Integra LifeSciences Corporation

Integra Non-Sterile Family Group 1 Devices Cleaning, Sterilization and Inspection Instructions

110 Pages

Preview

Page 1

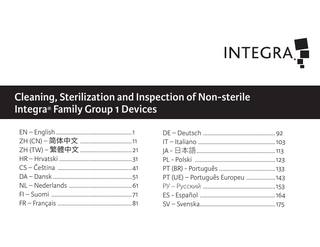

Cleaning, Sterilization and Inspection of Non-sterile Integra® Family Group 1 Devices EN – English...1 ZH (CN) – 简体中文 ...11 ZH (TW) – 繁體中文...21 HR – Hrvatski...31 CS – Čeština ...41 DA – Dansk...51 NL – Nederlands ...61 FI – Suomi ...71 FR – Français ...81

DE – Deutsch ...92 IT – Italiano ...103 JA - 日本語...113 PL - Polski ...123 PT (BR) - Português...133 PT (UE) – Português Europeu ...143 РУ – Русский ...153 ES - Español ...164 SV – Svenska...175

This page is intentionally left blank.

EN – English

Cleaning, Sterilization and Inspection of Non-sterile Integra® Family Group 1 Devices 1. DESCRIPTION AND INTENDED USE Integra LifeSciences Corporation reusable surgical device sets consist of various configurations of orthopedic devices in cases or trays. The sets are constructed from durable metal and/or plastic materials. The reusable surgical devices are intended for use in orthopedic surgical procedures according to the Instructions for Use and Surgical techniques that accompany Integra® implants. Reusable devices are to be cleaned, inspected, and sterilized between uses.

2. INSPECTION BEFORE USE Reusable Devices can be used indefinitely if not damaged or worn. Device systems should be cleaned and then inspected between uses. DO NOT use broken or damaged devices. Contact Integra for repair or replacement of damaged items. If damage or malfunction is detected, the device should not be used. Disposable Devices should be disposed of according to hospital procedure and any applicable laws.

1

EN – English

3. PREPARATION/GENERAL GUIDANCE FOR CLEANING Verify that all instruments required for use are present in the case. For Manual Cleaning, devices should be grouped according to similar metals before subsequent processing in order to prevent galvanic corrosion. In addition, it is not recommended to use chloride containing cleaning solutions since its use has been linked to corrosion of metallic instruments, especially stainless steel. Please also note the following: •

Disinfect and clean devices immediately after use in order to avoid device encrustations.

•

Solutions used for cleaning must always be prepared in accordance with the manufacturer’s instructions.

•

Never use metal brushes or metal sponges for manual cleaning.

•

Use a suitably sized non-metallic bristle brush for cleaning lumens, cannulations, blind holes, and cavities, making sure that every part of the inner surface can be properly accessed.

•

Clean jointed instruments in closed as well as open positions.

•

Disassemble instruments as far as possible before cleaning.

•

Be sure to arrange the items so that the water can easily flow out of cannulations, blind holes, and cavities.

2

EN – English •

For instruments with long or narrow lumens, standard processing should be used only if the disinfectant can flow easily through the lumens and safe rinsing is guaranteed.

•

The cases/trays used for cleaning must always be loaded correctly to ensure proper cleaning.

•

After cleaning, check instruments for cleanliness (visible dirt). This especially applies to cannulated instruments or those with blind holes and crevices.

•

To ensure proper instrument functioning, verify that all movable parts have been thoroughly cleaned.

•

Pay special attention to slots, ratchets, joints and box locks, narrow lumens, blind holes, and other areas that are hard to access.

•

Demineralized or distilled water should be used for the final rinse.

4. MANUAL CLEANING INSTRUCTIONS The following steps should be completed in sequence. Please note that all instructions provided are as validated by Integra LifeSciences. Depending upon the detergent selection, minimum processing times and temperature settings may need to be adjusted for optimal processing:

3

EN – English a) Prepare a neutral pH enzymatic detergent as per the manufacturer’s recommendation (e.g. Enzol® prepared at 1 oz. per gallon of lukewarm deionized water). b) Disassemble instruments to lowest level. c) Rinse instruments under lukewarm running water to remove all gross soil. Use a soft bristled brush to aid in the brushing. Agitate the instruments under the running water. Agitation includes actuating all movable parts such as opening and closing hinges and moving the instruments around under the running water. Use a clean soft bristled brush and/or pipe cleaner to brush and aid in the rinse for the exterior and interior of instruments. Use a syringe to flush any lumens. d) Fully immerse each device in the prepared detergent and allow it to soak for a minimum of two minutes. e) After soaking the devices, scrub them using a soft bristle brush and circular strokes to remove any visible soil. Pay particular attention to all the areas where the soil could be imbedded (i.e. grooves, crevices, lumens, blind holes). Use a syringe to flush lumens and a pipe cleaner to clean lumens and holes. Perform cleaning under the surface of the prepared detergent solution to limit aerosolization of the cleaning fluid and soil, as well as for worker and environmental safety.

4

EN – English f) Rinse devices in lukewarm water for a minimum of one and a half (1.5) minutes to remove any detergent residuals. In accordance with Step C, agitate the instruments under the running water, being sure to actuate all movable parts, and using a soft bristled brush for internal and exterior device surfaces. g) Prepare a neutral pH enzymatic detergent (eg. Enzol) in a sonicator, as per the manufacturer’s recommendation using lukewarm water. Fully immerse the devices in the detergent and sonicate for 10 minutes. h) After sonication, rinse the devices with running lukewarm water (use the highest grade of water available, distilled or deionized water is recommended) for three (3) minutes. Agitate the instruments under the running water, being sure to actuate all movable parts, and using a clean soft bristled brush for internal and exterior device surfaces, and flush all lumens with a syringe. i)

Dry the devices using a clean lint free cloth and visually examine to determine if all adherent visible soil has been removed.

j)

Repeat the above cleaning procedure, if visible debris is detected.

5

EN – English

5. AUTOMATED CLEANING PROCEDURE The following steps should be completed in sequence: a) Prepare an enzymatic detergent using lukewarm deionized water as per the manufacturer’s recommendation. b) Fully immerse the devices and allow to soak for a minimum of two (2) minutes. c) Following the soak time, flush any lumens of the device using a syringe. d) Rinse the devices under lukewarm running deionized water for a minimum of one (1) minute, while agitating the devices. Agitation includes actuating all movable parts, such as opening and closing hinges and moving the devices around under the running water. e) Use a clean soft bristled brush and/or pipe cleaner to brush and aid in the rinse for the exterior and interior of device components. Use a syringe to flush any lumens. f) Place the devices back into the designated locations of the case/tray, and load the case/tray set into an automated washer (Steris 444 or equivalent).

6

EN – English g) The washer cycle parameters are as follows: Phase Pre-Wash Enzyme Wash Wash Rinse

Recirculation Time (Min.) 02:00 01:00 02:00 10:00

Water Temperature Cold Water Hot Water 60°C Hot Water*

Detergent NA Enzymatic Cleaner Neutral Detergent NA

* Note: The highest grade of water available should be used during the final rinse cycle. h) After washing, dry the devices using a clean lint free cloth and visually examine to determine if all adherent visible soil has been removed. i) Repeat the cleaning procedure if visible debris is detected.

6. INSPECTION AFTER CLEANING Following cleaning, the instruments must be macroscopically clean, i.e. free from visible dirt or deposits. All movable parts, working tips and blades (scissors) should be inspected with particular care. 7

EN – English

7. STERILIZATION Integra LifeSciences Corporation has completed sterilization validations for our instrument sets. The validation protocols were performed in accordance with

AAMI ST 79:2010 Steam Sterilization and Sterility Assurance in Health Care and AAMI ST77-2006 Containment Devices for Reusable Medical Device Sterilization All testing was done using the overkill approach with Geobacillus stearothermophilus spores. The results confirmed 106 Sterility Assurance Level (SAL) for the sets when using the recommended cycles. In accordance with our validation results, the following cycles are recommended for wrapped goods:

8

EN – English Recommended Sterilization Parameters Device Set System Axial Cannulated Cutters Capture™ High Torque 1 (3 Sets) Movement® Great Toe 1 NuGrip® (RADEL Case) PyroSphere® & TMT PyroDisk® Silicone PIP Tarsalis (Normed) 1 TFS Forefoot/Tarsalis Gen I 1 TFS Rearfoot Gen I* 1 Integra Silicone CGT Instrument Set 1 Integra Silicone FGT Instrument Set 1 Integra Silicone LMP Instrument Set 1

Pre-vacuum 132°C/4 Min.

Gravity Pre-vacuum2 Pre-vacuum2 132°C/15 Min. 134°C/3 Min. 134°C/18 Min. Dry Time Requirements (minutes)

40

30

40

40

30

30

30

30

* Dry time data for the shared cells is based upon the highlighted sterilization challenge set for the device set family grouping (#1). 1 This system does not have a registered CE mark. 2 134°C setting is for use outside the USA only.

9

EN – English

Authorized Representative:

EC REP

Integra LifeSciences Services Integra LifeSciences Corporation Immeuble Séquoïa 2 97 allée Alexandre Borodine Parc Technologique de la Porte des Alpes 69800 Saint Priest – France Phone: +33 (0) 4 37 47 59 10

Manufactured by: Ascension Orthopedics, Inc. 11101 Metric Blvd Austin, TX 78758 USA Phone: 1(800) 654-2873 Fax: 1(888) 980-7742 integralife.com n

Made in the U.S.A.

0123

2797 Integra, the Integra logo, Movement, NuGrip, PyroSphere and PyroDisk are registered trademarks of Integra LifeSciences Corporation or its subsidiaries in the United States and/or other countries. Capture is a trademark of Integra LifeSciences Corporation or its subsidiaries. Enzol is a trademark of Johnson and Johnson. ©2020 Integra LifeSciences Corporation. All rights reserved. Printed in the USA LC-04-0000-0011 Rev D 2020-07 0532739-3

10