Directions for Use

14 Pages

Preview

Page 1

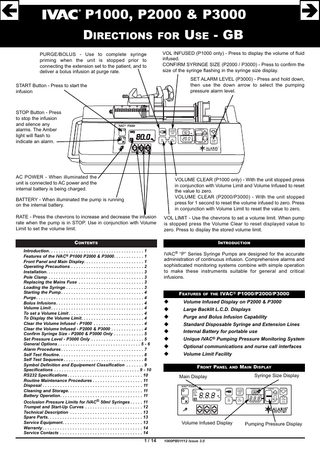

P1000, P2000 & P3000 DIRECTIONS FOR USE - GB PURGE/BOLUS - Use to complete syringe priming when the unit is stopped prior to connecting the extension set to the patient, and to deliver a bolus infusion at purge rate.

VOL INFUSED (P1000 only) - Press to display the volume of fluid infused. CONFIRM SYRINGE SIZE (P2000 / P3000) - Press to confirm the size of the syringe flashing in the syringe size display. SET ALARM LEVEL (P3000) - Press and hold down, then use the down arrow to select the pumping pressure alarm level.

START Button - Press to start the infusion

STOP Button - Press to stop the infusion and silence any alarms. The Amber light will flash to indicate an alarm.

CONFIRM SYRINGE SIZE

VOL LIMIT

VOL CLEAR

AC POWER - When illuminated the unit is connected to AC power and the internal battery is being charged.

SYRINGE SIZE

PUMPING HIGH

ALARM

LOW

VOLUME INFUSED

PRESSURE

SET ALARM LEVEL

VOLUME CLEAR (P1000 only) - With the unit stopped press in conjunction with Volume Limit and Volume Infused to reset the value to zero. VOLUME CLEAR (P2000/P3000) - With the unit stopped press for 1 second to reset the volume infused to zero. Press in conjunction with Volume Limit to reset the value to zero.

BATTERY - When illuminated the pump is running on the internal battery. RATE - Press the chevrons to increase and decrease the infusion rate when the pump is in STOP. Use in conjunction with Volume Limit to set the volume limit.

VOL LIMIT - Use the chevrons to set a volume limit. When pump is stopped press the Volume Clear to reset displayed value to zero. Press to display the stored volume limit.

CONTENTS

INTRODUCTION

Introduction... 1 Features of the IVAC® P1000 P2000 & P3000... 1 Front Panel and Main Display... 1 Operating Precautions... 2 Installation... 3 Pole Clamp... 3 Replacing the Mains Fuse... 3 Loading the Syringe... 3 Starting the Pump... 4 Purge... 4 Bolus Infusions... 4 Volume Limit... 4 To set a Volume Limit... 4 To Display the Volume Limit... 4 Clear the Volume Infused - P1000... 4 Clear the Volume Infused - P2000 & P3000... 4 Confirm Syringe Size - P2000 & P3000 Only... 5 Set Pressure Level - P3000 Only... 5 General Options... 5 - 6 Alarm Procedures... 7 Self Test Routine... 8 Self Test Sequence... 8 Symbol Definition and Equipement Classification... 9 Specifications... 9 - 10 RS232 Specifications... 10 Routine Maintenance Procedures... 11 Disposal... 11 Cleaning and Storage... 11 Battery Operation... 11 Occlusion Pressure Limits for IVAC® 50ml Syringes... 11 Trumpet and Start-Up Curves... 12 Technical Description... 13 Spare Parts... 13 Service Equipment... 13 Warranty... 14 Service Contacts... 14

1 / 14

IVAC® “P” Series Syringe Pumps are designed for the accurate administration of continuous infusion. Comprehensive alarms and sophisticated monitoring systems combine with simple operation to make these instruments suitable for general and critical infusions. FEATURES OF THE IVAC® P1000/P2000/P3000 u

Volume Infused Display on P2000 & P3000

u

Large Backlit L.C.D. Displays

u

Purge and Bolus Infusion Capability

u

Standard Disposable Syringe and Extension Lines

u

Internal Battery for portable use

u

Unique IVAC® Pumping Pressure Monitoring System

u

Optional communications and nurse call interfaces

u

Volume Limit Facility FRONT PANEL AND MAIN DISPLAY FRONT PANEL AND MAIN DISPLAY Syringe Size Display

Main Display IVAC® P3000 KVO RATE VOL LIMIT

CONFIRM SYRINGE SIZE

REM

VOL LIMIT

Volume Infused Display

1000PB01112 Issue 3.0

VOL CLEAR

SYRINGE SIZE

PUMPING HIGH

ml

ALARM

ml VOLUME INFUSED

LOW

PRESSURE

SET ALARM LEVEL

Pumping Pressure Display

OPERATING PRECAUTIONS

This IVAC® pump has been calibrated for use with single use disposable syringes. To ensure correct and accurate operation, only use Luer-Lock versions of the syringe make specified on the pump or described in the directions for use. Use of nonspecified administration sets or syringes may impair the operation of the pump and the accuracy of the infusion. Uncontrolled flow or syphoning may result if the syringe is located on the pump without its finger grips and plunger correctly located in the slots provided, or if it is removed from the pump before the extension line is properly isolated from the patient. Isolation may include closing a tap in the patient line or activating a flow stop clamp. When combining several apparatus and/or instruments with administration sets and other tubing, for example via a 3 way tap, the performance of the pump may be impacted and should be monitored closely. Do not mount the pump in a vertical position with the AC power inlet or the syringe pointing upwards as this could affect electrical safety, in the event of a fluid spill over the unit or lead to an infusion of air which may be in the syringe. To protect against the introduction of air the user should regularly monitor the progress of the infusion, syringe, extension line and patient connections and follow the priming procedure specified herein. This is a positive pressure device designed to achieve very accurate fluid administration by automatically compensating for resistance encountered in the infusion system. The pumping pressure alarm system is not designed to provide protection against, or detection of, infiltration conditions which can occur at low pressures. Several alarm conditions detected by this pump will stop the infusion and generate audible alarms. Users must perform regular checks to ensure that the infusion is progressing correctly and no alarms are operating. This instrument is protected against the effects of external interference, including high energy radio frequency emissions, magnetic fields and electrostatic discharge (for example, as generated by electrosurgical and cauterising equipment, large motors, portable radios, cellular telephones etc.) and is designed to fail safe if unreasonable levels of interference are encountered. In some circumstances the unit may be affected by an electrostatic discharge of +/8kV (contact), +/-15kV (air), at test levels lower than these values the unit will operate normally. In rare circumstances the unit may be affected by radiation at a level of 10V/m. If the unit is affected by this external interference the unit will fail safe or reset, ( a call back alarm will occur after 2 minutes). Should false alarm conditions be encountered either, remove the source of the interference, or regulate the infusion by another appropriate means. This unit emits a certain level of electromagnetic radiation which is within the levels specified by IEC60601-2-24 and IEC60601-1. If however the unit interacts with other equipment, measures should be taken to minimise the effects, for instance by repositioning or relocation. If this instrument is dropped, subjected to excessive moisture, humidity or high temperature, or otherwise suspected to have been damaged, remove it from service for inspection by a qualified service engineer. An explosion hazard exists if the instrument is used in the presence of flammable anaesthetics. Exercise care to locate the unit away from any such hazardous sources. An electrical shock hazard exists if the units casing is opened or removed. Refer all servicing to qualified service personnel. A comprehensive service manual containing circuit descriptions, servicing and testing information is available for this unit. It can be ordered from your ALARIS Medical Systems® authorised distributor (Technical Service Manual Part Number 1000PB00048)

2 / 14

1000PB01112 Issue 3.0

GETTING STARTED INSTALLATION

LOADING THE SYRINGE

Check that the pump is complete, undamaged and that the voltage rating specified on the base plate is compatible with your AC power supply. Items supplied with this ALARIS Medical Systems® syringe pump are;

Place the pump on a stable horizontal surface or secure using the pole clamp fitted.

IVAC® P SERIES PUMP POLE CLAMP DIRECTIONS FOR USE AC POWER CABLE (AS REQUESTED) PROTECTIVE PACKAGING Connect the unit to the AC power supply for 24 hours to ensure that the internal battery is fully charged. Should the pump fail to perform correctly, replace it in its original protective packaging and contact a qualified service engineer for investigation. POLE CLAMP The pole clamp is supplied fitted to the rear of the unit and will provide secure fixing to standard I.V. poles of a diameter of up to 40mm. The pole clamp can also be fitted in a choice of 4 fixing positions allowing the unit to be mounted to vertical and horizontal poles, equipment rails and hospital furniture in a variety of convenient operating orientations. The pole clamp may be adjusted for use with horizontal fittings by using the existing fixing screws with the alternative fixing holes in the pole clamp. The pole clamp may be also secured to the base of the unit in a choice of four positions.

Prepare, load and prime the single use disposable syringe and extension line using standard aseptic techniques. Important: Only use a syringe of the type stated on the pump labelling. 1. Squeeze the finger grips on the plunger holder and slide the mechanism to the left. Lift the syringe clamp and rotate to the left. 2.

Insert the syringe into the slots on the plunger holder.

3.

Squeeze the finger grips on the plunger holder and slide the mechanism to the right until the syringe finger flanges locate in the V slot.

Important: Advance the syringe until the finger flanges touch the front of the V slot closest to the syringe clamp. This is important to prevent delay at the start of the infusion. 4. Rotate the syringe clamp forward until it locks onto the syringe barrel. 5.

Check that the syringe plunger and finger flanges are correctly located in their slots.

Important: Only use a syringe of the type and size indicated on the pump or in this manual. Using an incorrect syringe could adversely affect the accuracy of the infusion and the performance of the pump. When initially loading the syringe, allow for the volume of fluid contained in the extension line and retained in the syringe at the end of infusion as this ‘dead-space’ will not be infused.

Important: Do not mount the unit with the AC power inlet or the syringe pointing upwards. This could affect the electrical safety in the event of a fluid spill or lead to the infusion of air which may be in the syringe.

REPLACING THE MAINS FUSE If the pump continually illuminates the battery symbol and the AC power indicator light does not illuminate when the pump is connected to the AC power supply and switched ON, suspect that either, the power supply fuse in the AC power plug, or, the internal fuse has blown. First check the power supply fuse in the AC mains plug, if the AC power indicator light does not illuminate remove the pump from service. It is recommended that the mains fuse is only replaced by a qualified service engineer. For further information regarding the replacement of the internal fuse refer to the technical service manual.

3 / 14

1000PB01112 Issue 3.0

GETTING STARTED STARTING THE PUMP

BOLUS INFUSIONS

1.

Connect the pump to an AC power supply using the AC power cable. Switch the ON/OFF switch to the ON position.

2.

LOAD SYRINGE - Load the syringe according to the Load syringe procedure in this user manual.

3.

P2000 / P3000 only - Check the syringe size displayed corresponds with the syringe fitted to the pump. Press CONFIRM when the correct type and size are shown.

4.

PURGE - Press the PURGE/BOLUS button twice and hold down until fluid flows and the purging of the syringe extension line is complete. The audible alarm will operate during use of the PURGE buttons and the volume used during purging will be shown on the display.

The bolus feature can be used at the beginning of an infusion or during an infusion. If the volume of the bolus reaches the bolus volume limit the bolus will stop and the pump will automatically revert to infuse at the set rate. If the volume to be infused is reached during a bolus, the volume to be infused complete alarm will operate and the unit will revert to its previous state. 1.

Press the PURGE/BOLUS button twice within 2 seconds. Hold the PURGE / BOLUS button down during the bolus operation.

2.

The pump will drive at the bolus rate, alarm and display the bolus volume as it is being delivered. If the volume delivered reaches the BOLUS VOLUME LIMIT the pump will revert to continue the infusion at the set rate.

3.

When the PURGE / BOLUS button is released the purge will automatically stop and the volume infused will revert to its previous state.

5.

Press VOL CLEAR (for P1000 press VOL INFUSED and CLEAR) to zero any volume shown in the infused display.

6.

Use the chevron buttons to select the infusion rate in ml/h required.

7.

CONNECT PATIENT - Connect the extension line to the patient access device.

If the volume limit is reached during the bolus the VOL LIMIT alarm will operate and Keep Vein Open (KVO) operation will commence.

8.

START - Press START to commence operation. The amber stop light will be replaced by the flashing green start light to indicate that the pump is operating.

VOLUME LIMIT A volume limit can be set in conjunction with the chervon keys.

Important: The unit will automatically operate from its internal battery if the pump is switched on without being connected to the AC power supply. Each time the unit is switched ON, check that the alarm beeps twice and that all the segments of the display, the green and amber lights are illuminated during the self test routine. During PURGE / BOLUS: The volume expelled from the syringe during the use of the PURGE / BOLUS button when the unit is stopped will not be added to the volume infused display. If a default syringe size has been selected the syringe size display will automatically show the default syringe size and no other selection will be possible.

PURGE

1.

TO SET A VOLUME LIMIT Press the STOP button.

2.

Press and hold down the VOL LIMIT button to display the volume limit screen.

3.

Using the chervon keys to select the required volume limit

1.

Press the VOL LIMIT button to display the set volume limit.

TO DISPLAY THE VOLUME LIMIT CLEAR THE VOLUME INFUSED - P1000 The volume infused display provides a continuous record of the volume being delivered during the infusion and while a bolus is being administered. 1.

Press the STOP button to stop the infusion.

2.

Press and hold down the VOL INFUSED and VOL CLEAR.

The volume infused display will be reset to 0.0ml.

The PURGE button allows the delivery of a limited volume of fluid in order to purge the extension line prior to being connected to a patient. 1.

To use the purge option stop the pump and press the PURGE/BOLUS button twice within 2 seconds. Hold the PURGE / BOLUS button down during the purging operation

2.

The pump will drive at the purge rate, alarm and display the purge volume as it is being delivered. If the volume delivered reaches the BOLUS VOLUME LIMIT the purge will automatically stop.

3.

Important: No alarms are disabled during the operation of the bolus function.

When the PURGE/BOLUS button is released the purge will automatically stop and the volume infused will revert to its previous state.

Important: No alarms are disabled during the operation of the purge feature.

Important: If a volume limit has been set, the remaining volume to be infused before the volume limit alarm will not be cleared when the volume infused display is reset to zero. CLEAR THE VOLUME INFUSED - P2000 & P3000 The volume infused display provides a continuous record of the volume being delivered during the infusion and while a bolus is being administered. The volume infused can be reset to 0.0ml. 1.

Press the STOP button.

2.

Press and hold down the VOL CLEAR button for 1 second.

Important: If a volume limit has been set, the remaining volume to be infused before the volume limit alarm will not be cleared when the volume infused display is reset to zero.

The PURGE button allows the delivery of a limited volume of fluid in order to purge the extension line prior to being connected to a patient.

4 / 14

1000PB01112 Issue 3.0

GETTING STARTED CONFIRM SYRINGE SIZE - P2000 & P3000 ONLY

SET PRESSURE ALARM LEVEL - P3000 ONLY

The syringe size display shows the syringe size fitted to the pump. The display will flash each time a new syringe is fitted, or the syringe clamp is raised, until the CONFIRM SYRINGE SIZE button is pressed to confirm the syringe size displayed.

The pumping pressure alarm level can be set while the pump is infusing. The pumping pressure display provides a continuous indication of the current pumping pressure and an adjustable alarm level (flashing bar).

1.

Load the syringe according to the load syringe procedure in this manual.

1.

Press and hold down the SET ALARM LEVEL button.

2.

The syringe size fitted will flash in the syringe size display.

2.

3.

Check that the syringe size displayed corresponds with the syringe fitted to the pump.

To adjust the alarm level press the down arrow key. Higher alarm levels can be accessed by passing through the lower alarm levels.

3.

Release the SET ALARM LEVEL button when the required alarm level flashes.

4.

To confirm the size displayed, press the CONFIRM SYRINGE SIZE button.

CONFIGURED OPTIONS General Options For a full list of access codes please refer to the technical service manual 1000PB00048. 1. Press the ON/OFF power switch to the OFF position. 2.

Hold down the START button and press the power switch to the ON position.

3.

The main display will show “- - - ”.

4.

Enter the access code using the chevron keys.

5.

When the complete code has been entered press the STOP button.

6.

Use the chevron keys to select the required options from those displayed.

7.

Press the STOP button to save the selection.

8.

Turn the pump OFF to store all the selections made.

Keep Vein Open E-0 - KVO enabled E-1 - KVO disabled The Keep Vein Open (KVO) flow rate provides the slow infusion rate required to keep the patient line open and cannula free from blockage after the Near End of Infusion warning and during the Volume Limit alarms. Under some circumstances, the reduction from the set infusion rate to the KVO rate of 2.0ml/h may not be desired. This option allows the user to disable KVO operation allowing the pump to continue infusing at the set infusion rate during Near End of Infusion and Volume Limit alarms. Stop Infusion at Volume Limit t-0 - KVO / continue infusion at Vol Limit alarm t-1 - Auto-stop at Volume Limit alarm If a volume limit has been selected the unit will provide a warning alarm and automatically revert to the K.V.O. rate, (or remain at the set rate if it is less than 2.0ml/h or K.V.O. has been disabled), when the set volume has been administered. This option allows the unit to be configured to alarm and automatically stop infusing when the volume limit is reached. K.V.O. operation at the near end of infusion alarm is unaffected by selection of this option. Default Syringe Size - P2000 & P3000 Only d00 10ml, 20ml, 30ml and 50ml syringes d10 10ml syringe only d20 20ml syringe only d30 30ml syringe only d50 50ml syringe only dA1 100ml syringe only (option kit) IVAC® P2000 & P3000 syringe pumps are supplied for use with syringes of a specified make and range of sizes. Under normal circumstances any of the sizes specified on the unit can be used requiring confirmation of the syringe size each time the syringe clamp is raised or the unit is switched ON. If the unit is to be dedicated to an application where only one size of syringe is required, for example only 20ml syringes are used, this can be set as the default syringe size. When a default syringe size is selected the CONFIRM SYRINGE SIZE button is disabled and the unit will by-pass the confirm syringe size operation and automatically display the default syringe size. Other functions will be unaltered and the unit will alarm if the default syringe is not used. The IVAC® P1000 can also be set for use with an alternative size of syringe. Contact ALARIS Medical Systems®, or your ALARIS® distributor, for further information.

5 / 14

1000PB01112 Issue 3.0

CONFIGURED OPTIONS Bolus Volume Limit LIMIT Set value in range 0.0ml to 9.9ml (Set at 0.0ml to disable BOLUS button) This syringe pump incorporates an automatic limit on the maximum volume that can be delivered during a BOLUS operation. When the PURGE/BOLUS limit is reached the unit will give a short alarm and then automatically return to its previous mode of operation.The normal value for the PURGE/BOLUS limit is 2.0ml on the P1000, P2000 and P3000. The BOLUS volume administered during the infusion is automatically added to the total volume infused display, the VOL LIMIT feature can also be used to monitor the volume which may be administered in successive BOLUS infusions delivered by pressing the PURGE/BOLUS button. The PURGE/BOLUS function may be disabled by setting the limit to 0.0ml. Default Pumping Pressure Alarm Level L- 4 375mmHg (nominal) - normal default level Each time the unit is switched ON it will automatically select the default pumping pressure alarm level. This is shown as the flashing bar on the IVAC® P3000 pumping pressure display. The normal default level for the pumping pressure alarm is level 4 (L-4) which is equal to 375mmHg (nominal) and is suitable for the majority of infusions. If the unit is to be used in a clinical situation where an alternative default pumping pressure alarm level would be an advantage, for example in arterial applications, this can be achieved by using this option to select one of 7 default pumping pressure alarm levels ranging from level 0 (L-0) at 0mmHg (nominal) up to level 6 (L-6) at 650mmHg (nominal). Each of the first six levels (L-0 to L-5) represents an increase in pumping pressure of approximately 93mmHg while the top level (L-6) is an increase of approximately 180mmHg. In addition to allowing selection of an alternative default alarm level, the IVAC® P3000 also provides for the adjustment of the pumping pressure alarm level while the infusion is being delivered. Autosave of Set-Up Parameters A- 0 Infusion rate reset to zero A- 1 Infusion rate saved b- 0 Volume infused reset to zero b- 1 Volume infused saved F- 0 Volume limit reset to zero F- 1 Volume limit saved These IVAC® syringe pumps automatically reset the infusion rate, volume limit and volume infused back to zero each time the unit is switched OFF. This ensures that there are no stored values in the unit when it is switched ON and the user is required to select set up parameters each time the pump is used. Some clinical situations may benefit from set up information being saved, for example if the pump is to be dedicated to a single application, or where operation must be interrupted for a long period while a procedure is performed. This option allows the current set up information to be retained when the unit is switched OFF, including the flow rate, volume infused and volume limit. When the unit is switched back ON it will display all stored values as part of the start up routine then return to the previous set-up. If the volume limit is saved there is an implication that if the pump is switched off with a limited volume partically delivered then on power up if the volume limit is not reset the pump will first complete the partically delivered volume. Note:- The pump will retain the stored information for a minimum of 10 years. Disable AC Power Failure Alarm n-0 AC Power fail alarm enabled n-1 AC Power fail alarm disabled The unit is designed to warn the user with an audible and visual alarm when it has switched to battery operation following disconnection of the AC power supply. This option allows this alarm to be disabled. In the event of an AC power failure, there will be no alarm and the unit will automatically switch from AC power to battery operation and the battery symbol will replace the AC power indicator. RS232 Interface & Nursecall Connector - Option must be fitted C-0 Communications disabled C-1 Communications enabled nc - 0 Nurse call disabled nc - 1 Nurse call enabled This IVAC® syringe pump can be fitted with an RS232 interface and a NurseCall Connector through which remote monitoring and / or control may be performed via a suitable central monitoring or computer system. To enable these options, the unit must be fitted with the appropriate connectors adjacent to the AC power inlet. These connectors can be ordered with the unit or upgraded later by installation of a retro fit kit by ALARIS Medical Systems® or your ALARIS® distributor. IVAC® 100ml Syringe Option - Option must be fitted Y0 100ml option disabled Y1 100ml option enabled The 100ml syringe option allows the unit to be configured to use a special IVAC® 100ml disposable syringe thereby increasing the volume that can be delivered before the syringe requires changing. To enable this option, the 100ml syringe kit comprising a special syringe clamp adaptor and syringe label, must be fitted to the unit. Contact ALARIS Medical Systems®, or your ALARIS® distributor, for further information. When fitted to an IVAC® P2000 or P3000 syringe pump, this option allows the use of the 50ml syringe for which the unit is already calibrated and the special 100ml syringe (identified as size A1 in the syringe size display). The 10ml, 20ml and 30ml syringe options are automatically disabled. When the 100ml syringe option has been fitted to a unit it is then possible to select the 100ml syringe as the default syringe size. B. Braun Perfuser / Janpol Syringes - Option must be fitted This option allows the unit to be configured to use B.Braun Perfuser and Janpol syringes. To enable this option, a special kit must be fitted to the unit. Contact ALARIS Medical Systems®, or your ALARIS® distributor, for further information. 6 / 14

1000PB01112 Issue 3.0

ALARM PROCEDURES Alarms are indicated by a combination of an audible alarm, flashing amber STOP light and a descriptive message in the display. 1.

A continuous audible alarm indicates that the infusion has stopped. First check the display for an alarm message, then press STOP to silence the alarm.

2.

When the cause for the alarm has been rectified, press the START button to restart the infusion. CONTINUOUS AUDIBLE ALARMS Description

Display

PUMP DRIVE DISENGAGED - The drive system has been disengaged during operation. Check the finger grips and the position of the syringe.

dEC

SYRINGE SIZE ERROR / SYRINGE FITTED INCORRECTLY - Incorrect size of syringe has been fitted, the syringe clamp has not been positioned correctly on the syringe or has been lifted during operation, plunger is not fitted in plunger slot. Check syringe size, position of syringe clamp, syringe and plunger. EXCESSIVE PUMPING PRESSURE - Pumping pressure has reached the alarm limit. Squeeze finger grips on the plunger holder to release the drive mechanism and relieve any excessive pressure in the syringe and patient line. Identify and remove the cause of the blockage in the drive, syringe, or administration system before restarting the infusion. END OF INFUSION - The pump has reached the end of the infusion. About 1% of the syringe volume will remain in the syringe helping to prevent the infusion of air bubbles into the extension line. BATTERY EXHAUSTED - Internal battery exhausted. To silence the alarm switch the ON/OFF switch to the OFF position and reconnect unit to AC power supply. To restart operation on AC power while charging the internal battery press the ON/OFF switch to the ON position. VOLUME LIMIT REACHED - STOP OPTION ENABLED - Infusion has reached volume limit and unit has stopped infusing. INTERNAL MALFUNCTION - The alarm system has detected an internal malfunction. Remove unit from service for examination by a qualified service engineer.

Syr

OCC

EOI

LO RATE VOL LIMIT Er_

ERROR CODES Er0 - Microprocessor fault. Er1 - Linear speed too fast - grid. Er2 - Linear speed too slow - grid. Er3 - Too many motor encoders. Er4 - Zero motor encoders. Er5 - RAM data invalid. Er6 - Watchdog failure - slow.

Er7 - Watchdog failure - fast. Er8 - Invalid syringe data. Er9 - Motor Malfunction ErA- Voltage Reference. Erb - Strain gauge current. ErC - Motor drive transistor - off. Erd - Motor drive transistor - on.

ErE - Plunger detect error. ErF - RAM error - complement fault. Err - Pumping pressure offset error. Ery - Motor data error. ErL - CRC error. Ern - Watchdog window error. Er- - Memory stack overflow.

INTERMITTENT AUDIBLE ALARMS Description

Display

AC POWER SUPPLY DISCONNECTED - AC - Power has been disconnected and the pump is operating on battery power. Reconnect AC power supply or press START to silence the alarm and continue battery operation. The alarm will automatically cancel if the AC power supply is reconnected. BATTERY CHARGE LOW - Battery charge low with 30 minutes operation remaining. After 30 minutes a continuous audible alarm will indicate that the battery is exhausted. Reconnect to AC power supply to continue operation and charge internal battery. VOLUME LIMIT REACHED - KVO ENABLED - Infusing at the KVO rate of 2.0ml/h (or set rate if lower). Press STOP, or START, to silence alarm and continue at the set flow rate. (To disable KVO - see USER DEFINED OPTIONS).

AC (flashing)

LO (flashing)

KVOèRATEèVOLèLIMIT (flashing)

NEAR END OF INFUSION - KVO ENABLED - Syringe almost empty with about 3% of its volume remaining and infusing at KVO rate of 2.0ml/h ( or set rate if lower). Press STOP, or START to silence alarm and continue at the kvo rate of 2.0ml/h, unless flow rate is less than 2.0ml/h, then pump runs at rate set.

KVOèRATE (flashing)

VOLUME LIMIT REACHED - KVO DISABLED - KVO operation has been disabled. Volume limit reached and infusion continuing at the set rate until START or STOP is pressed.

RATEèVOLèLIMIT (flashing)

NEAR END OF INFUSION - KVO DISABLED - Syringe almost empty with about 4% of its volume remaining, pump continuing to infuse at the set rate.

RATE (flashing)

NURSE ATTENTION ALARM - Unit left switched ON for over 2 minutes without starting the infusion. Press STOP to silence the alarm for a further 2 minutes. Alternatively, press and hold down STOP for 2 seconds to silence the alarm for 15 minutes. 7 / 14

1000PB01112 Issue 3.0

3 BEEPS

SPECIFICATIONS SELF TEST ROUTINE The self test routine is designed to allow confirmation of many of the pump functions, defaults and calibrations without requiring internal inspection. It does not represent a full calibration check.

1.

Press the ON/OFF power switch to the OFF position.

2.

Hold down the START button and press the power switch to the ON position.

3.

The main display will show “- - -”. Enter the Access Code “123” using the chevrons.

4.

When the access code has been entered press the STOP button to access the self test.

5.

The pump will now proceed through a series of tests. Press the STOP button to move to the next test.

6.

To exit the test press the START button, this will return the pump to normal operation.

Important: Should the pump fail the test sequence, it should be taken out of service and inspected by a qualified service engineer. SELF TEST SEQUENCE Display PUMP MODEL:

Test Description Displays pump model.

PUMP IDENTITY NUMBER:

Set via RS232 communications link. Default 0: can be set in range 0 - 127.

SOFTWARE FITTED:

Displays software version fitted to the unit.

SYRINGE CALIBRATION CHECK:

Confirm that the code corresponds with syringe label fitted on the pump.

100ml SYRINGE OPTION:

Y-1 enabled Y-0 disabled

DEFAULT SYRINGE SIZE:

Displays default syringe size

OCCLUSION ALARM LEVEL:

Refer to USER DEFINED OPTIONS. Normal Default Level L-4 : can be set in range L-0 to L-6

AUTO SAVE OPTIONS:

Indicate if unit is configured to reset all set up parameters to zero, or, retain infusion rate, volume infused and/or volume limit values, each time the unit is switched OFF

USER DEFINED OPTIONS

A-0 b-0 F-0 C-0 nc0 E-0

Infusion Rate reset to zero Volume Infused reset to zero Volume Limit reset to zero Communications Disabled Nurse call disabled KVO Enabled

A-1 b-1 F-1 C-1 nc1 E-1

Infusion Rate retained Volume Infused retained Volume Limit retained Communications Enabled Nurse call enabled KVO Disabled

PURGE/BOLUS LIMIT 5.0 ml

Can be set in range 0.0ml up to 9.9ml

t-1

Check continuous alarm

AUDIBLE ALARM TEST:

00-FFF DISPLAY TEST:

Check display through the full sequence

3-1 4-0 5-0 6-1 7-1

Drive Engaged Normal State OPTO over slot in linear grid Encoders PASS Control Buttons PASS

3-0 4-1 5-1 6-0 7-0

8-0 L_ _ C_ _

Syringe plunger fitted Normal Base Level Range Normal Range

Drive Disengaged NEOI Alarm Position and beyond OPTO over bar in linear grid Encoders FAIL Control Buttons FAIL - button continuously operating 8-1 No syringe fitted L08-L20 - hexadecimal format C10-CD4 - hexadecimal format.

Press STOP to exit self test mode and return to normal operation

8 / 14

1000PB01112 Issue 3.0

SPECIFICATIONS SYMBOL DEFINITION AND EQUIPMENT CLASSIFICATIONS Attention (Consult accompanying documents) Potential Equalisation Connector RS232 / Nursecall Connector (Optional)

Type CF Equipment (Degree of protection against electrical shock) Protected against splashing fluid (Degree of protection against fluid ingress)

Device complies with the requirements of the EC Directive 93/42/EEC. Registered with the CE Mark. SPECIFICATIONS Regulatory Compliance

EMC - Complies with BS EN 60601-1-2

Syringe Types The unit is calibrated and labelled for use with single use disposable luer-lock syringes. Only use the size and type of syringe specified on the pump display . Options include

10ml 20ml 30ml 50ml 100ml* ü ü ü ü ü ü ü ü ü ü ü ü ü ü ü ü ü ü ü ü ü(35) ü ü ü ü ü ü ü ü ü

IVAC® 100/120ml Luer-Lock Syringe

Volume Infused 0.1ml - 99.9ml 0.1ml steps 100ml - 999ml 1ml steps Volume Limit 0.1ml - 99.9ml 0.1ml steps

Near end of Infusion (NEOI) Alarm 4% of remaining syringe volume Classification Continuous Mode Operation, Transportable Critical Volume The maximum-over infusion which can occur in the event of a single fault condition is 0.5ml

System Accuracy Drive Linearity +/- 1% Volumetric Mean +/- 2% (Nominal) Important: (System accuracy is +/-2% typical by volume as measured using the trumpet curve test method defined in IEC601-2-24 at rates of 1.0ml/h and above when the instrument is used with the recommended syringes. Differences in factors such as size and plunger force in compatible syringes can cause variations in accuracy and trumpet curves.) also see trumpet curves section. Battery Type Rechargeable Sealed Lead Acid. Automatically charges when the pump is connected to AC power.) Battery Life 15 h @ 5.0ml/h (20 degrees C). Without RS232 and or Nursecall fitted

Compatible Extension Lines and Syringes The unit uses a standard, single use, disposable extension line and syringes with luer-lock connectors, of type designed for use on syringe pumps.

30120

KVO Rate 2.0ml/h, or continue at set rate

Maximum Pumping Pressure Limit 375mmHg - nominal at L-4: Factory Preset, 650mmHg - nominal at L-6: highest alarm level. Occlusion levels L-0 to L-6

Electrical/Mechanical Safety - Complies with IEC601-1 1988 (EN60601-1: 1993)

IVAC® 50/60ml Luer-Lock Syringe

10ml syringes 20m/30ml syringes 50ml/100ml syringes

End Of Infusion (EOI) Alarm 1% of remaining syringe volume

Alternating Current

3062N

Purge/Bolus Rate 40ml/h 100ml/h 200ml/h

Purge Limit 2.0ml (User adjustable from 0.0ml - 9.9ml)

Class II Equipment

IVAC® BD Plastipak Terumo B Braun Omnifix Sherwood Monoject R R Pronto † B D Worldwide Once Fresenius Injectomat B Braun Perfusor* Janpol* *=Option kit required

Infusion Rate 0.1ml/h - 39.9ml/h. 10ml syringes 0.1ml/h - 99.9ml/h 20ml/30ml/50ml syringes 0.1ml/h - 99.9ml/h 100ml syringes 0.1ml/h - 99.9ml/h - 0.1ml/h steps

Battery Charging 10 hours from discharge to 80% charge and 24 hours to 100% charge Memory Retention The electronic memory of the unit will be retained for more than 6 months when not powered up AC Power Supply 110-120VAC, 50/60Hz, 12VA (nominal). 220-240VAC, 50/60Hz, 12VA (nominal).

G40015 Standard Syringe Extension Set - 150cm G40020 Standard Syringe Extension Set - 200cm G40615 Low Sorbing Syringe Extension Set - 150cm G40620 Low Sorbing Syringe Extension Set - 200cm G40215 Opaque Syringe Extension Set - 150cm G40320 Opaque Syringe Extension Set - 200cm It is recommended that the extension sets are changed according to the hospital protocols. 9 / 14

1000PB01112 Issue 3.0

SPECIFICATIONS Environmental

Case Material Noryl FN 150 (with fire retardant to UL94V-0) Dimensions 370mm (w) x 95mm (h) x 170mm (d). Weight: 3.0kg (excluding pole clamp and power cable). Alarm Conditions Pressure Limit Exceeded Drive Disengaged Infusion Complete Internal Malfunction Purge / Bolus Activated Nurse Attention Volume Limit Reached Near End of Infusion AC Power Disconnected Low Battery Warning Battery Exhausted Syringe Error

Operating Temperature Relative Humidity Atmospheric Pressure

+10°C - +40°C 30% - 75% 700mbar - 1060mbar

Transport/Storage Temperature Relative Humidity Atmospheric Pressure

-40°C - +70°C 10% - 100% 500mbar - 1060mbar

Manufacturers Patent Notice This instrument is designed and manufactured in the U.K. by ALARIS Medical UK Ltd under patent GB222444. ALARIS Medical UK Ltd reserves the right to alter product specifications without notice. Electrical Safety Complies with - VDE 750/10.90, IEC 601-1 Typical 0.002mA -0.004mA

RS232 SPECIFICATIONS RS232/NURSECALL OPTION The RS232 / Nursecall option fitted to this IVAC® “P” Series Syringe Pump allows the pump to be monitored remotely and/or controlled via a suitable central monitoring or computer system. When the pump is started by a command from the serial interface, a communication must take place every 15 seconds or the pump will alarm, display communications failure and stop infusing. This failure protects against failure of the communications, including the removal of the RS232 cable. Important: The nursecall interface provides a remote backup to the internal audible alarm. It should not be relied upon to replace monitoring of internal alarm. Refer to the technical service manual for further information regarding the RS232 interface. Since it is possible to control the syringe pump using the RS232 interface at some distance from the pump and hence remote from the patient, responsibility for the control of the pump is vested in the software run on the computer control system. The assessment for the suitability of any software used in the clinical environment to control or receive data from the pump lies with the user of the equipment. This software should include detection of the disconnection or other failure of the RS232 cable. The protocol is detailed in the technical service manual and is for general information only. This relates to IVAC® “P” Series Syringe pumps fitted with the RS232 communication interface. Any connected analogue and digital components are required to meet EN60950 for data processing and EN60601 for medical devices. Anyone connecting additional devices to the signal input or output is a system configurator and responsible for meeting the requirements of the system standard EN60601-1-1. RS232/NURSECALL SPECIFICATION

TYPICAL CONNECTION DATA

Connector D Type - 9 Pin TXD/RXD EIA RS232-C Standard TXD Output Voltage Range Minimum: -5V (mark), +5V (space) Typical: 7V (mark, +7V (space) with 3K load to ground RXD Input Voltage Range -30V - +30V max. RXD Input Thresholds Low: 0.6V minimum / High: 3.0V maximum RXD Input Resistance 3K minimum Enable Active Low:-7V to -12V Active, High:+7V to +12V, powers up the isolated RS232 circuitry Inactive: Floating/open circuit, allows isolated RS232 circuitry to power down. Isolation Socket/Pump 4KV (dc, or ac peak) Baud Rate 9600 Baud Start Bits 1 Start Bit Data Bits 8 Data Bits Parity Odd Parity / No Parity Stop Bits 1 stop bits Nurse Call Pins 6 + 9, 30V dc, 1A rating 10 / 14

1 2 3 4 5 6 7 8 9

Description Not used Received data (RXD) Transmit data (TXD) Not used Ground (GND) Nurse Call Common Not used Enable input (EN) (connects to RTS on computer) Nursecall Normally Open

Important: The IBM connector pins grouped in pairs above should be linked at the connector. 1000PB01112 Issue 3.0

SPECIFICATIONS ROUTINE MAINTENANCE PROCEDURES

BATTERY OPERATION

To ensure that this instrument remains in good operating condition, it is important to keep it clean and carry out the routine maintenance procedures described below. All servicing should only be performed by a qualified service engineer with reference to the technical service manual (TSM) for this product (Service Manual reference:1000PB00048).

The internal rechargeable battery allows continued operation when the AC power is unavailable, for example during patient transfer or AC power failure. A fully charged battery will provide over 15 hours operation at typical infusion rates. From the battery low alarm it will take about 24 hours to fully recharge when reconnected to the AC power supply, whether the unit is in use or not. The battery is automatically charged during AC operation and whenever the unit is connected to the AC power supply and the AC power indicator is illuminated.

Technical service features are available use access code “376”, refer to the technical service manual. Important: If the pump is dropped, damaged, subjected to excessive moisture or high temperature, immediately take it out of service for examination by a qualified service engineer. INTERVAL

ROUTINE MAINTENANCE PROCEDURE

As Required

Thoroughly clean external surfaces of the pump before and after prolonged period of storage.

12 Monthly

1. Inspect AC power supply plug and cable for damage. 2. Perform functional OPERATIONAL AND ALARM TEST see TSM

It is good practice to periodically operate the unit on battery power until the battery low alarm then charge the battery to confirm battery operation and charging. When not in use, connect the unit to the AC power supply in order to maintain the battery in the fully charged state. The battery is a maintenance free, sealed lead acid type and requires no routine servicing. However, to achieve optimum operation, ensure that the battery is fully recharged after full discharge, before storage, and at regular 3 month intervals during storage.

4. Perform rate accuracy verification test see TSM.

The internal rechargeable battery will retain charge if utilised as described above on a regular basis. Charge retention will eventually degrade. Where retention is critical the internal battery should be replaced every 3 years.

5. Perform pressure calibration verification test see TSM.

OCCLUSION PRESSURE LIMITS FOR IVAC® 50ML SYRINGES

3. Perform the SELF TEST ROUTINE.

6. Operate the pump on battery power until the battery low alarm then charge the battery to confirm battery operation and charging.

The following tables show the worst case values for line pressure, time to alarm and bolus volume that can be expected in the event of an occlusion when the IVAC® 50ml syringe is selected, G40020 administration set.

DISPOSAL The pump should be disposed of taking environmental factors into consideration. To ensure no risk or hazard remove the internal rechargeable battery and the nicad battery (component B1) from the control board and dispose of as outlined by the local country regulations. Do not send back to manufacturer. All other components can be safely disposed of in the normal manner. CLEANING AND STORAGE Before the transfer of the pump to a new patient and periodically during use, clean the pump by wiping over with a lint-free cloth lightly dampened with warm water and a standard disinfectant / detergent solution. The syringe and extension line are disposable single use items and should be discarded after use according to their manufacturers instructions. If the pump is to be stored for an extended period it should be first cleaned and the internal battery fully charged. Store in a clean, dry atmosphere at room temperature and, if available, employ the original packaging for protection.

*

Rate (ml/h)

1 4 6

1.0 1.0 1.0

2:30 67:00 81:00

375mmHg 650mmHg

0.1 0.3 0.7

1 4 6

5.0 5.0 5.0

00:40 09:00 14:00

375mmHg 650mmHg

0.1 0.5 0.7

1 4 6

99.9 99.9 99.9

00:10 00:30 00:50

375mmHg 650mmHg

0.1 0.6 0.7

Tests at these levels may alarm immediately - the force at these levels is commonly less than the friction in the syringe (with no additional fluid pressure). The result is that the pressure relating to the low forces will be less than the nominal quoted occlusion pressure.

Once every 3 months during storage, carry out functional tests as described in the OPERATIONAL AND ALARM TEST in the technical service manual and SELF TEST ROUTINE and ensure that the internal battery is fully charged. Important: Before cleaning always switch OFF and disconnect from the AC power supply. Never allow liquid to enter the casing and avoid excess fluid build up on the pump. Do not use aggressive cleaning agents as these may damage the exterior surface of the pump. Do not steam autoclave, ethylene oxide sterilise or immerse this pump in any fluid.

11 / 14

Maximum Nominal Maximum Time Bolus Occlusion Alarm to Occulsion Alarm (h:min) Pressure (mmHg) Volume (ml)

Alarm Level

1000PB01112 Issue 3.0

TRUMPET AND START-UP CURVES In this instrument, as with all infusion systems, the action of the pumping mechanism and variations in individual syringes cause shortterm fluctuations in rate accuracy. The following curves show typical performance of the system in two ways: 1) the accuracy of fluid delivery over various time periods is measured (trumpet curves), and 2) the delay in onset of fluid flow when infusion commences (start-up curves). Trumpet Curves Trumpet curves are named for their characteristic shape. They display discrete data averaged over particular time periods or 'observation windows', not continuous data versus operating time. Over long observation windows, short term fluctuations have little effect on accuracy as represented by the flat part of the curve. As the observation window is reduced, short term fluctuations have greater effects as represented by the "mouth" of the trumpet. Knowledge of system accuracy over various observation windows may be of interest when certain drugs are being administered. Short term fluctuations in rate accuracy may have clinical impact depending on the half-life of the drug being infused and the degree of inter vascular integration, the clinical effect cannot be determined from the trumpet curves alone. Start-up Curves The start-up curves represent continuous flow versus operating time for two hours from the start of the infusion. They exhibit the delay in onset of delivery due to mechanical compliance and provide a visual representation of uniformity. Trumpet curves are derived from the second hour of this data. Tests performed per IEC601-2-24 (draft) standard. Important: Start-up and trumpet curves may not be indicative of operation under negative pressure. Differences in factors such as size and plunger force in compatible syringes produced by other manufacturers can cause variations in accuracy and trumpet curves as compared to those represented. Additional curves for compatible syringes are available upon written request. For applications where flow uniformity is a concern, rates of 1.0ml/hr or above are recommended.

12 / 14

1000PB01112 Issue 3.0

TECHNICAL DESCRIPTION The following details outline the safety checks designed into IVAC® Syringe Pumps to minimise the possibility of under/over infusions. MONITORING OF THE SYSTEM CLOCK FREQUENCY / WATCHDOG The system clock , which is used to control the rate of the pump is derived from the microprocessor crystal oscillator. A watchdog circuit is implemented in the pump to monitor the correct time period. The watchdog circuit requires the microprocessor to send a reset pulse every 10mS to stop the counter from timing out and triggering the watchdog alarm. The reset signal has to be in a time ' window' of between 8 to 12mS. If it is either too fast or too slow the watchdog hardware will detect this and generate an alarm and disable the motor drive. Additionally, on power up the watchdog is allowed to time-out and the period is measured and tested to be within a set tolerance. This then confirms that both the microprocessor crystal and the watchdog crystal frequencies are correct. DETECTION OF LINEAR MOVEMENT Linear grid with optical switch is incorporated in the unit to detect the movement of the pumping mechanism. This movement is monitored in the electronics and software of the system. If it is detected that the mechanism is either moving too fast, too slow, or not moving at all then an error code will be displayed, the motor drive will be disabled and the pump will stop. CONTROL OF LINEAR SPEED / INFUSION RATE The pump mechanism is driven using a d.c. motor; feedback for the control system is provided by two opto switches. To enable the motor drive there are three transistors which need to be turned on. The correct operation of these transistors is tested on power up. The control system monitors the feedback from the opto encoders and adjusts the motor on time to maintain the required speed. If there are no encoder signals feedback, indicating that an opto has failed or the transmission has jammed, an error code will be displayed and the pump will fail-safe. If there are too many encoders detected an error code will be displayed and the pump will fail-safe. The pump calculates the appropriate motor control rate from the set infusion rate and syringe constant data stored within the pump software. The syringe constant data converts ml’s to mm’s of movement for each syringe type and size.

SPARES AND SERVICE EQUIPMENT SPARE PARTS

SERVICE EQUIPMENT

A comprehensive list of spare parts for IVAC® Syringe pumps is included within the service manual. This can be ordered from ALARIS Medical Systems®, or authorised distributor. For part number please refer to summary parts list below:

These IVAC® “P” Series Syringe pumps have been designed to allow simple and low cost servicing. Standard components are employed where possible so that no special test, calibration or tools are required. However, the following items may be useful for general servicing.

Part Number 1000PB01112

Description Directions For Use IVAC® P1000/2000/3000

1000PB00048

Technical Service Manual IVAC® “P” Series Syringe Pumps

0000EL00004

Part Number 0000TG00020

Description Occlusion Test Gear

0000TG00080

Linear Accuracy Test Gear

Internal Battery - 6V NP2.6 - 6 Rechargeable

1000EL00043

Ribbon Cable Extension

1001FAOPT91

AC Power Lead - U.K.

0000JG00004

Cradle Support

1001FAOPT92

AC Power Lead - European

0000JG00010

50ml Syringe Sizing Test Gear

1001FAOPT93

AC Power Lead - Unterminated

0000JG00011

100ml Syringe Sizing Test Gear

1000SP00076

Pole Clamp Assembly

1000LB01009

Label Set V4

13 / 14

1000PB01112 Issue 3.0

WARRANTY

SERVICE CONTACTS

ALARIS Medical Systems® (hereinafter referred to as "ALARIS") warrants that:

For service contact your local ALARIS Medical Systems® Affiliate Office or Distributor. ALARIS Medical Systems® Service Centre Addresses:

(A)

(B)

Each new instrument (pump, controller or peripheral instrument) is free from defects in material and workmanship under normal use and service for a period of one year from the date of delivery by ALARIS to the first purchaser. Each new accessory is free from defects in material and workmanship under normal use and service for a period of ninety (90) days from the date of delivery by ALARIS to the first purchaser.

If any product requires service during the applicable warranty period, the purchaser should communicate directly with the local ALARIS service centre to determine appropriate repair facility. Repair or replacement will be carried out at ALARIS's expense, subject to the terms of this warranty. The product requiring service should be returned promptly, properly packed, and postage prepaid. Loss or damage in return shipment to ALARIS shall be at purchaser's risk. In no event shall ALARIS be liable for any incidental, indirect or consequential damages in connection with the purchase or use of any ALARIS product. This warranty shall not apply to, and ALARIS shall not be responsible for, any loss arising in connection with the purchase or use of any ALARIS product which has been repaired by anyone other than an authorised ALARIS service representative or altered in any way so as, in ALARIS's judgement, to affect its stability or reliability, or which has been subject to misuse or negligence or accident, or which has had the serial or lot number altered, effaced or removed, or which has been used otherwise than in accordance with the instructions furnished by ALARIS. This warranty is in lieu of all other warranties, express or implied, and of all other obligations of liabilities on ALARIS's part, and ALARIS neither assumes nor authorises any representative or other person to assume for it any other liability in connection with the sale of ALARIS products. See packing inserts for international warranty. ALARIS DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FOR FUNCTION OF FITNESS FOR A PARTICULAR PURPOSE OR APPLICATION

AE

HU

ALARIS Medical Systems Middle East Office, PO Box 5527, Dubai, United Arab Emirates. Tel: (971) 4 28 22 842 Fax: (971) 4 28 22 914

ALARIS Medical Systems Office Döbrentei tér 1, H - 1013 Budapest. Magyarország. Tel: (36) 12 14 2229 Fax: (36) 12 01 5987

AU

IT

ALARIS Medical Australia Pty Ltd, 3/167 Prospect Highway, Seven Hills, NSW 2147, Australia. Tel: (61) 2 9838 0255 Fax: (61) 2 9674 4444

ALARIS Medical Italia S.P.A. Via Ticino 4, 50019 Sesto Fiorentino, Firenze, Italia. Tél: (39) 055 34 00 22 Fax: (39) 055 34 00 25

BE

NL

ALARIS Medical Belgium B.V., Otto De Mentockplein 19, 1853 Strombeek - Bever, Belgium. Tel: (32) 2 263 09 75 Fax: (32) 2 267 99 21

ALARIS Medical Holland, B.V., Kantorenpand “Hoefse Wing”, Printerweg 5, 3821 AP Amersfoort. Nederland Tel: (31) 33 455 51 00 Fax: (31) 33 455 51 01

CA ALARIS Medical Canada, Ltd. 5975 Whittle Road, Suite #120, Mississauga, Ontario L4Z 3N1, Canada. Tel: (1) 905-507-1131 Fax: (1) 905-507-6664

NO

CN

NZ

ALARIS Medical Systems Office, Suite 401 No. 88 Chang Su Road, Shanghai PC 200040, China. Tel: (56) 8621-62488591 Fax: (56) 8621-62482567

ALARIS Medical NZ Ltd., Unit 14, 13 Highbrook Drive, East Tamaki, Auckland, New Zealand. Tel: (64) 9 273 3901 Fax: (64) 9 273 3098

DE

SE

ALARIS Medical Deutschland, GmbH, Pascalstr. 2, 52499 Baesweiler, Deutschland. Tel: (49) 2401 604 0 Fax: (49) 2401 604 121

ALARIS Medical Nordic, AB Box 452, 191 24 Sollentuna Sverige. Tel: (46) 8 544 43 200 Fax: (46) 8 544 43 225

ES ALARIS Medical Espãna, S.L., Avenida Valdelaparra 27, Edifico Alcor, 28108 - Alcobendas, Madrid, España Tel: (34) 91 657 20 31 Fax: (34) 91 657 20 42

FR ALARIS Medical France, S.A., 95, rue Péreire, 78105 St Germain en Laye Cedex. France. Tél: (33) 1 39 10 50 09 / 10 Fax: (33) 1 30 61 22 23

GB - Manufacturer’s Address: ALARIS Medical UK Ltd., The Crescent, Jays Close, Basingstoke, Hampshire, RG22 4BS, United Kingdom. Tel: (44) 0800 389 6972 Fax: (44) 1256 388 411

14 / 14

1000PB01112 Issue 3.0

ALARIS Medical Norway A/S Hamang Terrasse 55, PO Box 248, N-1301 Sandvika, Norge. Tel: (47) 67 57 58 50 Fax: (47) 67 57 58 60

SG ALARIS Medical Systems Office, 65 Chulia Street, #40-04 OCBC Centre, Singapore 049513. Tel: (65) 5345351 Fax: (65) 5345516

US ALARIS Medical Systems, Inc. 10221 Wateridge Circle San Diego, CA 92121, USA. Tel: (1) 800 854 7128 Fax: (1) 858 458 6179

ZA ALARIS Medical S.A. (Pty) Ltd., Unit 2 Oude Molen Business Park, Oude Molen Road, Ndabeni, Cape Town 7405, South Africa. Tel: (27) 0860 597 572 Fax: (27) 21 5107567