Pre-Use Checkout Guide

2 Pages

Preview

Page 1

Series 3 software

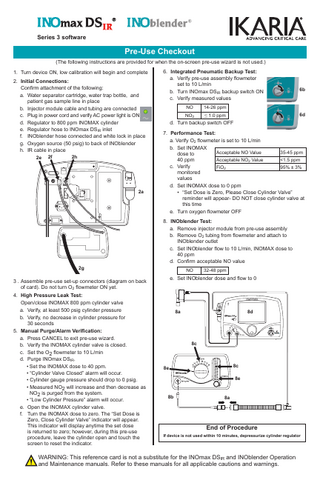

Pre-Use Checkout (The following instructions are provided for when the on-screen pre-use wizard is not used.) 1. Turn device ON, low calibration will begin and complete 2. Initial Connections: Confirm attachment of the following: a. Water separator cartridge, water trap bottle, and patient gas sample line in place b. Injector module cable and tubing are connected c. Plug in power cord and verify AC power light is ON d. Regulator to 800 ppm INOMAX cylinder e. Regulator hose to INOmax DSIR inlet f. INOblender hose connected and white lock in place g. Oxygen source (50 psig) to back of INOblender h. IR cable in place 2e

2f

2h

2a

2g

6. Integrated Pneumatic Backup Test: a. Verify pre-use assembly flowmeter set to 10 L/min b. Turn INOmax DSIR backup switch ON c. Verify measured values NO

6d

≤<

7. Performance Test: a. Verify O2 flowmeter is set to 10 L/min b. Set INOMAX Acceptable NO Value 35-45 ppm dose to 40 ppm Acceptable NO2 Value <1.5 ppm c. Verify FiO2 95% ± 3% monitored values d. Set INOMAX dose to 0 ppm • “Set Dose is Zero, Please Close Cylinder Valve” reminder will appear- DO NOT close cylinder valve at this time e. Turn oxygen flowmeter OFF 8. INOblender Test: a. Remove injector module from pre-use assembly b. Remove O2 tubing from flowmeter and attach to INOblender outlet c. Set INOblender flow to 10 L/min, INOMAX dose to 40 ppm d. Confirm acceptable NO value NO

32-48 ppm

e. Set INOblender dose and flow to 0

3 . Assemble pre-use set-up connectors (diagram on back of card). Do not turn O2 flowmeter ON yet. 4. High Pressure Leak Test: Open/close INOMAX 800 ppm cylinder valve a. Verify, at least 500 psig cylinder pressure b. Verify, no decrease in cylinder pressure for 30 seconds 5. Manual Purge/Alarm Verification: a. Press CANCEL to exit pre-use wizard. b. Verify the INOMAX cylinder valve is closed. c. Set the O2 flowmeter to 10 L/min d. Purge INOmax DSIR. • Set the INOMAX dose to 40 ppm. • “Cylinder Valve Closed” alarm will occur. • Cylinder gauge pressure should drop to 0 psig. • Measured NO2 will increase and then decrease as NO2 is purged from the system. • “Low Cylinder Pressure” alarm will occur. e. Open the INOMAX cylinder valve. f. Turn the INOMAX dose to zero. The “Set Dose is Zero, Close Cylinder Valve” indicator will appear. This indicator will display anytime the set dose is returned to zero; however, during this pre-use procedure, leave the cylinder open and touch the screen to reset the indicator.

14-26 ppm

≤ 1.0 ppm d. Turn backup switch OFF NO2

6b

8a

8d

8c

8c

8e

8e

8b

8a

End of Procedure If device is not used within 10 minutes, depressurize cylinder regulator

WARNING: This reference card is not a substitute for the INOmax DSIR and INOblender Operation and Maintenance manuals. Refer to these manuals for all applicable cautions and warnings.

Pre-Use Assembly 1

1. O2 Flowmeter 2. O2 Tubing 3. 15M x 4.5 mm Adapter 4. 22M / 15F x 22M / 15F Adapter 5. Injector Module 6. 300 mm of 22 mm hose 7. Patient Gas Sample Line with Nafion 8. Gas Sample Tee 9. Injector Module Electrical Cable 10. NO/N2 Injector Tube

10 LPM Off 7 3

2

5

4

6

8 10

9

“88” Cylinder Duration

FiO2 Dilution Set FiO2

5 L/min

10 L/min

20 L/min

40 L/min

5

39 Days

19.5 Days

9.8 Days

4.9 Days

10

19.4 Days

9.7 Days

4.8 Days

2.4 Days

20

9.6 Days

4.8 Days

2.4 Days

1.2 Days

40

4.7 Days

2.3 Days

1.2 Days

14 Hours

80

2.2 Days

1.1 Days

13.3 Hours 6.6 Hours

INOMAX Dose (ppm)

INOMAX Dose (ppm)

FLOW .21

.40

.60

.80

1.00

10

0.21

0.40

0.59

0.79

0.99

20

! 0.20

0.39

0.59

0.78

0.98

40

! 0.20

0.38

0.57

0.76

0.95

80

! 0.19

0.36

0.54

0.72

0.90

Actual FiO2

* All calculations in the table above are based on a full cylinder, 138 bar (2000 psig), 1963 liter “88” cylinder, with a cylinder change at 14 bar (200 psig). The figures are calculated based on a total continuous breathing circuit gas flow and a cylinder conversion factor of 14.2 liters per bar/0.98 liters per psig. • INOMAX flow = [Desired dose × total ventilator flow] ÷ [Cylinder concentration - desired dose] • Cylinder volume = Cylinder conversion factor × cylinder pressure (bar/psig) • Cylinder duration (hours) = (Cylinder volume ÷ INOMAX flow rate) ÷ 60

INO Therapeutics LLC d/b/a Ikaria, Hampton, NJ 08827-9001 USA For assistance contact Technical Support 877-566-9466.

20570 Rev 02

2014-08