Cleaning Procedure

5 Pages

Preview

Page 1

Wipe off/ discard

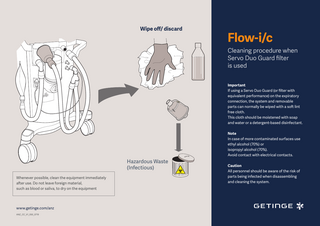

Flow-i/c Cleaning procedure when Servo Duo Guard filter is used Important If using a Servo Duo Guard (or filter with equivalent performance) on the expiratory connection, the system and removable parts can normally be wiped with a soft lint free cloth. This cloth should be moistened with soap and water or a detergent-based disinfectant. Note In case of more contaminated surfaces use ethyl alcohol (70%) or isopropyl alcohol (70%). Avoid contact with electrical contacts.

Hazardous Waste (Infectious) Whenever possible, clean the equipment immediately after use. Do not leave foreign material, such as blood or saliva, to dry on the equipment

www.getinge.com/anz ANZ_CC_V1_050_0719

Caution All personnel should be aware of the risk of parts being infected when disassembling and cleaning the system.

Flow Family

Disinfection Manually

Refer to the User Manual, Cleaning and maintenance, for detailed information.

Wiping and Discarding

2

Rinsing

3

Disinfectant and Rinsing Disinfectant

Whenever possible, clean and disinfect the equipment immediately after use. Do not leave foreign material, such as blood or saliva, to dry on the equipment.

4

Drying Shake/Tilt Manually remove as much water as possible before using a drying cabinet.

Caution

Let the parts soak in a disinfectant:

All personnel should be aware of the

Cidex OPA

risk of parts being infected when disassembling and cleaning

>2.5 hours maximum 90°C (194°F)

Rinsing

the system.

If available, connect a 22 mm hose to the expiratory connection. Also connect a 22 mm hose to the volume reflector.

Hazardous Waste (Infectious)

Important: If using a Servo Duo Guard (or filter with equivalent performance) on the expiratory connection, the system and removable parts can normally be wiped with a soft lint free cloth. This cloth should be moistened with soap and water or a detergent-based disinfectant.

Note. In case of more contaminated surfaces use ethyl alcohol (70%) or isopropyl alcohol (70%). Avoid contact with electrical contacts.

Rinse the parts thoroughly in water (<35°C/95°F). Attach the special cleaning adapters to the patient cassette and connect these to a source of running water. Let the water flow through the parts (flow: >10 l/min).

Note. Immediate rinsing can remove particles and reduces the risk of cross contamination between patients.

Important: Rinse the parts thoroughly in water to remove all traces of disinfectant. Let the water flow through the parts. Use the cleaning adapters when rinsing the patient cassette.

If the System checkout fails after this process, ventilate using a testlung and redo the System checkout. Assemble and run the system with a testlung 15 min at a flowrate of >10 l/min

Caution! Never dry the cassette by applying high pressure air as you may damage the internal tubing.

www.getinge.com/anz

ANZ_CC_V1_050_0719

1

Flow Family

Disinfection Washer-Disinfector

1

Refer to the User Manual, Cleaning and maintenance, for detailed information.

Wiping and Discarding

2

Rinsing

3

Washer-Disinfector Disinfectant

Whenever possible, clean and disinfect the equipment immediately after use. Do not leave foreign material, such as blood or saliva, to dry on the equipment.

90-95°C (194-203°F)

Caution

4

Drying Shake/Tilt Manually remove as much water as possible before using a drying cabinet.

>1.5 hours maximum 90°C (194°F)

All personnel should be aware of the risk of parts being infected when disassembling and cleaning

Hazardous Waste (Infectious)

Important: If using a Servo Duo Guard (or filter with equivalent performance) on the expiratory connection, the system and removable parts can normally be wiped with a soft lint free cloth. This cloth should be moistened with soap and water or a detergent-based disinfectant.

Note. In case of more contaminated surfaces use ethyl alcohol (70%) or isopropyl alcohol (70%). Avoid contact with electrical contacts.

Rinse the parts thoroughly in water (<35°C/95°F). Attach the special cleaning adapters to the patient cassette and connect these to a source of running water. Let the water flow through the parts (flow: >10 l/min).

Note. Immediate rinsing can remove particles and reduces the risk of cross contamination between patients.

Position and flow Attach the special cleaning adapters to the patient cassette and connect these to the washer-disinfector water outlets using connective tubings. Also connect the volume reflector to a water outlet. The water pressure in the washer-disinfector should not exceed 1.5 bar. The water flow should be at least 10 l/min. The water must have free passage through the cassette.

If available, connect a 22 mm hose to the expiratory connection. Also connect a 22 mm hose to the volume reflector.

If the System checkout fails after this process, ventilate using a testlung and redo the System checkout. Assemble and run the system with a testlung 15 min at a flowrate of >10 l/ min

Caution! Never dry the cassette by applying high pressure air as you may damage the internal tubing.

www.getinge.com/anz

ANZ_CC_V1_050_0719

the system.

Flow Family

Autoclaving Procedure

1

Refer to the User Manual, Cleaning and maintenance, for detailed information.

Wiping and Discarding Whenever possible, clean and disinfect the equipment immediately after use. Do not leave foreign material, such as blood or saliva, to dry on the equipment.

2

Rinsing and Dry Rinsing

3

Autoclaving Disinfectant

4

Drying Shake/Tilt Manually remove as much water as possible before using a drying cabinet.

4 min 134°C (273°F)

Caution

15 min 121°C (250°F)

All personnel should be aware of the risk of parts being infected when

Drying cabinet >1.5 hours maximum 90°C (194°F)

disassembling and cleaning the

Hazardous Waste (Infectious)

Note Autoclaving reduces the lifetime of the patient cassette and volume reflector

Important If using a Servo Duo Guard (or filter with equivalent performance) on the expiratory connection, the system and removable parts can normally be wiped with a soft lint free cloth. This cloth should be moistened with soap and water or a detergent-based disinfectant.

Note In case of more contaminated surfaces use ethyl alcohol (70%) or isopropyl alcohol (70%). Avoid contact with electrical contacts.

Rinse the parts thoroughly in water (<35°C/95°F). Attach the special cleaning adapters to the patient cassette and connect these to a source of running water. Let the water flow through the parts (flow: >10 l/min). Note. Immediate rinsing can remove particles and reduces the risk of cross contamination between patients.

Dry Make sure the equipment is dry before continuing with the sterilization procedure.

Important Rinse and dry the equipment before using the steam autoclave. Note Only use validated processes

Instrument parts are typically autoclaved at a temperature of 134°C (273°F) for 4-7 minutes. Rubber parts are typically autoclaved at a temperature of 121°C (250°F) for 15 minutes.

If available, connect a 22 mm hose to the expiratory connection. Also connect a 22 mm hose to the volume reflector.

If the System checkout fails after this process, ventilate using a testlung and redo the System checkout. Assemble and run the system with a testlung 15 min at a flowrate of >10 l/ min Caution Never dry the cassette by applying high pressure air as you may damage the internal tubing.

www.getinge.com/anz

ANZ_CC_V1_050_0719

system.

Flow Family

Prion Autoclaving Procedure

1

Wiping and Discarding

2

3 Disinfecting

Rinsing

4

Washer-Disinfector

Refer to the User Manual, Cleaning and maintenance, for detailed information.

90-95°C (194-203°F)

Caution

Rinsing

All personnel should be aware of the

Hazardous Waste (Infectious)

risk of parts being infected when disassembling and cleaning the system.

Note The Prion autoclaving procedure reduces the lifetime of the patient

5

6

Drying

Autoclaving

7 Drying

8

Notes

cassette and volume reflector Drying cabinet

For summary information on each step comprising this guide, refer to:

18 min 134°C (273°F)

>1.5 hours maximum 90°C (194°F)

>1.5 hours maximum 90°C (194°F)

If available, connect a 22 mm hose to the expiratory connection. Also connect a 22 mm hose to the volume reflector.

If available, connect a 22 mm hose to the expiratory connection. Also connect a 22 mm hose to the volume reflector.

Manual Disinfection Wall Diagram Washer-disinfector Wall diagram, and Steam Autoclave Procedure Wall diagram

www.getinge.com/anz

ANZ_CC_V1_050_0719

Drying cabinet