Medicraft Hill-Rom

Medicraft Elecrtic Tilt Bed Model FE 5000 User Manual

User Manual

19 Pages

Preview

Page 1

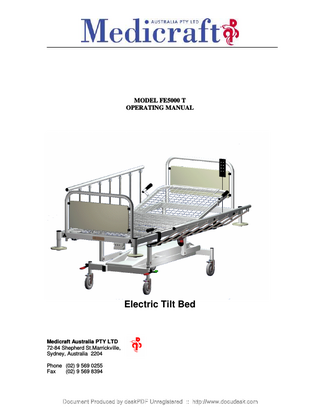

MODEL FE5000 T OPERATING MANUAL

Electric Tilt Bed

Medicraft Australia PTY LTD 72-84 Shepherd St.Marrickville, Sydney, Australia 2204 Phone (02) 9 569 0255 Fax (02) 9 569 8394

TABLE OF CONTENTS PAGE PAGE PAGE PAGE PAGE PAGE PAGE PAGE PAGE PAGE PAGE PAGE PAGE PAGE PAGE

3 4 5 6-7 8 9 10 11 12 13 14 15 / 16 17 18 19

-

UNPACKING & TESTING – STORAGE/TRANSPORT CONDITIONS GENERAL DESCRIPTION OF BED FUNCTIONS DEFINITION OF SYMBOLS MARKED ON THE BED ELECTROMAGNETIC INTERFERENCE CENTRAL LOCKING CASTORS HANDSET OPERATION ATTENDANT CONTROL OPERATION QUICK RELEASE BACKREST OPERATION KNEE BREAK OPERATION SAFETY SIDE RAILS HEIGHT RANGE AND BED POSITION ANGLES ELECTRICAL COMPONENT SPECIFICATIONS IP CODES AND WHAT THEY MEAN CLEANING AND DISINFECTION MAINTENANCE - POWER CABLE NOTICE

COPYRIGHT© MEDICRAFT AUSTRALIA ® 2004

2

UNPACKING & TESTING. 1 2 3 4 5 6 7

8 9 10 11 12 13 14 15

Remove all bubble wrap from bed. Remove protective foam pad from the end of the bed. Remove ties from safety side rails Remove ties from the backrest, thigh section and the foot section. Remove tie, which secures the upper mattress frame to the wheelbase. Plug the handset into the handset socket. The handset will be stored under the bed frame. Remove the plastic sheath from the handset cable and make sure that the handset is fully inserted into the socket. Remove bubble wrap from the Attendant Control Panel. The Attendant Control Panel will be located under the bed frame. Hook the Attendant Control Panel onto the foot end of the bed. Set all of the lockout switches on the Attendant Control Panel to the unlocked position (see page 6). Remove bubble wrap from the head & footboards. Insert the head & footboards into the sockets and tighten the tri wheel screws. Uncoil the power cable and plug into mains power. Ensure that the IEC quick release socket on the power cable is properly connected. Check that a green charging light on the control box is illuminated. Check operation of all functions with the mains power turned on. Check operation of all functions with the mains power turned off. (If fitted with battery backup). Check operation of all functions from the Attendant Control Panel. Check lockout functions on the Attendant Control panel. Note, The power button on the Attendant Control Panel must be pressed while operating functions from the ACP. See page 6. Check that the safety side rails lock into all positions. Clean the bed with a general-purpose spray.

STORAGE & TRANSPORT CONDITIONS Ambient temp. range: +10°C to +40°C Rel. humidity range: 30% to 75% Atmospheric Pressure range: 700 hPa to 1060 hPa Inspect all cables particularly the mains power cable for any damage; replace where necessary. Stow the mains power cable on the storage hooks and clip the handset to the head –board frame when transporting the bed. For ease of steering, set the castors to the steering position (see page:4) prior to transportation. When the bed needs to moved to either side, set the castors to the free position (see page:4). When bed has been positioned, set the castors to the fully locked position (see page:4). The bed must be placed on a level surface to ensure all castors make contact with the floor. Be sure to check for obstructions both above and below the bed frame and position the bed so that it can operate through the full height range without any chance of collision. Also check for obstructions through full Trendelenburg and Reverse Trendelenburg operations.

COPYRIGHT© MEDICRAFT AUSTRALIA ® 2004

3

GENERAL DESCRIPTION OF BED FUNCTIONS. The Medicraft ® FE 5000 T is an electrically operated hospital bed with 4 basic movement functions. Hi – Lo adjustment Backrest adjustment Knee break adjustment Trendelenburg adjustment An option to simultaneously operate the backrest and knee break is also available. Each of these functions can be accessed by either the handset or via the attendant control panel. The attendant control enables each or all functions to be locked out. The electrical components run from a standard 240-volt AC outlet, which is stepped down to 24 volts DC. The control box power cable is a three pin earthed cable which is earthed to the bed frame via the control box. Also the mains power cable has a quick release function, which allows the cable to separate should excessive strain be applied. HI LOW Operation A dual actuator system operates the Hi – Lo function. When raising the bed the actuators extend simultaneously. When lowering the bed the actuators retract simultaneously. Backrest Operation A single actuator extends to raise, and retracts to lower. This actuator is also fitted with a cable operated quick release system. This actuator is free wheeling which means that it cannot pull. If an obstruction is present the actuator will free wheel. Knee Break Operation A single actuator extends to raise, and retracts to lower. This actuator is fitted with internal limit switches to stop the piston at the fully extended and fully retracted positions. This actuator cannot pull. If an obstruction is present the actuator will free wheel. Trendelenburg Operation The same dual actuator system used for the Hi – Lo function also operates the trendelenburg system. When the bed is tilting, one actuator extends while the other retracts. These actuators are fitted with internal limit switches. These internal limit switches allow the bed to self- level at the extreme low position and at the extreme high position. The self-leveling function is designed so that the bed can be lowered while in full head end or foot end down positions without the risk of any collision between bed parts. A further four external limit switches are fitted to limit the amount of tilt in both directions. This is also to eliminate any collision of bed parts. Simultaneous Backrest / Knee Break Operation This option allows both the backrest and the knee break to be operated simultaneously by pressing one button. As the knee break actuator is 100mm stroke and the backrest actuator is 150mm stroke, the knee break will reach the end of stroke before the backrest. The knee break actuator is fitted with internal limit switches so that it will stop a the end of stroke and still allow the backrest actuator travel to the desired angle.

COPYRIGHT© MEDICRAFT AUSTRALIA ® 2004

4

EXPLANATION OF SYMBOLS

Applied Part Type “B” Can intentionally or unintentionally come into contact with the patient. Not suitable for Direct Cardiac Application.

POTENTIAL EQUALISATION TERMINAL A terminal for the connection of a potential equalization conductor.

SAFE WORKING LOAD

Symbol placed before value of safe working load.

COPYRIGHT© MEDICRAFT AUSTRALIA ® 2004

5

ELECTROMAGNETIC INTERFERENCE WHAT IS ELECTROMAGNETIC DISCHARGE (ESD) AND HOW IS IT GENERATED?

An electrostatic potential is achieved, when two non-conductive materials are exposed to friction between each other and one material gains electrons (static electricity) from the other material. A spark is released when two parts with different electrostatic potential approach each other. The combination of synthetic fabrics and a dry atmosphere especially favour the generation of electrostatic charge. Walking on carpet, where each step looses or gains electrons from the person’s body to the carpet fabric, causes that person to be charged to a certain level of static electricity with respect to ground. Equipment using castors (such as a bed) that is rolling on a vinyl floor can easily become charged with static electricity, as a result of the friction between the castors and the floor. When a static charge generated on a bed or other equipment is discharged, an electromagnetic field is produced which can damage the electronic components. Experience has shown that these discharges can reach 30kV or higher. Linak considers ESD to be an important issue and their years of experience have shown that equipment designed to meet the 8kV level specified in the Standards such as IEC601-1-2, EN50082-2 are insufficient to protect electronic equipment in certain environments. Typical conditions that contribute to ESD problems. • • •

Low relative humidity (higher ESD risk in winter season with dry atmosphere) Synthetic fabrics: clothes, shoes, carpets, sheets, castors, plastic covers. Building construction (concrete)

What can the manufacturer and end user do to prevent ESD problems? There are several ways to minimize the ESD problems. Preventing a static charge occurring (Avoid dry air, use conditioner when washing, use cotton-cloth-bedding-carpet) Using ESD secure castors (conductive castors) on beds Using ESD immune electronics Patient monitoring-equipment in hospitals and dealing with noise problems deriving from low frequency electromagnetic fields. The use of high sensitive monitoring equipment, which measure low-level signals e.g. EEG (ElectroEncephaloGraph) demands awareness of the surrounding installations and equipment because this type of equipment is very sensitive to disturbing signals. Problems can arise when using ECG (Electro Cardio Graph), since this equipment measures signals in the 0-125Hz range. Mains power can therefore be a disturbing source with a frequency of 50-60Hz. When beds are used in the presence of sensitive measuring equipment, consideration should given to using class 1 and providing an adequate earth connection, with or without impedance for potential equalization.

COPYRIGHT© MEDICRAFT AUSTRALIA ® 2004

6

There are several ways to avoid electromagnetic interference problems, when using an electric bed: Use class 1, earth connected bed frame Use class 1, earth connected bed frame with impedance Consider the mounting and positioning of the cables, control box and actuators. The closer these items are to the patient and probe the greater the risk of interference. Other points to consider: If the earth connection is being used to protect against electrostatic discharge or electromagnetic interference then an earth connection may be appropriate. If the earth connection is being used to provide patient safety in intensive care then a potentially equalized metal bed frame must be considered. If the bed frame is to be earthed then the requirement for the 200-500K impedance should also be considered. However, a 200-500K impedance in the earth connection will not provide protection against electrostatic discharge. Will the different metal parts of the bed frame be connected together (potentially equalized) or are they isolated because of insulated connection points. Are their residual current devices RCD in the power supply which sense current draw to earth and shut off the power supply. Older model of ECG units and other sensitive measuring equipment are generally more susceptible to interference than newer models designed to comply with current EMC standards.

COPYRIGHT© MEDICRAFT AUSTRALIA ® 2004

7

CENTRAL LOCKING CASTORS

TO APPLY THE BRAKES

The central locking braking system is activated by depressing either of the Red pedals at the foot end of the bed. The two foot end castors and one head end castor will then be locked from swiveling and rotating.

TO RELEASE THE BRAKES Depress either of the Green pedals at the foot end of the bed until the pedal returns to the horizontal position. All four wheels should rotate and swivel freely.

TO APPLY STEERING LOCK Depress either of the Green pedals at the foot end of the bed to the locked position. Push the bed forward; one castor at the head end of the bed will lock into a non-swivel mode. This allows straight steering by the attendant, when pushing from the foot end.

TO RELEASE THE STEERING LOCK Depress either Red pedal at the foot end of the bed until the pedal returns to the horizontal position. All four wheels should rotate freely.

COPYRIGHT© MEDICRAFT AUSTRALIA ® 2004

8

HANDSET OPERATION TO RAISE AND LOWER THE BACKREST To raise the backrest, press the backrest up button until the desired posture is reached To lower the backrest, press the backrest down button until the desired posture is reached TO RAISE AND LOWER THE BED To raise the bed, press the bed up button until the desired height is reached To lower the bed, press the bed down button until the desired height is reached. TO RAISE AND LOWER THE KNEE-BREAK To raise the knee-break, press the knee-break up button until the desired posture is reached To lower the knee-break, press the knee-break down button until the desired posture is reached TRENDELENBURG To tilt the head end down, press the head end down button. To tilt the foot end down, press the foot end down button. Note. If the bed is in a tilt position, self-leveling will occur at both the extreme low and extreme high positions. This is to prevent any collisions between the upper mattress frame and the lower wheelbase assemblies.

Backrest up button

Backrest down button

Bed up button

Bed down button

Knee-break up button Head end down tilt button

Knee-break down button Foot end down tilt button

COPYRIGHT© MEDICRAFT AUSTRALIA ® 2004

9

ATTENDANT CONTROL OPERATION TO PREVENT MOVEMENT OF BED The attendant control panel (ACP) is fitted to allow any or all of the functions to be locked out. If the attendant wishes to alter to posture of the bed, unlocking the appropriate channel and pressing the desired button can do this. This must be done while the power switch is being pressed. To lock a channel, turn the rotating switch anti-clockwise to the locked position. This position is indicated by a locked padlock symbol. Backrest Lockout Switch

Hi-Lo Lockout Switch

Knee-Break Lockout Switch

Trendelenburg Lockout Switch

Power switch

In the event that the ACP lockout switch fails to disconnect a required function from being activated, the handset could be placed in such a position that would not allow the patient to have access to the controls. Also the handset can be totally disconnected if required. If this is done, the attendant can alter the bed posture by using the ACP only, as described above.

COPYRIGHT© MEDICRAFT AUSTRALIA ® 2004

10

QUICK RELEASE BACKREST OPERATION The backrest actuator is fitted with a quick-release system to allow the backrest to be lowered quickly in an emergency. To lower the backrest using the quick release, hold one of the handles at the side of the backrest and at the same time, pull up on the quick-release lever located at each side of the bed. Use the handle to control the rate of descent.

Backrest handle

Quick-release lever

COPYRIGHT© MEDICRAFT AUSTRALIA ® 2004

11

KNEE-BREAK OPERATION To raise or lower the knee-break, press the appropriate button on the handset or ACP. When the knee-break is raised, the lower leg section will remain parallel with the bed frame.

To lower the foot section, hold one of the handles with one hand and slightly pull up. Lift the adjusting handle out of the groove and allow the foot section to lower. This mechanism will reset itself when the knee-break is lowered back to the flat position.

Adjusting Handle

Knee-break up button

Knee-break down button

COPYRIGHT© MEDICRAFT AUSTRALIA ® 2004

12

SAFETY SIDE RAILS The safety side rails have 4 positions. Fully up position.

Mid position.

Check position. When lowering the rail it will stop at this position. This allows the attendant to check for any obstructions prior to lowering to the fully down position. *NOTE*The rail must never be left in this position. If the rail is to be lowered, it must be fully lowered immediately after reaching this position.

Fully Down position. IMPORTANT This position must be set prior to patient transfer. If the rail is to be lowered, it must be fully lowered to this position.

COPYRIGHT© MEDICRAFT AUSTRALIA ® 2004

13

SPECIFICATIONS Minimum & maximum bed height can vary with different castor sizes. The measurement shown below are with standard 150mm central locking castors fitted. All angles shown are with respect to horizontal. Equipment Class

Class 1

IP Rating

IP54

Safe Working Load

170Kg.

Mass

140 Kg.

Minimum Height

415mm

Maximum Height

855mm

Maximum head end down tilt (trendelenburg)

14º

Maximum foot end down tilt (reverse trendelenburg)

14º

Maximum backrest angle

70º

Maximum upper leg section angle

25º

Lower leg section maximum angle with upper leg Section fully raised

23º

Max. Backrest Angle

Max. Head End Down Tilt

Knee-Break Angles

Max. Foot end Down Tilt

COPYRIGHT© MEDICRAFT AUSTRALIA ® 2004

14

ELECTRICAL COMPONENT SPECIFICATIONS Control Box

Type: Item: V in: I in: U out: Op:

CB12-004-AT-24 CB1200944A0132J 230V – 240V ~, +-10%. 50Hz Max, 3,0A 24V , max. 70 VA Int., 10% . Max 6 min. in 1 hour

Class 1:

Earth connection outside control box and 3-wire mains cable.

Protection Class:

IP 66

Battery Back Up

The batteries are a lead-acid gel cell type that can be trickle charged continuously (batteries used for standby) and have a high current discharge capacity. The batteries are not the nickel cadmium type and must not be periodically fully discharged. Life is greatly reduced by deep or complete discharging of the batteries. The best lifetime is achieved by charging the batteries as often as possible. Replacement of the battery kit is generally required every 3-5 years depending on the duty cycle and use of batteries. HANDSET

Type: Protection Class:

HB74 (4 channel) / HB 75 (5 channel) IP66

ATTENDENT CONTROL PANEL (ACP)

COPYRIGHT© MEDICRAFT AUSTRALIA ® 2004

15

Type: Protection Class:

AP1004K30-2211 IP65 IP 65

BED LIFT / TILT ACTUATORS

Type: Item: Protection Class:

LA31.40BM-200-24-001-IP54 310745-00 IP54

BACKREST ACTUATOR

Type: Item: Protection Class:

LA32.50FW-150-24-001-IP65 32810W-00150410 IP65

KNEE – BREAK ACTUATOR

Type: Item: Protection Class:

LA31.40BM-100-24-302- IP54 314200-31100040 IP65

COPYRIGHT© MEDICRAFT AUSTRALIA ® 2004

16

IP Codes: IP51:

5: Protection against dust – limited degrees (No harmful deposit) 1: Protection against vertically falling drops of water Provides: Complete protection against contact with live or moving parts inside the enclosure. Protection against harmful deposits of dust. Protection against drops of condensed water. Units with IP51 rating are not normally labeled IP51.

IP54:

5: Protection against dust - – limited degrees (No harmful deposit) 4: Protection against water sprayed from all directions. Limited ingress permitted. Provides: Protection against harmful deposits of dust. Protection against water sprayed from any direction. Units are labeled IP54

IP 65:

6: Totally protected against dust. 5: Protection against low-pressure jets of water from all directions. Limited ingress permitted. Provides: Complete protection against contact with live or moving parts inside the enclosure. Protection against the ingress of dust. Protection against water jets from any direction. Units are labeled IP65

IP66:

6: Totally protected against dust 6: Protection against strong jets of water from all directions. Limited ingress permitted. Provides: Complete protection against contact with live or moving parts inside the enclosure. Protection against ingress of dust. Protection against stronger water jets and temporary submersion. Incorporating high temperature materials for wash tunnels. Tested 100% for air tightness during manufacture. Units are labeled IP66.

COPYRIGHT© MEDICRAFT AUSTRALIA ® 2004

17

CLEANING AND DISINFECTION The materials used in the control boxes handsets and actuators are resistant to many detergents and disinfectants commonly used in hospital and care sectors. Units with IP51 protections ratings must not be washed down. Disconnect the mains power cable and use a slightly damp cloth to wipe over. The control box material used in IP66 protection ratings are resistant to hot and cold water and softeners. Organic solvents like Halogenide / aromatic hydrocarbons and ketones must not be used. Units rated to IP66 protection ratings are suitable for cleaning in wash tunnels which correspond to those, manufactured by KLEINDIENST, type Clean- Station ES3-387, provided that the following conditions are observed: -

All handset and actuator cable connection must be secure and be fully inserted into the control box before the bed enters the wash tunnel. The “O” ring seals on the cable plugs must be intact. Check the locking ring is in place on the CB12. The cleaning and disinfection cycle in wash tunnels must not exceed 10 minutes. Pressures on jet nozzles in wash tunnels must not exceed 10 bar. Distance between the jet nozzles and electric actuator parts must be at least 300mm. Water temperature must not exceed 85º C. Chilling with cold water is not permitted.

It is recommended to run the actuators in to their minimum stoke length before washing them to avoid degreasing of the spindle tubes. The following must be observed as regards to detergents: -

They must not be strongly alkaline or acidic (pH-value 6-8) They must not contain corrosive or caustic matters They must not contain chemicals that will change the surface structure or adhesive ability of the plastics. They must not dissolve grease.

The following disinfectants with detergents are recommended: -

NEODISCHER DEKONTA, Dose 1-3%, make: CHEMISCHE FABRIK Dr. WEIGERT CCOTRADE RW, Dose 0.5%, make: CCOTRADE GmbH. (CCOTRADE and NEODISCHER are trademarks.)

NOTE. Cleaning by means of a hand controlled jet pipe, which is for example connected to a steam cleaner, is not permitted, since it is not possible to maintain a minimum distance of 300mm to the electric parts.

COPYRIGHT© MEDICRAFT AUSTRALIA ® 2004

18

RECOMMENDED MAINTENANCE SHEDULE

Please note* 12 monthly maintenance schedule recommended in AS/NZS 3200.2.38:1997 More frequent checks may be carried out at the discretion* of engineering services. PROCEDURE Lubricate all moving and sliding parts and hinge points. Inspect all fasteners to ensure proper fit, position, and tightness Cleaning Bed frame

SHEDULE 12 months*

MATERIALS REQD. Lubricating oil / grease.

12 months*

Correct size spanners, sockets, screw drivers, hex keys, ect.

Periodically

Inspect all surfaces and remove any user developed sharp or burred areas, apply touch up where required Adjust & Clean castors

Periodically

Soap, Water, and medium strength cleaners. (Do not pressure clean) Metal file, correct match touch up paint.

Battery Backup

12 months*

Correct size spanner 13mm

12 months* Batteries must be kept fully charged for longest life.

TORX® T-15 ( Screw driver)

Power Cable Notice. Be aware, that mains power cable management must be of a high priority when operating potential for the cable to be caught or severed by the bed frames moving parts.

If the mains power cable has been damaged in any way use the battery back up system in place of mains power until such time that the cable has been replaced. Medicraft has fitted a quick release in line power cable socket to minimize the risk of damage. If the bed is moved before the attendant unplugs the cable from the wall outlet, the in line socket will separate, thus eliminating damage to the cable. Be sure to check for proper connection of this socket.

Mains power cable with IEC plug.

Quick release socket

COPYRIGHT© MEDICRAFT AUSTRALIA ® 2004

19