Instructions for Use

16 Pages

Preview

Page 1

%O2

60 50

70

40

80

30

90 21

100

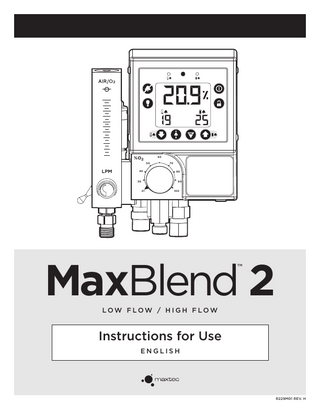

MaxBlend 2 ™

LOW FLOW / HIGH FLOW

Instructions for Use ENGLISH

R229M01 REV. H

Maxtec 2305 South 1070 West Salt Lake City, Utah 84119 USA

phone: (800) 748.5355 fax: (801) 973.6090 email: sales@maxtec.com web: www.maxtec.com

Conforms to: AAMI STD ES60601-1, ISO STD 80601-2-55, IEC STDS 606011-6, 60601-1-8 & 62366 Certified to: CSA STD C22.2 No. 60601-1

AUTHORIZED REPRESENTATIVE: QNET BV Kantstraat 19, NL-5076 NP Haaren The Netherlands

NOTE: The latest edition of this operating manual can be downloaded from our website at www.maxtec.com

Read this entire manual before attempting to operate or service the MaxBlend 2. Attempting to operate the MaxBlend 2 without fully understanding its features and functions may result in unsafe operating conditions.

electromagnetic interference when operated in the intended use environments described in this manual. MRI Notice This equipment contains electronic and ferrous components, whose operation can be affected by intense electromagnetic fields. Do not operate the MaxBlend 2 in an MRI environment or in the vicinity of high-frequency surgical diathermy equipment, defibrillators, or shortwave therapy equipment. Electromagnetic interference could disrupt the operation of the MaxBlend 2.

CLASSIFICATION

Protection class ... II, Type B Protection against water... IPX1 Mode of operation ...Continuous Safety of application in the presence of a flammable anesthetic mixture...See section 9.4 Power specification ...7.5V(MAX) 1.9W/250mA(MAX)

WARNINGS

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION: Federal law restricts this device to sale by, or on the order of, a medical professional.

The following warnings apply any time you operate or service the MaxBlend 2: ◆ Always confirm prescribed flow before administering to patient and monitor flow on a frequent basis.

Product Disposal Instructions: The sensor, batteries, and circuit board are not suitable for regular trash disposal. Return sensor to Maxtec for proper disposal or dispose according to local guidelines. Follow local guidelines for disposal of other components.

◆

WARRANTY

The MaxBlend 2 is designed for air/oxygen delivery. Under normal operating conditions, Maxtec warrants the MaxBlend 2 to be free from defects of workmanship or materials for a period of three years from the date of receipt from Maxtec, provided that the unit is properly operated and maintained in accordance with Maxtec’s operating instructions. Based on Maxtec’s product evaluation, Maxtec’s sole obligation under the foregoing warranty is limited to making repairs, or issuing credit, or replacement for equipment found to be defective. This warranty extends only to buyers purchasing new equipment directly from Maxtec, or through Maxtec’s designated distributors and agents. Maxtec warrants the MAX-550E oxygen sensor in the MaxBlend 2 to be free from defects in material and workmanship for a period of two years from Maxtec’s date of shipment in a MaxBlend 2 unit. Should a sensor fail prematurely, the replacement sensor is warranted for the remainder of the original sensor warranty period. Routine maintenance items, such as batteries, are excluded from warranty. Maxtec, and any other subsidiaries, shall not be liable to the purchaser or other persons for incidental or consequential damages to equipment that has been subject to abuse, misuse, misapplication, alteration, negligence, or accident. THESE WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING WARRANTY OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

DO NOT operate the MaxBlend 2 unless qualified personnel are in attendance to promptly respond to alarms, inoperative conditions, or sudden malfunctions. ◆

Patients on life-support equipment should be visually monitored at all times. DO NOT ignore audible alarms of the MaxBlend 2. Alarms indicate conditions that require your immediate attention. DO NOT use parts, accessories, or options that have not been authorized for use with the MaxBlend 2. Using unauthorized parts, accessories, or options may be harmful to the patient or damage the MaxBlend 2.

◆

Check all audible and visual alarms periodically to ensure they are operating properly. If an alarm fails to activate, contact your Maxtec Certified Service Technician. DO NOT operate the MaxBlend 2 with the monitor powered off or without setting the adjustable alarms. All adjustable alarms must be set to ensure safe operation. DO NOT steam autoclave or otherwise subject the MaxBlend 2 to temperatures above 122°F (50°C).

NOTE: In order to obtain optimum performance from your MaxBlend 2, all operation and maintenance must be performed in accordance with this manual. Please read the manual thoroughly before using the MaxBlend 2, and do not attempt any repair or procedure that is not described herein. Maxtec cannot warranty any damage resulting from misuse, unauthorized repair, or improper maintenance of the instrument.

◆

EMC Notice This equipment uses, generates, and can radiate radio frequency energy. If not installed and used in accordance with the instructions in this manual, electromagnetic interference may result. The equipment has been tested and found to comply with the limits set forth in IEC 60601-1-2 for medical products. These limits provide reasonable protection against

◆

ENGLISH

Always follow ANSI and CGA standards for medical gas products, flowmeters, and oxygen handling.

If either the air or oxygen source pressure is reduced or increased sufficiently to create a pressure differential of 20 PSI or more, an audible alarm will sound. This condition may significantly alter the FiO2 and flow output from the MaxBlend 2. DO NOT tape, obstruct, or remove the alarm during clinical use. DO NOT occlude the sensor port on the side of the MaxBlend 2. An air inlet/water filter is recommended for use with the MaxBlend 2. See section 6.1. DO NOT use lubricants on the MaxBlend 2. DO NOT use the MaxBlend 2 until correct performance has been verified. See section 3.0.

2

WWW.MAXTEC.COM • (800) 748-5355

◆

If a condition is detected that could possibly prevent the monitor from continuing to operate safely, it will sound an alarm. If, at any time, EOx (i.e. EO2, EO4, etc.) appears on the LCD refer to section 4.0, or contact a Maxtec Certified Service Technician.

◆

All service should be referred to a Maxtec Certified Service Technician.

◆

Maxtec recommends that the MaxBlend 2 be serviced by Maxtec at a minimum of every three years, or if a leak or other performance problem is suspected.

◆

If the MaxBlend 2 is dropped, follow the procedures outlined in section 3.0 for a performance check before reusing the device.

◆

When the unit is going to be stored (not in use for more than 30 days), always remove the batteries to protect the unit from potential damage due to battery leakage.

◆

Always replace batteries with high-quality, name-brand “AA” alkaline batteries.

◆

The low oxygen alarm can be set below 18%, and as low as 15%. See section 2.3 on setting alarms. This is in accordance with IEC 80601-2-55.

◆

In the event of exposure to an ELECTROMAGNETIC DISTURBANCE the analyzer may display an E06 or E02 error message. If this occurs, refer to Section 4.0 for instructions to resolve the problem.

Always operate the MaxBlend 2 with clean, dry medical-grade gases. Contaminants or moisture can cause defective operation. Oxygen should have a minimum dewpoint of -80°F (-62°C) or moisture content less than 7.9 PPM (0.0059mg/L). Oxygen “purity” should be at least 99.0% and the air used should be medical-grade. Water vapor content must not exceed a dew point of 5°F (-15°C) below the lowest ambient temperature to which the delivery system is exposed.

◆

Particulate content must not exceed that which would be found immediately downstream of a 15 micron absolute filter. Refer to CGA commodity specifications G-4.3 and G7.1 for more information. Water vapor content of medical air or O2 supply to the blender must not exceed 5.63 x 103 milligrams H2O per cubic meter of non-condensable gas. DO NOT disassemble the MaxBlend 2. All service should be performed by a Maxtec Certified Service Technician.

To prevent risk of burns, fire, or injury to person(s): ◆ Mixed gases continuously bleed into the atmosphere at the oxygen concentration rate set at the control knob. Bleeding oxygen into any closed area could increase the risk of fire or explosion.

◆

Be sure the MaxBlend 2 is securely mounted. This device is usually mounted to a hospital rail system or an infusion stand. Dropping the device may cause injury or damage to the device.

◆

The outlets of this device are capable of delivering pressure as high as the inlet pressure. Ensure that the devices that carry the gas from the blender to the patient prevent excessive pressure to the patient. DO NOT use the oxygen sensor if it appears to be damaged or is leaking. The oxygen sensors contain a weak acidic solution encapsulated in a plastic housing. Under normal operating conditions the solution (electrolyte) is never exposed.

NOTES

DO NOT operate this device in the presence of any flame or source of ignition, or when using devices such electrosurgical equipment or defibrillators.

Indicates supplemental information to assist in the use of the device.

DO NOT operate the MaxBlend 2 in the presence of flammable anesthetics or in an atmosphere of explosive gases. Operating the MaxBlend 2 in flammable or explosive atmospheres may result in fire or explosion. ◆

◆

Galvanic O2 sensor electrolyte gel is acidic and may cause skin or eye irritation and/or burns. Take care when handling or replacing exhausted or damaged disposable O2 sensors. Be sure to dispose of expired sensors in accordance with hospital and/or governmental regulations (O2 Sensor SDS available upon request from Maxtec).

◆

The MaxBlend 2 is tested for compliance with ISO 11195, and meets requirements regarding reverse gas flow as delivered.

◆

Applicable parts used in the MaxBlend 2 have been cleaned and degreased for oxygen service. Any lubricants used are designed specifically for the application.

◆

As long as the absolute pressure of the gas mixture being monitored is constant, the MaxBlend 2 will accurately read oxygen concentrations. However, if the absolute pressure varies the reading will fluctuate proportionately, as the sensor actually measures the partial pressure of oxygen in the mixture. The sensor readings will also change proportionately with barometric pressure changes; because of this, frequent calibration of the sensor is recommended.

◆

Users are advised to use pressure regulators which display the outlet pressure.

◆

All specifications assume the following standard environmental conditions, unless specified otherwise: ambient and sample gas temperatures of 77°F (25°C), barometric pressure of 30inHg (760mmHg), sea level altitude, ambient relative humidity of 50%, sample gas relative humidity of 0%.

◆

It is important to note that the oxygen concentration selection scale is provided only as a guideline for selecting O2 concentrations. The clinician should use the MaxBlend 2’s display panel to adjust the O2 concentration to the desired setting.

◆

The alarm limits can be set to levels that would render them useless for a particular patient’s clinical condition. Ensure that the delivered oxygen level and flow rate are set to values prescribed by the patient’s physician. Also ensure that the high and low alarm limits are set to levels such that they will sound if the oxygen level is outside of safe limits. Be sure to review and, if necessary, re-set the alarm limits when the patient’s clinical condition changes, or when the patient’s physician prescribes a change in oxygen therapy.

◆

This device does not contain automatic barometric pressure compensation.

◆

Gas leaks that cause room air to mix with the gas sample may cause inaccurate oxygen readings. Ensure the O-rings on the sensor and flow diverter are in place and intact prior to use.

DO NOT smoke in an area where oxygen is being used.

CAUTIONS

Indicates a potentially hazardous situation which, if not avoided, could result in minor or moderate injury and property damage. DO NOT store the MaxBlend 2 in hot areas for prolonged periods of time. Temperatures above 80°F (27°C) can shorten battery life. ◆

To minimize the potential for electrostatic shock, conductive hoses with the MaxBlend 2.

DO NOT use antistatic or electrically

When cleaning the MaxBlend 2: DO NOT use harsh abrasives. DO NOT immerse the MaxBlend 2 in liquid sterilizing agents or liquids of any kind. DO NOT spray cleaning solution directly onto the sensor port, bleed muffler, or buzzer opening. DO NOT allow cleaning solution to pool on the front panel, sensor port, or bleed muffler. DO NOT sterilize the MaxBlend 2. Standard sterilization techniques may damage the blender. DO NOT clean or dry the MaxBlend 2 with a high pressure air gun. Applying high pressure air to the MaxBlend 2 may damage components and render the system inoperable. DO NOT over-clean the MaxBlend 2. Repeated use of a cleaning agent can cause residue build-up on critical components. Excessive residue buildup can affect the MaxBlend 2’s performance. ◆

Dropping or severely jarring the sensor after calibration may shift the calibration point enough to require recalibration.

WWW.MAXTEC.COM • (800) 748-5355

3

ENGLISH

TABLE OF CONTENTS CLASSIFICATION...2 WARRANTY...2

3.0 PERFORMANCE CHECK...9 3.1 Blender Safety Check... 10

WARNINGS

...2

4.0 TROUBLESHOOTING... 10

CAUTIONS

...3

5.0 CLEANING AND DISINFECTING... 11

NOTES...3

6.0 SERVICE AND MAINTENANCE... 11 6.1 Maintenance... 11 6.2 Replacing O2 Sensor... 11 6.3 Monitor Alarm Testing... 11

1.0 INTRODUCTION...5 1.1 Indication for Use...5 1.2 MAX-550E Oxygen Sensor...5 1.3 Symbol Guide...5 1.4 Component Identification...6 1.5 Display Indicators...6 1.6 Back View... 7 1.7 Requirements for Operating the Blender... 7

7.0 ABBREVIATION GUIDE... 12 8.0 SPECIFICATIONS... 12 8.1 Instrument Specifications...12 8.2 Alarm Specifications...12 8.3 O2 Sensor Specifications...12

2.0 OPERATING PROCEDURES...7 2.1 Setup and Installation... 7 2.1.1 Battery Installation... 7 2.1.2 MaxBlend 2 Setup... 7 2.1.3 Sensor Installation... 7 2.2 Monitoring... 7 2.3 Alarm Setting Procedure...8 2.3.1 Low Alarm Setting ...8 2.3.2 High Alarm Setting...8 2.3.3 Smart Alarm Mode...8 2.4 Basic Operation...8 2.5 Alarm Conditions and Priorities...8 2.6 Backlight Operation...9 2.7 External Power Supply Operation...9 2.8 Calibration Procedures...9 2.8.1 Calibration to 100% Oxygen...9 2.8.2 Calibration to Room Air...9 2.9 Flowmeter Operation...9

ENGLISH

9.0 FACTORS INFLUENCING CALIBRATION... 12 9.1 Temperature Effect...12 9.2 Pressure Effect...12 9.3 Humidity Effect...12 9.4 Exposure to Anesthetic Gases...13 10.0 SPARE PARTS AND ACCESSORIES... 13 11.0 THEORY OF OPERATION... 13 11.1 Operational Diagram...13 11.2 Mixing Operation...13 11.3 Gas Outlet...13 11.4 Alarm/Bypass Function...14 12.0 FLOW CHARACTERISTICS... 14 13.0 ELECTROMAGNETIC COMPATABILITY... 14

4

WWW.MAXTEC.COM • (800) 748-5355

1.0 INTRODUCTION

The MAX-550E is a galvanic, partial pressure sensor that is specific to oxygen. It consists of two electrodes (a cathode and an anode), a teflon membrane and an electrolyte. Oxygen diffuses through the teflon membrane and immediately reacts electrochemically at a gold cathode. Concurrently, oxidation occurs electrochemically at a lead anode, generating an electrical current and providing a voltage output. Electrodes are immersed in a unique gelled weak acid electrolyte, which is responsible for the sensor’s long life and motion insensitive characteristic. Since the sensor is specific to oxygen, the current generated is proportional to the amount of oxygen present in the sample gas. When no oxygen is present, there is no electrochemical reaction, and therefore, negligible current is produced. In this sense, the sensor is self-zeroing.

The MaxBlend 2 is a compact air/oxygen gas mixing device which incorporates the use of a battery powered oxygen monitor. The gas mixing device (blender) provides precise mixing of medical-grade air and oxygen, while the monitor measures the selected oxygen concentrations from the blender’s gas flow and displays these measured concentrations on a digital display. The monitor provides high and low alarm limits which, when exceeded, cause an audible and visual alarm.

1.1 Indication for Use

The MaxBlend 2 is designed to provide a continuous air/oxygen gas mixture and to continuously monitor the concentration of oxygen being delivered to infant, pediatric, and adult patients. It is a restricted medical device intended for use by qualified, trained personnel, under the direction of a physician, in professional healthcare settings, i.e., hospital, subacute, and nursing-care facilities where the delivery and monitoring of air/oxygen mixtures is required. This is not intended as a life supporting device.

CAUTION: The MAX-550E oxygen sensor is a sealed device containing a mild acid electrolyte and lead (Pb). These materials are hazardous waste constituents and should be disposed of properly, or returned to Maxtec for proper disposal or recovery. CAUTION: Dropping or severely jarring the sensor after calibration may shift the calibration point enough to require recalibration.

1.2 MAX-550E Oxygen Sensor

1.3 Symbol Guide

The following symbols and safety labels are found on the MaxBlend 2 and/or labeling: ON/OFF Key

Silent Key

Backlight Key

Unlock Key

Smart Alarm Key

CAL (Calibration Key)

Sleep Mode Indicator

High Alarm Indicator

Low Alarm Indicator

Calibration Reminder

Smart Alarm Mode Indicator

Alarm Silence Indicator

Below 18% Alarm Indicator

Low Battery Indicator

DOWN (Low Alarm Key)

UP (High Alarm Key)

Do Not

MR Unsafe

Caution

Warning

Corrosive

Manufacturer

Federal law (USA) restricts this device to sale by or on order of a physician.

Type B Applied Parts

Attention, consult accompanying documents

Ingress Protection Rating

Liters Per Minute

Oxygen Percent

Catalog Number

Serial Number

Inlet

Outlet

Do not throw away. Follow local guidelines for disposal

Meets ETL standards

Authorized Representative in the European Community

50°C (122°F) -15°C (5°F)

Oxygen Enriched Air

Read Flow at Center of Ball

Direct Current

Storage Temperature Range

Use No Oil

For use in dry indoor locations.

Combined UL / CSA Mark

POWER SUPPLY SYMBOL GUIDE The following symbols and safety labels are found on the MaxBlend 2 power supply (sold separately): Two means of patient protection (double insulated)

WWW.MAXTEC.COM • (800) 748-5355

Conforms to EU requirements. Combined UL / CSA Mark

5

ENGLISH

1

i u

o

y t r e

%O2

70

40

80

30

90 21

l k j

3 4

a s h f g d

5 6 e FLOW CONTROL KNOB - The flow control knob controls the flow of gas exiting the flowmeter.

60 50

p

2

r OXYGEN FLOWMETER - Measures the flow of mixed gas exiting the flowmeter outlet. t SMART ALARM KEY - The Smart Alarm key is used to help set the High-Low Alarm win-

100

dow quickly. See section 2.3.3 for instructions on using the Smart Alarm setting.

w

y DOWN (LOW ALARM) KEY -

The down key is used in setting the low FiO2 alarm limit. The device must be in the unlocked state for the key to operate. See section 2.3.1 for instructions on setting the low FiO2 alarm limit.

q

u BACKLIGHT KEY - The backlight key will manually activate the backlight for 30 seconds.

98 7

See section 2.6 for more information on backlighting operation.

1.4 Component Identification

i SILENT KEY -

In an alarm condition, pressing the SILENT key will deactivate the audio alarm for 2 minutes.

1 LOW ALARM LED - In a low alarm condition, the “LOW ALARM” LED will flash twice a second, accompanied by the audio buzzer.

o LCD DISPLAY - The digit liquid crystal display (LCD) provides direct readout of oxygen

concentrations. The digits also display error codes, alarm set modes, and calibration codes as necessary.

2 HIGH ALARM LED - In a high alarm condition, the “HIGH ALARM” LED will flash twice a second, accompanied by the audio buzzer.

1.5 Display Indicators

3 ON/OFF KEY -

This key is used to turn the device on or off. To turn the device OFF, the button must be held while a rapid 3-2-1 countdown takes place to prevent accidental power-off.

p OXYGEN CONCENTRATION - Current oxygen concentration percentage from the oxygen sensor.

4 UNLOCK KEY - The unlock key is used to lock and unlock the instrument. a HIGH ALARM INDICATOR - The high alarm setting is displayed at all times just below the “HIGH” icon on the LCD readout. The indicated value represents the oxygen 5 UP (ALARM HIGH) KEY - The up key is used in setting the high FiO2 alarm limit. percentage at which the high alarm will be activated. The device must be in the unlocked state for the key to operate. See section 2.3.2 for instructions on setting the high FiO2 alarm limit.

s OXYGEN HIGH ALARM LIMIT - High oxygen alarm setpoint. Audible and visual alarms will trigger when this limit is exceeded.

6 CALIBRATION KEY -

This key is used to calibrate the device. The device must be in the unlocked state for the key to operate. See section 2.8 for instructions on calibrating.

d CALIBRATION REMINDER -

The calibration reminder symbol is located at the bottom of the display. This symbol will display after one week has elapsed from the previous calibration.

7 O2 INLET FITTING - An O2 fitting for connection to the O2 inlet hose from the gas source. 8 OXYGEN CONCENTRATION SELECTOR CONTROL - A knob which allows for selections of f SLEEP MODE INDICATOR - mixed oxygen concentrations from 21% to 100%.

The sleep mode indicator is used to help with battery

consumption.

9 MEDICAL AIR INLET CONNECTOR - An air fitting for connection to an air inlet hose from g LOW BATTERY INDICATOR - the air gas source.

The Low Battery Indicator is located at the middle of the display and is only activated when the voltage on the batteries is below a normal operating level.

q FLOWMETER OUTLET - A fitting for connection to the patient delivery tubing. SILENCE/SMART ALARM INDICATOR - When the Silent key is pressed the indicaw BLEED TOGGLE SWITCH - The Bleed Toggle Switch turns on the auxiliary bleed. For the h ALARM tor will display with cross bars to alert the condition. When Smart Alarm key is blender to accurately mix the oxygen and air, the bleed must be turned on whenever the total flow delivered to the patient is less than 15 LPM for high flow model, or less than 3 LPM for low flow model.

ENGLISH

pressed the indicator

6

will display with T-bars to alert the condition.

WWW.MAXTEC.COM • (800) 748-5355

v

1.7 Requirements for Operating the Blender

b

All operator-detachable inlet pressure hoses supplied with the gas mixer comply with ASTM/ ISO 5359. PRESSURIZED OXYGEN: The compressed oxygen source must provide clean, dry, medicalgrade oxygen at the pressure specified in Section 8.0.

W

PRESSURIZED AIR: The compressed air source must provide clean, dry, medical-grade air at the pressure specified in Section 8.0.

n

2.0 OPERATING PROCEDURES 2.1 Setup and Installation

m

Q /

2.1.1 Battery Installation

All MaxBlend 2 units are powered by four “AA” alkaline batteries (4 x 1.5 Volts) and are shipped without the batteries installed. Only name-brand batteries should be used. Batteries should be replaced by trained service personnel.

,

To install the batteries: Open the battery drawer by squeezing inward on both tabs as shown in the figure below. If you have difficulty squeezing the tabs in with your fingers, use two flat screwdrivers or two coins. Remove the battery drawer completely from the MaxBlend 2. Install four new, “AA” alkaline batteries into the unit, observing the orientation shown on the plastic inside the drawer. Slide the drawer back in with the batteries facing upward. Press in on the drawer until both tabs latch into place.

. j OXYGEN LOW ALARM LIMIT - Low oxygen alarm setpoint. Audible and visual alarms will

When batteries are replaced, the unit will start up and perform an automatic calibration. Ensure calibration is performed as directed in Section 2.8.

trigger when this limit is exceeded.

k LOW ALARM INDICATOR -

The low alarm setting is displayed at all times just below the “LOW” icon on the LCD readout. The indicated value represents the oxygen percentage at which the low alarm will be activated.

WARNING: Battery replacement by inadequately trained personnel could result in a safety hazard. WARNING: Electrical shock or damage to the equipment may occur if an inappropriate external power supply is used. Maxtec recommends using only the Maxtec MaxBlend 2 External Power Supply-R230P10.

l <18% ALARM INDICATOR - The <18% alarm indicator is located above the Low Alarm

Indicator digits. When the low alarm setting is set below <18%, the indicator will flash each second to alert the operator of this special condition. See section 2.3.1 for setting this low alarm condition.

1.6 Back View

v BATTERY COMPARTMENT - The MaxBlend 2 is powered by four “AA” alkaline batteries. b SENSOR CABLE - The cable connects the MaxBlend 2 to the MAX-550E Sensor. n SENSOR WITH DIVERTER - The sensor with flow diverter is designed to fit into a port

2.1.2 MaxBlend 2 Setup

1. Connect the pressurized air source to the Air Inlet Connector. 2. Connect the pressurized oxygen source to the O2 Inlet Fitting. 3. Flush gas at the highest possible flow rate through the blender for at least one minute to eliminate any particulate that may have been introduced into the system during handling and installation.

behind the flowmeter.

m O2 SENSOR PORT - A sampling port for the oxygen sensor. It allows mixed gas from the blender to flow over the sensor membrane.

, PRESSURE DIFFERENTIAL REED ALARM - An audible alarm which, when activated,

2.1.3 Sensor Installation

indicates that an unacceptable pressure differential exists between the two gas source pressures.

1. Attach the flow diverter onto the oxygen sensor. 2. Place the sensor into the sensor port located behind the flowmeter. 3. Attach the sensor cable directly to the sensor and the sensor jack on the back of the monitor enclosure. Ensure the cable is fully inserted into both connections. 4. Calibrate the sensor prior to use according to the calibration procedures in section 2.8

. AUXILIARY MIXED GAS OUTLET - The outlet can be used as power take off. / AUXILIARY MIXED GAS OUTLET - The outlet can be used to add additional flowmeters. Q MOUNT ADAPTER - An adapter which allows the MaxBlend 2 to be mounted onto a

2.2 Monitoring

bracket for attaching to a rail or ventilator system.

Before use on a patient, the oxygen concentration of the delivered gas should be checked at the setting intended for use.

W EXTERNAL POWER SUPPLY PORT - The port provides connection for the external power

1. To begin monitoring, press the ON/OFF key will begin immediately.

adapter. See section 2.7 for more information on the power supply.

WWW.MAXTEC.COM • (800) 748-5355

7

located on the front panel. Monitoring

ENGLISH

2.3.3 Smart Alarm Mode

2. Should oxygen level exceed either the HIGH or LOW alarm set points, the alarm indicator on the front panel will illuminate indicating either a high or low oxygen condition. The alarm will cease when oxygen levels are within limits, or the limits are adjusted.

1. Press the Unlock Key to unlock the keypad. Note the LOW, SMART ALARM, CAL, and HIGH icons will begin to flash indicating the SET OPERATING MODE. 2. Press the Smart Alarm key on the keypad. Note the LOW digits, Alarm Mode and HIGH digits begin a slow flash indicating SMART ALARM MODE. The high alarm will now be set equal to the current oxygen reading +3% (rounded to the nearest integer). The low alarm will now be set equal to the current oxygen reading -3% (rounded to the nearest integer, but never lower than 18%. 3. Pressing of the UP key will add 1% to the high alarm setting and subtract 1% from the low alarm setting. Pressing the DOWN key will subtract 1% from the high alarm setting and add 1% to the low alarm setting. In other words, the UP key widens the alarm band and the DOWN key tightens the alarm band. This feature will not set the alarm levels above 100% or below 18%. 4. Once the desired alarm settings are attained, press the Unlock key again to save the settings and return to normal operation mode. If 30 seconds elapse without a key press by the user, the device will automatically save the latest alarm settings and return to normal operation mode.

NOTE: The MaxBlend 2 will monitor the oxygen concentration of the gas delivered from the blender regardless of which outlet port is in use. Therefore, the integrated flowmeter has ultimately no effect on the oxygen sensing.

2.3 Alarm Setting Procedure 2.3.1 Low Alarm Setting

To adjust the low alarm setting: 1. Press the Unlock key to unlock the keypad. Note the LOW, SMART ALARM, CAL, and HIGH icons will begin to flash indicating the SET OPERATING MODE. 2. Press the DOWN (Low Alarm) key on the keypad. NOTE: The Low Alarm digits begin to flash indicating the Low Alarm manual setting. 3. Use the UP and DOWN keys to set the low alarm to the desired value. Pressing the arrow keys changes the value in 1% increments. If the keys are held down for more than 1 second, the display will scroll at a rate of 1% per second.

2.4 Basic Operation

To check the oxygen concentration of the delivered gas: 1. Ensure the sensor is connected to the flow diverter and inserted completely in the sensor port behind the flowmeter. 2. Set the oxygen blender control knob to the desired oxygen setting. 3. Using the ON/OFF key , make sure the unit is in the power on mode. 4. Allow the oxygen reading to stabilize. 5. Adjust the flowmeter to the desired flow rate. Read the flow rate at the center of the float ball.

NOTE: If 30 seconds elapse between key actuations, the system will store the latest low alarm setting and will revert to normal operation. If this occurs inadvertently, simply repeat the alarm setting procedure. There is a special condition that allows the low oxygen alarm to be set below 18%. To access this condition, press the DOWN arrow key for three seconds while the low alarm reading displays 18%. The alarm setting can now be adjusted to 17, 16, or 15%. A bar will blink above the setting to provide further indication that the alarm has been set to this special <18% condition.

2.5 Alarm Conditions and Priorities

In the event of either a low alarm or high alarm condition, the corresponding LED will begin to flash, accompanied by the audio buzzer. Pressing the Silent key will deactivate the buzzer, but the LED and the alarm value digits on the display will continue to flash until the alarm condition has been rectified. If the alarm condition still exists 120 seconds after silencing the audio buzzer, the beeper will start to sound again.

The low alarm value cannot be set lower than 15%, nor can it be set closer than 1% from the high alarm value. For example, if the high alarm is set at 25%, the system will not accept a low alarm setting greater than 24%. When the low alarm value is set, press the Unlock key again to accept the low alarm setting and return to normal operation. NOTE: The default low alarm setting is 18% O2. Removing the batteries, or shutting the unit OFF will reset the low alarm limit to 18%.

2.3.2 High Alarm Setting

To adjust the high alarm setting: 1. Press the Unlock key to unlock the keypad. Note the LOW, SMART ALARM, CAL and HIGH icons will begin to flash indicating the SET OPERATING MODE. 2. Press the UP (High Alarm) key on the keypad. NOTE: The High Alarm digits begin to flash indicating the High Alarm manual setting. 3. Use the UP and DOWN keys to set the high alarm to the desired value. Pressing the arrow keys changes the value in 1% increments. If the keys are held down for more than 1 second the display will scroll at a rate of 1% per second. NOTE: If 30 seconds elapse between key actuations, the system will store the latest high alarm setting and will revert to normal operation. If this occurs inadvertently, simply repeat the alarm setting procedure. 4. When the high alarm setting is set above 100%, the high alarm will indicate two dashes – –. This special condition turns off, or deactivates, the high alarm. 5. When the high alarm value is set, press the Unlock again to accept the high alarm setting and return to normal operation. NOTE: The default high alarm setting is 50% O2. Removing the batteries will reset the high alarm limit to 50%.

ENGLISH

8

ALARM

ALARM PRIORITY

LOW HIGH ALARM LED ALARM LED

AUDIBLE ALARM

AUDIBLE ALARM REPEAT

Line Power Plugged In

Informational

Off

Off

2 Pulses

No Repeat

Line Power Unplugged

Informational

Single Yellow Pulse

Single Yellow Pulse

2 Pulses

No Repeat

External DC Power Supply Voltage Out of Range

Informational

Solid Yellow

Solid Yellow

2 Pulses

Every 15 Sec.

Battery Voltage too low for device to operate (E04)

Medium

Pulsing Yellow

Pulsing Yellow

3 Pulses

Every 25 Sec.

Oxygen/ pressure level above the high alarm setting

Medium

Off

Pulsing Yellow

3 Pulses

Every 25 Sec.

Oxygen/pressure level below the low alarm setting

Medium

Pulsing Yellow

Off

3 Pulses

Every 25 Sec.

Oxygen level below the low oxygen alarm setting and lower than 18%

High

Pulsing Red

Off

5+5 Pulses

Every 15 Sec.

WWW.MAXTEC.COM • (800) 748-5355

2.8.2 Calibration to Room Air

• A low alarm condition will remain until the actual concentration is 0.1% higher than the

low alarm setting. • A high alarm condition will remain until the actual concentration is 0.1% lower than the high alarm setting. To differentiate the level of severity, the monitor provides three unique sound bursts.

The MaxBlend 2 can quickly be calibrated to room air (20.9%).

To calibrate to room air: 1. Connect the air supply line (pressure differential alarm may sound). Verify the sensor is plugged into the O2 sensor port and connected to the sensor cable DO NOT connect oxygen supply line at this time. (If preferred, room-air calibration may be performed by removing the sensor from the O2 sampling port and detaching the flow diverter. If using this method, the gas-supply lines may remain attached.) 2. Using the ON/OFF key, make sure the MaxBlend 2 is in the power on mode. 3. Rotate the FiO2 control knob to the 21% stop. Allow a few minutes for the reading to stabilize. 4. Press the Unlock key to unlock the keypad. Note the LOW, SMART ALARM, CAL and HIGH icons will begin to flash indicating the SET OPERATING MODE. 5. Press the CAL (Calibration) key on the keypad. The word “CAL” will appear on the display for approximately 5 seconds and then finish with 20.9%. 6. The unit is now calibrated and in the normal operating mode.

2.6 Backlight Operation To turn on the backlighting: 1. When the unit is on, pressing the Backlight button will turn the backlighting on for 30 seconds. An additional press will turn off the backlighting. 2. If the device is being used in a dark location, any button press will activate the backlight. CAUTION: Excessive use of the backlight can reduce the life of the batteries.

2.7 External Power Supply Operation

To extend the life of the batteries, an external Maxtec approved 7.5V DC external power supply can be purchased. Once connected to the unit, total power is supplied by the power supply. Batteries are still required in the unit and will provide emergency power in the event main AC power is lost.

2.9 Flowmeter Operation

1. Adjust the flowmeter to the desired setpoint as read by the center of the float ball. • To increase flow-turn knob counter-clockwise • To decrease flow-turn knob clockwise 2. Check the toggle bleed switch to ensure it is in the appropriate position. • For a low flow blender the bleed toggle switch should be turned on (up position) if the total combined flow from the blender is less than 3LPM. • For a high flow blender the bleed toggle switch should be turned on (up position) if the total combined flow from the blender is less than 15LPM. • At delivered flows greater than the above limits, the bleed toggle switch can be turned off (down position) to conserve gas.

NOTE: Use only the Maxtec external power supply described in section 10.0. NOTE: The power supply is not a battery charger. DO NOT use rechargeable batteries.

2.8 Calibration Procedures 2.8.1 Calibration to 100% Oxygen

The MaxBlend 2 should be calibrated before being placed into clinical use. Thereafter, Maxtec recommends calibration of the unit on a weekly basis. Frequent calibration will have no adverse effect on the performance of the MaxBlend 2. Calibration should also be performed upon replacement of a sensor.

CAUTION: Failure to activate the bleed as described above may result in inaccurate oxygen concentrations from the blender. However, the MaxBlend 2 will always display the actual delivered concentration.

The sensor is best calibrated while mounted in the MaxBlend 2 sensor port. As in normal operation, the oxygen sensor responds best when installed in a vertical position with the sensor facing down.

CAUTION: The outlets of this device are capable of delivering pressure as high as the inlet pressure. Ensure that the devices that carry the gas from the blender to the patient prevent excessive pressure to the patient.

Changes in barometric pressure can affect the oxygen reading. A 1% change in the barometric pressure results in an error of 1% of the actual reading. (Example: If you are reading a 50% oxygen mix and the barometric pressure drops from 1000mbar to 990mbar the reading will drop to 50% x (990/1000) = 49.5%). Maxtec recommends that you recalibrate after changing point-of-use elevation by more than 500 feet (150m).

3.0 PERFORMANCE CHECK

Prior to placing the MaxBlend 2 into clinical use, perform the following tests. WARNING: If the MaxBlend 2 does not function as described on the next page, contact your Maxtec Distributor or contact a Maxtec Certified Service Technician at:

It is best to calibrate the MaxBlend 2 using the sensor port with a technical grade oxygen standard (99.0% or better). Calibration of the unit with room air is less accurate over the full FiO2 operating range.

Maxtec 2305 South 1070 West Salt Lake City, UT 84119 (385) 549-8000 or (800) 748-5355

To calibrate to 100% oxygen: 1. Connect the oxygen supply line (pressure differential alarm may sound). Verify the sensor is plugged into the O2 sensor port and connected to the sensor cable. DO NOT connect air supply line at this time. 2. Using the ON/OFF key, make sure the MaxBlend 2 is in the power on mode. 3. Rotate the FiO2 control knob to the 100% stop. Allow a few minutes for the reading to stabilize. 4. Press the Unlock key to unlock the keypad. Note the LOW, SMART ALARM, CAL, and HIGH icons will begin to flash indicating the SET OPERATING MODE. 5. Press the CAL (Calibration) key on the keypad. The word “CAL” will appear on the display for approximately 5 seconds and then finish with 100.0%. 6. The unit is now calibrated and in the normal operating mode.

WWW.MAXTEC.COM • (800) 748-5355

DO NOT use the MaxBlend 2 until correct performance has been verified.

9

ENGLISH

3.1 Blender Safety Check

PROBLEM: Selected oxygen concentration accurate only when gas pressures are equal. POTENTIAL CAUSES AND SOLUTIONS: • MaxBlend 2 balance module not functioning properly. Contact Maxtec for repair.

NOTE: Before proceeding, ensure that the high alarm set point control is OFF [display reads (--)], and that the low alarm set point control is below 20%. PROCEDURE

BLENDER RESPONSE

1. Connect the blender to 50 ±5 PSIG air/oxygen gas sources. Adjust the blender control knob to 60%. Turn the bleed toggle switch on (up position) and adjust the flowmeter to a minimum of 2 LPM.

No response. Monitor display reads 60% ±3%.

PROBLEM: Blank display. POTENTIAL CAUSES AND SOLUTIONS: • Batteries not installed. Install batteries. Refer to section 2.1.1, Battery Installation. • Battery completely dead. Replace batteries. Refer to section 2.1.1, Battery Installation. • Monitor defective. Contact Maxtec for repair. PROBLEM: Partial or distorted display. POTENTIAL CAUSES AND SOLUTIONS: • Monitor damaged. Contact Maxtec for repair.

2. Disconnect the 50 PSIG AIR source from the MaxBlend 2. Audible alarm sounds. Monitor NOTE: The blender must be flowing display reads 100% ±3%. gas for the alarm to activate. 3. Reconnect 50 PSIG AIR source to the MaxBlend 2.

Audible alarm stops. Verify the monitor display reads 60% ±3%.

4. Disconnect 50 PSIG OXYGEN source from the MaxBlend 2.

Audible alarm sounds. Monitor display reads 20.9% ±3%.

5. Reconnect 50 PSIG OXYGEN to the MaxBlend 2.

Audible alarm stops. Verify the monitor display reads 60% ±3%.

6. Adjust both air and oxygen inlet regulators to 0 PSIG.

No response.

7. Remove air inlet hose at regulator and insert end into beaker of water.

No response.

8. Slowly raise pressure of oxygen regulator to 50 PSIG and back to 0 PSIG while observing air hose end in beaker.

No bubbles should be observed. Audible alarm sounds.

9. Dry and reattach air inlet hose to regulator.

No response.

10. Remove oxygen inlet hose at regulator, and insert end into beaker of water.

No response.

11. Slowly raise pressure of air regulator to 50 PSIG and back to 0 PSIG while observing oxygen hose end in beaker.

No bubbles should be observed. Audible alarm sounds.

12. Dry and reattach oxygen inlet hose to regulator.

No response.

PROBLEM: Sensor will not calibrate. POTENTIAL CAUSES AND SOLUTIONS: • Sensor cell exhausted. Replace sensor. Refer to section 6, Replacing O2 sensor. • Sensor cable defective. Return to Maxtec. • Monitor defective. Contact Maxtec for repair. PROBLEM: Sensor will calibrate, but takes too long or does not return to 21% ±2% oxygen in air (2 to 5 minutes) when performing calibration. POTENTIAL CAUSES AND SOLUTIONS: • Disposable oxygen sensor damaged or defective. Replace sensor. Refer to section 6.2, Replacing O2 sensor. PROBLEM: Sensor will calibrate, but reading at any constant level drifts more than ±3% over a 24 hour period. POTENTIAL CAUSES AND SOLUTIONS: • Barometric pressure change since last calibration. Recalibrate. Refer to section 2.8, Calibration Procedures. • Room or gas temperature went below 59°F (15°C) or above 104°F (40°C). Correct temperature and recalibrate. PROBLEM: Low battery icon. POTENTIAL CAUSES AND SOLUTIONS: • If, at any time, the low battery icon is displayed on the LCD readout, the batteries should be replaced as quickly as possible. PROBLEM: E01: Sensor voltage is too low to perform a valid calibration. POTENTIAL CAUSES AND SOLUTIONS: • Manually attempt a new calibration. Refer to section 2.8, Calibration Procedures. • If unit repeats this error more than three times, contact Maxtec’s Customer Service Department for possible sensor replacement.

4.0 TROUBLESHOOTING PROBLEM: Oxygen concentration discrepancy between oxygen concentration selection knob and actual reading on display, greater than 3%. POTENTIAL CAUSES AND SOLUTIONS: • Bleed is turned off. Turn bleed toggle switch on. Refer to section 2.9, Flowmeter Operation. • Monitor out of calibration. Calibrate. Refer to section 2.8, Calibration Procedure. • Sensor exhausted. Replace sensor. Refer to section 6.2. • Gas supply contaminated. Contact Maxtec for repair of the MaxBlend 2. • Blender out of calibration. Contact Maxtec for repair.

PROBLEM: E02: No sensor attached. POTENTIAL CAUSES AND SOLUTIONS: • Disconnect the sensor and reconnect, making sure the male plug is fully inserted into the receptacle. The analyzer should now perform a new calibration with the error cleared. • If the error still persists, remove the batteries, wait 30 seconds, then reinstall, to perform a factory reset and diagnostic on the analyzer. The analyzer should again perform a new calibration with the error cleared. • Contact Maxtec Customer Service Department if the error code cannot be cleared.

PROBLEM: Pressure differential alarm sounding. POTENTIAL CAUSES AND SOLUTIONS: • Inlet pressure differences of 20 PSI or more. Correct pressure difference. • Pressure alarm not calibrated properly. Contact Maxtec for repair. • MaxBlend 2 blender operation out of calibration. Contact Maxtec for repair.

PROBLEM: E03: No valid calibration data available. POTENTIAL CAUSES AND SOLUTIONS: • Make sure unit has reached thermal equilibrium and perform a calibration routine. Refer to section 2.8, Calibration Procedures.

PROBLEM: Inlet pressure has supply loss, no audible pressure differential alarm. POTENTIAL CAUSES AND SOLUTIONS: • Reed alarm cap damaged or defective. Contact Maxtec for repair.

ENGLISH

PROBLEM: E04: Battery below minimum operating voltage. POTENTIAL CAUSES AND SOLUTIONS: 10

WWW.MAXTEC.COM • (800) 748-5355

• Replace batteries. A medium priority alarm will sound every 25 seconds until the

batteries are replaced or become too dead to sound the alarm. Refer to section 2.1.1, Battery Installation. PROBLEM: E05: Sensor voltage is too high to perform a valid calibration. POTENTIAL CAUSES AND SOLUTIONS: • Manually attempt a new calibration. Refer to section 2.8, Calibration Procedures. • If unit repeats this error more than three times, contact Maxtec’s Customer Service Department for possible sensor replacement. PROBLEM: E06: Non-compatible oxygen sensor. POTENTIAL CAUSES AND SOLUTIONS: • Disconnect the sensor and reconnect, making sure the male plug is fully inserted into the receptacle. The analyzer should now perform a new calibration with the error cleared. • If the error still persists, remove the batteries, wait 30 seconds, then reinstall, to perform a factory reset and diagnostic on the analyzer. The analyzer should again perform a new calibration with the error cleared. • Contact Maxtec Customer Service Department if the error code cannot be cleared.

DO NOT spray cleaning solution directly onto the sensor port, bleed muffler or buzzer openings. Be sure to thoroughly clean and disinfect the areas depicted in the images below. These regions are contacted during normal use and may contribute to cross-contamination if not disinfected properly. CAUTION: Excessive rubbing of labels may cause them to become illegible.

PROBLEM: E07: Sensor signal is not stable enough to perform a valid calibration. POTENTIAL CAUSES AND SOLUTIONS: • Wait for displayed oxygen reading to stabilize when calibrating the device at 100% oxygen. • Wait for unit to reach thermal equilibrium. Please note that this can take up to one half hour, if the device is stored in temperatures outside the specified operating temperature range.

DO NOT immerse the device or sensor into liquid decontamination agents. DO NOT use strong solvent cleaners. DO NOT allow cleaning liquids to contact the face of the sensor as this may impair the readings of the sensor. DO NOT Attempt to sterilize the device with steam, ethylene oxide or irradiation.

6.0 SERVICE AND MAINTENANCE

PROBLEM: E08: Battery voltage is too low to perform a valid calibration. POTENTIAL CAUSES AND SOLUTIONS: • Replace batteries. Refer to section 2.1.1, Battery Installation.

6.1 Maintenance

Maxtec recommends that the Performance Check listed in section 3.0 is performed at least once a year.

NOTE: Use only the Maxtec-approved Max-550E sensor described in section 10.0, Spare Parts and Accessories. The Max550E sensor is equipped with an authentication chip to ensure the monitor is used with an approved sensor. NOTE: The operator must be facing the device and positioned within 4 meters to distinguish the visual alarm indicators. Audible alarms can be distinguished as long as the operator is in the same room, and the ambient noise level is typical for a clinical setting.

When using the MaxBlend 2 with a medical-grade compressed air source, it is recommended that an air inlet watertrap/filter be attached to the air inlet of the MaxBlend 2 prior to use. Contaminants from hospital air lines may compromise the function of the MaxBlend 2. Maxtec recommends that the MaxBlend 2 be overhauled and serviced at a minimum of every three years. Repair of this equipment must be performed by a Maxtec Certified Service Technician experienced in the repair of this device.

5.0 CLEANING AND DISINFECTING

The external surfaces of the device, and its accessories, can be cleaned and disinfected using the process detailed below. Under normal use conditions, the sensing surfaces of the sensor should not become contaminated. If you suspect that the sensing face of the sensor or internal surfaces of the flow diverter have become contaminated, these items should be discarded and replaced. Store the device in a clean, dry location when not in use.

6.2 Replacing O2 Sensor

The oxygen sensor is designed to operate for two years under normal use conditions. The oxygen sensor should be replaced whenever any of the problems listed in section 4.0, Troubleshooting dictate the need to do so.

To clean and disinfect: 1. Ensure battery drawer is closed and sensor/diverter are inserted into their port. 2. Using disposable Super Sani-Cloth germicidal wipes (medical-grade 2-in-1 cleaning/ disinfecting wipes), remove all visible contamination from the external surfaces of the device and its accessories. Be sure to closely inspect and remove contamination from seams and recesses on the device that may trap contaminants. Wipe with clean paper towel to remove debris and bioburden. 3. After all visible contamination is removed, use a second germicidal wipe to thoroughly wet the surfaces of the device and accessories. Allow to remain wet for 4 minutes. Use additional wipes, if needed, to assure surfaces are wetted continuously for 4 minutes. 4. Allow device to air dry completely. 5. Visually inspect the device for visible contamination. Repeat cleaning/disinfection process if visible soil remains. DO NOT allow the liquid or spray to penetrate the device.

WWW.MAXTEC.COM • (800) 748-5355

To replace the O2 sensor: 1. Remove the sensor from the sensor monitor port. 2. Remove the sensor from the sensor cable. 3. Install a new O2 sensor with flow diverter and attach to the sensor cable. 4. Calibrate the sensor following the instructions for calibration listed in section 2.8.

6.3 Monitor Alarm Testing

• Testing of alarms should be performed on a yearly basis. • To check the low alarm, adjust the low alarm setting to 23%, or higher, and expose the

sensor to room air (20.9%). The low alarm LED should flash with the alarm sound. • To check the high alarm, adjust the low alarm setting to 17%, or lower, and the high

alarm setting to 18% and expose the sensor to room air (20.9%). The high alarm LED should flash with the alarm sound. If one, or both alarms malfunction, contact a Maxtec Certified Service Technician.

11

ENGLISH

7.0 ABBREVIATION GUIDE TERM

DESCRIPTION

Air/O2

Mixture of compressed air and oxygen

°C

Degrees Celsius

CGA

Compressed Gas Association

DISS

Diameter Indexed Safety System

°F

Degrees Fahrenheit

FiO2

Fractional Concentration of Inspired Oxygen

O2

Oxygen

LPM

Liters Per Minute

PSIG

Pounds Per Square Inch Gauge

8.3 O2 Sensor Specifications

Total accuracy*... ±3% actual oxygen level over full operating temperature range Oxygen Measurement Accuracy... ±1% oxygen Linearity... ± 1% at constant temperature and pressure Error Over Operating Temp Range... ±3% oxygen, maximum Response Time to 90% of Final Reading*... @ 77°F (25°C) ≤20 seconds Storage Temperature Range... 5°F to 122°F (-15°C to 50°C) Expected Useful Life...1,500,000 O2% hours (approx. 2 years average use) *The accuracy of the oxygen monitor is not affected by supply gas inlet pressure to the blender, however, pressures below 50 PSIG may result in a longer response time. NOTE: All specifications assume the following standard environmental conditions, unless specified otherwise: • Ambient and sample gas temperatures of 77°F (25°C) • Barometric pressure of 30 inHg (102 kPa) • Ambient relative humidity of 50% • Sample gas relative humidity of 0%

8.0 SPECIFICATIONS

9.0 FACTORS INFLUENCING CALIBRATION

8.1 Instrument Specifications

Weight (unpackaged)... 5.3 lbs. (2.4 kg.) Power Source...Four “AA” alkaline batteries, 1.5 V each Battery Life...5000 hours (continuous operation, no alarming) Oxygen Measurement Range...0% to 100% oxygen Display Resolution...0.1% oxygen O2 Concentration Adjustment Range... 21% to 100% O2 Gas Supply Pressure...The gas supplies must provide clean, dry, medical-grade air and oxygen at a pressure of 30 to 75 PSIG (2.0 to 5.2 BAR). Air and oxygen must be within 20 PSI (1.3 BAR). Optimal performance is achieved at 50 PSIG inlet pressures. Pressure Drop...Less than 6 PSIG (0.4 BAR) @ 50 PSIG (3.4 BAR) supply pressures and 10 LPM flow rate Sensor Bleed Flow... 0.1LPM @ 50 PSIG (3.4 BAR) Bleed Flow (toggle ON)...3 LPM for low flow blender and 13 LPM for high flow blender Outlet Flow Range... 0-30 LPM for low flow blender and 2-100 LPM for high flow blender with inlet pressures at 50 PSIG (3.4 BAR) Mixed Gas Stability* Ambient Operating Conditions... ±1% oxygen Operating Temperature Range...59°F to 104°F (15°C to 40°C) Relative Humidity Range...0-95%, non-condensing Ambient Storage Conditions Temperature Range... 5°F to 122°F (-15°C to 50°C) Flowmeter accuracy**... +/-10% of indicated value or 0.5 LPM whichever is greater, with inlet pressure set to 50PSIG. Flush Flow... 3 LPM Flowmeter: 20-30 LPM 15 LPM Flowmeter: 20-30 LPM 30 LPM Flowmeter: 35-45 LPM 70 LPM Flowmeter: 70-80 LPM *The delivered oxygen concentration will remain constant within ±1% of the set point value with constant inlet pressures. The displayed value may vary more than this due to sensor accuracy, age, environmental conditions, and the length of time since last sensor calibration.

9.1 Temperature Effect

The MaxBlend 2 Monitor will hold calibration and read correctly within +/-3% when in thermal equilibrium within the operating temperature range. The device accuracy will be better than +/-3% if operated at the same temperature at which it was calibrated. The device must be thermally stable when calibrated and allowed to thermally stabilize after experiencing temperature changes before reading is accurate. For these reasons, the following is recommended: 1. Allow adequate time for the sensor to equilibrate to a new ambient temperature. Please note that this can take up to one half hour, if the device is stored in temperatures outside the specified operating temperature range. 2. For best results, perform the calibration procedure at a temperature close to the temperature where analysis will occur.

9.2 Pressure Effect

Changes in barometric pressure can affect the oxygen reading. A 1% change in the barometric pressure results in an error of 1% of actual reading (Example: If you are reading a 50% oxygen mix and the barometric pressure drops from 30kPa to 29kPa, the reading will drop to: 50% x (29/30) = 48.3%. Maxtec recommends that you recalibrate after changing point-of-use elevation by more than 500 feet (150m).

9.3 Humidity Effect

Humidity in the sample gas will affect the oxygen reading. Maxtec recommends that the gas delivered to the MaxBlend 2 be medical-grade, clean, and dry. Refer to ISO 7396-1 for further details.

**Position the device such that the flowmeters are vertical to ensure accuracy.

8.2 Alarm Specifications

Pressure Differential Alarm Activation...When supply pressures differ by 20 PSI (1.3 BAR) or more alarm is activated Low Oxygen Alarm Range...15%-99% (>1% lower than high alarm) High Oxygen Alarm Range... 16%-100% (>1% higher than low alarm) (according to IEC 60601-1-8 Audible Alarms in Medical Equipment)

ENGLISH

12

WWW.MAXTEC.COM • (800) 748-5355

11.0 THEORY OF OPERATION

9.4 Exposure to Anesthetic Gases

Because of the unique chemistry of the oxygen sensors provided with the MaxBlend 2, there are no significant effects when exposed to commonly used anesthetic gases; however, the monitor is not designed for exposure to flammable gas mixtures (See WARNING page 2). INTERFERENT

VOLUME % DRY

INTERFERENCE IN O2%

Nitrous Oxide

60%, balance O2

<1.5%

Halothane

4%

<1.5%

Enflurane

5%

<1.5%

Isoflurane

5%

<1.5%

Helium

50%, balance O2

<1.5%

Sevoflurane

5%

<1.5%

Desflurane

15%

<1.5%

11.1 Operational Diagram 1st Stage Balance Module

2nd Stage Balance Module

Proportioning Valve Alarm/Bypass

O2

NOTE: Balance mixture 30% O2/70%N2O, unless otherwise specified.

Mixed Gas Outlet to Flowmeter Sensor Bleed Manifold

10.0 SPARE PARTS AND ACCESSORIES DESCRIPTION

PART NUMBER

MAX550E Oxygen Sensor

R140P02-001

Oxygen Inlet

R228P49

Rail Mount Bracket

R100P09

Adjustable Pole Mount Bracket

R100P22

Pole Mount Bracket

R100P26

Compact Wall Mount

RP05P07

Maxtec-Approved Power Supply

R230P10

Wall Mount Large Bracket

RP05P09

10’ Dual Blender hose (DISS)

R129P01

Air Inlet

Mixed Gas Outlet

11.2 Mixing Operation

The MaxBlend 2 is designed to utilize two 50 PSIG (3.4 BAR) gas sources. The two gas sources enter through the air and oxygen inlet connectors located on the bottom of the MaxBlend 2. Each inlet connector incorporates a 30 micron particulate filter. Once through the filters, each gas passes through a duckbill check valve, which prevents possible reverse gas flow from either the air or the oxygen supply systems.

ACCESSORIES DESCRIPTION Monitor Cable

Audible Alarm

The two gases then pass through a two-stage balance regulator. The purpose of this regulator is to equalize the operating pressures of the air and oxygen gas sources. Once these pressures have been balanced, the gases are proportioned according to the oxygen concentration selected on the oxygen concentration selection knob. The oxygen concentration knob allows the clinician to select a desired oxygen concentration from 21% to 100% O2. From this point, the mixed gas flows to the outlet port.

11.3 Gas Outlet

There are three gas outlets on the MaxBlend 2. One is a fixed acrylic flowmeter, the other two are auxiliary ports (one on the bottom of the unit, and one on the right side). These outlets are capable of delivering combined metered flows of 0-30 LPM for the low flow model and 0-120 LPM for the high flow model. The auxiliary outlet ports are fitted with an automatic shut-off valve. The flow of gas from either outlet port is automatically initiated by attaching a pneumatic device (such as a flowmeter) to the outlet port.

Repair of this equipment must be performed by a Maxtec Certified Service Technician, experienced in the repair of this device. Equipment in need of repair shall be sent to: Maxtec Service Department 2305 South 1070 West Salt Lake City, Ut 84119 1.800.748.5355 (Include RMA number issued by Customer Service)

Regardless of whether or not the outlet has any device connected to it, a minimal gas bleed flow of 0.1 LPM flows from the MaxBlend 2 sensor port on the left side of the blender. It is from this bleed flow that the gas is analyzed by the oxygen sensor. In addition, a toggle switch is provided allowing the user to activate an additional gas bleed, which ensures the blender has sufficient flow to function accurately when the total flow delivered to the patient is below a certain minimum threshold. For a low flow model, this additional bleed should be activated if the total flow delivered to the patient is less than 3 LPM. For a high flow model, the additional bleed should be activated if the total flow delivered to the patient is less than 15 LPM. At delivered flows greater than these limits, the bleed toggle can be deactivated to conserve oxygen. CAUTION: Failure to activate the bleed as described above may result in significant drift in the oxygen concentration delivered to the patient.

WWW.MAXTEC.COM • (800) 748-5355

13

ENGLISH

13.0 ELECTROMAGNETIC COMPATABILITY

11.4 Alarm/Bypass Function

The MaxBlend 2 includes a pressure differential alarm which provides an audible alarm if gas source pressures differ by 20 PSI (1.3 BAR) (nominal) or more, or if there is a gas supply failure of one of the source gases. This alarm is generated by a reed alarm located in a cap on the bottom of the MaxBlend 2.

The information contained in this section (such as separation distances) is in general specifically written with regard to the MaxBlend 2. The numbers provided will not guarantee faultless operation but should provide reasonable assurance of such. This information may not be applicable to other medical electrical equipment; older equipment may be particularly susceptible to interference.

The primary purpose of the alarm is to audibly warn the operator of an excessive pressure drop or depletion of either source gas pressure. Should both gas pressures increase or decrease simultaneously, an alarm will not activate.

NOTE: Medical electrical equipment requires special precautions regarding electromagnetic compatibility (EMC) and needs to be installed and put into service according to the EMC information provided in this document and the remainder of the instructions for use this device.

If either source gas pressure drops, the outlet pressure will drop similarly, as the mixed gas is always balanced to that of the lower gas source. The gas bypass function operates in unison with the alarm. Once the pressure alarm is activated, the bypass function is actuated and the gas with the higher pressure flows directly to the outlet port, bypassing the mixing function of the MaxBlend 2. The oxygen concentration flowing out of the MaxBlend 2 will be that of the gas with the higher pressure. In the alarm/ bypass mode, the blender will deliver oxygen (100%) or medical air (21%) until pressures have been restored to a differential of 6 PSI or less (0.4 BAR).

Portable and mobile RF communications equipment can affect medical electrical equipment. Cables and accessories not specified within the instructions for use are not authorized. Using other cables and/or accessories may adversely impact safety, performance and electromagnetic compatibility (increased emission and decreased immunity). Care should be taken if the equipment is used adjacent to or stacked with other equipment; if adjacent or stacked use is inevitable, the equipment should be observed to verify normal operation in the configuration in which it will be used.

If the MaxBlend 2 is set to deliver 21% and the OXYGEN source pressure is reduced enough to produce a 20 PSI (1.3 BAR) differential, the unit may not alarm because it will continue to deliver 21% concentration according to the setting. If the setting is moved slightly from 21%, the pressure differential alarm will sound. Similarly, if the MaxBlend 2 is set to deliver 100% and the AIR source pressure is reduced or lost, the unit may not alarm because it will continue to deliver 100% concentration.

ELECTROMAGNETIC EMISSIONS This equipment is intended for use in the electromagnetic environment specified below. The user of this equipment should assure that it is used in such an environment. EMISSIONS

12.0 FLOW CHARACTERISTICS

COMPLIANCE ELECTROMAGNETIC ENVIRONMENT ACCORDING TO

The outlet pressure of the MaxBlend 2 decreases as the total flow rate increases. The total flow rate is the measurement of the total flow from all outlet ports. The charts below indicate the pressure drop that occurs for both low flow, and high flow, models at 3 inlet pressure settings; 30 PSIG (2.07 BAR), 50 PSIG (3.45 BAR), and 75 PSIG (5.17 BAR).

RF Emissions (CISPR 11)

Group 1

The MaxBlend 2 uses RF energy only for its internal function. Therefore, its RF emissions are very low and are not likely to cause any interference in nearby electronic equipment.

The fixed acrylic flowmeter on the left side of the MaxBlend 2 has been pressure compensated to accommodate for the pressure loss through the blender at each flow rate, using an inlet pressure of 50 PSIG.

CISPR Emissions Classification

Class A

Harmonic Emissions (IEC 61000-3-2)

Class A

The MaxBlend 2 is suitable for use in all establishments other than domestic and those directly connected to the public lowvoltage power supply network that supplies buildings used for domestic purposes. NOTE: The EMISSIONS characteristics of this equipment make it suitable for use in industrial areas and hospitals (CISPR 11 class A). If it is used in a residential environment (for which CISPR 11 class B is normally required) this equipment might not offer adequate protection to radiofrequency communication services. The user might need to take mitigation measures, such as relocating or re-orienting the equipment.

Flow Rate -vs- Pressure Drop:

Pressure drop (PSIG)

Voltage Fluctuations Complies

For High Flow Blender

25

50 psig

20

30 psig

15

75 psig

10 5 0

0

20

40

60

80

100

120

Flow Rate (LPM)

For Low Flow Blender

Pressure drop (PSIG)

25

30 psig

20 15

50 psig

10

75 psig

5 0

0

5

10

15

20

25

30

35

Flow Rate (LPM)

ENGLISH

14

WWW.MAXTEC.COM • (800) 748-5355

ELECTROMAGNETIC IMMUNITY

This equipment is intended for use in the electromagnetic environment specified below. The customer or the user of this equipment should assure that it is used in such an environment.

This equipment is intended for use in the electromagnetic environment specified below. The user of this equipment should assure that it is used in such an environment. IMMUNITY AGAINST

IEC 60601-1-2: (4TH EDITION) TEST LEVEL

IMMUNITY IEC 60601-1-2: 2014 (4TH TEST EDITION) TEST LEVEL

ELECTROMAGNETIC ENVIRONMENT

Professional Healthcare Facility Environment

Professional Home Healthcare Facility Healthcare Environment Environment Electrostatic Contact discharge: ±8 kV discharge, ESD Air discharge: ±2 kV, ±4 (IEC 61000-4-2) kV, ±8 kV, ±15 kV Electrical fast transients / bursts (IEC 61000-4-4)

Power supply lines: ±2 kV Longer input / output lines: ±1 kV

Surges on AC Common mode: ±2 kV mains lines Diferential mode: ±1 kV (IEC 61000-4-5) 3 A/m power frequency magnetic field 50/60 Hz (IEC 61000-4-8)

30 A/m 50 Hz or 60 Hz

Voltage dips and short interruptions on AC mains input lines (IEC 61000-4-11)

Dip>95%, 0.5 periods Dip 60%, 5 periods Dip 30%, 25 periods Dip >95%, 5 seconds

Floors should be wood, concrete, or ceramic tile. If floors are covered with synthetic material, the relative humidity should be kept at levels to reduce electrostatic charge to suitable levels. Mains power quality should be that of a typical commercial or hospital environment. Equipment which emits high levels of power line magnetic fields (in excess of 30A/m) should be kept at a distance to reduce the likelihood of interference. If user requires continued operation during power mains interruptions, ensure that batteries are installed and charged. Ensure that battery life exceeds longest anticipated power outages or provide an additional uninterruptible power source.

Conducted 3V (0.15 - 80 MHz) RF coupled 6V (ISM bands) into lines (IEC 61000-4-6)

3V (0.15 - 80 MHz) 6V (ISM & Amateur bands)

Radiated RF immunity (IEC 61000-4-3)

3 V/m

10 V/m

80 MHz - 2.7 GHz 80% @ 1 KHz AM Modulation

80 MHz - 2.7 GHz 80% @ 1 KHz AM Modulation

Portable and mobile RF communications equipment (including cables) should be used no closer to any part of the equipment than the recommended separation distance calculated from the equation applicable to the frequency of the transmitter as below. Recommended sparation distance: d=1.2 √P d=1.2 √P 80 MHz to 800 MHz d=2.3 √P 800 MHz to 2.7 GHz

Field strengths from fixed RF transmitters, as determined by an electromagnetic site survey a, should be less than the compliance level in each frequency range b. Interference may occur in the vicinity of equipment marked with the following symbol:

Separation distance according to frequency of transmitters in meters

W

150 kHz to 80 MHz d=1.2/V1] √P

80 MHz to 800 MHz d=1.2/V1] √P

800MHz to 2.5 GHz d=2.3 √P

0.01

0.12

0.12

0.23

0.1

0.38

0.38

0.73

1

1.2

1.2

2.3

10

3.8

3.8

7.3

100

12

12

23

The ISM (industrial, scientific and medical) bands between 150 kHz and 80 MHz are 6,765 MHz to 6,795 MHz; 13,553 MHz to 13,567 MHz; 26,957 MHz to 27,283 MHz; and 40,66 MHz to 40,70 MHz. Field strengths from fixed transmitters, such as base stations for radio (cellular/cordless) telephones and land mobile radios, amateur radio, AM and FM radio broadcast and TV broadcast cannot be predicted theoretically with accuracy. To assess the electromagnetic environment due to fixed RF transmitters, an electromagnetic site survey should be considered. If the measured field strength in the location in which the equipment is used exceeds the applicable RF compliance level above, the equipment should be observed to verify normal operation. If abnormal performance is observed, additional measures may be necessary, such as reorienting or relocating the equipment.

For transmitters rated at a maximum output power not listed above, the recommended separation distance d in meters (m) can be estimated using the equation applicable to the frequency of the transmitter, where P is the maximum output power rating of the transmitter in watts (W) according to the transmitter manufacturer. NOTE 1: At 80 MHz and 800 MHz, the separation distance for the higher frequency range applies. NOTE 2: These guidelines may not apply in all situations. Electromagnetic propogation is affected by absorption and reflection from structures, objects, and people.

WWW.MAXTEC.COM • (800) 748-5355

Home Healthcare Environment

Where P is the maximum output power rating of the transmitter in watts (W) according to the transmitter manufacturer and d is the recommended separation distance in metres (m).

Recommended separation distances between portable and mobile RF communications equipment and the equipment RATED MAXIMUM OUTPUT POWER OF TRANSMITTER

ELECTROMAGNETIC ENVIRONMENT - GUIDANCE

15

ENGLISH