MR7 Pneumatic High-Speed System Instruction Manual PTSC224

45 Pages

Preview

Page 1

PTSC224

Symbols The following symbols may appear within this manual, on product labeling, or on the product itself: Attention, see Instructions for Use.

Tube Control

United States federal law restricts this device to sale by or on the order of a physician.

Air Pressure Relief

Reference Number

Use with

Lot Number

Multi-Use Disposable Attachment

Serial Number Quantity

STERILE

Dissecting Tool

Approximately equal to

Attachment

Attachment

Non-Sterile

Control Unit

Control Unit

Sterilized by Gamma Irradiation

Refurbished

Refurbished

Temperature Limitations Unlock Lock

EC REP

Lubricant/Diffuser

Dissecting Tool

Date of manufacture

+

Lubricant/Diffuser

Instrument Case

For single patient use only. Do not re-use, re-process, or re-sterilize this product. Re-use, re-processing or re-sterilization may compromise the structural integrity of the device and/ or create a risk of contamination of the device, which could result in patient injury, illness, or death.

Use by date

|

Instrument Case

On

Accessory REGULATOR Bone Mill MOTOR Brush Adapter

Accessory

Regulator

Bone Mill Motor Brush Adapter

Off

USA Only

Finger-Operated Control

Manufacturer

Foot-Operated Control

Do not dispose to unsorted municipal waste.

Compliant with European Council Directive MDD 93/42/EEC.

Tool Control

Authorized Representative in the European Community

Consult Instructions for Use

PTSC224

Contents General Information...1 Indications for Use ...1 Contraindications ...1 Special Notices ...1 General Safety Precautions ...2 No Latex Policy ...2 System Components ...3 Non-Disposable Components ...3 Disposable Components ...7 Legend® Dissecting Tools ...8 General Guidelines For Attachment and Tool Applications ...9 Setting up the Operating Room ... 12 Power Source Requirements ... 12 Pneumatic Connections... 12 Setting up the MR7 System... 13 Installing the Oiler Cartridge ... 13 Connecting the Motor ... 14 Installing an Attachment and Tool ... 15 Straight Attachments ... 15 Specialized Attachments ... 15 Activating the Motor ... 16 Disassembling the MR7 System ... 17 Depressurize the System ... 17 Disconnect Hoses ... 17 Discard the Lubricant/Diffuser Cartridge ... 17 Remove the Attachment and Tool ... 17 Cleaning & Sterilizing the MR7 System ... 18 MR7 Motor ... 18 Legend Attachments / Tubes ... 19

i

PTSC224 MR7 Pneumatic Control Unit / Regulator Hose / Triton Adapter / Instrument Case ... 21 Transmissible Spongiform Encephalopathies (TSE) Return Policy... 21 Troubleshooting ... 22 Refurbishing or Repairs ... 25 Preventative Maintenance... 26 Limited Warranty ... 27 Appendix A-Specialized Attachments ... 28 Angled Attachments... 28 Angled Double Lock Attachments ... 29 Curved Bur Attachments ... 30 Variable Exposure Attachments ... 31 Footed Attachments ... 32 Rotating Footed Attachments ... 33 Contra-Angle Attachment (16-MF)... 34 Metal Cutting Attachments ... 35 Telescoping Attachments ... 36 Perforator Driver Attachments ... 37 Jacobs® Chuck Attachments ... 38 Bone Mill Attachment... 39

ii

General Information

PTSC224

General Information Read and understand this manual before use of the MR7 System. The Midas Rex® MR7 system is designed for use by medical professionals familiar with powered surgical instrumentation. The surgeon is responsible for learning the proper techniques in the use of this system, as inappropriate use may potentially be harmful. It is strongly recommended that the surgeon and dedicated operating room personnel are knowledgeable with the use of this equipment by being trained in Medtronic Midas Rex Hands-On Workshops or by one of the local authorized representatives. The MR7 system consists of the following components: • MR7 or MR7 Touch Motor • MR7 Pneumatic Control Unit with Various Connectors • MR7 Regulator Hose • MR7 Lubricant/Diffuser Cartridge • MR7 Triton® Adapter (optional) • Legend® Attachments* • Legend® Dissecting Tools* *The MR7 system uses the same attachments and dissecting tools as the Legend® Pneumatic High-Speed System.

Indications for Use The Medtronic Midas Rex MR7 System is a pneumatically operated surgical instrument system. The pneumatic motors provide power to operate removable rotating surgical cutting tools and their accessories intended for use in neurosurgery, including craniotomy and spinal surgery; as well as Ear, Nose and Throat (ENT), orthopedic and general surgical applications including maxillofacial, craniofacial and sternotomy surgeries.

Contraindications None

Special Notices The words warning, caution and note have special meanings in this manual, and should be carefully reviewed: WARNING: A warning indicates that the personal safety of the patient or physician may be involved. Disregarding this information could result in injury to the patient or physician. CAUTION: A caution indicates that there is a risk of damaging equipment. NOTE: A note is intended to provide additional information, which may be useful, but is not essential to complete the procedure.

1

General Information

PTSC224

General Safety Precautions WARNINGS: •

Do not use the Midas Rex MR7 System before proper cleaning and sterilization.

•

Do not operate the Midas Rex MR7 System in the presence of Magnetic Resonance Imaging devices.

•

Do not use damaged, faulty, or modified Midas Rex MR7 System components. Inspect the Midas Rex MR7 System for damage prior to each use: • • •

Check the motor’s exhaust hose for cracks or tears. Visually inspect attachments and tools. Do not use bent or damaged tools. Install attachment and dissecting tool, then briefly run motor. * Check motor for overheating and leaking lubricant. * Check attachment for overheating. * Check dissecting tool for flail.

•

Do not operate the Midas Rex MR7 System without eye protection.

•

Motors and attachments which fail due to extended use may allow a component to detach and fall from the motor or attachment, and may cause patient injury.

•

Heavy side loads and/or long operating periods may cause the device to overheat. If overheating occurs: • • •

Never place an overheated motor on the patient or draping during surgery. Discontinue use and rest the motor by using intermittently, or wrap the motor/attachment interface with a moist sterile towel. If the motor is passed off, the receiver should grasp the motor by the proximal end close to the motor hose.

•

To avoid injury to the patient or user, do not place the handpiece on the patient or in an unsecured location, when not in use.

•

Midas Rex MR7 motors should only be operated when the attachment is in the position.

If a dissecting tool package is opened, but the tool is not used or contaminated, the tool can be re-sterilized by steam sterilization. Remove tool from all original packaging and place into an approved autoclave package. Steam sterilize as follows: High Vacuum Steam: 270° F (132° C) for 5 minutes Gravity Displacement: 270° F (132° C) for 15 minutes The re-sterilized tool must be used promptly following re-sterilization. If rust or corrosion is encountered after re-sterilization, do not use the re-sterilized tool.

No Latex Policy Legend and MR7 products, packaging materials, labels, package inserts, and similar items manufactured by and/or for Medtronic Powered Surgical Solutions (MPSS) do not contain latex.

2

System Components

PTSC224

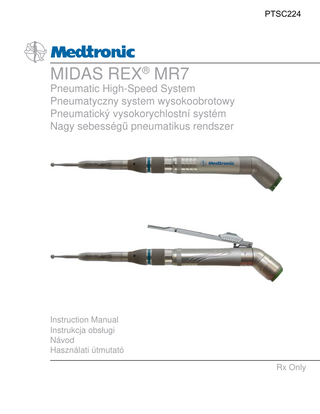

System Components Non-Disposable Components MR7 Motor The MR7 motor is a high-speed, high-torque motor used to dissect bone and biomaterials. Figure 1: Motor Components

1

3

2

4 5

6

1. Collet 2. Motor Case 3. Swivel 4. Hose 5. Finger Control Lever 6. Safety Slide (MR7 Touch Only) In addition to the components listed in Figure 1, each MR7 motor has a lubricant/diffuser housing at the end of the motor hose, as seen in Figure 2. Figure 2: Lubricant/Diffuser Housing

3

System Components

WARNING: Use only Medtronic Midas Rex Legend or MR7 devices with an MR7 motor. Use of other devices may cause injury or damage equipment, and will void the manufacturer’s warranty.

PTSC224 Figure 3: Pneumatic Control Unit

Pneumatic Control Unit The pneumatic control unit (Figure 3) provides variable speed motor control controls through a foot pedal. It also allows the user to switch between finger and foot control of the motor (if applicable).

Regulator The regulator (Figure 4) controls the delivery pressure of compressed gas to the pneumatic control unit. The pressure gauges monitor cylinder pressure (right gauge) and delivery pressure (left gauge). Note: Outlet pressure gauge accurate to +/- 12 psi.

Instrument Case

Figure 4: Regulator

The instrument case (Figure 5) is used to organize equipment.

Regulator Hose Connects from the gas source to the pneumatic control unit to deliver compressed gas.

Figure 5: Instrument Case

4

System Components

PTSC224 N2 DISS to Male Schrader Adapter

Figure 6: N2 DISS to Male Schrader Adapter

The N2 DISS to male Schrader adapter (Figure 6) allows for the regulator hose to be attached to a female Schrader in-house gas connection. A N2 DISS to female Schrader adapter is also available for connection of the regulator hose to a male Schrader in-house gas connection.

N2 DISS to Air DISS Adapter The N2 DISS to air DISS adapter (Figure 7) allows for the regulator hose to be attached to an Air DISS in-house gas connection.

N2 DISS to WF4 Adapter

Figure 7: N2 DISS to Air DISS Adapter

The N2 DISS to WF4 adapter (Figure 8) allows for the regulator hose to be attached to a Midas Rex safety valve regulator previously used for Midas Rex Classic or Midas Rex III motors. The in-line oiler must be removed from the safety valve regulator.

Motor Wrench The motor wrench (Figure 9) is used to align arrows on motor collet flats prior to installation of a Legend attachment.

Figure 8: N2 DISS to WF4 Adapter

Triton Adapter The Triton adapter (Figure 10) allows the Triton handpiece to be driven by the MR7 pneumatic control unit. It functions much the same way as the Triton port on the Legend pneumatic control unit, except that it is connected between the control unit and the gas source, rather than being integrated into the control unit Figure 9: Motor Wrench

Figure 10: Triton Adapter

5

System Components

PTSC224

Legend Attachments Legend motor attachments are available in various designs to facilitate a variety of surgical procedures. Attachments vary in length, diameter, and overall design. They are marked and color-coded to correspond with their associated dissecting tools. A few of the Legend attachments available are listed in the table below. Attachment

Example

Standard Straight Attachments

AS09

Standard Angled Attachments

AA14

Straight Variable Exposure Attachments

AVS07

Angled Variable Exposure Attachments

AVA07

Fixed Footed Attachments

AF01

Rotating Footed Attachments

AF01R

Telescoping Attachments

AT10 (base) TT12A (tube)

Contra-Angle Attachment

AC16

Metal Cutting Attachment

ASMC

Perforator Attachment

AD01

5/32” Jacobs Chuck Attachment

AD02

Bone Mill Attachment

BM100

Other Details/Options

The telescoping attachment requires the use of the AT10 attachment base, as well as a telescoping tube. Tubes are available in straight, curved, or hooded form.

Available in 800 RPM or 1000 RPM form.

NOTE: Angled and straight attachments with the same length, marking, and color band share the same dissecting tool. Curved and straight telescoping tubes with the same length, marking, and color band also share the same dissecting tool. Example: The 14-AM straight and 14-AM angled attachments are 14 cm long, marked 14-AM and have a green color band. All dissecting tools with the prefix 14 (14MH30) may be used in either the 14-AM straight or 14-AM angled attachment. Be sure to match the color code and nomenclature on the Legend Dissecting Tool packaging with the color band and nomenclature on the Legend Attachment.

6

System Components

PTSC224 Disposable Components Figure 11: Lubricant/Diffuser Cartridge WARNING: Use only Medtronic Midas Rex Legend or MR7 devices with an MR7 motor. Use of other devices may cause injury or damage equipment, and will void the manufacturer’s warranty.

Lubricant/Diffuser Cartridge The lubricant/diffuser cartridge (Figure 11) provides lubrication to the motor and filters oil from exhausted air.

Telescoping Tubes Telescoping tubes (Figure 12) provide support to the rotating dissecting tool. Telescoping tubes are disposable following multiple uses and should be discarded when heat or excessive vibration is noticed or insertion of tools becomes difficult.

Figure 12: Telescoping Tube

Cleaning Brushes Cleaning brushes (Figure 13) are used to clean debris from lumen of attachments and telescoping tubes. Sized for an internal bore diameter of 3.2 mm, 2.4 mm or 1.2 mm in Legend Attachments and Telescoping Tubes. NOTE: Cleaning brushes will not pass through angled, contra-angle, metal cutting, perforator, or Jacobs Chuck attachments, because they are not cannulated. Figure 13: Cleaning Brushes

3.2mm

2.4mm

1.2mm

7

System Components

PTSC224

Legend® Dissecting Tools Legend dissecting tools are sterile cutting tools, intended for cutting bone and biomaterials.

Dissecting Tool Nomenclature Part numbers for Legend dissecting tools follow a standard naming convention, which is described in the diagram below. A basic part number consists of the associated attachment length, the tool head shape, and the tool head diameter. Part numbers may also include a variety of prefixes to identify specific attachment types, as well as a variety of suffixes to provide additional information about the dissecting tool. Tools that use a design taken from the Mednext line are designated by an additional “-MN” suffix.

Associated Attachment Length

Tool Head Diameter (x.x millimeters)

Optional Pre¿x

Tool Head Shape

Optional Suf¿x

Tool Number Pre¿xes (not all inclusive) F...

For use with footed attachments

MC

For use with metal cutting attachments

T

For use with telescoping attachments

Tool Head Shapes (not all inclusive) AC

Acorn

MH

Match Head

BA

Ball

OV

Oval

CY

Cylinder

RT

Reverse Taper

HM

Hole Maker

TA

Tapered

HS

Hole Saw

TD

Twist Drill

Tool Number Suf¿xes (note that more than one of the suffixes listed may be combined in a single part number)

8

L

Long

S

Spiral

D

Diamond

SH

Short

X

Extra

DC

Diamond Coarse

F

Fine

DX

Diamond Extra Coarse

C

Carbide

MN

Mednext Tool Design

System Components

PTSC224 WARNINGS: •

Dissecting tools are for single-use only. Do not attempt to sterilize them. The dissecting tools are packed sterile and are not intended for repeat use. To prevent contamination, use only once.

•

Do not use an attachment and dissecting tool combination that results in tool flail or excessive vibration.

•

Do not attempt to remove a tool while the motor is running.

•

Do not attempt to remove a tool from an overheated motor or attachment.

•

Do not use the device if the package is opened or damaged.

General Guidelines For Attachment and Tool Applications These are general guidelines for dissecting tool applications and are not an all-inclusive listing. WARNING: Be sure to match the color code and nomenclature on the Legend Dissecting Tool packaging with the color band and nomenclature on the Legend Attachment. Failure to do so could result in injury to the patient or operating room staff. Surgical Application Spine

Commonly Used Attachments

Commonly Used Dissecting Tools

Suggested Motor(s)

MR7, MR7 8-B, 9-M, 14-AM, Match Head Touch 15-A Elongated spherical design allows controlled, delicate dissection. For entry hole, nerve decompression, osteophyte removal, sinus dissection, etc. Ball Helical cutting flutes dissect bone or cement effectively from a wide variety of approach angles. For debridement, decortication, sinus dissection, etc. Oval Helical cutting flutes and curved design blend acorn and ball styles to vary dissection efficiency with approach angle. For decortication, laminotomy, entry hole, nerve decompression, osteophyte removal, etc. Hole Maker/Saw Matched sets of Hole Makers and Hole Saws are efficient and effective for interbody fusion. Cylinder Effective bone sculpting and planing. For graft shaping, debridement, corpectomy, decortication, interbody fusion, fusion takedown, etc. Acorn Curved design varies dissection efficiency with varied approach angles. For entry hole, laminotomy, bone shaping, debridement, corpectomy, decortication, fusion takedown, etc. Telescoping

Match Head Elongated spherical design allows controlled, delicate dissection. For entry hole, nerve decompression, osteophyte removal, sinus dissection, etc.

Footed, Straight

Tapered Slender design for precise dissection with minimal bone loss. For transection, osteotomy, graft harvesting, bone shaping, entry hole, suture hole, midface advancement, etc.

MR7, MR7 Touch

9

System Components

Surgical Application Neurosurgical– Cranial

General Surgery and Plastic Surgery (Craniofacial/ Maxillofacial/ Sternotomy)

PTSC224 Commonly Used Attachments

Suggested Motor(s)

7-6ST, 8-B, 9-M, 10-9ST, 14-AM, 15-A

MR7 Match Head Elongated spherical design allows controlled, delicate dissection. For entry hole, nerve decompression, osteophyte removal, sinus dissection, etc. Ball Helical cutting flutes dissect bone or cement effectively from a wide variety of approach angles. For debridement, decortication, sinus dissection, etc. Twist Drill Helical design with stop produces a hole with a precise depth. Ideal for plating. Acorn Curved design varies dissection efficiency with varied approach angles. For entry hole, laminotomy, bone shaping, debridement, corpectomy, decortication, fusion takedown, etc.

Telescoping

Match Head Elongated spherical design allows controlled, delicate dissection. For entry hole, nerve decompression, osteophyte removal, sinus dissection, etc.

Footed

Tapered Slender design for precise dissection with minimal bone loss. For transection, osteotomy, graft harvesting, bone shaping, entry hole, suture hole, midface advancement, etc.

7-6ST, 8-B, 9-M, 10-9ST, 14-AM

Match Head MR7, MR7 Elongated spherical design allows controlled, delicate Touch dissection. For entry hole, nerve decompression, osteophyte removal, sinus dissection, etc. Ball Helical cutting flutes dissect bone or cement effectively from a wide variety of approach angles. For debridement, decortication, sinus dissection, etc. Tapered Slender design for precise dissection with minimal bone loss. For transection, osteotomy, graft harvesting, bone shaping, entry hole, suture hole, midface advancement, etc. Twist Drill Helical design with stop produces a hole with a precise depth. Ideal for plating.

Ear, Nose, and 7-6ST, 10-9ST Throat (Otology, Neurootology)

10

Commonly Used Dissecting Tools

Ball Helical cutting flutes dissect bone or cement effectively from a wide variety of approach angles. For debridement, decortication, sinus dissection, etc.

MR7

System Components

PTSC224 Surgical Application Orthopaedics

Biometals/ Bioceramics/ Biomaterials

Commonly Used Attachments

Commonly Used Dissecting Tools

Suggested Motor(s)

8-B, 9-M, 14-AM, 21-TU, 26-R, Footed, Telescoping

MR7, MR7 Ball Touch Helical cutting flutes dissect bone or cement effectively from a wide variety of approach angles. For debridement, decortication, sinus dissection, etc. Tapered Slender design for precise dissection with minimal bone loss. For transection, osteotomy, graft harvesting, bone shaping, entry hole, suture hole, midface advancement, etc. Acorn Curved design varies dissection efficiency with varied approach angles. For entry hole, laminotomy, bone shaping, debridement, corpectomy, decortication, fusion takedown, etc. Cylinder Effective bone sculpting and planing. For graft shaping, debridement, corpectomy, decortication, interbody fusion, fusion takedown, etc.

Footed

Tapered Slender design for precise dissection with minimal bone loss. For transection, osteotomy, graft harvesting, bone shaping, entry hole, suture hole, midface advancement, etc.

MC

Metal Cutter Cutting flutes or diamond wheel design remove metals, ceramics and other biomaterials effectively from a variety of approach angles. For cutting rods, pins, plates, implants, screws, etc.

MR7, MR7 Touch

11

Setting up the Operating Room

PTSC224

Setting up the Operating Room Power Source Requirements Required Operating (Dynamic) Pressure

Nominal Operating (Dynamic) Pressure

Approximate Flow Rate Required

Gas Type

80–120 psi

100 psi

12 cubic feet/min.

5.5–8.3 bar

6.9 bar

340 liters/min.

Nitrogen or Dry-Filtered Compressed Air

CAUTION: Do not run the motor at an operating pressure above or below the required operating pressure range. Operating pressure below 80 psi (5.5 bar) may not provide proper lubrication to the motor. Operating pressure above 120 psi (8.3 bar) may damage or reduce the life of the motor.

Pneumatic Connections Figure 14: Gas Connection Options

1. Regulator Hose (N2 DISS) 2. N2 DISS to Air DISS Adapter Gas Source 3. N2 DISS to Male Schrader Adapter Gas Source 4. Gas Source (N2 DISS) 5. Regulator 6. DISS/WF4 Adapter 7. Regulator

CAUTION: If you are using the Midas Rex Safety Valve Regulator instead of the Legend Regulator, you must replace the in-line oiler with the DISS/WF4 adapter before use.

12

Setting up the MR7 System

PTSC224

Setting up the MR7 System Installing the Oiler Cartridge WARNING: Do not use the MR7 system with the Midas Rex in-line oiler. The MR7 motor is sufficiently lubricated by the lubricant/diffuser on the motor hose, and will be over-lubricated if the Midas Rex in-line oiler is used. 1.

2.

3. 4.

Figure 15: Aligning the Lubricant/Diffuser Cartridge with the Housing

Set the non-running (static) pressure to 80–120 psi (5.5–8.3 bar) at the gas source. Operating (dynamic) pressure may be adjusted later. Hold the lubricant/diffuser cartridge perpendicular to the housing (Figure 15), and press the cartridge’s circular fitting onto the housing’s circular receptacle (Figure 16), breaking the foil seal. Rotate the cartridge down until it clicks into place. Verify that the symbol on the cartridge is lined up with the notch on the housing (Figure 17).

WARNINGS: •

Failure to properly secure the lubricant/diffuser cartridge may cause injury to operator and/or operating room staff.

•

Do not attempt to remove the lubricant/diffuser cartridge while the system is pressurized.

Figure 16: Pressing the Cartridge onto the Housing

CAUTIONS: •

Do not use an MR7 motor without a lubricant/ diffuser installed.

•

Do not use a lubricant/diffuser cartridge for more than one hour of drill time.

•

Do not re-use a lubricant/diffuser cartridge. It is a single-use product.

•

Do not attempt to refill a used lubricant/diffuser cartridge.

•

Do not use a lubricant/diffuser cartridge if it appears to be damaged, or if the inner foil seal is punctured.

Figure 17: Correctly Installed Lubricant/Diffuser Cartridge

13

Setting up the MR7 System

Connecting the Motor

PTSC224 Figure 18: Connecting the Motor Hose to the Motor Port

Connect the motor hose to the motor port on the top of the pneumatic control unit, by swinging the port cover to the side and pressing the end of the hose into the port (Figure18). WARNING: Do not pinch, kink, obstruct, cut, tear, or step on the motor/exhaust hose. This may cause the hose to burst, potentially injuring the patient or user. NOTES: •

If using the MR7 Touch motor, slide the control slide on the pneumatic control unit to the position (Figure 19). This will automatically depress and lock the foot pedal. The control will not lock into the position unless the motor hose is connected into the motor port. When the motor hose is removed from the motor port, the foot pedal will return to normal position.

•

If using the Triton Power Surgical Instrumentation System in conjunction with the MR7 motor, use the optional Triton adapter to connect the Triton hose. Refer to the documentation accompanying the adapter for connection instructions.

•

The motor’s exhaust hose may have an oily film on the external surface from pressure and/or temperature differentials following sterilization. Wipe the exhaust hose with a sterile cloth prior to use. If motor continues to have oil on the exhaust hose, return the motor to MPSS for refurbishing.

Figure 19: Finger/Foot Control Slide

WARNING: To avoid injury to the patient or user, do not use the pneumatic control unit to operate systems other than the MR7, Legend, and Triton systems. Prior to installation of a Legend attachment and dissecting tool, ensure that the arrows on the motor collet flats are aligned (Figure 20). If the arrows are not aligned, use the motor wrench to turn the collet flat closest to the motor case until its arrow is aligned with the arrow on the other collet flat. WARNING: To avoid injury when using the MR7 Touch motor, ensure the safety slide is in the “O” position before installing the attachment and tool.

14

Figure 20: Aligning the collet flats

Installing an Attachment and Tool

PTSC224

Installing an Attachment and Tool WARNING: Dissecting tool flutes are sharp and may perforate surgical gloves. Tools may be grasped with a hemostat to aid in installation and removal.

Figure 21: Sliding the Attachment over the Motor Collet

Straight Attachments Installation: 1.

2.

3.

Slide the attachment over the motor collet, aligning the triangular markers (Figure 21). You will feel and hear the attachment click into place when it is fully seated. Insert the dissecting tool into the attachment with a slight rotational motion (Figure 22). You will feel and hear the tool click into place when it is fully seated in the attachment. Turn the attachment to the position on the motor case (Figure 23). Gently pull on the shaft of the dissecting tool to verify proper installation.

Figure 22: Inserting the Dissecting Tool into the Attachment

Removal: Removal is the reverse of installation.

Specialized Attachments See Appendix A-Specialized Attachments for installation and removal instructions for other attachments.

Figure 23: Attachment in the Locked Position

15

Activating the Motor

PTSC224

Activating the Motor NOTE: In order to activate the MR7 Touch motor, the safety slide on the finger control switch must be in the | position, and the control slide on the foot control must be in the position. The control slide will not lock in the position unless a motor is connected to the motor port. 1. 2.

Activate the motor by pressing on the foot control pedal (Figure 24), or by pressing on the finger control lever (MR7 Touch motor only). Adjust operating pressure as needed at the compressed gas source until supply pressure gauge on pneumatic control unit reads within a range of 80–120 psi (5.5–8.3 bar) as required. Operating pressure (with motor running) will decrease slightly from the non-running (static) pressure setting when the motor is activated. Figure 24: Foot Control Pedal

Foot Control Pedal Air Pressure Gauge

Control Slide

Figure 25: MR7 Finger Control Switch Finger Control Lever

WARNINGS: •

Do not use excessive force to pry or push bone with the attachment or tool during dissection. This could cause the tool to break and cause injury to the patient or operating room staff.

•

Use adequate irrigation during dissection, to prevent thermal necrosis.

•

MR7 motors should only be operated when the attachment is in the position.

NOTE: To decrease pressure, turn down the in-house compressed gas source or loosen the pressure handle on the regulator. Push down on the pressure relief at the pneumatic control unit to exhaust excess pressure in the hoses. Then re-adjust pressure as needed.

16

Disassembling the MR7 System

PTSC224

Disassembling the MR7 System Depressurize the System 1. 2.

Turn off the compressed gas at the source. Press the pressure relief button on the pneumatic control unit, to release remaining gas.

WARNING: Do not disassemble equipment before the gas is released from control unit.

Disconnect Hoses Release the motor hose from the control unit, by holding the hose firmly and pressing the motor port connection button. Figure 26: Motor Port Connection and Pressure Relief Buttons

Motor Port Connection Button

Pressure Relief Button

Discard the Lubricant/Diffuser Cartridge Remove the lubricant/diffuser cartridge from the housing and discard it. CAUTION: Do not re-use a lubricant/diffuser cartridge. It is a single-use product.

Remove the Attachment and Tool 1.

Follow the applicable removal instructions in the Installing an Attachment and Tool section of this manual to remove the attachment and tool from the motor.

WARNING: Dissecting tool flutes are sharp and may perforate surgical gloves. Tools may be grasped with a hemostat to aid in installation and removal. 2.

Discard used dissecting tools in an appropriate container.

17