Instructions for Use

6 Pages

Preview

Page 1

Page 1/6

Instructions for use for vacuum cleander Ref. OSC 206-V00 and OSC 206-V90 with automatic start/stop and adjustable function power 1

Technical description and instructions of use

1.1

Technical description

This equipment collect the plaster dust created by the OSCIMED cast cutter saw. The vacuum cleaner consists of a tank in stainless steel with four rolling wheels and a removable head with the motor at the bottom. In the tank, there are three stages of filtering, the paper bag, the polyester filter and the HEPA filter. The head is equipped with a socket for the saw and a switch to turn on. This power output is only for OSCIMED Cast Cutter saw use. 1.2

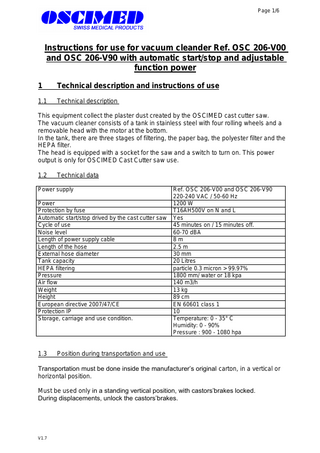

Technical data

Power supply Power Protection by fuse Automatic start/stop drived by the cast cutter saw Cycle of use Noise level Length of power supply cable Length of the hose External hose diameter Tank capacity HEPA filtering Pressure Air flow Weight Height European directive 2007/47/CE Protection IP Storage, carriage and use condition.

1.3

Ref. OSC 206-V00 and OSC 206-V90 220-240 VAC / 50-60 Hz 1200 W T16AH500V on N and L Yes 45 minutes on / 15 minutes off. 60-70 dBA 8m 2.5 m 30 mm 20 Litres particle 0.3 micron > 99.97% 1800 mm/ water or 18 kpa 140 m3/h 13 kg 89 cm EN 60601 class 1 10 Temperature: 0 - 35° C Humidity: 0 - 90% Pressure : 900 - 1080 hpa

Position during transportation and use

Transportation must be done inside the manufacturer’s original carton, in a vertical or horizontal position. Must be used only in a standing vertical position, with castors’brakes locked. During displacements, unlock the castors’brakes.

V1.7

Page 2/6

2

Assembling

2.1

Frame assembly

- Put the upper steel frame (4) into the tube of the lower frame (5) and screw the button (6).

- Fix the basket (7) on the upper part (4) with the button (8).

- Lay the saw and his power adapter into the basket (7)

2.2

4

8 7

6 5

Insertion of the hose on the tank

- Insert the hose inside the tank.

2.3

Vacuum hose insertion

OSCIMED PSV cast cutter saw: Place the screws of the hose coupling/connection in a vertical position, as shown on the photo, and insert on the end-piece/housing saw.

V1.7

Turn a quarter in order to get the screws „horizontal“ and lock the connecting part.

Page 3/6

OSCIMED 2000 and Ergo cast cutter saws: 10

- Insert the vacuum nozzle (9) on the saw vertically and fix it with the screw (10).

9

- Insert the black link (11) vertically on the vacuum nozzle (9). Fix with the screw (12).

11

9 12

2.4

Assembly of the hose and the power cord

Fasten the power cord (13) and the hose (14) with the Velcro straps (15).

15 13

15

14 25 cm

V1.7

Page 4/6

3

Use – safety - Maintenance

3.1

Instructions of use

After assembly (see chapter 2), connect the plug of the vacuum cleaner into the wall socket of your electrical supply. The wall socket must have a protective earth. Connect the plug of the cast cutter saw into the socket (1) of the vacuum cleaner. If the switch (2) is on position I, the vacuum will start automatically. If the switch of the vacuum cleaner is on position II, when the operator start the cast cutter saw, the vacuum cleaner automatically starts. It will automatically stop with a delay of some seconds after the stop of the saw. This delay is longer if the aspiration power is weak. The power can be driven by turning the potentiometer (3). 3

2

3.2

1

Fields of use, contra-indications

In a general way, every use outside of the frame of cutting cast in combination with a cast cutter saw is neither advised nor authorised. The vacuum cleaner must not be used alone for traditional room cleaning purposes. 3.3

Protection against electric shocks, norms, labelling

Meaning of the symbols: Read the documentation,

At the end of life of the device, please contact the relevant local authorities or your distributor concerning the disposing of sorted waste.

Product in compliance with european directives and standards.

Alternative current.

Serial number.

Reference number.

V1.7

Page 5/6

3.4

Cleaning

Unplug the power supply before any maintenance or cleaning operation. Check that no electric cable is damaged, and the airflow of the aspiration is not blocked by an accumulation of cast cutting wastes in the hose. Please make sure that it is cleane by wiping it with a damp cloth on surface. Do not immerse the device into the water or every other liquid, Do not immerse or shower the device. Photo 3

3.5 Frequency for changing the filters: (for information only) Filter Hepa ref. OSC 208-3 (9) on the motor:

5 years

Filter Hepa ref. OSC 208-2 (10) under the motor:

1 year

Filter Polyester ref. OSC 208-1 (11) in the tank:

6 months

Paper dust bag (12) ref. OSC 207:

2 weeks.

3.6

Changing the paper dust bag

- Open the two fixations, lift up the vacuum head, take of the polyester filter (11) then remove the paper bag. - Clean the filter if necessary and set the new paper bag. - Put the filter and the head on and close the vacuum cleaner.

V1.7

Page 6/6

4

Instructions to be strictly observed

- The device can be used only by an operator competent in plaster room who has attentively read this present instruction. - Every modification of the device in comparison with its original version is strictly forbidden. - The vacuum cleaner has to be connected to a grounded cable. - Be careful not to pick up too big dusts which could obstruct the hose and damage the vacuum cleaner. - This unit is for dry use only and must be stored in a dry room. - The use of this machine for anything else not specified in this manual may be dangerous and must be avoided. - The suction nozzle should be kept away from the body, especially from delicate areas such as the eyes, ears and mouth. - The equipment should be correctly assembled before use. - Ensure that power socket used is correct for the machine. - Check the voltage indicated on the rating plate is the same as the supply voltage. - These machines are not designed for picking up any health endangering dust or inflammable explosive substances. - Never use this equipment to pick up any kind of liquid. - Never leave the equipment unattended whilst in use. - Never carry out any maintenance on the machine without first disconnecting from the main supply, if the machine is to be left unattended the supply must also be terminated. - Never let the device unattended with children or with people irresponsible from their doings. - The main supply cable should not be used to pull or lift the machine. - The machine should never be immersed in water or a jet water used for cleaning. - Periodically examine the mains cables and machine for damage. If any damage is found, contact your service centre for repair. - Should extension cables be used, ensure that the cable rating is suitable for use with the equipment, and that those extension are on dry places, protected from any water. - Do not use the cable coiled as this could result in voltage drop or overheating. Keep dry at all times. - Service and repairs must be carried out by qualified personnel only. Replacement parts for the machine must be manufacturer original spare parts only. - The manufacturer cannot be held responsible for any damage/injury caused to persons or property, because of the incorrect use of the machine due to procedures being used which are not specified in this manual. - In case of breakdown or automatic stop from the device because of overheat, unplug the device and keep an eye on it till it is cold again. Do not let it unattended and connected !

Manufacturer’s address: OSCIMED SA - Allée du Quartz 3 - CH-2300 La Chaux-de-Fonds

V1.7