Integra LifeSciences Corporation

Subtalar MBA Implant System Cleaning and Sterilization Instructions

1 Page

Preview

Page 1

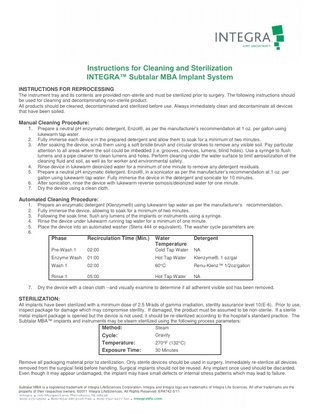

Instructions for Cleaning and Sterilization INTEGRA™ Subtalar MBA Implant System INSTRUCTIONS FOR REPROCESSING The instrument tray and its contents are provided non-sterile and must be sterilized prior to surgery. The following instructions should be used for cleaning and decontaminating non-sterile product. All products should be cleaned, decontaminated and sterilized before use. Always immediately clean and decontaminate all devices that have been soiled.

Manual Cleaning Procedure: 1. Prepare a neutral pH enzymatic detergent, Enzol®, as per the manufacturer’s recommendation at 1 oz. per gallon using 2. 3.

4. 5. 6. 7.

lukewarm tap water. Fully immerse each device in the prepared detergent and allow them to soak for a minimum of two minutes. After soaking the device, scrub them using a soft bristle brush and circular strokes to remove any visible soil. Pay particular attention to all areas where the soil could be imbedded (i.e. grooves, crevices, lumens, blind holes). Use a syringe to flush lumens and a pipe cleaner to clean lumens and holes. Perform cleaning under the water surface to limit aerosolization of the cleaning fluid and soil, as well as for worker and environmental safety. Rinse device in lukewarm deionized water for a minimum of one minute to remove any detergent residuals. Prepare a neutral pH enzymatic detergent, Enzol®, in a sonicator as per the manufacturer’s recommendation at 1 oz. per gallon using lukewarm tap water. Fully immerse the device in the detergent and sonicate for 10 minutes. After sonication, rinse the device with lukewarm reverse osmosis/deionized water for one minute. Dry the device using a clean cloth.

Automated Cleaning Procedure: 1. 2. 3. 4. 5. 6.

7.

Prepare an enzymatic detergent (Klenzyme®) using lukewarm tap water as per the manufacturer’s recommendation. Fully immerse the device, allowing to soak for a minimum of two minutes. Following the soak time, flush any lumens of the implants or instruments using a syringe. Rinse the device under lukewarm running tap water for a minimum of one minute. Place the device into an automated washer (Steris 444 or equivalent). The washer cycle parameters are:

Phase

Recirculation Time (Min.)

Water Temperature

Detergent

Pre-Wash 1

02:00

Cold Tap Water

NA

Enzyme Wash

01:00

Hot Tap Water

Klenzyme®, 1 oz/gal

Wash 1

02:00

60°C

Renu-Klenz™ 1/2oz/gallon

Rinse 1

05:00

Hot Tap Water

NA

Dry the device with a clean cloth --and visually examine to determine if all adherent visible soil has been removed.

STERILIZATION: All implants have been sterilized with a minimum dose of 2.5 Mrads of gamma irradiation, sterility assurance level 10(E-6). Prior to use, inspect package for damage which may compromise sterility. If damaged, the product must be assumed to be non-sterile. If a sterile metal implant package is opened but the device is not used, it should be re-sterilized according to the hospital’s standard practice. The Subtalar MBA™ implants and instruments may be steam sterilized using the following process parameters: Steam Method:

Cycle: Temperature: Exposure Time:

Gravity 270°F (132°C) 30 Minutes

Remove all packaging material prior to sterilization. Only sterile devices should be used in surgery. Immediately re-sterilize all devices removed from the surgical field before handling. Surgical implants should not be reused. Any implant once used should be discarded. Even though it may appear undamaged, the implant may have small defects or internal stress patterns which may lead to failure. Subtalar MBA is a registered trademark of Integra LifeSciences Corporation. Integra and Integra logo are trademarks of Integra Life Sciences. All other trademarks are the property of their respective owners. ©2011 Integra LifeSciences. All Rights Reserved. ER4742-5/11