HELMER

i.Series and Horizon Series Operation Manual ver A and B

Operation Manual

73 Pages

Preview

Page 1

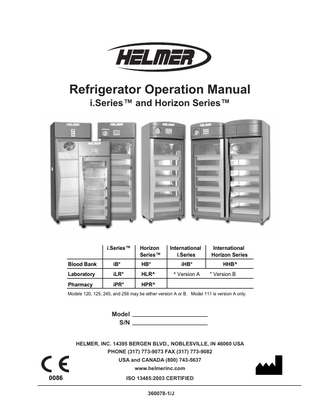

Refrigerator Operation Manual i.Series™ and Horizon Series™

i.Series™

Horizon Series™

International i.Series

International Horizon Series HHB^

Blood Bank

iB*

HB*

iHB*

Laboratory

iLR*

HLR^

^ Version A

Pharmacy

iPR*

HPR^

* Version B

Models 120, 125, 245, and 256 may be either version A or B. Model 111 is version A only.

Model S/N HELMER, INC. 14395 BERGEN BLVD., NOBLESVILLE, IN 46060 USA PHONE (317) 773-9073 FAX (317) 773-9082 USA and CANADA (800) 743-5637 www.helmerinc.com

0086

ISO 13485:2003 CERTIFIED 360078-1/J

Contents

Contents

i

About this manual... iv 1 Working safely... 1 1.1 1.2 1.3 1.4

Understanding safety-related labels... 1 General safety... 1 Electrical safety... 2 Chemical and biological safety... 2

2 Touring the refrigerator... 3 2.1 2.2 2.3

Touring the front and the chamber... 3 Touring the rear... 5 Touring the top... 6

3 Installing the refrigerator... 7 3.1 3.2 3.3 3.4 3.5 3.6 3.7 3.8 3.9

Recording identification information... 7 Selecting an appropriate location... 7 Installing batteries for backup power... 8 Connecting to power... 9 Placing the refrigerator... 10 Preparing the temperature probes... 10 Configuring the refrigerator setpoint... 12 Preparing the chart recorder... 16 Connecting external monitoring devices... 17

4 Preparing the independent alarm monitoring system... 18 4.1 4.2 4.3 4.4 4.5 4.6 4.7 4.8

Touring the HOME screen... 18 Touring the MAIN screen... 20 Viewing current settings... 22 Changing settings... 23 Viewing historical information... 30 Testing alarms... 32 Viewing manufacturer and product information... 36 Getting help... 36

5 Preparing the combined alarm monitoring and control system... 37 5.1 5.2 5.3 5.4

Touring the monitoring and control system... 37 Viewing current settings... 39 Changing settings... 40 Testing alarms... 42

360078-1/J

Refrigerator Operation Manual

ii

6 Configuring and using the refrigerator... 44 6.1 6.2 6.3 6.4 6.5 6.6 6.7 6.8 6.9 6.10 6.11

Moving drawers, shelves, and baskets... 44 Moving slides and brackets... 45 Medication management locking systems... 46 Storing items in the refrigerator... 46 Locking the doors... 46 Turning the light on and off... 46 Understanding normal operation... 47 Identifying active visual alarms... 48 Controlling the sound for audible alarms... 49 Changing the chart paper... 50 Connecting to the internal outlet... 50

7 Maintaining the refrigerator... 51 7.1 7.2 7.3 7.4 7.5

Reviewing the preventive maintenance schedule... 51 Checking and replacing batteries for the monitoring system... 53 Replacing light bulbs... 54 Cleaning the refrigerator... 54 Testing the ground fault circuit interrupter on the internal outlet... 56

8 Understanding and addressing operational issues... 57 8.1 8.2 8.3 8.4 8.5 8.6

Addressing general operation problems... 57 Addressing chamber temperature problems... 58 Addressing alarm activation problems... 59 Addressing testing problems... 61 Addressing condensation problems... 62 Resetting the monitoring system... 62

9 Reference information... 63 9.1 9.2 9.3

Monitoring system screen reference... 63 Alarm reference... 65 Technical Specifications... 65

Rel.i™ Product Warranty... 68

360078-1/J

iv

Refrigerator Operation Manual

About this manual Welcome to the Refrigerator Operation Manual. This section explains the symbols and conventions used in this manual, copyright information about this document, and trademark information for products supplied by Helmer.

Symbols and conventions Several symbols and conventions are used in this manual.

Cautions A Caution is used to call attention to a condition or possible situation that could damage or destroy the equipment or the operator’s work. Cautions are identified as follows:

!

Caution

This is a sample of a caution: Follow all chemical handling and disposal requirements and procedures specified by your organization.

Notes Notes contain additional information about a topic. Notes are used to provide information about how a topic relates to another topic, or background information about a design characteristic. Notes are identified as follows: NOTE

This is a sample of a note: The control display normally shows the air temperature in the unit cooler. This should not be confused with the chamber temperature or the refrigerator setpoint.

Model references Generic references are used throughout this manual to group models that contain similar features. For example, “iHB” refers to all models (iHB111, iHB120, iHB125, iHB245, iHB256) in the international i.Series, while “125 models” refers to all models of that size (iB125, HB125, iHB125, HHB125, iLR125, HLR125, iPR125, HPR125). If a feature or procedure applies to a specific model or a specific voltage, it is stated as such.

Copyright and trademark information Copyright © 2009 Helmer, Inc. Horizon Series™, i.Help™, and Rel.i™ are trademarks of Helmer, Inc. i.Center™ and i.Series™ are registered trademarks of Helmer, Inc. in the United States of America. All other trademarks and registered trademarks are the property of their respective owners. 360078-1/J

1

Working safely

Working safely

This section describes general safety information for installing, using, and maintaining the refrigerator. Your organization may provide additional safety information.

1.1

Understanding safety-related labels The following safety-related labels appear on the refrigerator.

1.2

Caution, risk of danger

Caution, hot surface

Caution, shock hazard

Caution, unlock all casters

Protective earth ground terminal

Earth ground terminal

General safety To avoid injury to yourself and the refrigerator, follow these safety instructions: ► Use the refrigerator for the purpose for which it was designed. Protection provided by the refrigerator may be impaired if the refrigerator is used improperly. ► Do not use the refrigerator if its components are damaged. Notify the appropriate personnel in your organization for guidance regarding usage and maintenance. ► Never attempt to physically restrict any of the moving components. ► Before performing the procedures in this manual, review the specific safety instructions for them. ► Perform only the maintenance described in this manual. Maintenance other than specified in this manual should only be performed by technical service representatives authorized by Helmer.

360078-1/J

1

2

Refrigerator Operation Manual

1.3

Electrical safety !

CAUTION

The refrigerator has the potential of being a shock hazard. Review all safety instructions.

Review the following safety instructions before installing, using, or maintaining the refrigerator: ► Inspect all electrical equipment and address any problems prior to installation. ► Avoid removing covers from the refrigerator unless instructed to do so. ► Use only the power cords supplied with the refrigerator. ► Avoid using multi-plug power strips. Connect directly to properly grounded wall outlets.

1.4

Chemical and biological safety !

CAUTION

In addition to the instructions included in this manual, follow all chemical handling and disposal requirements and procedures specified by your organization.

Chemical handling and disposal requirements for your organization may include the following: ► Use of appropriate protective equipment when cleaning the refrigerator ► Use of specific cleansers and cleaning supplies ► Appropriate handling and disposal of materials that are infectious, toxic, pathological, radioactive, or otherwise biologically or environmentally harmful. ► Notification of appropriate chemical and biological safety personnel when handling or disposing of materials that are infectious, toxic, pathological, radioactive, or otherwise biologically or environmentally harmful.

!

CAUTION

360078-1/J

Before sending parts to Helmer or your distributor for service or repair, decontaminate them as appropriate. Any items that have not been decontaminated appropriately will not be accepted. Documentation stating that the contents are not contaminated and are safe to handle must accompany all returns. Contact Helmer or your distributor for decontamination instructions and a return authorization number.

2

Touring the refrigerator

Touring the refrigerator

Congratulations on your purchase of a Helmer refrigerator. Helmer refrigerators provide the most secure temperature controlled environments for your valuable blood and life science products. This section gives a brief overview of the components of the refrigerator. Note that some components vary by options selected at the time of purchase.

2.1

Touring the front and the chamber

A

G

B C

H

D

E

I

J

K

F

L Left: View of front of refrigerator (HB120 model shown). Top right: Detail of bezel area of HHB, HLR, or HPR model. Bottom right: Detail of standard and slide.

360078-1/J

3

4

Refrigerator Operation Manual Label A

B C D

E

F

G H

I J

Description Chart recorder (Optional feature - may not appear on the refrigerator) Door lock Unit cooler Upper probe bottle with temperature monitoring probe and chart recorder probe (included if chart recorder is installed) Drawer

Lower probe bottle with temperature probe (hidden) (Applies to iB, iHB, iLR, and iPR models, but not 111 models) Independent monitoring system (iB, HB, iHB, iLR, and iPR models) Combined alarm monitoring and control system (HHB, HLR, and HPR models) Light Standard

K L Not shown

Slides Casters Shelf (iLR, iPR, HLR, and HPR models)

Not shown

Half shelf (applies to iLR, iPR, HLR, and HPR models that are not 111 models)

Not shown Not shown

Basket (iLR, iPR, HLR, and HPR models) Access port (iLR, iPR, HLR, and HPR models)

Not shown Not shown

Pole mast (applies to iLR and HLR models with chromatography option) Internal outlet (applies to iLR, iPR, HLR, and HPR models that are 115 V).

Not shown

Optional adapter kits for medication dispensing locks.

360078-1/J

Function Records seven days of chamber temperature information Prevents unauthorized access to the chamber Circulates and cools air in the chamber Collects temperature data from the top of the chamber

Holds and organizes items stored in refrigerator. Included in standard configuration of Blood Bank and Pharmacy models. Collects temperature data from the bottom of the chamber

Displays current status information and provides an interface to change alarm setpoints Displays current status information, provides an interface to change alarm setpoints, and controls the chamber temperature Illuminates the chamber Supports the slides and enables drawers, shelves, and baskets to be moved up or down Supports the drawers and baskets Used to move the refrigerator and lock it into position Holds and organizes items stored in refrigerator. Included in standard configuration of Laboratory models. Holds and organizes items stored in refrigerator. Included as part of the Chromatography option, which is available for iLR and HLR models (except 111 models). Holds and organizes items stored in refrigerator Allows user-supplied external probes to enter the chamber from the side. The number and location of ports varies by model. Holds equipment used for chromatography and other laboratory processes. Provides a separate power source inside the refrigerator. Included as part of the Chromatography option, which is available for iLR and HLR models (except 111 models). Facilitates patient care. Call Helmer or your distributor for specific system information.

Touring the refrigerator

2.2

Touring the rear A

I E

B

J K

C D

F G

H

Left: View of rear of refrigerator (iB245 model shown). Right: Detail of side of electrical box. Label A B C D E

Description Condenser grill Drain line Condensate evaporator Water evaporation tray Electrical box

F G

Power cord Product Specification label

H

Circuit breakers (Applies to 230 V models) RS232 COM port (Optional feature for iB, iHB, iLR, and iPR models) Flash port (iB, HB, iHB, iLR, and iPR models) Remote alarm interface

I

J

K

Function Air intake for the compressor Directs condensate to the water evaporation tray Evaporates water in the water evaporation tray Contains condensate from the condensing unit On iB, HB, iHB, iLR, and iPR models, the electrical box contains the temperature controller, which controls the temperature of the chamber. Provides AC power to the refrigerator Provides the model number, serial number, and electrical requirements for the refrigerator Prevents current overload Provides data to external software. Contact Helmer or your local distributor for software availability. Allows a flash card to be inserted to change the language used for the monitoring software and to update the software Provides a dry contact connection to external central alarm systems

360078-1/J

5

6

2.3

Refrigerator Operation Manual

Touring the top Components on top of the refrigerator vary slightly by model. For 111 models, a service cover covers the components, and an access panel provides access to the monitoring system battery backup.

F

A B C D E Components on the top of the refrigerator (various models shown). Label A B C D

E

F

360078-1/J

Description Condenser Condenser probe (iB, iHB, iLR, and iPR models) Compressor Monitoring system battery backup (iB, HB, iHB, iLR, and iPR models) Monitoring system battery backup (HHB, HLR, HPR, and HLR models) Access port (Number and location vary by model)

Function Cools the refrigerant to liquid form Collects temperature data from the condenser discharge line Increases pressure of the refrigerant Provides power to the monitoring system if power to the refrigerator is lost

Provides power to the monitoring system if power to the refrigerator is lost

Allows temperature probes to enter the chamber from the top

3

Installing the refrigerator

Installing the refrigerator

7

This section explains how to record identifying information, select an appropriate location, and install the refrigerator. Packaging materials include instructions for the proper way to move the refrigerator. Before using the refrigerator, remove all packaging materials.

3.1

Recording identification information For easy reference, write the model and serial numbers on the front of this manual. Many of the procedures in this manual vary by model, and both model and serial numbers are needed to provide efficient service. Product information appears in two places on the refrigerator: on the Product Specification label, located on the rear of the refrigerator below the electrical box, and on a label located in the chamber on the upper side of the right wall. REF SN VER

IPR245 000000 B

A B C

www.helmerinc.com

D

REF

IPR245

SN

000000 B

VER

Pharmacy Refrigerator Weight 800 lb

/ 363 kg

2009

E

www.helmerinc.com Noblesville, IN USA VOLT HZ Amps

115 V 60 11.5 A

F 0086

G

Sample product identification labels. Left: Label (located in the chamber). Right: Product Specification label (located on the rear). Label A B C D E F G

3.2

Description Model Serial number (S/N) Version WEEE symbol. For more information, see Section 9.3.5, “Energy conservation and regulatory compliance.” Date of manufacturing Power requirements CE symbol. For more information, see Section 9.3.5, “Energy conservation and regulatory compliance.”

Selecting an appropriate location To optimize refrigerator operation, the location for the refrigerator must meet the following requirements: ► Has a grounded outlet meeting the electrical requirements as listed on the Product Specification label ► Is clear of direct sunlight, high temperature sources, heating vents, and air conditioning vents ► Has a minimum of 8 inches (20 cm) of space above the refrigerator; and a minimum of 3 inches (8 cm) of space behind the refrigerator for ventilation ► Has a level floor so the doors self-close and the chamber drains properly ► Meets the limits specified for ambient temperature and relative humidity. For more information, see Section 9.3.4, “Operating conditions.” 360078-1/J

8

Refrigerator Operation Manual

3.3

Installing batteries for backup power The monitoring system and the chart recorder (if installed) each have a battery backup system, enabling them to continue operating if power to the refrigerator is lost. With backup batteries installed, the monitoring system can continue operating if power to the refrigerator is lost. However, the monitoring system cannot start with batteries alone: the refrigerator must be connected to AC power. Battery life varies by battery manufacturer and the voltage level remaining on the batteries. Providing no battery-related alarms are active, backup power for both the monitoring systems is provided for up to two hours, and for the temperature chart recorder, up to 14 hours. For more information about battery-related alarms, see Section 9.2, “Alarm reference.” For more information about preparing the chart recorder, see Section 3.8, “Preparing the chart recorder.”

3.3.1

Installing batteries for the monitoring system The battery holder is located on the top of the refrigerator behind the monitoring system. For 111 models, a service cover covers the components, and an access panel provides access to the monitoring system battery backup.

Battery holders. Left: Independent alarm monitoring system. Right: Combined alarm monitoring and control system. The quantity and type of batteries for the monitoring system varies by model: Models iB, HB, iHB, iLR, and iPR

Monitoring system Independent alarm monitoring system

HHB, HLR, and HPR

Combined alarm monitoring and control system

Battery requirements Six non-rechargeable 1.5 V D-cell alkaline (or equivalent) batteries One non-rechargeable 9 V lithium (or equivalent) battery

Refrigerator models with an independent alarm monitoring system are shipped from the factory with six batteries. Five batteries are installed, and one is taped next to the battery holder. Models with the combined alarm monitoring and control system are shipped with the battery taped next to the battery holder.

!

CAUTION

360078-1/J

Before installing or replacing batteries, disconnect power to the refrigerator to eliminate the potential of electric shock and injury from surrounding components.

Installing the refrigerator

3.4

Connecting to power

9

When the power is connected for the first time, the compressor cycles frequently to achieve normal operating temperature. This may cause an alarm to sound. When normal operating temperature is reached, the condensing unit cycles normally and automatically clears the alarm. For iB, HB, iHB, iLR, and iPR models, each time power is connected, it is necessary to select the language used to display text on the monitoring system. The monitoring system can store two languages, which are loaded from the flash memory card. By default, English is loaded and selected. To use a language other than English, it must first be loaded from the flash memory card to be stored on the monitoring system. If a flash memory card is not included with the refrigerator, your distributor may have loaded the appropriate languages prior to shipment. For more information about available languages and instructions for loading them, refer to the documentation provided with the flash memory card or contact Helmer or your local distributor.

!

CAUTION

As with any electronic device, before connecting to power, make sure the refrigerator is at room temperature.

To connect to power (iB, HB, iHB, iLR, and iPR models) 1 2

3 4 5

Confirm the refrigerator is at room temperature. Plug the power cord into a grounded outlet that meets the electrical requirements that appear on the Product Specification label on the refrigerator. The monitoring system lights up and the SYSTEM OPTIONS screen appears with the text displayed in the most recently selected language. The Language setting is highlighted, and the language currently being used is selected. For more information about the monitoring system, see Section 4, “Preparing the independent alarm monitoring system.” If an alarm sounds, mute the alarm by pressing the MUTE button. For more information, see Section 6.9.1, “Muting audible alarms for a variable amount of time.” To select a different language, press the INC or DEC button until the desired language appears. Press the HOME button. The HOME screen appears. Display text for all screens changes to the selected language.

To connect to power (HHB, HLR, and HPR models) 1 2

3

Confirm the refrigerator is at room temperature. Plug the power cord into a grounded outlet that meets the electrical requirements that appear on the Product Specification label on the refrigerator. The temperature appears on the display. For more information about the monitoring system, see Section 5, “Preparing the combined alarm monitoring and control system.” If an alarm sounds, mute the alarm by pressing the Down Arrow button. For more information, see Section 6.9.2, “Muting audible alarms.”

To connect the internal outlet to power NOTE

This section applies if the refrigerator has an internal outlet installed.

► Plug the power cord for the internal outlet into a grounded outlet that meets the electrical requirements that appear on the Product Specification label on the refrigerator.

360078-1/J

10

Refrigerator Operation Manual

3.5

Placing the refrigerator The refrigerator is equipped with locking swivel casters, enabling it to be rolled and locked into place.

!

CAUTION

► Do not use the water evaporation tray, located on the rear of the refrigerator, as a handle.

!

CAUTION

► The water evaporation tray may be hot. Avoid contact with the tray while moving the refrigerator. ► To prevent tipping, ensure the casters are unlocked and the doors on the refrigerator are closed before moving the refrigerator.

Procedure 1 2 3 4

3.6

Ensure all the casters are unlocked and the doors are closed. Roll the refrigerator into place. Lock the casters. Ensure the refrigerator is level so the doors self-close and the refrigerator drains properly.

Preparing the temperature probes Temperature probes monitor the temperature of the chamber. The number and location of the temperature probes varies by model. In addition to using the probes installed by Helmer, additional external probes may be used. Additional probes access the chamber through the same holes as the standard probes, and are immersed in the same bottles. The probe can also be inserted through a side access port (availability varies by model). For each probe bottle, the following is needed. ► Approximately 4 oz (120 ml) of product simulation solution (not provided). Solution is a 10:1 ratio of water to glycerol (glycerin).

Left: Probe bottle with temperature and chart recorder probes (iB245 model shown). Middle: Access port (circled) as seen from the top of the refrigerator. Right: Access port on side of refrigerator. The number and location of ports varies by model.

360078-1/J

Installing the refrigerator

To install an additional external probe through the top 1 2 3 4

On the top of the refrigerator, peel back the putty to expose the access port. Insert the third-party probe through the access port into the chamber. Insert the probe into the bottle. Replace the putty, ensuring a tight seal.

To install an additional external probe through the side 1 2 3 4

On the side of the refrigerator, remove the interior and exterior plugs to expose the access port. Insert the third-party probe through the access port into the chamber. Insert the probe into the bottle. Replace the plugs, ensuring a tight seal.

To fill a temperature probe bottle

!

CAUTION 1 2 3 4 5 6 7

Temperature probes are fragile. Handle them with care.

Remove all probes from the bottle. Remove the bottle from the bracket by pulling the top of the bottle upward. Unscrew the cap from the bottle. Fill the bottle with approximately 4 oz (120 ml) of the product simulation solution. Screw the cap on the bottle, ensuring it fits tightly to minimize evaporation. Place the bottle in the bracket by pushing the bottle downward. Place the probes in the bottle, immersing them at least 2 inches (5 cm) in the solution.

360078-1/J

11

12

3.7

Refrigerator Operation Manual

Configuring the refrigerator setpoint The refrigerator setpoint is used by the temperature controller to adjust the chamber temperature of the refrigerator. If the chamber temperature goes above the refrigerator setpoint, the temperature controller activates the compressor. The temperature controller senses the temperature in the unit cooler through a probe. The temperature in the unit cooler typically varies from the temperature in the chamber, so an offset is added to determine the chamber temperature. The temperature in the unit cooler is combined with the offset to establish the refrigerator setpoint. NOTE

3.7.1

The probes in the bottles are connected to the monitoring system and sense the chamber temperature. They do not control the refrigerator setpoint.

Determining the current refrigerator setpoint Before determining what the value is, confirm the following is true: ► The refrigerator has run for at least 24 hours to stabilize the chamber temperature. ► The chamber temperature is not fluctuating because of excessive door openings and closings. ► The refrigerator has been placed according to the requirements in Section 3.2, “Selecting an appropriate location.” ► Preventive maintenance has been completed according to the schedule in Section 7.1, “Reviewing the preventive maintenance schedule.” ► Troubleshooting items associated with the chamber temperature have been reviewed. For more information, see Section 8, “Understanding and addressing operational issues.” The following is needed to complete this procedure: ► Thermometer. The thermometer must be independent of the refrigerator, and be calibrated and traceable according to the policy of the National Institute of Standards and Technology (NIST), or to the equivalent national or international measuring equipment standards as identified in regulations for your organization. ► Tape. This is used to secure the probe to the thermometer.

360078-1/J

Installing the refrigerator

13

To determine the current refrigerator setpoint 1 2 3 4 5

6 7 8

3.7.2

Remove all probes from the upper probe bottle. Unscrew the cap from the bottle. Tape the independent thermometer to the temperature probe, and replace them in the bottle so their ends are immersed at least 2 inches (5 cm) in the solution. On the independent thermometer, monitor the temperature for about 10 minutes to determine an approximate range. From the range, calculate the approximate average temperature. This is the current refrigerator setpoint. For example, if the temperature were to fluctuate between 4.3 °C and 4.7 °C, the current refrigerator setpoint would be 4.5 °C. Remove the thermometer and probe from the bottle and remove the tape from them. Screw the cap on the bottle, ensuring it fits tightly to minimize evaporation. Place the probes in the bottle, immersing them at least 2 inches (5 cm) in the solution.

Changing the refrigerator setpoint At the factory, the refrigerator setpoint is set at 4.0 °C. Change the refrigerator setpoint in the following circumstances: ► If your organization requires a normal chamber temperature different from 4.0 °C. ► If the normal temperature in the chamber is too high or too low, even after all appropriate preventive maintenance and troubleshooting tasks are completed. Before changing the refrigerator setpoint, confirm the following is true: ► The refrigerator has been placed according to the requirements in Section 3.2, “Selecting an appropriate location.” ► Preventive maintenance has been completed according to the schedule in Section 7.1, “Reviewing the preventive maintenance schedule.” ► Troubleshooting items associated with the chamber temperature have been reviewed. For more information, see Section 8, “Understanding and addressing operational issues.”

360078-1/J

14

Refrigerator Operation Manual

3.7.2.1

Changing the refrigerator setpoint on the independent temperature controller NOTE

This section applies to iB, HB, iHB, iLR, and iPR models.

The temperature controller is located in the electrical box on the rear of the refrigerator. A screwdriver is needed to remove the cover from the electrical box.

Left: Temperature controller in the electrical box (circled). Right: Temperature controller display and buttons.

Procedure

!

CAUTION 1 2

3

!

Determine what the normal temperature for the chamber should be. The factory has determined the normal temperature to be 4.0 °C, but it may be different for your organization. Determine how much the refrigerator setpoint needs to be changed to reach the desired normal temperature. The adjustment amount should be about half of the difference. For example, if the desired normal temperature is 4.0 °C, but the current setpoint is 4.5 °C, then the difference is -0.5 °C, and the setpoint would need to be adjusted -0.3 °C. On the rear panel, use the screwdriver to remove the cover from the electrical box and expose the temperature controller.

CAUTION 4

Do not change the refrigerator setpoint to a value outside the temperature control range. For more information, see Section 9.3.4, “Operating conditions.”

Removing the cover exposes users to the risk of electric shock. Use appropriate safety precautions.

On the temperature controller, access the setpoint adjustment function by pressing and holding the button on the left (*). The control display shows a reference temperature, which is typically higher than the chamber temperature.

360078-1/J

Installing the refrigerator 5

6 7

3.7.2.2

15

While holding the button on the left (*), use the middle and right buttons to adjust the refrigerator setpoint the amount determined in step 2. ► Press and release the middle button once to decrease by 0.1 °C. ► Press and release the right button once to increase by 0.1 °C. When finished adjusting the setpoint, release all the buttons. The setpoint is changed. Replace the cover on the electrical box.

Changing the refrigerator setpoint on the combined temperature controller NOTE

This section applies to HHB, HLR, and HPR models.

For more information about the combined temperature controller, see Section 5, “Preparing the combined alarm monitoring and control system.”

Procedure

!

CAUTION 1 2

3 4 5

6 7

Do not change the refrigerator setpoint to a value outside the temperature control range. For more information, see Section 9.3.4, “Operating conditions.”

Determine what the normal temperature for the chamber should be. The factory has determined the normal temperature to be 4.0 °C, but it may be different for your organization. Determine how much the refrigerator setpoint needs to be changed to reach the desired normal temperature. For example, if the desired normal temperature is 4.0 °C, but the current setpoint is 4.5 °C, then the setpoint would need to be adjusted -0.5 °C. On the monitoring system, change to Control mode by pressing and releasing the SEL button until the CONTROL lamp is lit. Press and hold the SET button. The control display shows a reference temperature, which is typically higher than the chamber temperature. While holding the SET button, use the up arrow and down arrow buttons to adjust the refrigerator setpoint the amount determined in step 2. ► Press and release the down arrow button once to decrease by 0.1 °C. ► Press and release the up arrow button once to increase by 0.1 °C. When finished adjusting the setpoint, release all the buttons. The setpoint is changed. Return to Monitor mode by pressing and releasing the SEL button until the MONITOR lamp is lit.

360078-1/J

16

3.8

Refrigerator Operation Manual

Preparing the chart recorder NOTE

This section applies if the refrigerator has a chart recorder installed.

Complete the following tasks to prepare the chart recorder for use: ► Installing the backup battery ► Adding paper ► Calibrating the chart recorder to match the upper chamber temperature. For more information and instructions, refer to the Temperature Chart Recorder Operation and Service Manual for your refrigerator.

3.8.1

Accessing the chart recorder Use the following procedure to access the chart recorder.

To open the chart recorder door

► For iB, iLR, and iPR models (except 111 models): Open the door by pressing and releasing it. ► For HB, iHB, HHB, HLR, HPR models and 111 models: Pull the door open.

Opening the chart recorder door. Left: iB, iLR, and iPR models (except 111 models). Right: HB, iHB, HHB, HLR, HPR models, and 111 models.

3.8.2

Setting the timer to change the chart paper NOTE

This section applies to iB, iHB, iLR, and iPR models.

The independent alarm monitoring system provides a timer to alert users when the chart paper needs to be changed. For more information and instructions to enable or disable this alarm, see Section 4.4.6, “Changing the setting for the chart paper timer.”

360078-1/J