KCI

FluidAir II and ELITE Quick Reference Guide Rev C May 2009

Quick Reference Guide

2 Pages

Preview

Page 1

INTRODUCTION (cont.) Patient Bathing - Fluids remaining on the controls can cause corrosion, which may cause components to fail, possibly producing potential hazards to the patient and staff. Daily Care - Check and replace filters and sheets as often as needed. Dehydration and Electrolyte Imbalance - Air flowing upward past the patient may cause an increase in evaporative fluid loss and an increased potential for dehydration and electrolyte imbalance. Fluid intake and output should be carefully monitored and fluid requirements adjusted as necessary. Pulmonary and Renal Functions - All patients undergoing treatment on unit (or any other stationary surface), should be turned at least once every two hours to promote normal pulmonary and renal functions. Skeletal Traction - Patients requiring skeletal traction should be placed on the RotoRest™ Therapy System or KinAir™ Therapy System.

SAFETY INFORMATION General Protocol - Follow all applicable safety rules and institution protocols concerning patient and caregiver safety. Temperature - Normal operating temperature is between 88ºF (31ºC) and 92ºF (33ºC). Temperatures below 88ºF (31ºC) diminish support surface fluidization. If the unit senses an excessive Microsphere temperature, an audible alarm sounds and the unit will automatically deactivate until the Microsphere temperature drops. The caregiver should consider whether it is necessary to monitor the temperature of the patient at regular intervals. Filter Sheet Condition and Microsphere Containment - The Filter Sheet helps to regulate the fluidizing air flowing up through the Microshperes and also helps to contain the Microspheres within the tank. The following procedures should be followed to ensure Microsphere containment: • Do not use Filter Sheet as a draw sheet. • Do not pin or clip items onto Filter Sheet. • Cover sharp edges of X-Ray cassette with a pillowcase or other linen to avoid damaging Filter Sheet. • Inspect Filter Sheet regularly for damage, wear, or any other evidence of unserviceability. Repair or replace immediately if integrity of Filter Sheet is compromised. Brakes - Caster brakes should always be locked once the unit is in position. Verify wheels are locked before any patient transfer to or from the unit. Microsphere Spills - Microspheres spilled on the floor may be slippery. Any Microspheres on the floor or other exposed surfaces should be wiped up immediately using a damp mop or cloth. Fluids - Avoid spilling fluids on unit controls. If spills do occur, unplug unit. Clean fluid from unit, wearing rubber gloves to avoid any possibility of shock. Once fluid is removed, check operation of components in area of spill. Fluids remaining on the electronic controls can cause corrosion, which may cause the electronic components to fail or operate erratically, possibly producing hazards for patient and caregivers. Petroleum-based Topical Medications and Silver Compounds - Prevent petroleum-based topical medications and silver compounds from entering the Fluidization Tank. These compounds may damage Microspheres and reduce their fluidization properties. Side Rails - Whether and how to use Side Rails is a decision that should be based on each patient’s needs and should be made by the patient and the patient’s family, physician and caregivers, with facility protocols in mind. Caregivers should assess risks and benefits of rail/restraint use (including entrapment and patient falls from unit) in conjunction with individual patient needs, and should discuss use or non-use with patient and/ or family. Consider not only the clinical and other needs of the patient but also the risks of fatal or serious injury from falling out of unit and from patient entrapment in or around the side rails, restraints or other accessories. For a description of entrapment hazards, vulnerable patient profile and guidance to further reduce entrapment risks, refer to FDA’s Hospital Bed System Dimensional and Assessment Guidance to Reduce Entrapment and other information referenced at www.kci1.com/products/FDASafetyAlert or www.fda. gov. Consult a caregiver and carefully consider the use of bolsters, positioning aids, or floor pads especially with confused, restless or agitated patients. It is recommended that side rails (if used) be locked in the full upright position when the patient is unattended. Make sure a capable patient knows how to get out of unit safely (and, if necessary how to release the side rails) in case of fire or other emergency. Monitor patients frequently to guard against patient entrapment. Lock-Outs - Lock-Out of fluidization and temperature adjustments should be used at the staff’s discretion to ensure against unauthorized tampering with settings. Avoid Strains - Like any other conventional bead unit, the FluidAir™ II and FluidAir™ Elite™ units are heavier than non-specialized hospital beds. Extra care should be taken during transport to avoid straining. Make sure assigned staff members are physically capable of maneuvering the unit with ease.

SAFETY INFORMATION (cont.) Moving Parts - Keep all equipment, loose clothing and hair away from moving parts and pinch points. Power Cord - Ensure power cord is kept free from all pinch points and moving parts and is not trapped under casters nor covered with rugs or carpets. Visually inspect the cord for signs of damage or wear. Improper handling of the power cord can cause damage to the cord, which may possibly product risk of fire or electric shock. Skin Care - Monitor skin conditions regularly, especially at bony prominences and in areas where incontinence and drainage occur or collect, and consider adjunct or alternative therapies for high acuity patients. Its is recommended that skin pressure points be assessed at least every two hours. Early intervention may be essential to preventing serious skin breakdown. Home Placement - In view of the heavy weight of conventional bead units, ensure adequacy of home structures by placing unit only directly atop concrete foundation. Patient weight should not exceed 250 lbs. (113 kg). Disposal - At the end of useful life, dispose of waste and contaminated Microspheres according to local requirements or contact the manufacturer.

™

™

E LITE

™

SPECIFICATIONS* Maximum Recommended Patient Weight Length Inside Length Width Inside Width Height Weight (without Microspheres) Microspheres Weight (with Microspheres) Weight (with Microspheres, includes 50 lb. (23 kg) Inverter

250 lbs. (113 kg ) 89” (226 cm) 84” (213 cm) 37” (94 cm) 32” (81 cm) 34.5” (88 cm) 775 lbs. (351 kg) 1250 lbs. (567 kg) 2025 lbs. (918 kg) 2075 lbs. (941 kg)

Operating Temperature

88º - 92ºF (31º - 33ºC)

ELECTRICAL Volts Cycles Amps Max. Electrical Leakage Power Consumption - 780 Watts at 90% fluidization, low cool setting.

115V (230V) 60 Hz (50 Hz) 2-10 Amps 30 mA

*Specification subject to change without notice.

CAUTION: Federal law (United States) restricts this device to sale or rental by or on the order of a physician.

QUESTIONS AND INFORMATION For additional information concerning the FluidAir™ II/FluidAir™ Elite™ please contact your local KCI representative or: KCI USA, Inc. San Antonio, Texas 78219 USA 1-800-275-4524 FAX 1-800-275-3417 www.kci1.com All trademarks designated herein are property of KCI, its affiliates and licensors. Those KCI trademarks designated with the “®” or “™” symbol are registered in at least one country where the product/work is commercialized, but not necessarily all such countries. Most KCI products referenced herein are subject to patents and pending patents. ©2009 KCI Licensing, Inc. All Rights Reserved P/N 205461 Rev C.

MAY 2009 205461 Rev C This guide is intended solely as a quick reference source and is not intended to be a comprehensive guide. For more detailed information concerning the proper use of the FluidAir™ II and FluidAir™ Elite™ units refer to the User Manual. For medical questions please contact a physician. For additional information, call the Toll Free number in the Questions and Information section of this guide.

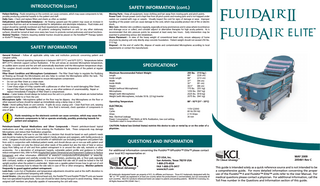

MAIN CONTROL DISPLAY AND SCALE CONTROL DISPLAY PANELS HOME DISPLAYS ON: FLUIDAIR™ II AND FLUIDAIR™ ELITE™

SWITCHED OFF keypad is locked

RUNNING

HEATING

LOW COOL

HIGH COOL

FLUID TIME TEMP

FLUID TIME TEMP

FLUID TIME TEMP

FLUID TIME TEMP

Fluidizing at target temperature

Blinking temperature indicates heater is on Warms to pre-selected target temperature

Activates 1º above target temperature Shuts off 1º below target temperature

Activates 3º above target temperature Switches to Low Cool 1º above target temperature

On/Off Switch Off for CPR

*

PAUSED, T-29 min keypad is locked Defluidizes unit for up to 30 minutes. Can be refluidized by pressing PAUSE Same function provided by Hand and Foot Controls

# DISPLAY

POWER

A

B

PAUSE

Fluid Adjust = XX decr incr home

Timer Select? nurse pt home

A Decrease Fluidization B Increase Fluidization C Return to Home Display

A Reset/View Nurse Timer B View Patient Timer C Return to Home Display

Temp is: XXX F Adjust C/F home Display Actual Temperature A Select Target Temperature Increase/Decrease Display B Select Centigrade or Fahrenheit Scale C Return to Home Display

MAIN CONTROL PANEL SCALE CONTROL PANEL (only on FluidAir™ Elite™) The Scale Control Panel shown below is located in a pull-out enclosure at the foot of the unit. Press LB/KG to select either Pounds or Kilograms. PAT WT

WEIGHT CHANGE XXX . X Lb. RESET

Press PAT WT/WT CHG to view accumulative weight change since zeroing scale.

RESET

WT CHG

LB KG

Press and hold the blank button next to RESET (for 5 seconds) for set-up screen. SET-UP XXX . X Lb. ENT

PATIENT WEIGHT START

000.0 Lb. RESET

Press blank button under “START” to return to Home Display.

ZERO

The FluidAir™ II and FluidAir™ Elite™ units are designed to provide Air Fluidized Therapy by supporting the patient on a surface of fluidized Microspheres (or “beads”). A large volume of air is forced upward through the Microsphere mass causing the beads to behave as a fluid, helping to maintain interface pressures below capillary closure. A dry patient environment is provided as the conditioned air flows up past the patient and moisture and contamination pass downward into the Fluidization Tank, away from the patient. The Microspheres clump, producing dense particles that sink to the bottom of the tank. The fluidization level of the Microspheres and the temperature of the air flowing upward through the Microshphere mass can be adjusted to meet individual patient needs, helping to minimize dehydration and electrolyte imbalance. Fluidization can be temporarily stopped from the Main Control Panel located at the foot end of the unit, or by using the remote Hand Control or Foot Control. A built-in Scale allows patient weight change to be monitored without removing the patient from the unit. GENERAL • •

Use “RESET” button to view current patient weight after power is restored to unit. After plugging unit into a electrical AC outlet, system will prompt user to wait two minutes for scales to stabilize, then press “RESET”. Patient weight is displayed.

EXIT

Loosen and smooth out filter sheet from under patient. Reposition patient per institution protocol.

CPR • • •

ALARM SILENCE

C

INTRODUCTION

Press POWER button on Main Control Panel, or on Foot or Hand Control (if equipped) to turn off unit. Lower Side Rail. Begin CPR. No crashboard is required.

INDICATIONS The FluidAir™ II and FluidAir™ Elite™ units are indicated for patients who would benefit from advanced pressure relief and a dry patient environment. Particular classes of such patients include (among others) patients with the following: • Skin Flaps and Grafts • Pressure Ulcers (especially draining) • Burns • Acute Exfoliative Dermatitis • Patients with limited mobility • Oncology • Aids in pain relief • Reduces risk of Pathological Fractures CONTRAINDICATIONS The FluidAir™ II and FluidAir™ Elite™ units are contraindicated for the following patient conditions: • Acute or unstable spinal cord injury • Pulmonary concerns RISKS AND PRECAUTIONS Side Rails and Restraints - Use of restraints, including side rails, can be critical to patient safety. Serious injury or death can result from the use (potential entrapment) or non-use (potential patient falls) of side rails or other restraints. See related Safety Information. Transfer - Precaution should be taken during patient transfer, including locking of caster wheels. Refer to the Patient Transfer in the Patient Placement and Nursing Care chapters of the User Manual. Shock Hazard - Electrical shock hazard, do not remove cover. Refer to qualified service personnel. Patient Migration - Specialty surfaces have different shear and support characteristics than conventional surfaces and may increase the risk of patient movement, sinking and/or migration into hazardous positions of entrapment and/or inadvertent unit exit. Monitor patients frequently to guard against patient entrapment. Exposure to Beads - May cause temporary skin irritation. If exposed, wash the exposed area immediately with soap and running water. Scrub vigorously with lots of lather. If exposure is to the membranes of the eye or mouth, flush area with copious amounts of water until sure that the irritant/substance is removed. See related Safety Information on Filter Sheet Condition and Microspheres.

ENTER WEIGHT XXX . X Lb. INC.

DEC.

EXIT RESET

Select blank button under “INC” and “DEC” to adjust weight. Press “RESET” when finished.

RESET

Select blank button under “ENT” to enter a known weight change.

PATIENT WEIGHT

Select blank button under “ZERO” to zero scales.

START

0.0 Lb. RESET

Press blank button under “START” to return to Home Display.

Care should be taken, especially with restless, agitated or highly mobile patients to avoid rips and tears in the cover sheets that may lead to exposure of beads. Monitor patients and cover sheet conditions frequently. Oxygen Use - DANGER: Risk of explosion if this product’s Hand Control is used in the presence of flammable anesthetics. Use of this product in an oxygen-enriched environment may produce potential of fire hazard. This equipment is not suitable for use in the presence of flammable anesthetic mixture with air or with oxygen or nitrous oxide.