MAQUET

ALPHAMAXX 1133.22 series Operating Instructions July 2005

Operating Instructions

56 Pages

Preview

Page 1

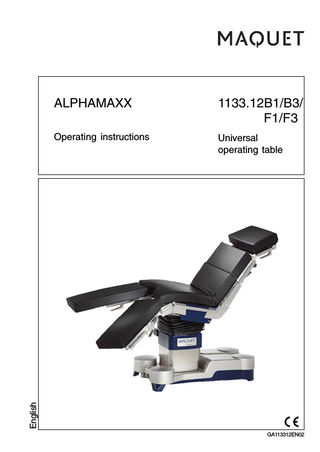

1133.12B1/B3/ F1/F3

Operating instructions

Universal operating table

English

ALPHAMAXX

GA113312EN02

1133.12B1/B3/F1/F3

8

9

11

22

6

4

1

5

12

10

21

7

3

12

2

14

14 20

13

15

Pictorial guide

17 15 16

18

2

19

1.

Head plate (e.g. 1130.64)

2.

Fastening screws for head plate

3.

Locking lever for extension segment 1131.31XX

4.

Locking lever for extension segment 1131.31XX (optional)

5.

Mounting point for back plates

6.

Lower back plate

7.

Bellows

8.

Leg plates 1133.53XX (optional)

9.

Locking lever for leg plate abduction

10.

Unlocking of leg plates

11.

Seat plate

12.

Infrared receiver and transmitter

13.

Override system with status indicators for operating table (on the rear)

14.

Sockets for corded hand control and foot switch

15.

Socket for mains cable

16.

Mains cable

17.

Potential equalization

18.

Corded hand control (optional)

19.

IR remote control (optional)

20.

Interface for servicing (on the rear)

21.

Seat plate extension 1131.55XX (optional)

22.

Mounting point for leg plates GA113312EN02

1133.12B1/B3/F1/F3

Table of contents Pictorial guide ... 2 I. Important safety notes ... 5 II. Important information ... 7 1. Important information on these operating instructions: ... 7 2. Intended use of an operating table ... 7 3. Intended purpose: ... 7 4. Fundamental safety aspects ... 7 III. General description ... 8 1. General features ... 8 2. Control of functions ... 9 2.1 Corded hand control ... 10 2.2 Override system = emergency operation ... 11 2.3 IR remote control (optional) ... 13 2.3.1 IR system code ... 14 2.3.2 Charging station ... 15 2.4 Control via IR wall control panel ... 15 2.5 Control via foot switch 1009.81DX (optional) ... 16 2.6 „Neurolock“ function ... 16 3. Table top ... 17 3.1 General features ... 17 3.2 Mechanical adjustments ... 18 3.2.1 Mount / remove the head plate ... 18 3.2.2 Extension segment 1131.31B0/F0 ... 23 3.3 Collision protection at the leg plate mounting point ... 24 3.3.1 Seat plate extensions ... 25 3.3.2 Leg plates ... 26 3.4 Table top padding ... 27 3.5 Accessories ... 27 4. Autodrive in the base ... 28 IV. Use of the operating table ... 29 1. General ... 29 2. Operation on battery power ... 29 3. Operation on mains power ... 30 4. HF surgery, use of defibrillators ... 30 V. Patient positioning ... 31 1. General ... 31 2. Positioning a patient weighing between 225 kg and 450 kg (500 lb - 1000 lb) ... 33 2.1 Approved accessories ... 33 2.2 Operating table immobilized (LOCK) ... 33 3. Positioning a patient weighing between 135 kg and 225 kg (300 lb - 500 lb) ... 34 3.1 Approved accessories ... 34 3.2 Operating table not immobilized (UNLOCK) ... 34 3.2.1 NORMAL patient orientation / operating table not immobilized (UNLOCK) ... 35 3.2.2 REVERSE patient orientation / operating table not immobilized (UNLOCK) ... 36 3.3 Operating table immobilized (LOCK) ... 37 3.3.1 NORMAL patient orientation / operating table immobilized (LOCK) ... 37 3.3.2 REVERSE patient orientation / operating table immobilized (LOCK) ... 38 4. Positioning a patient weighing up to 135 kg (300 lb) ... 39 4.1 Approved accessories ... 39 4.2 Operating table not immobilized (UNLOCK) ... 39 4.2.1 General ... 39 4.2.2 NORMAL patient orientation / operating table not immobilized (UNLOCK) ... 40 4.2.3 REVERSE patient orientation / operating table not immobilized (UNLOCK) ... 41 4.3 Operating table immobilized (LOCK) ... 42 4.3.1 NORMAL patient orientation / operating table immobilized (LOCK) ... 42 4.2.2 REVERSE patient orientation / operating table immobilized (LOCK) ... 43

GA113312EN02

3

1133.12B1/B3/F1/F3 VI. Care and maintenance ... 44 1. Cleaning ... 44 2. Disinfection ... 44 3. Maintenance ... 45 4. Malfunctions ... 45 5. Environmental protection ... 46 VII. Technical specifications ... 47 1. Operating table adjustments ... 47 2. Electrical specifications ... 47 VIII. List of accessories ... 48 1. Accessories for head-side mounting point: ... 51 1.1 For patients weighing up to 450 kg (1000 lb) ... 51 1.2 For patients weighing up to 225 kg (500 lb) ... 51 1.3 For patients weighing up to 135 kg (300 lb) ... 51 2. Accessories for the back plate mounting point ... 52 2.1 For patients weighing up to 450 kg (1000 lb) ... 52 2.2 For patients weighing up to 225 kg (500 lb) ... 52 2.3 For patients weighing up to 135 kg (300 lb) ... 52 3. Accessories for leg plate mounting point ... 52 3.1 For patients weighing up to 450 kg (1000 lb) ... 52 3.2 For patients weighing up to 225 kg (500 lb) ... 52 3.3 For patients weighing up to 135 kg (300 lb) ... 52 4. Accessories for side rails ... 53 5. Special-purpose accessories ... 54 6. Control units ... 54 IX. Spare parts list ... 55

4

GA113312EN02

1133.12B1/B3/F1/F3

I.

I. Important safety notes

Important safety notes Mount only the accessories listed in chapter VIII. Make sure the operating table is set up horizontally and that it is stable. Immobilize the operating table prior to use! Press the LOCK button! Immobilize the operating table prior to transferring the patient! Press the LOCK button! The patient may be transferred only from the side of the operating table. If the patient is transferred from head or foot end, there is a danger of tipping over! Injury hazard! If the patient is not secured during transportation, when adjusting the operating table or when positioning the patient (particularly when the slope feature is used), then the patient could slip, uncontrolled, off the operating table. Always secure the patient and maintain continuous observation.

Hazard of burns to the patient! When using HF surgical equipment, defibrillators and defibrillation monitors, make sure to avoid that the patient comes into contact with metal parts of the operating table, the table tops or the accessories. Also make sure to avoid that the patient is lying on moist underlays or sheets on the conductive pads. Be absolutely sure to comply with the manufacturers operating instructions! Hazard of damage! Avoid any collisions between the accessories and the operating table during adjustment procedures! Consult MAQUET prior to using accessories produced by other manufacturers if they affect the longitudinal geometry of the table top. There is no explosion protection while recharging the batteries or when the operating table is on mains power. When connecting or removing the mains cable, observe the correct order of the procedure! (See page 22) Avoid endangering the patient’s respiratory system, nerve pathways and circulatory system by ensuring the patient is properly positioned and observing the patient’s condition. The operating table’s electrical conductivity has to be checked once a year! This check should be performed only by trained servicing personnel. Before opening the equipment, disconnect the mains plug. Electrical devices (e. g. cellphones, radios, magnetic resonance tomographs) can interfere with the functioning of the operating table when used near the operating table. Please observe the Technical Description for the operating table. It contains imformation on electromagnetic compatibility (EMC) for the operating table (both radiation and resistance to interference). Adhere to those specifications when using electrical devices and respond properly in the event of effects on your operating table.

GA113312EN02

5

I. Important safety notes

1133.12B1/B3/F1/F3

Injury hazard! Before aligning the leg plates horizontally, check the patient’s position carfully, particularly when using knee crutches. Hazard of pinching and crushing! Do not touch the side rails in the area of the joints when adjusting the table top. Hazard of pinching! Do not reach under the table top or between the table top components during adjustment procedures. Hazard of pinching and crushing! When immobilizing the operating table (LOCK), the operator’s feet may be crushed or shorn. When setting the operating table, keep enough distance from the table base. Hazard of pinching and crushing!

Hazard of damage! Do not place any objects on the operating table base. Hazard of damage! Do not press or pull on the covers of the joints. Hazard of damage! Make sure the cable of the hand control does not get jammed when adjusting the operating table.

Collision hazard!

6

GA113312EN02

1133.12B1/B3/F1/F3

II. Important information

II. Important information Your hospital has opted for the 1133.12 operating table. We appreciate the confidence you have placed in us. 1. Important information on these operating instructions: • Please read these operating instructions completely and carefully. They were written to familiarize you with the features of this operating table. • Be sure to always follow the instructions given here. • Always store these operating instructions near the unit. • In these operating instructions we have used the following symbols: This symbol identifies information which is critical for safety as described in the international standard applicable to the field of medicine. Note This symbol precedes all notes which will help to avoid operational difficulties. X

An “X” in the order number (e.g. 1133.53XX) stands in place of the different versions.

2. Intended use of an operating table The operating tables distributed by MAQUET are to be used exclusively in the field of human medicine. Before the equipment is used, all users must be instructed in its proper use. This familiarization session is confirmed in an acceptance log. The location selected for the table must conform to the applicable standards and guidelines. Before using the equipment, you must be absolutely certain that it is properly installed and maintained. 3. Intended purpose: The operating table 1133.12 is used to support and position a patient for surgical treatment • immediately before, during and after the operative phase, • in rooms used for medical purposes which fulfil the following requirements: - equipment to protect against electric shocks - additional potential equalization - electrically conductive floor (corresponding to Group 1 or 2 as per VDE 0100 Part 710) • under medical supervision. • A max. patient weight of 450 kg (1000 lb.) is permissible in certain circumstances. Avoid excentric patient positions, i.e. the patient’s centre of gravity (near the navel) must be as close as possible to the centre of the column. The design of the table top makes the operating table suitable for every surgical discipline. The positioning options are listed in the operating instructions. The adjustments are made electrohydraulically using the corded hand control, the IR remote control, the IR wall control panel or a foot switch. Side rails are used to mount accessories, in accordance with the manufacturer’s instructions. The radiotranslucent operating table top allows for intraoperative use of X-ray equipment. Note: In accordance with generally accepted hygiene standards, the operating table top is to be covered with surgical drapes during use. 4. Fundamental safety aspects This operating table meets the requirements set forth in the IEC 60601-1 international standard which is equivalent to DIN VDE 0750, Part 1. The operating table is classified as a Class I equipment according to the Medical Device Directive. Whenever maintenance work is required, remember that the MAQUET Service Department is the right address in terms of quality and maintaining guarantee protection. You will certainly understand that MAQUET can be held responsable for the safety technology features only if assembly, enhancements, readjustment, modifications and repairs are made exclusively by our service department or by an authorized agent and if the unit is full in full compliance with the operating instructions.

GA113312EN02

7

III. General description

1133.12B1/B3/F1/F3

III. General description 1. General features In princliple, the operating table 1133.12 ALPHAMAXX is suitable for the following surgical procedures: • in the thorax and abdominal areas • in the head area • in gynaecology • in urology • in orthopaedics If required, separate accessories can be attached to the operating table.

Fig.III-1:

The preferred patient orientation

The table top is subdivided into 6 sections: • head plate (removable) • upper back plate (removable) • lower back plate • seat plate • split leg plates The lower back, seat and leg plates are adjusted under motor power. The head plate and the upper back plate are adjusted manually. X-ray cassettes can be inserted underneath the back plate. The side rails are used to attach accessories. For patients weighing up to 135 kg (300 lb), place the operating table on its castors (UNLOCK) only up to the maximum table top height of 940 mm (37 in)! The warning sign is not seen! For patients weighing between 135 kg and max. 225 kg (300 - 500 lb), place the operating table on its castors (UNLOCK) only when the table top is in its lowest position. Using the UNLOCK function for patient weights exceeding 225 kg (500 lb) is not permissible. 1.1 Versions

NO

Fig.III-2:

YES

Warning sign for table top height

Various versions of the operating table 1133.12 are available. 1133.12B1 Operating table incl. SFC padding and standard side rails 1133.12B3 Operating table incl. SFC padding, standard side rails and autodrive in the base 1133.12F1 Operating table incl. SFC padding and US side rails 1133.12F3 Operating table incl. SFC padding, US side rails and autodrive in the base The corded hand control, the IR transmitter, the charging station for the IR transmitter as well as head plates, upper back plates and leg plates are to be ordered separately. The order numbers are listed in chapters VIII and IX.

8

GA113312EN02

1133.12B1/B3/F1/F3

III. General description 2. Control of functions The electrohydraulic functions of the operating table can be activated using one of the following control elements: • Corded hand control (see 2.1) • Override system = emergency operation(see 2.2) or optionally via: • IR remote control (see 2.3) • Wall control panel (see 2.4) • Foot switch (see 2.5) The corded hand control and the IR remote control have almost the same function buttons. The override system is used only for emergency operation of the operating table. The foot switch functions are: operating table height, Trendelenburg/reverse Trendelenburg and another function (lateral tilt, longitudinal shift, back plate or leg plate adjustment) Note: For safety reasons, only the following functions can be used when the UNLOCK function is activated: TRENDELENBURG and REVERSE TRENDELENBURG. The sockets (14) for the corded hand control and the foot switch are located on the override panel. Note: If the functions are controlled simulataneously by more than one operating element, each movement of the operating table is stopped immediately. Hazard of operating table tipping over! Make sure to remove any potential hindrances before adjusting the operating table! Hazard of damage during adjustments! Do not place any objects on the operating table base. Hazard of pinching! Do not reach under the table top or between the table top components during adjustment procedures. Injury hazard! If the patient is not secured during transportation, when adjusting the operating table or when positioning the patient (particularly when the slope feature is used), then the patient could slip, uncontrolled, off the operating table. Always secure the patient and maintain continuous observation. Hazard of damage! When not in use, hang up the corded hand control at the side rail of the operating table. Make sure the cable of the hand control does not get jammed when adjusting the operating table.

GA113312EN02

9

III. General description

1133.12B1/B3/F1/F3

2.1 Corded hand control The corded hand control is connected to the operating table at one of the two sockets (14) (for simultaneous connection of corded hand control and foot switch) on the override panel (13). The electric motor-powered adjustments of the operating table can be made immediately by pressing down the corresponding function button. a) b) c) d) e) f) g) v

w

t

u h)

r

s

p

q

l

m

j

k

g

h

e

f

c

d

a

b

j) k) l) m) p) q) r)

s)

z t)

u)

v)

w)

10

Table top down Table top up Tilt to the left (view from head end) Tilt to the right (view from head end) Trendelenburg position Reverse Trendelenburg position Flex position Activates the functions reverse Trendelenburg and back plate down until a flex position is reached to force the surgical field upward. Beach chair Raises the back plate, moves the entire table top into the Trendelenburg position and lowers the leg plates. The patient is moved into a seated position. Slope (both) leg plates downward Slope (both) leg plates upward Slope (lower) back plate downward Slope (lower) back plate upward Shift table top toward the foot end Shift table top toward head end Adjust the left leg plate individually The left leg plate can be controlled individually only in conjunction with the appropriate function button for the desired movement, either downward (r+ j) or upward (r + k), under two-button control. Adjust the right leg plate individually Analogous to the control for the left leg plate, individually downward (s + j) or upward (s + k), under two-button control. Lock Press the LOCK button for at least 1 second: the table will be immobilized automatically. UNLOCK To unlock the operating table, press the UNLOCK button for at least 1 second, then the castors will be extended automatically and the table can be displaced. Autodrive in the base 1133.12B2 (optional) Displace the operating table backward (toward the head end). Displace the operating table forward (toward the foot end). When displacing the operating table under motor power, it must be guided with one hand.

GA113312EN02

1133.12B1/B3/F1/F3

III. General description z)

0-position Resets the lateral tilt, Trendelenburg/reverse Trendelenburg, back plate and leg plate adjustments to the horizontal position. If the function button z is pressed, the operating table top will first reset the adjustments in the following order: lateral tilt, Trendelenburg/reverse Trendelenburg, back plate. An acoustic signal will indicate that these adjustments have been reset. Release the function button z and press once again to reset the leg plates to the horizontal position; if the leg plates have been adjusted individually, they will be positioned in parallel to one another.

Notes: Manual adjustment functions such as those for the upper back plate, head plate and leg plate abduction will not be affected by the IR remote control (and, as a consequence, neither by the automatic 0-position function). The transmission power for the IR remote control ist sufficient to operate the draped operating table even from a greater distance. If the desired adjustment is not executed by the operating table, even though a function button is depressed completely, then you should re-aim the hand control or move to another position in the OR. In such cases the receiver is probably being blocked by a person’s body.

2.2 Override system = emergency operation 2.2.1 Override control panel In case of a malfunction or if the hand control is defective, you can control the operating table functions via the control panel (13) on the upper column casing (emergency operation). Note: Always press the ON button together with the desired function button. 13 Fig.III-4:

Override control panel

Note: If the operating table batteries are discharged, the override system will only work when the operating table is connected to the mains. Note: When using the override control panel, the collision protection feature is not activated. Avoid extreme adjustments - the combination of maximum Trendelenburg/reverse Trendelenburg position and maximum lateral tilt.

GA113312EN02

11

III. General description

1133.12B1/B3/F1/F3

The functions of the override control panel are shown in the following: A) LED-Status indicators of the operating table Note: The status indicators are only active when the corded hand control or the IR remote control is switched on.

A

CE GI L N

Description of the symbols from left to right: • Mains connection: the green LED lights up when the operating table is connected to the mains. • Battery charge level: the red LED flashes when the operating table batteries have to be recharged as soon as possible. • Operating table is immobilized: the green LED lights up when the operating table is immobilized, i.e. LOCK activated. • Operating table castors are extended: the red LED lights up when the operating table is on its castors and can be displaced, i.e. UNLOCK activated. B)

ON switches the motor on and must be pressed in addition to each function button

C)

TREND Table top into Trendelenburg position

D)

REV. Table top into reverse Trendelenburg position

E)

UP Table top up

F)

DOWN Table top down

G)

TILT Lateral tilt to the left

H)

TILT Lateral tilt to the right

I)

UP Slope back plate upward

K)

DOWN Slope back plate downward

L)

UP Slope leg plate upward

B D FHKMO Fig.III-5: Override control panel buttons

12

GA113312EN02

1133.12B1/B3/F1/F3

III. General description

v

w

t

u

r

s

p

q

l

m

j

k

g

h

e

f

c

d

a

b

M)

DOWN Slope leg plate downward

N)

LOCK Operating table immobilized

O)

UNLOCK Operating table on its castors, can be displaced

2.3 IR remote control (optional) The operating table can be equipped with an IR remote control, as desired. The required charging station for the IR remote control is not included with the order no. 1133.91A0. The layout of the function buttons for the operating table adjustments is the same on the corded hand control and the IR remote control apart from one exception: There are no function buttons for the autodrive in the base. For safety reasons, you can only activate this function via the corded hand control. Note: When switching on the IR remote control, the LED status indicators on the control panel on the operating table column are active (see chapter „Override system“). Note: When using the IR remote control or the corded hand control, the electronics generally avoid collisions with the floor or parts of the operating table. If accessories with manual adjustment functions are mounted, then it is not always possible to avoid collisions.

z

Fig.III-6:

IR remote control

GA113312EN02

13

III. General description

Fig.III-7:

1133.12B1/B3/F1/F3

2.3.1 IR system code Every IR remote control is unequivocally assigned to an operating table by way of the electronic encoding. The operating table has the same system code as the associated IR remote control. You can see from the label at the operating table column whether IR reception has been activated for this operating table. If the IR code is crossed out, then the infrared reception is blocked for the operating table. The encoding for the operating table and the IR remote control as well as activating/blocking the IR reception are performed by authorized personnel.

IR code

The operating table and the associated IR remote control are marked by adhesive labels bearing the system code which has been set: • The adhesive labels are affixed to the operating table column next to the IR receiver. • The adhesive labels are affixed to the back of the IR remote control. The two dot-shaped adhesive labels bear a number from 0 to 9 or a letter from A to F : • left 0,1,2,...,A,B,...,F • right 0,1,2,...,A,B,...,F

Examples of IR system codes which have been set: Identification: 1 5 3 A C 2 D A Note: The order of the identification letters/numbers is singificant, i.e. the IR system code 4 B does not equal B 4.

Note: Always leave the IR remote control at the working location for the associated operating table, since the operating table can be adjusted only by using this particular IR remote control. Of course, the operating table can be adjusted via a corded hand control or the override system at any time, regardless of the IR remote control.

0 Fig.III-8:

14

IR code

3

Note: The transmission power of the IR remote control ist sufficient to operate the draped operating table even from a greater distance. If the desired adjustment is not executed by the operating table, even though a function button is depressed completely, then you should re-aim the IR remote control or move to another position in the OR. In such cases the receiver is probably being blocked by a person’s body.

GA113312EN02

1133.12B1/B3/F1/F3

III. General description 2.3.2 Charging station Recharging the IR remote control: • Connect the mobile charging station to the mains. The green LED in the charging station indicates whether the required supply voltage is available or not. •

Fig.III-9:

Charging station

Place the IR remote control in the charging station as follows: – Keypad visible, in the position for normal use, i.e. the 0-position button (x) is located at the bottom right – the base of the hand control is in contact with the lower limit stop of the holder. Note: The capacity of the rechargeable battery for the IR remote control is sufficient to ensure several day’s use of the operating table. Nevertheless, we recommend that you insert the hand control into the holder of the charging station so that the battery is recharged overnight.

Fig.III-10: Charging station

2.4 Control via IR wall control panel The desired adjustment functions of the operating table can be controlled by means of the function buttons (1) at the wall control panel or the separate IR hand control (2). Note: The IR wall control panel can be mounted to the wall at a later date. For further information please refer to the operating instructions GA115095GBxx. Fig.III-11: IR wall control panel

GA113312EN02

15

III. General description

14 14

Fig.III-12: Foot switch

1133.12B1/B3/F1/F3

2.5 Control via foot switch 1009.81DX (optional) Connect the foot switch to one of the two sockets (14) at the column head. Three functions each can be activated using the following foot switch versions: 1009.81D0 Foot switch with the functions: height, Trendelenburg/rev. Trendelenburg, back plate 1009.81D1 Foot switch with the functions: height, Trendelenburg/rev. Trendelenburg, lateral tilt 1009.81D2 Foot switch with the functions: height, Trendelenburg/rev. Trendelenburg, leg plates 1009.81D3 Foot switch with the functions: height, Trendelenburg/rev. Trendelenburg, longitudinal shift Note: Observe the operating instructions for the foot switch. 2.6 „Neurolock“ function If requested, the MAQUET service personnel can set the „Neurolock“ function at the operating table. This function avoids adjustments of the table position due to unintentional actuation of the buttons on the hand control.

Fig.III-13: „Neurolock“ function

a+b) The „Neurolock“ function can be unlocked by pressing simultaneously the buttons „table top down“ (a) and „table top up“ (b) on the control module. The operating table can now be adjusted. If no further buttons on the control module are actuated for approx. 8 seconds, then the „Neurolock“ function will be activated again. Adjusting the operating table again is only possible after actuating simultaneously the „table top down“ (a) and „table top up“ (b) function buttons. Note: The „table top down“ and „table top up“ functions cannot be actuated simultaneously using the foot switch 1009.81X0. Use an IR hand control or a corded hand control to unlock the „Neurolock“ function.

16

GA113312EN02

1133.12B1/B3/F1/F3

III. General description 3.

Table top

3.1 General features The table top 1133.12 has been designed to meet the requirements of various surgical disciplines. Selecting from a variety of modules lets you adapt the geometry of the table top to accommodate the individual patient height. The table top is divided into a maximum of 6 sections, depending on the type of leg plate and upper back plate module selected. • Head plate • Upper back plate (extension segment) • Lower back plate • Seat plate • Leg plates The table top is equipped with a motor-powered longitudinal shift feature through 230 mm, and motorpowered adjustment functions for the back plate and leg plates. Furthermore the mounting sockets for the leg plates automatically detect whether one-piece components have been installed, thus increasing reliability and safety in use. Depending on the application, the adjustment ranges for the accessories mounted at the leg plate mounting point may be restricted. Please refer to the operating instructions for the accessory in question. Attaching different back plate modules at the lower/ upper back plate mounting point enables positions perfectly suited to the patient and more favourable functional working conditions for the surgical team and the procedure. Guide rails for X-ray cassettes are located underneath the back plate. The side rails are used to attach accessories. Various head positioning accessories can be mounted at the head end of the back plate modules instead of the head plate (see chapter V, Patient positioning). Note: According to the IEC 60601-1 international standard, the operating table is designed for safe handling of a patient weight of 450 kg (1000 lb). When using accessories, the maximum load may be restricted. Please observe chapter VIII List of accessories.

GA113312EN02

17

III. General description

1133.12B1/B3/F1/F3

3.2 Mechanical adjustments 3.2.1 Mount / remove the head plate Note Use and handling are described in detail in the operating instructions for this product. Note The head plate adapter 1130.81A0 is required to mount head plates at the back plate mounting point. 3.2.1.1 Mount the head plate using the head plate adapter 1130.81A0. Note The head plate adapter consists of a left and a right part. Please observe the markings L and R. If the adapters are mixed up, the distance of the mounting sockets is not correct. A

A

Mount the head plate ⌧ Insert the pins of the two head plate adpaters 1130.81A0 (A) in the sockets (B) at the back plate mounting point, up to the stop.

B

B

Fig.III-14: Mount the head plate adapter ⌧ Insert the head plate pins (C) into the mounting sockets (D) at the front of the table top, up to the stop.

C

D D

Fig.III-15: Mount the head plate

18

GA113312EN02

1133.12B1/B3/F1/F3

III. General description ⌧ Tighten the locking screws (E). ⌧ Pull on either side of the seat plate extension to ensure that it is properly secured.

E

E

Fig.III-16: Mount and secure the head plate Remove the head plate

C

⌧ Loosen the locking screws (E). ⌧ Remove the head plate (C). ⌧ Remove the two head plate adapters 1130.81A0.

E

Fig.III-17: Remove the head plate

GA113312EN02

19

III. General description

1133.12B1/B3/F1/F3

3.2.1.2 Mount / remove the joint adapters 1131.82A0 Note The joint adapter consists of a left and a right part. Please observe the markings L and R. If the joint adapters are mixed up, they cannot be used since the eccentric levers will point to the middle of the table top. Mount the joint adapter

R

L 1

⌧ Insert the left joint adapter 1131.82A0 (L) and the right joint adapter 1131.82A0 (R) with their pins fully in the sockets (A) of the back plate mounting point, at the front of the table top.

A

Fig.III-18: Insert the joint adapter

L

⌧ Swivel the joint adapters (L) and (R) downward in the direction of the arrows, up to the stop.

R

Fig.III-19: Swivel the joint adapters downward

20

GA113312EN02