Malmet

Models ES910, ES930 Operation and Maintenance Manual Issue 19 Oct 2011

Operation and Maintenance Manual

35 Pages

Preview

Page 1

Malmet (Australia) Pty Ltd Head Office & Customer Service McKay Avenue PO Box 373 LEETON NSW 2705 LEETON NSW 2705 Phone: (02) 6953 7677 Fax: (02) 6953 6266 Email: inquiries@malmet-aus.com.au

ABN 95 001 717 791

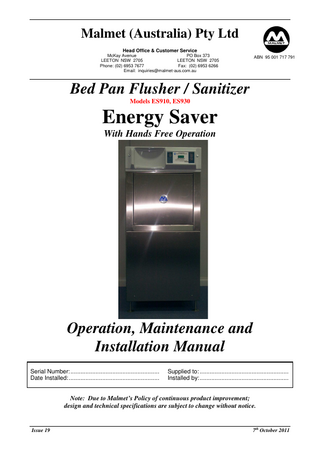

Bed Pan Flusher / Sanitizer Models ES910, ES930

Energy Saver With Hands Free Operation

Operation, Maintenance and Installation Manual Serial Number:... Date Installed:...

Supplied to: ... Installed by:...

Note: Due to Malmet’s Policy of continuous product improvement; design and technical specifications are subject to change without notice.

Issue 19

7th October 2011

Table of Contents Forward... 3 Quality Policy... 3 Design Parameters ... 4 Section A – Unit Operation ... 5 Hands Free Operation ... 5 Cycle of Operation ... 8 Sequence of Operation ... 9 Section B – Unit Maintenance... 14 Preventative Maintenance Schedule ... 14 Fault Finding Guide... 16 Appendix A – Faults ... 17 Appendix B – Additional faults not detected by controller ... 20 Electrical Diagram... 22 Section C – Unit Installation ... 24 Service Connections ... 24 Dimensions and Service Entry Points ... 25 Electrical ... 26 Post Installation Precautions ... 26 Positioning of Flusher / Sanitizer ... 27 Plumbing ... 29 Unit Specifications ... 30 Malmet Warranty Statement... 31 Quick Reference Guide... 33

Issue 19

Page 2

7th October 2011

Bed Pan Flusher / Sanitizer - Energy Saver With Hands Free Operation

Operation, Maintenance and Installation Manual Forward To obtain maximum life and efficiency from you Malmet Bed Pan Sanitizer and to ensure safe operation, please read this manual thoroughly and follow all instructions before operating the machine. This manual provides information on the operation of the machine. It is recommended that all persons operating the equipment have access to this manual for training purposes.

Quality Policy Malmet (Australia) Pty Ltd is Quality Certified to ISO 9001, AS 3902, NZS 9002 and guarantees the quality of this product. Should you have any problems with your machine, contact the company from whom you purchased it, or Malmet (Australia) Pty Ltd.

Certification Electrical Safety Q052115

Watermark WMKA 21156

Malmet (Australia) Pty Ltd Head Office and Factory PO Box 373 LEETON NSW 2705 Telephone: Facsimile: E-mail: Web Site:

Issue 19

(02) 6953 7677 (02) 6953 6266 inquiries@malmet-aus.com.au www.malmet.com.au

Page 3

7th October 2011

Bed Pan Flusher / Sanitizer - Energy Saver With Hands Free Operation

Operation, Maintenance and Installation Manual Design Parameters The Malmet Sanitizer has been designed within the following parameters: a)

A single bedpan with lid and two urine bottles can be emptied, cleaned and sanitized during each automatic cycle. The utensils that can be cleaned in the machine are:i) ii) iii) iv) v)

Standard size bed pans Standard commode bowl Standard male and female urine bottles Most plastic urine bottles including male non-spill and female cervec Slipper pan, with slipper pan rack (supplied)

b)

The cradle is designed to ensure that utensils are not dislodged during the cleaning cycle, the contents are emptied during door closure.

c)

The chamber and door are self-cleaning and do not permit water or soil to remain after a properly completed cycle. Steam sanitation ensures all internal surfaces are totally clean and safe.

d)

The flush and clean stage: i) ii)

e)

Removes the soil Clears the trap

A complete cycle is completed in approximately four (4) minutes for the 21 Amp Sanitisier and six (6) minutes and thirty (30) seconds for the 10 Amp Sanitiser. NOTE: Dependant on ambient air temperature.

Note: If the machine is turned off or on initial start up, the first cycle will take longer as the machine has to raise the temperature of cold water to 90°C.

Issue 19

Page 4

7th October 2011

Bed Pan Flusher / Sanitizer - Energy Saver With Hands Free Operation

Operation, Maintenance and Installation Manual

Section A – Unit Operation Hands Free Operation Zero Contamination – Totally Hands Free The Malmet “Energy Saver” is fully automatic. Door open, door close and cycle start can be activated without touching the machine.

Front View Manual operation of the door and a manual start button are available.

To Operate To Open Door –

Break Sensor Beam

To Close Door –

Break Sensor Beam

To Start Cycle –

Break Sensor Beam once when LED’s flash within 8 seconds after door Closure.

Note:

If door is opened then closed and cycle has not commenced the beam must be broken twice.

Should the cold water tank overflow into the soil line the water overflow red LED will illuminate. (Flashing LED refers to Detergent Unit Only) Issue 19

Page 5

7th October 2011

Bed Pan Flusher / Sanitizer - Energy Saver With Hands Free Operation

Operation, Maintenance and Installation Manual Bed Pan + Urinal Bottles

Slipper Pan + Urinal Bottles

Push down Slipper Pan until it locks into position

Issue 19

Page 6

7th October 2011

Bed Pan Flusher / Sanitizer - Energy Saver With Hands Free Operation

Operation, Maintenance and Installation Manual Standard Commode Bowl + Urinal Bottles

Large Commode Bowl + Urinal Bottles

Issue 19

Page 7

7th October 2011

Bed Pan Flusher / Sanitizer - Energy Saver With Hands Free Operation

Operation, Maintenance and Installation Manual Cycle of Operation Stage 1 – Initial Wash One rotating 180° back spray Two fixed 60° top sprays Two fixed urinal sprays 17 litres of water is used during a 17 second wash.

Stage 2 – Cleaning / Sanitizing Steam is delivered into the sealed wash chamber. Steam continues to clean the utensils and increases the surface temperature of utensils to a minimum of 90°C for 65 seconds Australian Standard AS4187 – Cleaning, Disinfecting of Reusable Hospital Equipment

Stage 3 – Cool Down Rinse One 60° fine mist top spray delivers cold water di rect from mains. Utensils are cooled to 55°C for safe handling.

Issue 19

Page 8

7th October 2011

Bed Pan Flusher / Sanitizer - Energy Saver With Hands Free Operation

Operation, Maintenance and Installation Manual Sequence of Operation 1.

Providing machine is installed into position with power and water connected push power on button.

2.

When the unit is turned on via the display panel the display shows fill indicating steam generator and cold water tanks are filling to the high water level. At this stage the unit will not commence a cycle until Step 5.

3.

Once the steam tank water level probes sense the tank is full it will start heating.

4.

The steam tank is heated to temperature 90°C - 9 2°C. The machine is now ready to commence a cycle. The display shows rdy (ready).

5.

The operator breaks the infra-red beam, which opens the door. The display shows open. Note: Whenever the door is opened the elements are in the off mode.

Issue 19

Page 9

7th October 2011

Bed Pan Flusher / Sanitizer - Energy Saver With Hands Free Operation

Operation, Maintenance and Installation Manual 6.

Once the machine is “loaded” the operator breaks the infra-red beam to close the door. The display shows shut.

7.

When the door is fully closed 2 LED’s will flash in the infra-red sensor area for 8 seconds to advise the user to break the beam again to start a cycle. The display shows rdy. If the 8 seconds has elapsed the flashing LED will stop and the unit will not start for a cycle. The operator has to repeat the process from Step 5 (or press manual start). Note: If this occurs the beam must be broken twice. Note: On 10A models if the steam generator temperature is not at 90°C and the beam has been broken or the manual start button pressed. The display will show “CYCL”, the red led’s will stop flashing and stay on. When the steam generator has reached operating temperature the display will show Rins the wash cycle will start automatically.

8.

Once a cycle has been initiated the elements are turned on in the steam tank to start heating the water. The wash pump is turned on for 17 seconds for the initial wash. The display shows rins.

Issue 19

Page 10

7th October 2011

Bed Pan Flusher / Sanitizer - Energy Saver With Hands Free Operation

Operation, Maintenance and Installation Manual 9.

Once the wash cycle is complete the display will flash 90 (indicating 90°C). This is the critical temperature that must be reached before the sanitation cycle can commence. At this point the fill solenoid is disabled and will not operate unit Step 12.

10.

The elements in the steam generator heat to produce steam, which is directed into the wash chamber raising the internal cabinet temperature above 90°C.

11.

Once the internal cabinet temperature has reached 90°C the sanitization cycle will commence. This display shows the actual cabinet temperature.

ACTUAL CABINET TEMP.

12.

All 3 elements on 21 amp models and on all 2 elements on 10 amp models will continue to heat during the sanitization cycle until the internal cabinet temperature reaches 91°C.

13.

At 91°C one element will turn off and at 92°C a nother element will turn off on 21 amp models, on 10 amp models at 91°C one element will t urn off. One element will remain on until 15 seconds before the end of the cycle. If the internal cabinet temperature falls below 92°C the second element is turned back on the third respectively if the cabinet temperature falls below 91°C. Note: Regardless of element combinations 15 seconds before the end of the cycle ALL elements will turn off. This is to overcome the effects of overshoot in the steam generator producing steam at the end of the sanitization cycle.

14.

The maximum time allowable for the sanitization cycle is 10 minutes. exceeded then the machine will go to fault and elements turn off.

Issue 19

Page 11

If this time is

7th October 2011

Bed Pan Flusher / Sanitizer - Energy Saver With Hands Free Operation

Operation, Maintenance and Installation Manual 15.

After the sanitization cycle is complete the cooling solenoid will turn on for 15 seconds. This will cool down the surface temperature of the utensils and make them safe to handle. The display shows cool. This water is direct from the mains.

16.

At the end of the cool down rinse, the display shows end. This will be displayed until the door is re-opened.

17.

If not used the unit steam generator temperature will be kept at the temperature of 85°C90°C for a period of 15 minutes. If the unit is st ill not used it will enter into idle mode and the elements will only come on at 50°C and rise to the temperature of 90°C repeatedly until the cycle is started again.

Issue 19

Page 12

7th October 2011

Bed Pan Flusher / Sanitizer - Energy Saver With Hands Free Operation

Operation, Maintenance and Installation Manual Display Board Green LED Display

Door Open

open

Door Closed

shut

Steam Generator Fill

fill

Cycle Ready

rdy

Cycle Started

rins

Sanitization Cycle Started

Flashing

90°C

Sanitization Temperature Reached

‘actual’ temp °C

Cool Down Final Rinse

cool

End Of Cycle

end

Red LED illuminates on Control Panel

Overflow

2 flashing Red LED in Activation Area (8 Seconds)

Cycle Can Be Started

Issue 19

Page 13

7th October 2011

Bed Pan Flusher / Sanitizer - Energy Saver With Hands Free Operation

Operation, Maintenance and Installation Manual

Section B – Unit Maintenance A qualified person should carry out all maintenance, preventative or breakdown. Failure to comply with this condition may result in unsafe conditions. The Malmet ‘Energy Saver’ is self-cleaning, but proper care should be taken to ensure that the unit is cleaned and maintained in accordance with the maintenance instructions for Malmet Flusher / Sanitizers and in accordance with all other regulatory and commonsense practices.

Preventative Maintenance Schedule Daily Maintenance a)

Wipe out the inside of the door and chamber with warm water and detergent. A wipe with disinfectant is also desirable.

b)

Wipe over outside stainless steel panels with stainless steel cleaner.

c)

Wipe the front control panel with a soft cloth and mild detergent as necessary. Care should be taken not to damage the digital display or to activate a cycle.

Maintenance – After One Month’s Operation (to be performed by a qualified maintenance person) a)

Check for steam or water leaks. Tighten union, hose clamps and glands where necessary.

b)

Remove and clean out sprays and bottle hooks (unscrew from inside chamber). Clean in ultrasonic cleaner if available

Issue 19

Page 14

7th October 2011

Bed Pan Flusher / Sanitizer - Energy Saver With Hands Free Operation

Operation, Maintenance and Installation Manual Recommended Preventative Maintenance Schedule (to be performed by a qualified maintenance person) To be performed THREE TIMES YEARLY for units in constant day and night use and HALF YEARLY for units in lesser usage situations.

WARNING 240 VOLTS ISOLATE UNIT FROM ELECTRIC SUPPLY BEFORE SERVICING a)

Remove top and side panels and front bottom panel. Note: Panel removal i) ii) iii)

Remove 2 self-tapping screws on the top panel. Push the side panel back then lift up to remove. Remove 2 x 3/16” screws from bottom front panel.

b)

Remove three sprays, two bottle hooks and rotary nozzle from inside the chamber – check that the holes are clear and clean as necessary (hold under tap and pressurise or clean in ultrasonic cleaner). In areas with hard water or high minerals in water supply, chemical descaler may be the quickest and easiest means to remove built up deposits. Replace sprays and bottle hooks.

c)

Start cycle and check that cold water pump is working, 17 seconds of the cycle.

d)

After ascertaining that the pump is working properly, check the solenoid operation in the cold water tank. Check steam sensor (steam generator) maintenance.

e)

Make sure the solenoids are completely shutting off and levels are not creeping up, if so, clean and/or replace the solenoid.

f)

Tighten the screws retaining the pan rack on the door. ONLY IF NECESSARY AFTER VISUAL CHECK a)

Issue 19

Clean dust and grit off components.

Page 15

7th October 2011

Bed Pan Flusher / Sanitizer - Energy Saver With Hands Free Operation

Operation, Maintenance and Installation Manual Fault Finding Guide The unit is controlled by a sophisticated micro-processor. The processor has fault detection capability and indicates faults by code on the digital display; Table B1 indicates these faults. For a more detailed description of these fault conditions see Appendix A – Faults.

Fault No.

Description

01

Door Open Fault – Not Confirmed Door Closed

02

Wash / Sanitize Cycle Time Out

03

Fault Hot Water Probes

04

Door Motor Activation Time Out

06

Hot Water Tank Fill Time Exceeded

07

Hot Water Tank Low Water Level Sensed During Cycle

08

Door Closure Fault – Not Confirmed Door Open

09

Failed To Reach Sanitize Start Temperature Resulting In Time Out

10

Sanitizer Temperature Not Maintained Resulting In Cycle Time Out

12

Hot Tank Short Circuit Temperature Sensor

13

Hot Tank Open Circuit Temperature Sensor

14

Sanitize Chamber Short Circuit Temperature Sensor

15

Sanitize Chamber Open Circuit Temperature Sensor

Table B1

Note: If a fault is displayed on the LED display, turn unit off and turn it back on, press START to try to complete a cycle. If a fault persists contact a service person. Record the fault code that has appeared for the Service Technician

Issue 19

Page 16

7th October 2011

Bed Pan Flusher / Sanitizer - Energy Saver With Hands Free Operation

Operation, Maintenance and Installation Manual Appendix A – Faults Diagram B1 (below) shows an example of fault mode display (Fault 01 indicated).

Diagram B1 Following is a more detailed list of fault conditions and most likely cause.

Fault 01

Door Open Fault – Not Confirmed Door Closed (i.e. Door switch still indicates open) Cause

Fault 02

Wash / Sanitize Cycle Time Out (taking too long to complete cycle) Cause

Fault 03

Faulty water level probe

Door Motor Activation Time Out (taking too long to close or open door) Cause

Issue 19

Steam leak Final rinse solenoid stuck open Faulty temperature sensor hot water tank Blown element leg Steam condensate leaking cold water into chamber Faulty temperature sensor – chamber

Faulty Hot Water Probes (high indicates water, but low does not indicate water) Cause

Fault 04

Door limit switch stuck out/broken

Faulty door actuator Door axle bar sticking

Page 17

7th October 2011

Bed Pan Flusher / Sanitizer - Energy Saver With Hands Free Operation

Operation, Maintenance and Installation Manual Fault 06

Hot Water Tank Fill Time Exceeded (high level not reached during pre-fill, resulting in time out) Cause

Fault 07

Hot Water Tank Low Water Level Sensed During Cycle Cause

Fault 08

Door limit switch stuck on

Failed To Reach Sanitize Start Temperature Resulting In Time Out Cause

Fault 10

Faulty water level probe Cold water tank empty or not filling quick enough Leaking tank or hose Element stuck on Condensing coil blocked

Door Closure Fault – Not Confirmed Door Open (door switch still indicates closed) Cause

Fault 09

Faulty fill solenoid Faulty water level probe Cold water tank empty or not filling quick enough Low water pressure

Steam leak Final rinse solenoid stuck open Faulty temperature sensor hot water tank Blown element leg Steam condensate leaking cold water into chamber Faulty temperature sensor chamber Door not reaching interlocking micro switch. Door not fully closed. Over Temperature Board (Power to element open circuit)

Sanitize Temperature Not Maintained Resulting In Cycle Time Out Cause

Steam leak Final rinse solenoid stuck open Faulty temperature sensor hot water tank Blown element leg Steam condensate leaking cold water into chamber Fault temperature sensor – chamber

Fault 12

Hot Tank Short Temperature Sensor

Fault 13

Hot Tank Open Circuit Temperature Sensor

Issue 19

Page 18

7th October 2011

Bed Pan Flusher / Sanitizer - Energy Saver With Hands Free Operation

Operation, Maintenance and Installation Manual Fault 14

Sanitize Chamber Short Circuit Temperature Sensor

Fault 15

Sanitize Chamber Open Circuit Temperature Sensor

Cold Water Overflow Indication The LED used to indicate Cold Tank Overflow. Overflow is indicated by a STEADY ON LED, whenever the overflow level is detected.

Issue 19

Page 19

7th October 2011

Bed Pan Flusher / Sanitizer - Energy Saver With Hands Free Operation

Operation, Maintenance and Installation Manual Appendix B – Additional Faults not detected by controller Section 1 – Faults These are other faults that may occur which the controller cannot detect (the controller may however indicate a fault with the following conditions).

Not Washing Pans

1. Check that the cold water pump is working. 2. Check that there is cold water in the tank. 3. Check sprays. 4. Check bedpan position in door cradle. (Diagram B2)

No Power to Control Box

1. Check main power. 2. Check power to control boards

Leaking Water onto the Floor

1. Check all hose fittings. 2. Check water levels and water probes. 3. Check pump seals. 4. Check door seal.

Issue 19

Page 20

7th October 2011