Liko

Uno 200 Instruction Guide Nov 2011

Instruction Guide

14 Pages

Preview

Page 1

Uno 200™ Instruction Guide English 7EN150105-03 2011-11-22

Applies to the following model: Uno 200

Prod. No. 2010020

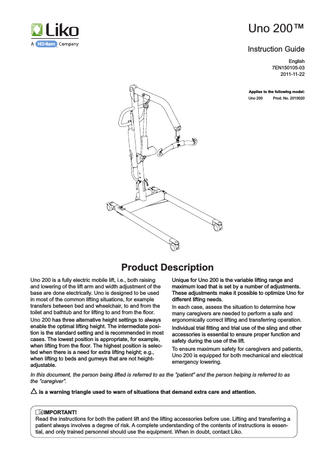

Product Description Uno 200 is a fully electric mobile lift, i.e., both raising and lowering of the lift arm and width adjustment of the base are done electrically. Uno is designed to be used in most of the common lifting situations, for example transfers between bed and wheelchair, to and from the toilet and bathtub and for lifting to and from the floor. Uno 200 has three alternative height settings to always enable the optimal lifting height. The intermediate position is the standard setting and is recommended in most cases. The lowest position is appropriate, for example, when lifting from the floor. The highest position is selected when there is a need for extra lifting height; e.g., when lifting to beds and gurneys that are not heightadjustable.

Unique for Uno 200 is the variable lifting range and maximum load that is set by a number of adjustments. These adjustments make it possible to optimize Uno for different lifting needs. In each case, assess the situation to determine how many caregivers are needed to perform a safe and ergonomically correct lifting and transferring operation. Individual trial fitting and trial use of the sling and other accessories is essential to ensure proper function and safety during the use of the lift. To ensure maximum safety for caregivers and patients, Uno 200 is equipped for both mechanical and electrical emergency lowering.

In this document, the person being lifted is referred to as the ”patient” and the person helping is referred to as the ”caregiver”. is a warning triangle used to warn of situations that demand extra care and attention.

IMPORTANT! Read the instructions for both the patient lift and the lifting accessories before use. Lifting and transferring a patient always involves a degree of risk. A complete understanding of the contents of instructions is essential, and only trained personnel should use the equipment. When in doubt, contact Liko.

Table of Contents Safety Instructions ...2 Definitions ...3 Technical Data ...3 Measurements ... 4-5 Assembly ... 6-7 Operation ... 7-8 Adjustments ...9 Charging the Batteries ...10 Maximum Load ...11 Recommended Lifting Accessories ...11-12 Simple Troubleshooting ...13 Care and Maintenance ...14 NOTE! This instruction guide contains information that is important for users of the product. A complete understanding of the contents of the instruction guide is essential, and only personnel who are well informed should use the equipment. Remember to keep the instruction guide readily accessible for users of the product.

Safety Instructions Before using the lift for the first time, make certain that: • the lift is assembled according to the assembly instructions • the lifting equipment is correctly applied to the lift • the batteries have been charged for at least 12 hours • you have read and understood the instruction guides for the lift and lifting accessories • personnel using the lift have received appropriate instructions and training. Before lifting always make certain that: • you have selected the correct type, size, material, and design of slings and accessories to safely meet the patient’s needs • lifting accessories are not damaged • the lifting accessory is correctly applied to the lifting equipment • the lifting accessory is correctly and securely applied to the patient, so that no personal injury can occur • the sling’s strap loops are correctly fastened to the sling bar hooks when the sling strap is extended, but before the patient is lifted from the underlying surface • the lift is set for the correct max. load. Never leave a patient unattended in a lifting situation!

Uno 200 is tested by an accredited testing institute and comply with the requirements of the directives for medicaltechnical Class 1 products (MDD 93/42/EEC). Uno 200 complies with the requirements according to IEC 60601-1, IEC 60601-1-2, EN ISO 10535, UL-60601-1 and CAN/CSA C22.2 No. 601.1. No modification of this product is allowed. Contact Liko for further information. Particular care must be taken when using strong sources of electromagnetic interference, such as diathermy, etc, so that cables are not positioned on or near the lift. If you have questions, please consult the responsible assistivedevice technician or the supplier. This equipment is not suitable for use in the presence of flammable mixtures. Maximum load: 160 kg (350 lbs) / 200 kg (440 lbs) depending on mounting alternative (see page 5).

Uno 200 • 7EN150105-03

2

www. liko. com

Definitions 1 2

1. 2. 3.

21

3

17

20

4

19

5 18

16

6

15

7 8

14

9

Forward direction

10 11

6 12 22 23

13

24

Upper attachment (lift motor) Lift mast Holder for quick reference guide with colour codes for sling sizes 4. Manoeuvering handle 5. Hand control 6. Control unit with built-in battery 7. Emergency stop 8. Cable for hand control 9. Locking handle 10. Motor for base-width adjustment 11. Rear wheels with brake 12. Base 13. Front wheels 14. Lower attachment (lift motor) 15. Lift motor (incl. actuator) 16. Product decal 17. Emergency lowering (mechanical) 18. Sling bar 19. Safety latches 20. Flexlink 21. Lift arm 22. LED (yellow light) - charger connected 23. LED (green light) - lift activated 24. Emergency lowering (electrical)

Technical Data Max. load:

160 kg (350 lbs) /200 kg (440 lbs) depending on mounting alternative

Operating forces of controls:

Buttons on hand control: 4 N Buttons on display: 4 N

Electrical data:

24 V

Material:

Painted steel with lacquer top coat.

Intermittent operation:

Weight:

Total: 39 kg (86 lbs) Heaviest dismountable part: 19 kg (42 lbs)

Int. Op 10/90, active operation max 2 min. Out of a time of 100, active must be less than 10, though not more than 2 min

Batteries:

Wheels:

Front: 75 mm (2.9 in) twin wheels. Rear: 75 mm (2.9 in) lockable twin wheels.

2 pcs. 12 V, 2,9 Ah, valve-regulated lead-acid gel-type batteries. New batteries are provided by your Liko representative.

Battery charger:

External charger, 100-240 V AC, 50-60 Hz, max 500 mA.

Lift motor:

24 V, permanent magnet motor with mechanical safety mechanism

Motor for base:

24 V, permanent magnet motor

Turning diameter: 1310 mm (52 in) Emergency lowering:

Mechanical and electrical

Lifting speed (without load):

22 mm (0.9 in)/s for max. load 160 kg (350 lbs) 18 mm (0.7 in)/s for max. load 200 kg (440 lbs)

Sound level:

42 dB(A)

The device is intended for indoor use.

Protection class:

IP X4

Expected life time:

Type B degree of protection against electrical shock.

10 years

Class II equipment.

Uno 200 • 7EN150105-03

3

www .liko. com

Measurements Side view

M

Amax N Amin O

E 600 mm

L Ref. 1

F F1

B3 B2 B1 B

Maximum reach of lift arm

Top view

C

D

D1

700 mm

Ref. 2

D2

Maximum reach of lift arm

Uno 200 • 7EN150105-03

4

www. liko. com

Adjustments of maximum load/lifting height X

Y

The lift motor can be mounted in four different combinations: X1: X2: Y1: Y2:

1 2

outer position (X) on the lift arm upper position (1) on the lift mast outer position(X) on the lift arm lower position (2) on the lift mast inner position (Y) on the lift arm upper position (1) on the lift mast inner position (Y) on the lift arm lower position (2) on the lift mast

The different mounting alternatives affect the lift's lifting height and maximum allowable load. See "Table of measurements" below.

Table of measurements Mounting alternative

Max. load

Lifting range

Max. load in kg. Dimensions in mm.

M

X1

637 1870 1430 200 1820 1380 1210 911 637 617 562 1770 1330

1374

667

1126

540

987

166

1093 1535 590 1043 102 27 1585 640 993 1635 690

945

320 225 395

X2

1776 1430 622 200 1726 1380 1210 911 637 562 1676 1330 562

1374

667

1126

540

987

166

1093 1435 495 1043 102 27 1485 545 993 1535 595

940

280 225 470

Y1

637 1980 1430 160 1930 1380 1210 911 637 617 562 1880 1330

1374

667

1126

540

987

166

1093 1668 535 1043 102 27 1718 585 1133 420 225 440 993 1768 635

Y2

1882 1430 622 160 1832 1380 1210 911 637 562 1782 1330 562

1374

667

1126

540

987

166

1093 1550 385 1043 102 27 1600 435 1265 330 225 630 993 1650 485

A*

C B

max

B1

D

L*

B2 B3**

min

D1 max

min

max

min

D2**

E*

F

F1 max min

N

O

Mounting alternative

Max. load

Lifting range

Max. load in lbs. Dimensions in inch.

M

X1

440

74 72 70

56 54 52

48

36

25

25 24 22

54

26.3

44

21

39

6.5

43 41 39

4

1

60 62 64

23 25 27

37

13

9

16

X2

440

70 68 66

56 54 52

48

36

25

24 22 22

54

26.3

44

21

39

6.5

43 41 39

4

1

56 58 60

19 21 23

37

11

9

19

Y1

350

78 76 74

56 54 52

48

36

25

25 24 22

54

26.3

44

21

39

6.5

43 41 39

4

1

66 68 70

21 23 25

45

17

9

17

Y2

350

74 72 70

56 54 52

48

36

25

24 22 22

54

26.3

44

21

39

6.5

43 41 39

4

1

61 63 65

15 17 19

50

13

9

25

A*

C B

max

min

B1

D

L*

B2 B3**

D1 max

min

max

min

D2**

E*

F

F1 max min

N

O

* Measures vary depending on height setting level, see "Assembly" page 6. NOTE! The measures apply for a lift equipped with standard sling bar and standard wheels. Before changing lifting equipment or wheels, ensure that the lift still achieves the desired lifting height. ** Reference measurements according to Standard EN ISO10535:2007.

Uno 200 • 7EN150105-03

5

www .liko. com

Assembly Before assembling, make sure you have the following components: • Lift mast with: lift arm, lift motor (incl. actuator), holder for quick reference guide, control unit and sling bar with safety latches • Base with motor for base-width adjustment • Hand control, incl. cable • Locking handles (1 pair)

1. On delivery, the lift is set for a max. load of 160 kg.

• Instruction guide and quick reference guide • Tools: 8 mm Allen wrench 17 mm closed-end wrench • Battery charger • Cable cover incl. screws (2 pcs).

2. Lock both rear wheels. Place the lift mast in the tube on the base.

3. The lifting height can be set at three different levels. The distance between two holes is 50 mm (2 in). The middle hole is recommended in most cases. See page 9 for more detailed information on the adjustment options.

3 2 1

4. Secure the lift mast by using the accompanying locking handles. Adjust the position of the handles so that they point downward.

Uno 200 • 7EN150105-03

5. Connect cables as follows: - Lift motor cable to socket 1 - Base-motor cable to socket 2 - Hand control to socket 3.

6

6. Guide the cables through the opening on the cable cover. Press the cable cover up into position. Use a screwdriver to secure the cable cover with the accompanying screws (2 pcs).

www. liko. com

XS S

MS

M L XL XX

L

7. Place the quick reference guide in its intended holder on the lift mast.

8.Reset the emergency stop by turning the button in the direction indicated by the arrows.

9. Before using the lift for the first time, charge the battery for a minimum of 12 hours, see page 10.

After assembly, check to ensure that: • wheel brakes work properly • base-width adjustment works properly • the lift is charging.

• lift arm motions correspond with the buttons on the hand control • emergency lowering (mechanical and electrical) functions properly

Operation

Emergency stop Activate emergency stop: Push the red emergency stop button on the control unit. Reset emergency stop: Turn the button in the direction of the arrows.

Hand control Operate the lift using the pushbuttons on the hand control. For raising and lowering, press either of the two upper pushbuttons. Directional arrows show the direction of movement (up/down) when the hand control is held as illustrated. For base-width adjustment, press either of the two lower push-buttons: wider narrower The movement stops when you release the buttons.

Uno 200 • 7EN150105-03

7

www .liko. com

Electrical emergency lowering The lift arm is lowered electrically by pressing the “ -button ".

Mechanical emergency lowering The lift arm is lowered mecanically by turning the red emergency-lowering cylinder in the direction of the arrows (clockwise).

Locking

Unlocking

Locking the wheels The rear wheels can be locked for rotation and lateral movement. To lock the wheels press the brake pedal down with your foot. Release the wheels by pressing the pedal up. During lifting, wheels should remain unlocked so that the lift may shift to the patient's center of gravity. The wheels should however be locked if there is a risk for the lift moving into the patient, for example when lifting from the floor.

Never move the lift by pulling the actuator!

Locked wheels during lifting increases the risk of the lift tilting over.

XS S

MS

M L XL XX

L

Quick reference guide A quick reference guide comes with the lift and should be kept easily accessible in its holder on the lift mast, so that users of the lift may easily remind themselves about the use of the lift. NOTE! The quick reference guide does not replace the lift's instruction guide. Uno 200 • 7EN150105-03

8

www. liko. com

Adjustments Adjustment of maximum load For guidance on adjustment alternatives, see "Adjustments of maximum load / lifting height", page 5.

Y Y

X

Max 160 kg

Max 200 kg

Max 160 kg

X Max 200 kg

1. Use Allen wrench 8 mm and closed-end wrench 17 mm to dismount the upper lift motor attachment from lift arm. For maximum load 160 kg/350 lbs choose position (Y) on the lift arm. For maximum load 200 kg/440 lbs choose position (X) on the lift arm. Note! Study the markings on the lift. On delivery, the lift is set for a max. load of 160 kg/350 lbs), in position (Y).

2. Secure the upper lift motor attachment in desired position using accompanying bolt and locking nut. Use Allen wrench 8 mm and closed-end wrench 17 mm.

Adjustment of lifting height

A

B

1

2

Via the lower lift motor attachment A. Use Allen wrench 8 mm and closed-end wrench 17 mm to dismount the lower lift motor attachment from the lift arm. Choose the upper hole (1) for a higher lifting height and the lower hole (2) for a lower lifting height. B. Secure the lower lift motor attachment in desired position using accompanying bolt and locking nut. Use Allen wrench 8 mm and closed-end wrench 17 mm. On delivery, the lower lift motor attachment is mounted in the lower hole (2).

Via the lift mast Release the lift mast by loosening the locking handles. The lifting height can be adjusted in three different levels on the lift mast. Choose one of the three holes according to the illustration above. The middle hole is recommended in most cases.The lower hole is recommended when extra lifting height is needed. The upper hole is recommended when a lower lifting height is needed. Secure the lift mast by using the accompanying locking handles. Adjust the position of the handles so that they point downward. The distance between two holes is 50 mm. See " Table of measurements", page 5. If this adjustment not is sufficient, see "Adjustment of lifting height - Via the lower lift motor attachment", page. 9.

Uno 200 • 7EN150105-03

9

www .liko. com

Charging the Batteries

For maximum battery life, batteries must be charged regularly. We recommend charging after use or each night. If the lift is not in daily use, we recommend that the emergency stop be pressed in after the lift has been used. This breaks the current and conserves battery power. Make sure the lift is fully charged before pressing in the emergency stop. On the control unit there is a display with a yellow LED (A) that illuminates while the charger is connected to an electric socket. Maximum charge is reached after about 12 hours. When the batteries are fully charged, the charger switches automatically to maintenance charging. When battery capacity is low (approx. 2-10 lift cycles remain) an audible signal sounds. In this case, charge the lift immedately. Never charge batteries in a wet area! The lift cannot be charged with the emergency stop button activated.

A

Charging procedure

1

With external charger: 1. Connect the charger cable to the charger socket under the control unit. 2. Connect the charger to a 100-240 V AC electric socket. 3. When the charger is connected a LED indicates: -yellow light indicates charging -green light indicates maintenance charging.

2

3

Note! The lift does not operate when the charger cable is plugged into an electric socket.

Old batteries are to be left at the nearest recycling station or given to personnel authorized by Liko.

Uno 200 • 7EN150105-03

10

www. liko. com

Maximum Load Different maximum allowable loads may apply to different products on the assembled lift system: lift, sling bar, sling and other accessories. For the total lift system, the lowest max. allowable load indicated for the respective products on the system always applies. For example: An Uno 200 that is approved for 160 kg (350 lbs)/200 kg (440 lbs) may be equipped with a lifting accessory that is approved for 300 kg (660 lbs). In this case, the applicable max. load is 160 kg(350 lbs)/200 kg (440 lbs) for the total lift system. Study markings on the lift and lifting accessories or contact your Liko representative if you have any questions.

Recommended Lifting Accessories Use of accessories other than those recommended may entail risk. Sling bars and accessories recommended for use with Uno 200 are described below. Changing sling bars and adding extra accessories affects the maximum lifting height of the lift. Before changing sling bars and accessories, it is important to ensure that it will still be possible to achieve the desired lifting height for situations in which the lift will be used. For choice of appropriate slings and other accessories, consult our brochure “Lifting Accessories”. For further guidance when selecting slings, study the instruction guides for the respective sling models. Here, you will find advice on suitable combinations of Liko sling bars and Liko slings. Contact your Liko representative or visit www.liko.com for advice and information on Liko’s range.

SlingBar Mini 220 Max 205 kg / 450 lbs.

Prod. No. 3156005

Universal SlingBar 350 Max 300 kg / 660 lbs.

Prod. No. 3156074

Universal SlingBar 450 (Standard for Uno 200) Max 300 kg / 660 lbs.

Prod. No. 3156075

Universal SlingBar 600 Max 300 kg / 660 lbs.

Prod. No. 3156076

Universal TwinBar 670 Max 300 kg / 660 lbs.

Prod. No. 3156077

Sling SideBars 450 incl. storage bag Max 300 kg / 660 lbs.

Prod. No. 3156079

Sling Cross-bar 450 Max 300 kg / 660 lbs.

Prod. No. 3156021

Sling Cross-bar 670 Max 300 kg / 660 lbs.

Prod. No. 3156018

Uno 200 • 7EN150105-03

11

www .liko. com

SlingBar Cover Paddy 30 (fits Universal SlingBar 350, 450 and 600 and SlingBar Slim 350)

Bag for SlingBars

Prod. No. 3607001

Prod. No. 2001025

Quick-release Hook Liko’s Quick-release Hook system enables quick and easy exchange of lifting accessories on Liko’s mobile and stationary lifts. Uno 200 requires Q-link 13 for use with Quick-release Hook. Quick-release Hook Universal fits Universal SlingBar 350, 450 and 600 (Prod. No. 3156074-3156076). Quick-release Hook TDM fits SlingBar Mini 220 (Prod. No. 3156005), Sling Cross-bar 450 and 670 (Prod. No. 3156021 and 3156018) and Universal TwinBar 670 (Prod. No. 3156077). When a sling bar mounted with the Quick-release Hook system is used, the lifting height will be 33 mm shorter than with a permanently mounted sling bar. See ”Guide to Liko´s Quick-release Hook System”, which can be downloaded from our website, www.liko.com, or contact Liko for more information on the advantages and use of the Quick-release Hook system.

Quick-release Hook Universal Prod. No. 3156508

Quick-release Hook TDM Prod. No. 3156502

Q-link 13 Prod. No. 3156509

0

Scale In need of weighing persons in combination with Uno 200 we recommend LikoScale 350 (Adapter 12 mm is required). Max. load 350 kg (770 lbs). LikoScale 350 is certified according to the european directive NAWI 90/384 (Non Automatic Weighing Instruments). Contact Liko for more information.

Uno 200 • 7EN150105-03

12

LikoScale 350

Adapter 12 mm

Prod. No. 3156228

Prod. No 2016504

www. liko. com

Simple Troubleshooting

The lift does not work up/down. Width adjustment does not work in/out.

1. Check that the emergency stop button is not pushed in (p. 7). 2. Check that the cables to the control unit are correctly connected (p. 6). 3. Check that the charger cable is not connected to an electric socket. 4. Check that the battery is charged (p. 10). 5. If the lift still does not work satisfactorily, contact Liko.

Battery charging does not work.

1. Check that the emergency stop button is not pushed in (p. 7). 2. Check to ensure that the electric socket is power-supplied. 3. Check that the charger cable is correctly connected (p.10). 4. If the lift still does not work satisfactorily, contact Liko.

The lift stops in the elevated position.

1. Check that the emergency stop button is not pushed in (p. 7). 2. Use the electrical emergency lowering to lower the patient to a stable underlying surface (p 8). 3. Use the mechanical emergency lowering to lower the patient to a stable underlying surface (page 8). 4. Check that the battery is charged (p.10). 5. If the lift still does not work satisfactorily, contact Liko.

If you hear unusual sounds.

Contact Liko.

Uno 200 • 7EN150105-03

13

www .liko. com

Care and Maintenance Care and inspection To ensure trouble-free operation, certain components should be checked each day the lift is used: • Inspect the lift and check for any signs of external damage. • Check the fixture of the sling bar. • Check safety latch function. • Check raising, lowering and base-width adjustment. • Check the emergency lowering function (both electrical and mechanical). • Charge the batteries each day the lift is used and check charger function. When necessary, clean the lift with common surface cleaners or disinfectants and check to ensure that the wheels are free of dirt and hair. NOTE! Do not use cleaning agents that contain phenol or chlorine, since these can damage aluminium and polyamide material. The lift should not be exposed to running water. Service Uno 200 must be inspected at least once per year, with particular attention to parts that are subject to wear. Repairs and maintenance may only be carried out in accordance with Liko service manuals, by authorized Liko service personnel and using original Liko spare parts.

Transportation and storage During transportation, or when the patient lift is not to be used for some time, the emergency stop button should be pushed in. The environment where the patient lift is transported and stored should have a temperature between 10 ˚C and 40 ˚C and a humidity between 30 % and 75 %. The air pressure should be between 700 and 1060 hPa. Recycling For instructions on how your Liko product should be recycled, please visit our website: www.liko.com. Product changes Liko’s products undergo continuous development, which is why we reserve the right to make product changes without prior notice. Contact your Liko representative for advice and information about product upgrades. Design and Quality by Liko in Sweden Liko is quality certified according to ISO 9001 and its equivalence for the medical device industry, ISO 13485. Liko is also certified according to environmental standard ISO 14001.

w w w . l i k o . com Manufacturer: Liko AB Nedre vägen 100 SE-975 92 Luleå Sweden [email protected]

© Copyright Liko AB 2011-11

Service agreements Liko invites you to sign a service agreement for regular maintenance and inspection of your Liko product.