Instructions For Use

4 Pages

Preview

Page 1

Page 1/4

Instructions of use for cast cutter saw OSCIMED PSV 1 Technical description 1.1

The electrical power supply

Supplied from a socket by a cable which passes through a transformer reducing voltage to 24 VDC, it is optimal for the security. The device complied with the latest version of medical standards EN 60601. 1.2 The electro-mechanical drive The oscillating movement of the blade is made by a DC motor and a mechanical device, which is made from high quality materials, with low wear and without maintenance. The motor and the high lifespan sensor switch are driven by a microprocessor card. The electromechanical device is mount trough anti-noise rubbers on the body of the cutter to avoid vibrations in the hand and noise. The switch, situated closed to the user’s hand, is a contactless long life time sensor. 1.3

The cutting blades

The blades have a synthetic coupling center. A special lock nut makes it easy to install or change the blade without any tool. 1.4

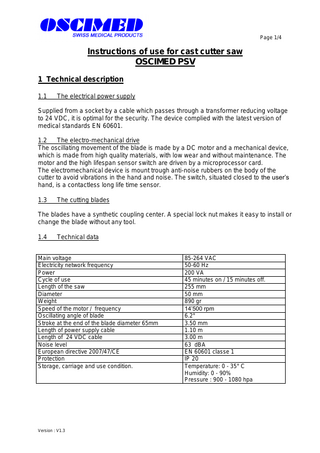

Technical data

Main voltage Electricity network frequency Power Cycle of use Length of the saw Diameter Weight Speed of the motor / frequency Oscillating angle of blade Stroke at the end of the blade diameter 65mm Length of power supply cable Length of 24 VDC cable Noise level European directive 2007/47/CE Protection Storage, carriage and use condition.

Version : V1.3

85-264 VAC 50-60 Hz 200 VA 45 minutes on / 15 minutes off. 255 mm 50 mm 890 gr 14’500 rpm 6.2° 3.50 mm 1.10 m 3.00 m 63 dBA EN 60601 classe 1 IP 20 Temperature: 0 - 35° C Humidity: 0 - 90% Pressure : 900 - 1080 hpa

Page 2/4

2 Use - Safety – Maintenance 2.1

Start and stop

Plug into electric socket. Press the red sensor switch to start the saw; press a second time to stop it.

2.2

Vacuum nozzle change

First disconnect the power supply. Then remove the vacuum nozzle to reach the blade, by pushing the supple parts on both sides in order to release the nozzle and slide it up.

Set the nozzle back by inserting it in the guide and push down to the bottom till the automatic lock. 2.3

Saw blade change

First disconnect the power supply. Remove the vacuum nozzle to reach the blade. Turn the blue blade lock nut (1) a quarterturn and pull it out. To remove the blade, incline it a little and pull out. Set the new blade (2) on notched spindle, return the lock nut and turn back a quarterturn on its internal locking notch (1).

Version : V1.3

Page 3/4

2.4

Vacuum hose insertion

Place the screws of the hose coupling/connection in a vertical position, as shown on the photo, and insert on the end-piece/housing saw.

Turn a quarter in order to get the screws „horizontal“ and lock the connecting part.

Proceed the opposite way to remove the hose. 2.5

Field of use

In a general way, every use other than cutting bandages and casts is forbidden. In the medical field, this saw is not authorized for use where the saw blade could be in direct contact with the patient or for surgery. 2.6

Protection against mechanical overload

To avoid overloads in case of fall and for the patient security, the saw stops automatically in case of brutal overload on the saw blade. In this case, disconnect the power supply, wait 2 minutes and reconnect the device to restart the saw. 2.7

Electric shocks protection, standards, labelling

Meaning of the symbols:

Read the documentation.

At the end of life of the device, please contact the relevant local authorities or your distributor concerning the disposing of sorted waste.

Product in compliance with european directives and standards.

Alternative current.

Serial number.

Reference number.

Class II device with Version : V1.3

Page 4/4

double electrical insulation, without protective earth. Remark concerning the immunity to the electro-static discharges: Trials according to the EN 61000-4-2 norm have shown a non-destructive and very short lasting stop of the saw in case of a more than 4000 volts electric shock. 2.8

Maintenance - Cleaning

Disconnect the power supply before any maintenance or cleaning operation. Check that no electric cable is damaged, that the oscillating shaft and the switch are not blocked in their movements by an accumulation of sawing wastes. The only maintenance this saw needs is that it has to be kept clean. Wipe clean with a damp rag. Do neither immerse the saw in water nor every other liquid, nor clean it with a shower.

3

Be sure to observe scrupulously the safety instructions

- The device can be used only by an operator competent in plaster room who has attentively read this present instruction. - Every modification of the device in comparison with its original version is strictly forbidden. - The duty cycle according to chapter 1.4 is only available when the saw is used together with the vacuum cleaner which is cooling the saw. - The device is designed only for a dry use and must be used or stored in a dry place only. - Every use other than the one indicated on the present manual may constitute a danger which can so be avoided. - Check that the socket in compliance with the plug of the device. - Check that the indicated voltage on the motor block is in compliance with the used power source. - Never let the device running unattended. - Always take the plug off before doing whichever intervention on the device, or when the device remains unattended or within reach of children or persons who are not responsible for their actions. - Do not pull neither lift the device when using the electric cable. - The maintenance and repairs must be provided by specialised persons; the possibly damaged parts will be replaced by original spare parts. - The manufacturer refuses to accept any responsibility in case of every third-party damage to people, animals or objects as a result of the lack of respect of these following instructions or if the device has been used on an unproper way.

Manufacturer’s address: OSCIMED SA - Allée du Quartz 3 - CH-2300 La Chaux-de-Fonds Version : V1.3