LIEBHEER

SUFsg 7001 MediLine Ultra Low Temperature Freezer Operating Manual April 2022l

Operating Manual

107 Pages

Preview

Page 1

Translation of the Original Operating Manual

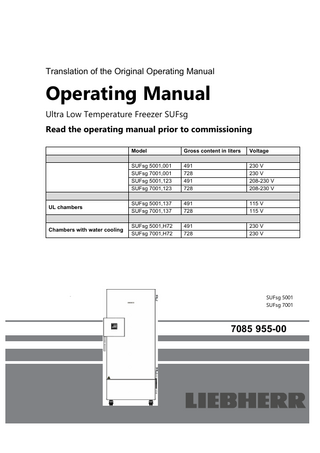

Operating Manual Ultra Low Temperature Freezer SUFsg

Read the operating manual prior to commissioning Model

Gross content in liters

Voltage

SUFsg 5001,001 SUFsg 7001,001 SUFsg 5001,123 SUFsg 7001,123

491 728 491 728

230 V 230 V 208-230 V 208-230 V

UL chambers

SUFsg 5001,137 SUFsg 7001,137

491 728

115 V 115 V

Chambers with water cooling

SUFsg 5001,H72 SUFsg 7001,H72

491 728

230 V 230 V

SUFsg 5001 SUFsg 7001

7085 955-00

Contents 1.

SAFETY ... 6

1.1 1.2 1.3 1.4

Personnel Qualification ... 6 Operating manual ... 6 Legal considerations ... 6 Structure of the safety instructions ... 7 1.4.1 Signal word panel ... 7 1.4.2 Safety alert symbol ... 7 1.4.3 Pictograms ... 8 1.4.4 Word message panel structure ... 8 1.5 Localization / position of safety labels at the chamber ... 9 1.6 Type plate... 10 1.7 General safety instructions on installing and operating the chamber ... 11 1.8 Intended use ... 13 1.9 Foreseeable Misuse ... 15 1.10 Residual Risks ... 15 1.11 Operating instructions ... 17 1.12 Measures to prevent accidents ... 17

2.

CHAMBER DESCRIPTION ... 18

2.1 2.2

Chamber overview ... 20 Door lock and controller housing ... 22 2.2.1 Operating the door lock ... 22 2.3 Main power switch ... 23 2.4 Chamber rear ... 24 2.5 Doors ... 25 2.5.1 Outer door ... 25 2.5.2 Compartment doors ... 25

3.

COMPLETENESS OF DELIVERY, TRANSPORTATION, STORAGE, AND INSTALLATION... 26

3.1 3.2

Unpacking, and checking equipment and completeness of delivery ... 26 Guidelines for safe lifting and transportation... 27 3.2.1 Moving the freezer inside a building ... 27 3.2.2 Transport outside a building ... 28 3.3 Storage ... 29 3.4 Location of installation and ambient conditions ... 29

4.

INSTALLATION AND CONNECTIONS ... 31

4.1 4.2 4.3 4.4

Operating instructions ... 31 Spacers for rear wall distance ... 31 Adjustable shelves ... 31 Connections of cooling water for chambers with water cooling ... 33 4.4.1 Connection of cooling water outlet for water cooling ... 33 4.4.2 Connection of cooling water inlet for water cooling ... 34 4.4.3 Connection kit for cooling water ... 34 4.5 Electrical connection ... 36

5.

FUNCTIONAL OVERVIEW OF THE CHAMBER CONTROLLER ... 37

5.1

Menu structure of the controller and access levels ... 38

6.

START UP ... 39

6.1 6.2

Preset factory parameters ... 39 Behavior after turning on the chamber ... 39

7.

TEMPERATURE SET-POINT ENTRY ... 40

SUFsg 04/2022

Page 2/108

8.

PLACING SAMPLES IN STORAGE IN THE FREEZER ... 41

9.

SETTING SPECIAL CONTROLLER FUNCTIONS ... 42

10. PASSWORD ... 43 10.1 Password request ... 43 10.2 Assign and modify a password ... 43 10.2.1 Assign and modify the User password ... 44 10.2.2 Assign and modify the Admin password ... 44 10.3 Performance during and after power failure and shut down ... 45

11. SAFETY CONTROLLER (TEMPERATURE SAFETY DEVICE) ... 45 11.1 11.2 11.3 11.4

Setting the safety controller mode ... 46 Setting the safety controller value ... 46 Message and measures in the state of alarm ... 47 Function check ... 47

12. GENERAL CONTROLLER SETTINGS ... 48 12.1 12.2 12.3 12.4 12.5 12.6 12.7

Selecting the controller’s menu language ... 48 Selecting the temperature unit ... 48 Setting the current date ... 49 Setting the current time ... 50 Function “Language selection at restart” ... 50 Setting the chamber address ... 51 Display brightness ... 51

13. SETTING THE ALARM LIMIT FOR RANGE ALARM AND THE ALARM DELAYS ... 52 13.1 Setting the delay time for door open alarm ... 52 13.2 Setting the delay time for range alarm ... 52 13.3 Setting the alarm limit of the range alarm ... 53

14. ALARM FUNCTIONS ... 54 14.1 Alarm messages ... 54 14.2 Information messages ... 56 14.3 Activating / deactivating the audible alarm (alarm buzzer) ... 56 14.4 Required actions in case of an alarm ... 57 14.4.1 Safety controller temperature alarm ... 57 14.4.2 Temperature range alarm (too high and too low temperature) ... 57 14.4.3 Door open alarm ... 58 14.4.4 Power failure alarm... 58 14.4.5 Messages on the battery management system ... 59 14.4.6 Messages referring to temperature sensor failure ... 60 14.4.7 Messages referring to CO2 emergency cooling (option CO2 emergency cooling) ... 61 14.5 Zero-voltage relay alarm output ... 62

15. ETHERNET NETWORK SETTINGS ... 63 15.1 Showing the network settings ... 63 15.1.1 Showing the chamber’s MAC address ... 63 15.1.2 Showing the IP address... 63 15.1.3 Showing the subnet mask ... 64 15.1.4 Showing the standard gateway ... 64 15.1.5 Showing the DNS server address ... 64 15.1.6 Showing the DNS chamber name ... 65 15.2 Changing the configuration of the network settings ... 65 15.2.1 Selecting the type of IP address assignment (automatic / manual) ... 65 15.2.2 Selecting the type of assignment of the DNS server address (automatic / manual) ... 66 15.2.3 Assigning the IP address ... 66

SUFsg 04/2022

Page 3/108

15.2.4 15.2.5 15.2.6

Setting the subnet mask ... 67 Setting the standard gateway ... 67 Assigning the DNS server address ... 68

16. DATA RECORDER ... 68 16.1 16.2 16.3 16.4

Recorded data ... 68 Storage capacity ... 69 Setting the storage rate for the “DL1” recorder data ... 69 Deleting the data recorder... 69

17. USB-MENU: DATA TRANSFER VIA USB INTERFACE ... 70 17.1 17.2 17.3 17.4 17.5 17.6

Connecting the USB stick ... 70 Import function ... 70 Export functions ... 71 Ongoing data transfer ... 71 Error during data transmission ... 72 Removing the USB stick ... 72

18. BATTERY MANAGEMENT SYSTEM ... 72 18.1 Battery operation ... 72 18.2 Charging voltage ... 73

19. SETTING AND ACTIVATING THE SERVICE SETPOINT ... 73 19.1 Setting the service setpoint ... 73 19.2 Activating the service setpoint... 74

20. CO2 EMERGENCY COOLING (OPTION) ... 75 20.1 Connecting and exchanging the pressurized CO2 cylinder... 76 20.2 Operating the CO2 emergency cooling system ... 78 20.3 Settings on the chamber controller ... 79 20.3.1 Setting the CO2 emergency cooling temperature setpoint ... 80 20.3.2 Activating the CO2 emergency cooling ... 80 20.3.3 Test run of the CO2 emergency cooling ... 81

21. DATA MONITORING AND RECORDING ... 82 21.1 Ethernet interface ... 82 21.2 Analog output for temperature (option) ... 82

22. CHAMBER INVENTORY: STORAGE RACK SYSTEMS AND CRYO BOXES (OPTION) ... 83 22.1 Storage rack systems with or without cryo boxes ... 83 22.2 Cryo boxes ... 83

23. CLEANING AND DECONTAMINATION ... 84 23.1 Cleaning ... 84 23.2 Decontamination / chemical disinfection ... 86

24. MAINTENANCE AND SERVICE, SERVICE, TROUBLESHOOTING, REPAIR, TESTING ... 87 24.1 General information, personnel qualification... 87 24.2 Maintenance work by the customer ... 88 24.2.1 Checking and cleaning / replacing the condenser air filter... 88 24.2.2 Cleaning the condenser... 89 24.2.3 De-icing and defrosting... 89 24.2.4 Maintenance of the door lock ... 90 24.3 Maintenance intervals, service ... 91 24.4 Service Reminder ... 91 24.5 Simple troubleshooting... 92 24.6 Sending the chamber back ... 94 SUFsg 04/2022

Page 4/108

25. DISPOSAL... 94 25.1 25.2 25.3 25.4

Disposal of the transport packing ... 94 Decommissioning ... 94 Disposal of the chamber in the member states of the EU ... 95 Disposal of the chamber in non-member states of the EU ... 96

26. TECHNICAL DESCRIPTION ... 96 26.1 26.2 26.3 26.4 26.5 26.6

Factory calibration and adjustment ... 96 Over current protection ... 96 Technical data ... 96 Equipment and options, accessories and spare parts (extract) ... 99 Dimensions SUFsg 5001 ... 101 Dimensions SUFsg 7001 ... 102

27. EU DECLARATION OF CONFORMITY ... 103 28. CONTAMINATION CLEARANCE CERTIFICATE ... 105

SUFsg 04/2022

Page 5/108

Dear Customer, For the correct operation of the SUFsg ultra-low temperature freezer, it is important that you read this operating manual completely and carefully and observe all instructions as indicated. Failure to read, understand and follow the instructions may result in personal injury. It can also lead to damage to the chamber and/or poor equipment performance.

1.

Safety

1.1

Personnel Qualification

The chamber must only be installed, tested, and started up by personnel qualified for assembly, startup, and operation of the chamber. Qualified personnel are persons whose professional education, knowledge, experience and knowledge of relevant standards allow them to assess, carry out, and identify any potential hazards in the work assigned to them. They must have been trained and instructed, and be authorized, to work on the chamber. The chamber should only be operated by laboratory personnel especially trained for this purpose and familiar with all precautionary measures required for working in a laboratory. Observe the national regulations on minimum age of laboratory personnel.

1.2

Operating manual

This operating manual is part of the components of delivery. Always keep it handy for reference in the vicinity of the chamber. If selling the unit, hand over the operating manual to the purchaser. To avoid injuries and damage observe the safety instructions of the operating manual. Failure to follow instructions and safety precautions can lead to significant risks.

DANGER Dangers due to failure to observe the instructions and safety precautions. Serious injuries and chamber damage. Risk of death. Observe the safety instructions in this Operating Manual. Follow the operating procedures in this Operating Manual. Carefully read the complete operating instructions of the chamber prior to installing and using the chamber. Keep the operating manual for future reference Make sure that all persons who use the chamber and its associated work equipment have read and understood the Operating Manual. This Operating Manual is supplemented and updated as needed. Always use the most recent version of the Operating Manual. When in doubt, call the manufacturer’s Service Hotline for information on the up-todateness and validity of this Operating Manual.

1.3

Legal considerations

This operating manual is for informational purposes only. It contains information for correct and safe installing, start-up, operation, decommissioning, cleaning and maintenance of the product. Note: the contents and the product described are subject to change without notice.

SUFsg 04/2022

Page 6/108

Understanding and observing the instructions in this operating manual are prerequisites for hazard-free use and safety during operation and maintenance. Images are to provide basic understanding. They may deviate from the actual version of the chamber. The actual scope of delivery can, due to optional or special design, or due to recent technical changes, deviate from the information and illustrations in these instructions this operating manual. In no event shall the manufacturer be held liable for any damages, direct or incidental arising out of or related to the use of this manual. This operating manual cannot cover all conceivable applications. If you would like additional information, or if special problems arise that are not sufficiently addressed in this manual, please ask your dealer or contact us directly, e.g. by phone at the number located on page one of this manual Furthermore, we emphasize that the contents of this operating manual are not part of an earlier or existing agreement, description, or legal relationship, nor do they modify such a relationship. All obligations on the part of the manufacturer derive from the respective purchase contract, which also contains the entire and exclusively valid statement of warranty administration and the general terms and conditions, as well as the legal regulations valid at the time the contract is concluded. The statements in this manual neither augment nor restrict the contractual warranty provisions.

1.4

Structure of the safety instructions

In this operating manual, the following safety definitions and symbols indicate dangerous situations in accordance with the standards ISO 3864-2 and ANSI Z535.6.

1.4.1 Signal word panel Depending on the probability of serious consequences, potential dangers are identified with a signal word, the corresponding safety color, and if appropriate, the safety alert symbol.

DANGER Indicates an imminently hazardous situation that, if not avoided, will result in death or serious (irreversible) injury.

WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or serious (irreversible) injury

CAUTION Indicates a potentially hazardous situation which, if not avoided, may result in moderate or minor (reversible) injury

NOTICE Indicates a potentially hazardous situation which, if not avoided, may result in damage to the product and/or its functions or of a property in its proximity.

1.4.2 Safety alert symbol Use of the safety alert symbol indicates a risk of injury. Observe all measures that are marked with the safety alert symbol in order to avoid death or injury.

SUFsg 04/2022

Page 7/108

1.4.3 Pictograms Warning signs

Electrical hazard

Very cold surface

Explosive atmosphere

Stability hazard

CO2 suffocation hazard

Gas cylinders

Pollution Hazard

Harmful substances

Biohazard

Risk of corrosion and / or chemical burns

Lift with mechanical assistance

Mandatory action signs

Mandatory regulation

Read operating instructions

Disconnect the power plug

Environment protection Prohibition signs

Wear protective gloves

Wear safety goggles

Do NOT touch

Do NOT spray with water

Do NOT climb

Information to be observed in order to ensure optimum function of the product.

1.4.4 Word message panel structure Type / cause of hazard. Possible consequences. ∅ Instruction on how to avoid the hazard: prohibition Instruction on how to avoid the hazard: mandatory action Observe all other notes and information not necessarily emphasized in the same way, in order to avoid disruptions that could result in direct or indirect injury or property damage.

SUFsg 04/2022

Page 8/108

1.5

Localization / position of safety labels at the chamber

The following labels are located on the chamber: Pictograms (Warning signs)

Information

Very cold surface: Risk of freezing

Energy Star Symbol (only UL chambers)

Risk of injury. Observe the safety instructions in the operating manual. (only UL chambers and chambers with optional CO2 emergency cooling)

Flammable refrigerants (only SUFsg 5001,123, SUFsg 7001,123, SUFsg 5001,137, SUFsg 7001,137)

SUFsg regular chamber

SUFsg with optional CO2 emergency cooling

SUFsg voltages 115V and 208-230 V, rear view

Figure 1: Position of labels on the ultra-low temperature freezer SUFsg

Keep safety labels complete and legible. Replace safety labels that are no longer legible. Contact the manufacturer’s Service for these replacements.

SUFsg 04/2022

Page 9/108

1.6

Type plate

The type plate sticks to the left side of the chamber, bottom right-hand. Nominal temp. Ambient temp. IP protection Phase Stage 1: R290 Stage 2: R170

-90 °C 1,60 kW / 7,0 A -130 °F 230 V / 50 Hz +16 °C - +32 °C 20 1N~ 107 Ultra Low Temperature Freezer 0,15 kg SUFsg 5001-70B 001 0,15 kg Liebherr Hausgeräte GmbH Memminger Straße 77-79 D-88416 Ochsenhausen

Gross volume: 491 liter Max. operating pressure 28 bar Contains hydrocarbon gases Ultra-Tiefkühlschrank Congélateur à ultra-basse temp Низкотемпературный морозильник

Service No. Serial No. 69.000.001.4 993356902 Made in Germany / Сделано в Германии

Figure 2: SUFg type plate (example SUFsg 5001,001)

Nominal temp. Ambient temp. IP protection Phase Stage 1: R290 Stage 2: R170

-90 °C 1,40 kW / 11,7 A -130 °F 115 V / 60 Hz +16 °C - +32 °C 20 1N~ 107 Ultra Low Temperature Freezer 0,15 kg SUFsg 5001-70B 137 0,15 kg Liebherr Hausgeräte GmbH Memminger Straße 77-79 D-88416 Ochsenhausen

Gross volume: 491 liter Max. operating pressure 28 bar Contains hydrocarbon gases Ultra-Tiefkühlschrank Congélateur à ultra-basse temp Низкотемпературный морозильник

Service No. Serial No. 69.000.001.4 090433602 Made in Germany / Сделано в Германии

Figure 3: SUFg type plate (example SUFsg 5001,137) Indications of the type plate (example): Indication LIEBHERR SUFsg 5001-70B 001 Ultra Low Temperature Freezer Serial No. 69.000.001.4 Service No. 993356901 Nominal temp. -90 °C -130 °F Ambient temp. +16 °C - +32 °C IP protection 20 1,60 kW 7,0 A 230 V / 50 Hz Phase 1 N ~ Gross volume: 500 liter Max. operating pressure 28 bar Contains hydrocarbon gases Stage 1: R290 – 0,15 kg Stage 2: R170 – 0,15 kg

SUFsg 04/2022

Information Distributor: Liebherr Hausgeräte GmbH Model designation Chamber name Serial no. of the chamber Service no. of the chamber Nominal temperature Permissible ambient temperature during operation IP type of protection acc. to standard EN 60529 Nominal power Nominal current Nominal voltage +/- 10% at the indicated power frequency Current type Volume of the chamber interior Max operating pressure in the refrigerating system Contains hydrocarbon gases Cooling 1st stage: Refrigerant type, filling weight Cooling 2nd stage: Refrigerant type, filling weight

Page 10/108

Symbols on the type plate: Symbol

Applies to

Information

All models

CE conformity marking

All models

Electrical and electronic equipment manufactured / placed on the market in the EU after 13 August 2005 and to be disposed of in a separate collection according to directive 2012/19/EU on waste electrical and electronic equipment (WEEE).

SUFsg 5001,001 SUFsg 7001,001 SUFsg 5001,H72 SUFsg 7001,H72

The chamber is certified according to Customs Union Technical Regulation (CU TR) for the Eurasian Economic Union (Russia, Belarus, Armenia, Kazakhstan Kyrgyzstan). The chamber is certified by Underwriters Laboratories Inc.® according to the following standards:

SUFsg 5001,137 SUFsg 7001,137

• UL 61010-1, 3rd Edition, 2012-05, Rev. 2018-11 • CAN/CSA-C22.2 No. 61010-1-12, 3rd Edition, Amendment 1:2018, 2012-05, Rev. 2018-11 • IEC 61010-2-011:2019 • UL 61010-2-011 (IEC 61010-2-011:2016)

1.7

General safety instructions on installing and operating the chamber

With regard to operating the chamber and to the installation location, please observe the local and national regulations relevant to your country. The manufacturer is only responsible for the safety features of the chamber provided skilled electricians or qualified personnel authorized by the manufacturer perform all maintenance and repair, and if components relating to chamber safety are replaced in the event of failure with original spare parts. To operate the chamber, use only original accessories from the manufacturer or accessories from thirdparty suppliers authorized by the manufacturer. The user is responsible for any risk caused by using unauthorized accessories.

NOTICE Danger of overheating due to lack of ventilation. Damage to the chamber. ∅ Do NOT install the chamber in unventilated recesses. Ensure sufficient ventilation for dispersal of the heat. Observe the prescribed minimum distances when installing the chamber (chap. 3.4)

NOTICE Danger to the environment by leakage of refrigerant in the event of a chamber defect. Alteration of the environment. Ensure sufficient ventilation of the installation site.

SUFsg 04/2022

Page 11/108

Do not install or operate the chamber in hazardous locations.

DANGER Danger of explosion due to combustible dusts or explosive mixtures in the vicinity of the chamber. Serious injury or death from burns and / or explosion pressure. ∅ Do NOT operate the chamber in potentially explosive areas. KEEP combustible dust or air-solvent mixtures AWAY from the chamber. The chamber does not dispose of any measures of explosion protection.

DANGER Danger of explosion due to introduction of flammable or explosive substances in the chamber. Serious injury or death from burns and / or explosion pressure. ∅ Do NOT introduce any substance into the chamber which is combustible or explosive at working temperature. ∅ Do NOT introduce any combustible dust or air-solvent mixture in the inner chamber. Any solvent contained in the charging material must not be explosive or inflammable. I.e., irrespective of the solvent concentration in the steam room, NO explosive mixture with air must form. The temperature inside the chamber must lie below the flash point or below the sublimation point of the charging material. Familiarize yourself with the physical and chemical properties of the charging material. Familiarize yourself with any potential health risks caused by the charging material. Take adequate measures to exclude any risk prior to putting the chamber into operation.

WARNING Danger of intoxication and infection through contamination of the chamber with toxic, infectious or radioactive substances. Damages to health. Protect the interior of the chamber against contamination by toxic, infectious or radioactive substances. Take appropriate measures when bringing in or taking out toxic, infectious or radioactive substances.

DANGER Electrical hazard by water entering the chamber. Deadly electric shock. ∅ The chamber must NOT become wet during operation, cleaning, or maintenance. ∅ Do NOT install the chamber in damp areas or in puddles. Set up the chamber in a splash-proof manner. The chambers were produced in accordance with VDE regulations and were routinely tested in accordance to VDE 0411-1 (IEC 61010-1).

SUFsg 04/2022

Page 12/108

The inner surfaces become very cold during operation.

CAUTION Danger of injury by freezing on when touching cold chamber parts during or after operation. Local frostbite. ∅ Do NOT directly touch the inner surfaces or the charging material during operation. ∅ AVOID skin contact with the inner surfaces and accessory equipment. Wear protective gloves when opening the inner doors and during manipulation.

WARNING Danger of injury and damages by the chamber tipping over or breakaway of the protruding lower housing cover. Injuries and damage to the chamber and the charging material ∅ Do NOT climb on the lower housing cover. ∅ Do NOT load the lower housing cover with heavy objects while the chamber door is open.

1.8

Intended use Following the instructions in this operating manual and conducting regular maintenance work (chap. 24) are part of the intended use.

Any use of the chambers that does not comply with the requirements specified in this Operating Manual shall be considered improper use. Other applications than those described in this chapter are not approved. Use SUFsg ultra-low temperature freezers are technical equipment and intended solely for use at work. They are suitable are designed for safe storage of varied materials at temperatures up to –90 °C / -130 °F, especially for long-term storage of biological, medical, and chemical samples at constant low temperature. They are suitable for the domains Pharmacy, Medicine, Life Sciences, plastic industry, electronic components, food etc. Freezers are designed for storage of harmless materials. In case of foreseeable use of the chamber there is no risk for the user through the integration of the chamber into systems or by special environmental or operating conditions in the sense of EN 61010-1:2010. For this, the intended use of the chamber and all its connections must be observed. Requirements for the chamber load The charging material shall not contain any corrosive ingredients that may damage the machine components made of stainless steel. Such ingredients include in particular acids and halides. Any corrosive damage caused by such ingredients is excluded from liability by the manufacturer. None of the components of the charging material must be able to form an explosive mixture with air. Any component of the charging material must NOT be able to release toxic gases.

SUFsg 04/2022

Page 13/108

The chamber does not dispose of any measures of explosion protection.

DANGER Explosion or implosion hazard and danger of poisoning through the introduction of unsuitable loading material. Poisoning. Serious injury or death from burns and / or explosion pressure. ∅ Do NOT introduce any substance combustible or explosive into the chamber, in particular no energy sources such as batteries or lithium-ion batteries. ∅ NO explosive dust or air-solvent mixture in the inner chamber. ∅ Do NOT introduce any substance which could lead to release of toxic gases. Contamination of the chamber by toxic, infectious or radioactive substances must be prevented

WARNING Danger of intoxication and infection through contamination of the chamber with toxic, infectious or radioactive substances. Damages to health. Protect the interior of the chamber against contamination by toxic, infectious or radioactive substances. Take appropriate measures when bringing in or taking out toxic, infectious or radioactive substances. Medical devices The chambers are not classified as medical devices as defined by the Medical Device Directive 93/42/EEC and 2017/745/EU. Personnel Requirements Only trained personnel with knowledge of the Operating Manual can set up and install the chamber, start it up, operate, clean, and take it out of operation. Service and repairs call for further technical requirements (e.g. electrical know-how), as well as knowledge of the service manual. Installation site requirements The chambers are designed for setting up inside a building (indoor use). The requirements described in the Operating Manual for installation site and ambient conditions (Chap. 3.4) must be met. WARNING: If customer should use a chamber running in non-supervised continuous operation, we strongly recommend in case of inclusion of irrecoverable specimen or samples to split such specimen or samples and store them in at least two chambers, if this is feasible.

SUFsg 04/2022

Page 14/108

1.9

Foreseeable Misuse

Other applications than those described in chap. 1.8 are not approved. This expressly includes the following misuses (the list is not exhaustive), which pose risks despite the inherently safe construction and existing technical safety equipment: • Non-observance of Operating Manual • Non-observance of information and warnings on the chamber (e.g. control unit messages, safety identifiers, warning signals) • Installation, startup, operation, maintenance and repair by untrained, insufficiently qualified, or unauthorized personnel • Missed or delayed maintenance and testing • Non-observance of traces of wear and tear • Insertion of materials excluded or not permitted by this Operating Manual. • Non-compliance with the admissible parameters for processing or storing the respective material. • Installation, testing, service or repair in the presence of solvents • Installation of replacement parts and use of accessories and operating resources not specified and authorized by the manufacturer • Bypassing or changing protective systems, operation of the chamber without the designated protective systems • Non-observance of messages regarding cleaning and disinfection of the chamber. • Spilling water or cleaning agent on the chamber, water penetrating into the chamber during operation, cleaning or maintenance. • Cleaning activity while the chamber is turned on. • Operation of the chamber with a damaged housing or damaged power cord • Continued operation of the chamber during an obvious malfunction • Insertion of objects, particularly metallic objects, in louvers or other openings or slots on the chamber • Human error (e.g. insufficient experience, qualification, stress, exhaustion, laziness) To prevent these and other risks from incorrect operation, it is recommended to issue operating instructions and Standard operating procedures (SOPs).

1.10 Residual Risks The unavoidable design features of a chamber, as well as its proper field of application, can also pose risks, even during correct operation. These residual risks include hazards which, despite the inherently safe design, existing technical protective equipment, safety precautions and supplementary protective measures, cannot be ruled out. Messages on the chamber and in the Operating Manual warn of residual risks. The consequences of these residual risks and the measures required to prevent them are listed in the Operating Manual. Moreover, the operator must take measures to minimize hazards from unavoidable residual risks. This includes, in particular, issuing operating instructions. The following list summarizes the hazards against which this Operating Manual and the Service Manual warn, and specifies protective measures at the appropriate spots:

SUFsg 04/2022

Page 15/108

Unpacking, Transport, Installation • Sliding or tilting the chamber • Setup of the chamber in unauthorized areas • Installation of a damaged chamber • Installation of a chamber with damaged power cord • Inappropriate site of installation • Missing protective conductor connection Normal operation • Assembly errors • Contact with cold surfaces on the housing and on the inside of the door • Emission of non-ionizing radiation from electrical operating resources • Contact with live parts in normal state Cleaning and Decontamination • Penetration of water into the chamber • Inappropriate cleaning and decontamination agents • Enclosure of persons in the interior Malfunction and Damage • Continued operation of the chamber during an obvious malfunction or outage of the cooling system • Contact with live parts during error status Operation of a unit with damaged power cord Maintenance • Maintenance work on live parts. • Execution of maintenance work by untrained/insufficiently qualified personnel • Electrical safety analysis during annual maintenance not performed Trouble-shooting and Repairs • Non-observance of warning messages in the Service Manual • Trouble-shooting of live parts without specified safety measures • Absence of a plausibility check to rule out erroneous inscription of electrical components • Performance of repair work by untrained/insufficiently qualified personnel • Inappropriate repairs which do not meet the quality standard specified by the manufacturer • Use of replacement parts other than original replacement parts • Electrical safety analysis not performed after repairs

SUFsg 04/2022

Page 16/108

1.11 Operating instructions Depending on the application and location of the chamber, we recommend that the operator of the chamber provides the relevant information for safe operation of the chamber in a set of operating instructions. Keep these operating instructions with the chamber at all times in a place where they are clearly visible. They must be comprehensible and written in the language of the employees.

1.12 Measures to prevent accidents The operator of the chamber must observe the locally applicable guidelines for operating the chamber and take precautions to prevent accidents Following measures have been taken by the manufacturer in order to prevent ignition and explosions: • Indications of the type plate See operating manual chap. 1.6 • Operating manual An operating manual is available for each chamber. • Temperature monitoring The chamber has a temperature display which can be read from outside. An additional temperature safety device is built into the chamber. A visual and an audible signal (buzzer) show exceeding of the temperature. • Safety, measurement and control devices The safety, measuring, and control devices are easily accessible. • Electrostatic charge The interior parts are grounded. • Non-ionizing radiation Non-ionizing radiation is not intentionally produced, but released only for technical reasons by electrical equipment (e.g. electric motors). The machine has strong permanent magnets. If persons with active implants (e.g. pacemakers, defibrillators) keep a safe distance (distance of field source to implant) of 30 cm, an influence of these implants can be excluded with high probability. • Protection against touchable surfaces Tested according to EN ISO 13732-3:2008. • Floors See operating manual chap. 3.4 for installation • Cleaning See operating manual chap. 23. • Examinations UL chambers only: The chamber is certified by Underwriters Laboratories Inc.® according to the standards UL 61010-1, 3rd Edition, 2012-05, Rev. 2018-11; CAN/CSA-C22.2 No. 61010-1-12, 3rd Edition, Amendment 1:2018, 2012-05, Rev. 2018-11; IEC 61010-2-011:2019; UL 61010-2-011 (IEC 61010-2011:2016).

SUFsg 04/2022

Page 17/108

2.

Chamber description

The SUFsg ultra-low temperature freezers were produced with great care using the latest tools for development and production. They were optimized for safe long-term storage of samples in the ultra-low temperature range. You can operate the freezer in a temperature range from -90 °C / -130 °F up to -40 °C / 40 °F. The freezers are available for several different voltages. Lockable protective flap for the main power switch (option) An additional locking system with key for the freezer’s main power switch is optionally available. Controller and safety The efficient chamber controller is equipped with a multitude of operating functions, in addition to recorder and alarm functions. Temperature setting is accurate to a tenth of a degree. The controller is mounted at the optimal height for operation. The controller offers an error diagnostics system generating audible and visual warning and alarm messages. In case of a power failure, alarm function and control remain active during 72h through the battery-buffered alarm system. The controller provides password protection for the setting menus. The controller monitors ambient temperature and issues an alarm if it exceeds an adjustable value. Thanks to the standard overtemperature safety device, the set temperature is maintained also in case of a controller failure. In case of power failure at -80 °C / -112 °F, a temperature of -60 °C / -76 °F will not be exceeded in an empty freezer for at least 3.5 hours, in a loaded freezer (measured with a 30 kg / 66 lb water load) for approx. 7 hours. Housing The inner chamber and the inside of the insulated outer door are made of stainless steel (German material no. 1.4016, US equivalent AISI 430). The housing including all corners and edges is plastic coated. The inner surfaces are smooth and therefore easy to clean. Easy front access permits filter cleaning without tools. Three 28 mm access port serve to introduce a sensor cable of a measuring device, the upper left one (6a) also to connect the optional CO2 emergency cooling The buildup of ice in the door area is minimal due to perfect closing of the inner and outer doors. Precise spatial distribution of the cold in the interior ensures storage of all samples at an identical storage temperature. The prevention of thermal bridges protects against defrosting. The combination of vacuum insulation panels (VIP technology) and CFC-free polyurethane foaming maximizes the insulation capacity. The freezer has two compartment doors. You can insert stainless steel shelves are make optimum use of the interior. You can flexibly arrange the shelves to use the interior in a variable and optimum manner. Inventory racks (stainless steel storage racks with cryo boxes, chap. 22) are optionally available. Castors with locks serve to move the freezer.

SUFsg 04/2022

Page 18/108

Cooling system The powerful, energy-efficient and low-noise refrigerating machine uses the environmentally friendly “green” refrigerants R290 (propane) und R170 (ethane). They are completely free of HCFCs (hydrochlorofluorocarbons) and CFCs (chlorofluorocarbon). Control of the two-stage refrigerating machine: The 1st stage cooling immediately turns on. In addition, the 2nd stage cooling turns on depending on the temperature. Battery-buffered alarm system The freezer is equipped with a rechargeable battery (12 V, 7.2 Ah). Battery voltage is regularly monitored. An alarm indicates too low battery voltage. You can check the battery voltage in the controller menu. An error diagnostics system monitors the chamber functions and generates audible and visual warning and alarm messages. E.g., the door is monitored for being closed. The CO2 emergency cooling (option, chap. 20) offers additional refrigeration, i.e., following introduction of a heat load, in case of a power failure or failure of the cooling system. Data monitoring and recording The chamber is regularly equipped with a zero-voltage relay alarm output (chap. 14.4.7) and optionally with an analog output (chap. 21.2) for integration into customer systems. The freezer is regularly equipped with an Ethernet interface (chap. 21.1) for computer communication, enabling monitoring via a network.

SUFsg 04/2022

Page 19/108

2.1

Chamber overview

(A)

(B)

(C)

(D) (E)

(F)

Figure 4: Ultra-low temperature freezer SUFsg (example SUFsg 7001), front view

(A)

Outer door

(B)

Door lock and controller housing (description chap. 2.2)

(C)

Door handle

(D)

Compressor housing

(E)

Cover flap (checking and cleaning / replacing the filter chap. 24.2.1)

(F)

Castors (front castors lockable by breaks)

SUFsg 04/2022

Page 20/108