slide the flow sensor lengthwise in fresh distilled water 60 times in a 10 cm path for 60 seconds. 10. Soak the sensor in fresh distilled water for a minimum of 30 minutes at room temperature. 11. Using a syringe, flush each tube with approximately 10 ml of fresh distilled water through the flow sensor connector. 12. Using a dry syringe, push air through the flow sensor connector to dry each tube. Dry each tube until all droplets are cleared. 13. Visually inspect internal and external surfaces of the sensor for soil contaminant or residue. Repeat the cleaning procedure if contaminant or residue remains. 6

2095125-MULTI Rev. C (2022 03)

14. Perform the "Flow sensor disinfection" or "Flow sensor sterilization (autoclave)" procedure.

2095125-MULTI Rev. C (2022 03)

7

AB.82.144

Flow sensor disinfection Note This disinfection procedure is applicable to 2089610-001 flow sensors. For all soaking, agitation, and rinsing steps, use a minimum of 500 ml of liquid per sensor. Make sure that all surfaces of the flow sensor (except the connector) are submerged in the liquid and there are no visible air bubbles. Do not allow sensors to dry between steps. A Flow Sensor Cleaning Kit M1086468 is available for soaking. Soak only 6 sensors maximum using the cleaning kit as shown.

CAUTION Do not submerge or get the flow sensor connector wet. Damage to the flow sensor will occur. 1. 8

Perform the "Flow sensor cleaning" procedure before disinfection.

2095125-MULTI Rev. C (2022 03)

2. 3.

AC.27.001

4.

Pour Sporox II disinfectant solution into a clean tray. Agitate the flow sensor in the disinfectant solution sliding it through the solution lengthwise 60 times in a 10 cm path for 60 seconds. Using a syringe, flush each tube with approximately 10 ml of clean disinfectant solution through the flow sensor connector.

5.

Soak the sensor in the disinfectant solution for a minimum of 45 minutes at approximately 20°C.

6.

Using a syringe, flush each tube with approximately 10 ml of distilled water through the flow sensor connector. Rinse the sensor by agitating it in room temperature fresh distilled water. Slide the flow sensor lengthwise in the distilled water 60 times in a 10 cm path for 60 seconds.

7.

2095125-MULTI Rev. C (2022 03)

9

8.

Soak the sensor in fresh distilled water for a minimum of 30 minutes at room temperature. 9. Using a syringe, flush each tube with approximately 10 ml of fresh distilled water through the flow sensor connector. 10. Rinse the sensor by agitating it in room temperature fresh distilled water. Slide the flow sensor lengthwise in the distilled water 60 times in a 10 cm path for 60 seconds. 11. Soak the sensor in fresh distilled water for a minimum of 30 minutes at room temperature. 12. Rinse the sensor by agitating it in room temperature fresh distilled water. Slide the flow sensor lengthwise in the distilled water 60 times in a 10 cm path for 60 seconds. 13. Using a syringe, flush each tube with approximately 10 ml of fresh distilled water through the flow sensor connector. 14. Using a dry syringe, push air through the flow sensor connector to dry each tube. Dry each tube until all droplets are cleared. 15. Completely dry the sensor in an oven at 105°C to 110°C for a minimum of 30 minutes. 10

2095125-MULTI Rev. C (2022 03)

16. Visually inspect internal and external surfaces of the sensor for soil contaminant or residue. Repeat "Flow sensor cleaning" and "Flow sensor disinfection" if contaminant or residue remains. Flow sensor sterilization (autoclave) This sterilization procedure is applicable to 2087640-001 flow sensors. CAUTION Only parts marked 134°C are autoclavable. 1. 2. 3.

4.

Perform the "Flow sensor cleaning" procedure before sterilization. Wrap the flow sensor in light-gauge sterilization wrap for autoclaving (oneply polypropylene wrap Kimberly-Clark Kimguard KC600 or equivalent). Sterilize in an autoclave at 132°C for 4 minutes, or 134°C for 3 minutes, using the pre-vacuum dynamic air removal cycle with a drying time of 30 minutes for either cycle. Do not exceed 134°C. Allow the flow sensor to cool to room temperature before use.

2095125-MULTI Rev. C (2022 03)

11

GE Healthcare P.O. Box 7550 Madison, WI 53707-7550 USA www.gehealthcare.com

© Datex-Ohmeda, Inc. – All rights reserved. GE and GE Monogram are trademarks of General Electric Company. Datex-Ohmeda, Inc., a General Electric Company, doing business as GE Healthcare.

2095125-MULTI 2022 05 C