Hall Surgical

PowerPro Electric II Reciprocator Handpiece

Hall PowerPro Electric II Handpieces Instruction Manual

36 Pages

Preview

Page 1

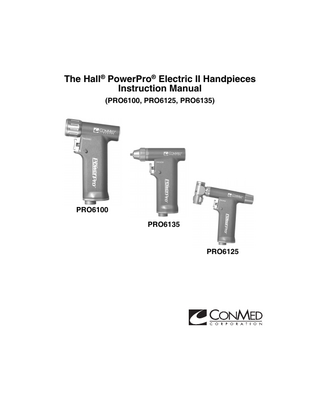

The Hall® PowerPro® Electric II Handpieces Instruction Manual (PRO6100, PRO6125, PRO6135)

PRO6100 PRO6135

PRO6125

Proprietary Information This manual contains information deemed proprietary to Linvatec Corporation. The information contained herein, including all of the designs and related materials, is the sole property of ConMed Linvatec and/or its licensors. ConMed Linvatec and/or its licensors reserve all patent, copyright and other proprietary rights to this document, including all design, manufacturing methodology and reproduction. This document, and any related materials, is confidential and is protected by copyright laws and shall not be duplicated, transmitted, transcribed, stored in a retrieval system, or translated into any human or computer language in any form or by any means, electronic, mechanical, magnetic, manual or otherwise, or disclosed to third parties, in whole or in part, without the prior express written consent of ConMed Linvatec. ConMed Linvatec reserves the right to revise this publication and to make changes from time to time in the contents hereof without obligation to notify any person of such revision or changes, unless otherwise required by law.

Linvatec, Hall, and PowerPro, are trademarks or registered trademarks of Linvatec Corporation.

Linvatec Corporation 2015. All Rights Reserved.

Record the Model and Serial Numbers of all attachments, and date received. Retain for future reference. Handpiece Model No.

Serial No

Date

Handpiece Model No.

Serial No

Date

Handpiece Model No.

Serial No

Date

Handpiece Model No.

Serial No

Date

Handpiece Model No.

Serial No

Date

Handpiece Model No.

Serial No

Date

1.0

2.0

INTRODUCTION 1.1

Operating Principle... 1

1.2

Indications for Use... 1

1.3

Intended Use... 1

1.4

Contraindications... 1

1.5

Warnings and Precautions... 2 1.5.1

Warnings... 2

1.5.2

Precautions... 3

1.6

Environmental Directives... 4

1.7

Product Photographs and Drawings... 4

1.8

Symbol Definitions... 5 1.8.1

Product Symbols... 5

1.8.2

Warnings and Information Symbols... 5

SYSTEM INSTALLATION AND OPERATION 2.1

2.2

2.3

2.4

Product Description... 7 2.1.1

PowerPro Electric II Modular Handpiece (PRO6100)... 7

2.1.2

PowerPro Electric II Oscillator Handpiece (PRO6125)... 8

2.1.3

PowerPro Electric II Reciprocator Handpiece (PRO6135)... 9

Assembly/Installation Instructions... 10 2.2.1

Handpiece Cord Installation... 10

2.2.2

Connecting and Removing Attachments to the Modular Handpiece... 11

2.2.3

Connecting and Removing Blades to the Oscillator Handpiece... 12

2.2.4

Connecting and Removing Blade to Reciprocator Handpiece... 13

Operating Instructions... 14 2.3.1

PowerPro Electric II Modular Handpiece (PRO6100) Operation... 14

2.3.2

PowerPro Electric II Oscillator Handpiece (PRO6125) Operation... 17

2.3.3

PowerPro Electric II Reciprocator Handpiece (PRO6135) Operation... 18

Preoperative Functional Test... 18

i

3.0

MAINTENANCE 3.1

3.2

4.0

Cleaning Information... 19 3.1.1

Warnings, Precautions and Notes... 19

3.1.2

Manual Cleaning Instructions... 19

3.1.3

Washer/Sanitizer Cleaning (Optional)... 20

Sterilization Information... 20 3.2.1

Warnings, Precautions and Notes... 20

3.2.2

Sterilization Instructions... 21

3.3

Troubleshooting... 22

3.4

Maintenance Schedule... 23

TECHNICAL SPECIFICATIONS 4.1

Product Technical Specifications... 25 4.1.1

4.2

4.3

5.0

Handpieces... 25

Product Environmental Requirements... 27 4.2.1

Environmental Technical Specifications... 27

4.2.2

Electromagnetic Requirements... 27

Handpieces, Attachments and Accessories... 28

CUSTOMER SERVICE 5.1

Assistance and Repair... 30

ii

1.0

INTRODUCTION

It is recommended that personnel study this manual before attempting to operate, clean, or sterilize this or associated equipment. The safe and effective use of this equipment requires the understanding of and compliance with all warnings, precautionary notices, and instructions marked on the product, and included in this manual. This equipment is designed for use by medical professionals completely familiar with the required techniques and instructions for use of the equipment. Service intervals, as listed in section “3.4 Maintenance Schedule”, are required to keep the equipment at its optimum operating performance.

1.1 Operating Principle The PowerPro Electric II Handpieces are electrically powered by ConMed Linvatec surgical consoles to provide rotary, reciprocating, or oscillating force to the accessory (drill bits, saw blades, reamers, drivers or other attachments) for bone cutting, drilling, driving and soft tissue resection. The handpieces use a detachable cable and are controlled by a single activation trigger and safety/direction lever on the handpiece.

1.2 Indications for Use The PRO6100 PowerPro Electric II Modular Handpiece, and its accessories, perform cutting of soft tissue and bone. The fields of application include: Orthopedic, Arthroscopic, Oral/Maxillofacial, Hand, Foot, and Plastic/Reconstructive surgical procedures. The PRO6125 PowerPro Electric II Oscillator Handpiece, and its accessories, perform cutting of soft tissue and bone. The fields of application include: Orthopedic, Arthroscopic, Otolaryngological, Oral/ Maxillofacial, Hand, Foot, and Plastic/Reconstructive surgical procedures. The PRO6135 PowerPro Electric II Reciprocator Handpiece, and its accessories, perform cutting of soft tissue and bone. The fields of application include: Orthopedic, Arthroscopic, Hand, Foot, and Plastic/ Reconstructive surgical procedures.

1.3 Intended Use Same as Indications for Use above.

1.4 Contraindications None

1

1.5 Warnings and Precautions

!

Do not bypass this section. It contains warnings and precautions that must be thoroughly understood before operating any of the equipment. Lack of understanding or adherence to these warnings and precautions may result in injury or even death to the patient. The words WARNING, PRECAUTION, and NOTE carry special meanings and they must be read carefully. WARNING: A warning contains critical information regarding serious adverse reactions and potential safety hazards that can occur in proper use or misuse of the equipment. Failure to observe the information or procedures presented in a Warning may result in injury or other serious adverse reactions to the patient and/or surgical staff. PRECAUTION: A precaution contains instructions for any special care to be exercised by the practitioner for the safe and effective use of the equipment. Failure to observe the information or procedures presented in a Precaution may result in damage to the equipment.

! !

NOTE: A note is added to provide additional focused information. This information has no critical effect on the patient or equipment. 1.5.1 Warnings

!

1.

Eye protection is recommended when operating equipment. Eye injury may result.

2.

It is the surgeon's responsibility to be familiar with the appropriate surgical techniques prior to use of the equipment and its associated accessories.

3.

Do not use equipment if, upon receipt, package is opened, damaged, or shows any signs of tampering.

4.

Do not use equipment in the presence of flammable anesthetics, gases, disinfecting agents, cleaning solutions, or any material susceptible to ignition due to electrical sparking.

5.

Do not use sterile equipment beyond the expiration date listed on the label. Sterility of the product cannot be assured beyond the expiration date.

6.

Do not excessively bend or kink the handpiece cord. Always inspect cords for signs of excessive wear or damage, or bent, broken or missing pins within the connector(s). If any wear or damage is found, discontinue use and replace handpiece immediately. Using a damaged power cord could possibly cause injury.

7.

Handpieces are supplied non-sterile. Clean and sterilize prior to each use.

8.

Do not contact the moving parts on the handpieces. Injury to the operator may occur.

9.

Continually check handpiece for overheating. If overheating is sensed, immediately discontinue use and return equipment for service. Overheating of the blade or bur may cause damage to the blade or bur and may cause burns or thermal necrosis.

10. While handpiece is not in use do not place on patient/surgical drapes. Place handpiece on mayo stand. 2

11. Do not immerse the equipment in fluids. Immersion may render the device inoperable. 12. Failure to follow the specified service interval could result in reduced instrument performance or overheating of the handpiece. Overheating can lead to possible burn injury to the patient or medical personnel. Rotation of handpiece usage per day will assist with proper performance. (Refer to section “3.4 Maintenance Schedule”).

!

13. Do not attach, insert or remove accessories or attachments while the handpiece is operating. Injury to the operator and/or damage to the equipment may occur. Place the handpiece safety mechanism in the “safe” position prior to installation or removal of items. 14. Avoid contact with cutting tip of blade or bur when locking into handpiece. Tips are sharp and may cause injury. 15. After use blades, burs and tubing sets may be a potential biohazard and should be handled and disposed in accordance with acceptable medical practice and applicable local and national requirements. 16. Do not use burs for plunge cutting. Injury or damage may occur. 17. Disposable blades and burs are supplied sterile and are for single-use only. Do not resterilize or reuse. The ability to effectively clean and re-sterilize these single use devices has not been established and subsequent re-use may adversely affect the performance, safety and/or sterility of the devices. 18. Do not operate the oscillating saw or reciprocator handpiece without a blade locked securely in place. 19. Always place the handpiece in the “safe” position when not in use and prior to repositioning the rotating head on the Oscillator Saw, rotating the collet on the Reciprocating Saw, or connecting or removing attachments and accessories. 20. When using the PowerPro Sagittal Saw attachment (PRO2043), placing excessive bending or twisting force on the sagittal saw blade may cause the collet to open and release the saw blade. Do not use saw blades to pry, remove bone grafts, or as a leverage point. Patient or user injury could occur. 1.5.2 Precautions

!

1.

United States Federal law restricts sale of this device to or on the order of a physician.

2.

This device should only be used in compliance with its intended use.

3.

Handle all equipment carefully. If any equipment is dropped or damaged in any way, return it immediately for service.

4.

Use only associated ConMed Linvatec approved equipment and accessories. Using unapproved accessories may result in improper operation, and may result in non-compliance to medical standards.

5.

The warranty becomes void and the manufacturer is not liable for direct or resulting damage if: • • •

The device or the accessories are improperly used, prepared or maintained; The instructions in the manual are not adhered to; Non-authorized persons perform repairs, adjustments or alterations to the device or accessories. 3

6.

There are no user-serviceable parts inside. No modification of this equipment is allowed.

7.

Prior to each use, perform the following: • Ensure all accessories are correctly and completely attached. (Refer to section “2.2 Assembly/Installation Instructions”). • Perform the required Preoperative Functional Tests for the equipment and accessories. (Refer to section “2.4 Preoperative Functional Test”).

8.

Clean and sterilize all equipment and associated accessories according to instructions for use. (Refer to section “3.1 Cleaning Information” and section “3.2 Sterilization Information”).

9.

Handpieces are factory sealed. Do not disassemble or lubricate, as this may void the warranty.

10. Always inspect for bent, dull or damaged blades or burs before each use. Do not attempt to straighten or sharpen. Do not use if damaged. 11. After each use, thoroughly clean the handpiece, attachments and accessories. (Refer to section “3.0 MAINTENANCE”). 12. Do not stall handpieces, damage can occur. 13. When using a saw attachment (Reciprocating Saw - PRO6045 or Sagittal Saw - PRO2043) or reaming attachment, do not operate in the screw, tap or oscillate mode. Handpieces should only be operated in the drill/ream mode when used with these attachments. 14. Do not handle the handpiece by the cord. Do not pull on the cord to remove it from the surgical console. Damage can occur. 15. The PRO2045 Reciprocating Saw attachment should not be used on the PowerPro Electric II Modular handpiece (PRO6100). The PRO6045 Reciprocating Saw attachment is recommended for the PRO6100 handpiece.

1.6 Environmental Directives WEEE Directive [2002/96/EC] on Waste Electrical and Electronic Equipment. This statement only applies to European countries with regard to the Waste Electrical and Electric Equipment (WEEE) European Directive. The WEEE symbol on the product or its packaging indicates that this product must not be disposed of with other waste. Instead, it is your responsibility to dispose of your waste equipment by handing it over to a designated collection point for the recycling of Waste Electrical and Electronic Equipment. The separate collection and recycling of your waste equipment at the time of disposal will help conserve natural resources and ensure that it is recycled in a manner that protects human health and the environment. For more information about where you can drop off your medical equipment at the end of its useful life for recycling, please contact ConMed Linvatec. 1.7 Product Photographs and Drawings The pictures in this manual are for reference only. Items shown may not represent the actual product. However, procedural steps are identical, unless otherwise specified. When necessary, the actual pictures will be represented. 4

1.8 Symbol Definitions 1.8.1 Product Symbols Indicates the “safe” or off position of the handpieces.

S

Indicates the “forward” position of the PRO6100 handpiece.

F

Indicates the “reverse” position of the PRO6100 handpiece.

R

R

Indicates the “run” positions of the PRO6125 and PRO6135 handpieces.

R

1.8.2 Warnings and Information Symbols Catalog Number

REF

! EC REP

STERILE

2

EO

Serial Number

SN

Manufacturer

Date of Manufacture

Consult Instructions for Use

Refer to Instruction Manual/Booklet (for critical safety instruction)

Caution

DEHP Symbol

Authorized Representative in the European Community

CE Mark of Conformity

Prescription Only: Federal Law restricts this device to sale by or on the order of a physician Non Sterile

No User Service Recommended. Refer servicing to qualified ConMed Linvatec service personnel Sterile

Sterile - Sterilized Using EO

STERILE

STERILE

R

Sterile - Sterilized Using Irradiation

Do Not Steam Sterilize

Do Not Sterilize

Do Not Resterilize

Do Not Reuse (for Single Use Only)

STERILIZE

5

Do Not Use Oil

Do Not Use for Plunge Cutting

Eye Protection Required

Biohazard Risk

Do Not Immerse

~

QTY

Quantity

Type B Applied Part

Type BF Applied Part

UL Classification Mark

UL Recognized Components

Rating Fuse

Fuse Location

Alternating Current

Protective Earth Ground

Equipotentiality (Equipment Potential)

Non-Ionizing Electromagnetic Radiation (RF Symbol)

Temperature Limitation

Humidity Limitation

Atmospheric Pressure Limitation

Use by Date

Fragile

This Side Up

Do Not Use if Package is Damaged

Keep Dry

Warning: Corrosive Substance

Warning: Electrical Hazard/High Voltage

Waste Electrical and Electronic Equipment (WEEE) Symbol. Regarding European Union end-of-life of product, indicating separate collection for electrical and electronic equipment Recycle. Batteries contain materials which must be recycled or disposed of properly. The disposal of batteries as municipal waste is prohibited. Dispose or recycle in accordance with your local, state and governmental regulations. In the U.S. call 1-800-237-0169. or outside the U.S. contact your local ConMed Linvatec representative for additional information on battery disposal or recycling. 6

2.0

SYSTEM INSTALLATION AND OPERATION

2.1 Product Description 2.1.1 PowerPro Electric II Modular Handpiece (PRO6100)

1

2 3

4 1.

Attachment Collet-Lock - Twist to release and remove attachments from the handpiece. It is not necessary to twist for insertion of attachment. Simply insert and push attachment to lock in place.

2.

Activation Trigger - Used to activate the handpiece. Depress when the safety/direction lever is in the “forward” or “reverse” position to operate.

3.

Safety/Direction Lever - To operate the handpiece, place in either the “forward” or “reverse” position. Place in the “safe” position prior to connecting or removing any attachment or accessory and during non-use of the handpiece.

4.

Handpiece Cord Receptacle - The handpiece cord connects here to provide power to the handpiece. Uses the MC5057 Handpiece Cord.

7

2.1.2 PowerPro Electric II Oscillator Handpiece (PRO6125)

1 2 3 4 5

6 1.

Blade Locking Collet - Holds and locks the blade in place.

2.

Rotating Head - The rotating head gives the surgeon the ability to position the cutting blade for appropriate surgical access. The oscillator handpiece may contain one of two different rotating heads; either a 4 position, 90 ° indexing head, or an 8 position, 45° indexing head. The 4 position indexing head is no longer manufactured. To position the rotating head, grasp the rotating head, pull it out from the handpiece body, and turn it to the desired position.

3.

Blade Locking Knob - Rotate to open or lock the blade locking collet to insert and lock the blade securely in place.

4.

Activation Trigger - Depress when the safety/direction lever is in the “run” position to operate the handpiece.

5.

Safety/Direction Lever - To operate the handpiece, place in the “run” position. Place in the “safe” position prior to connecting or removing an accessory and during non-use of the handpiece.

6.

Handpiece Cord Receptacle - Connect the MC5057 Handpiece Cord here to provide power to the handpiece.

8

2.1.3 PowerPro Electric II Reciprocator Handpiece (PRO6135)

1 2 3 4

5 The PowerPro Battery Reciprocator Handpiece is designed to accept Hall 5052-058 through -061, 073, -179, -258 through -261, -273, -276 and -279 series blades. Refer to the Hall Catalog for specific blade information. 1.

Blade Collet - Insert a blade here. Also used to rotate the blade to any of four (4) positions at 90° intervals for appropriate surgical access. Blade positioning must be done prior to locking the blade in the collet. To rotate, grasp the blade at the base of the collet and rotate to the desired position.

2.

Blade Locking Knob - Rotate counterclockwise to open the collet to insert a blade. Rotate clockwise to lock the blade securely in place.

3.

Activation Trigger - Used to activate the handpiece. Depress when the safety/direction lever is in the “run” position to operate the handpiece.

4.

Safety/Direction Lever - To operate the handpiece, place in the “run” position. Place in the “safe” position prior to connecting or removing an accessory and during non-use of the handpiece.

5.

Handpiece Cord Receptacle - Connect the MC5057 Handpiece Cord here to provide power to the handpiece.

9

2.2 Assembly/Installation Instructions NOTES: 1.

The controller and connected attachment (drill or reaming) determine the speed and torque of the handpiece. (Refer to section “4.1 Product Technical Specifications”).

2.

A handpiece cord may be disconnected from one handpiece and connected to another without turning off the controller.

3.

These handpieces will not operate by a footswitch.

2.2.1 Handpiece Cord Installation To attach the handpiece cord: 1.

Insert the handpiece cord into the cord receptacle of the handpiece. Push together until fully seated. Pull on the connector to ensure the cable is completely engaged.

To remove the handpiece cord: 1.

Press the latch on the cord and remove the cord from the handpiece.

10

2.

With the red dot on the male end of the handpiece cord connector, insert it into the appropriate handpiece receptacle of the controller (PowerPro Controller shown).

2.2.2 Connecting and Removing Attachments to the Modular Handpiece All attachments for the PowerPro Electric II Modular Handpiece connect/disconnect in the same manner. For more information, refer to the PowerPro Attachment Instruction Manual or the Information Insert supplied with the attachment. To connect an attachment: 1.

Place the safety/directional button/lever in the “safe” position.

NOTE: When placing the handpiece in the “safe” position, ensure the console displays the word “SAFE”. If the console is in the graphical mode, ensure the “safe” symbol displays. 2.

Orient the attachment shaft to the handpiece opening. Insert the shaft and press them until they snap together.

3.

Pull on the attachment to ensure it is completely attached to the handpiece.

To disconnect an attachment: 1.

Twist the attachment collet-lock.

2.

Remove the attachment.

11

2.2.3 Connecting and Removing Blades to the Oscillator Handpiece To attach a blade: 1.

Place the safety/direction button in the “safe” position.

NOTE: When placing the handpiece in the “safe” position, ensure the console displays the word “SAFE”. If the console is in the graphical mode, ensure the “safe” symbol displays.

S

2.

Rotate the blade locking knob in the direction of the arrow to the “OPEN” position. The blade locking collet will disengage.

3.

Align the blade shank to the desired angle with the blade locking collet. Insert the blade.

4.

Blades can be positioned 45° or 90° off the center line in either direction.

5.

Rotate the blade locking knob in the opposite direction of the arrow to lock the blade into place. 12

WARNING: The blade locking knob must be completely closed to hold the blade firmly in place.

!

To remove the blade: 1.

Ensure the safety/direction button is in the “safe” position.

NOTE: When placing the handpiece in the “safe” position, ensure the console displays the word “SAFE”. If the console is in the graphical mode, ensure the “safe” symbol displays.

S

2.

Rotate the blade locking knob to the “OPEN” position. The blade locking collet will disengage.

3.

Remove the blade.

2.2.4 Connecting and Removing Blade to Reciprocator Handpiece To attach a blade: 1.

Place the safety/direction button in the “safe” position.

2.

Rotate the blade locking knob counterclockwise to open the collet.

3.

Completely insert the blade shank.

13

S

4.

The rotating head may be set in any of 4 positions at 90° intervals for the appropriate surgical access. Position the blade to the desired position by grasping the blade at the base of the collet and rotating it to the desired position.

5.

Rotate the blade locking knob clockwise to lock the blade into place.

WARNING: The blade locking knob must be completely closed to hold the blade firmly in place. To remove the blade: 1.

Ensure the safety/direction button is in the “safe” position.

2.

Rotate the blade locking knob counterclockwise and remove the blade.

2.3 Operating Instructions 2.3.1 PowerPro Electric II Modular Handpiece (PRO6100) Operation The PowerPro Electric II Modular handpiece operates in four individual modes: Drill/Ream mode - used for drilling, and wire and pin driving, with a variable speed of 0-1500 rpm with all drilling, and wire and pin driving attachments, and a variable speed of 0-300 rpm with all 5:1 reaming attachments (identified with two of the same colored rings). Oscillating Drill mode - used for drilling around soft tissue. This handpiece will operate at a variable speed of 0-750 rpm with 270° of rotation oscillation. Use only with the drilling attachments. Tap mode - used in conjunction with a tap bit for making threads in holes for placement of screws. Screw mode - used for driving and/or setting screws, with a variable speed of 0-250 rpm. 14

! S

NOTE: Sawing and reaming attachments should not be used in the screw, tap or oscillating drill modes. The individual operating modes are selected through the controller menu options using the handpiece cord button. 1.

Place the handpiece safety/direction button in either the “forward” or “reverse” position.

2.

Access the menu by pressing the handpiece cord button twice.

The controller display will indicate “D/R” “Tap” “Scw” “OscDrill” (D/R - Drill/Ream, Tape, Scw - Screw, OscDrill - Oscillating Drill). The active mode will be blinking.

15

If the controller is set to graphical display mode, the following symbols will display with the active mode blinking.

1.

Press the handpiece cord button until the desired mode is selected. The selected mode will be blinking.

2.

Depress the handpiece trigger to operate the handpiece and activate the selected mode, or wait 2-3 seconds for the menu to time out. The handpiece is now ready for use in the selected operating mode.

Drill/Ream Selection Operation: NOTE: The attachment connected (drill or reaming) determines the speed and torque. 1.

2.

With the safety/direction button in the “forward” position, depressing the trigger operates the handpiece in the clockwise direction as viewed from the rear of the handpiece.The speed is variably controlled by the trigger. With the safety/direction button in the “reverse” position, depressing the trigger operates the handpiece in the counterclockwise direction as viewed from the rear of the handpiece. The speed is variably controlled by the trigger.

F

R

Tap Selection Operation: 1.

With the safety/direction button in the “forward” position, depressing the trigger operates the handpiece 720° clockwise, then 360° counterclockwise (2 turns CW, 1 turn CCW). The speed is variably controlled by the trigger between 0 and 250 rpm.

2.

With the safety/direction button in the “reverse” position, depressing the trigger operates the handpiece in the counterclockwise direction. The speed is variably controlled by the trigger. A brief audible beeping tone indicates “reverse” direction when the handpiece is initially activated.

Screw Selection Operation: 1.

With the safety/direction button in the “forward” position, depressing the trigger operates the handpiece in the clockwise direction. The speed is variably controlled by the trigger between 0 and 250 rpm. Torque is limited to 18 in-lbs.

NOTE: When the torque limit is reached, the handpiece shuts off and the controller displays “Maximum Torque”. To continue, release the trigger, then press again. If the controller is set to graphical display mode, the controller will display:

16