medtronic

Medtronic Navigation Computer Assisted Surgery Systems

Computer-Aided Surgery Systems Equipment Cleaning and Sterilization Instructions Rev 12 Jan 2011

Cleaning and Sterilization Instructions

13 Pages

Preview

Page 1

Computer-Aided Surgery Systems Equipment Cleaning and Sterilization

c

Valid from January 24, 2011; replaces all previous versions

(800) 595-9709 Toll Free (720) 890-3200 Local and International

Equipment Cleaning and Sterilization w Warning: Pre-sterilized single-use devices have the single-use symbol k on the label. Do not reprocess, re-sterilize, or re-use any single-use device. Attempts to re-process or re-sterilize a single-use device may be ineffective and may compromise its structural integrity. Any re-use creates a risk of contamination which could result in patient injury, illness, or death.

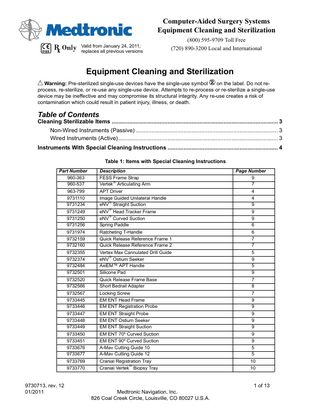

Table of Contents

Cleaning Sterilizable Items ... 3 Non-Wired Instruments (Passive) ... 3 Wired Instruments (Active)... 3 Instruments With Special Cleaning Instructions ... 4 Table 1: Items with Special Cleaning Instructions Part Number 960-363 960-537 963-799 9731110 9731234 9731249 9731250 9731256 9731974 9732159 9732160 9732355 9732374 9732484 9732501 9732520 9732566 9732567 9733445 9733446 9733447 9733448 9733449 9733450 9733451 9733676 9733677 9733769 9733770

9730713, rev. 12 01/2011

Description FESS Frame Strap Vertek® Articulating Arm APT Driver Image Guided Unilateral Handle eNV® Straight Suction eNV® Head Tracker Frame eNV® Curved Suction Spring Paddle Ratcheting T-Handle Quick Release Reference Frame 1 Quick Release Reference Frame 2 Vertex Max Cannulated Drill Guide eNV® Ostium Seeker AxiEM™ APT Handle Silicone Pad Quick Release Frame Base Short Bedrail Adapter Locking Screw EM ENT Head Frame EM ENT Registration Probe EM ENT Straight Probe EM ENT Ostium Seeker EM ENT Straight Suction EM ENT 70º Curved Suction EM ENT 90º Curved Suction A-Mav Cutting Guide 10 A-Mav Cutting Guide 12 Cranial Registration Tray Cranial Vertek® Biopsy Tray

Page Number 9 7 4 4 9 9 9 6 6 7 7 5 9 5 9 7 8 7 9 9 9 9 9 9 9 5 5 10 10

1 of 13 Medtronic Navigation, Inc. 826 Coal Creek Circle, Louisville, CO 80027 U.S.A.

Equipment Cleaning and Sterilization, cont. Table 1: Items with Special Cleaning Instructions Part Number 9733771 9734252 9734259 9734228 9734306 9734307 9734308 9734309 9734310 9734311 9734315 9734410 9734442 9734443 9734444 9734445 9734446 9734447 9734448

Description Cranial Navigation Tray Vertek® II Articulating Arm NavLock™ Tracker (orange) NavLock™ Tracker (gray) EM ENT 45º Frontal Suction EM ENT 90º Frontal Suction EM ENT Straight Suction, Small EM ENT 45º Suction Curette EM ENT 90º Suction Curette EM ENT Elevator NavLock™ Tracker (violet) Ratcheting Egg Handle StealthStation® NavLock™ Tray StealthStation® CD Horizon® Legacy™ Taps and Drivers Tray StealthStation® CD Horizon® Solera™ Taps and Drivers Tray StealthStation® Non-Cannulated Awl-Tip Taps Tray StealthStation® Universal Drill Guide Tray StealthStation® Tactile Probes Tray StealthStation® Spine Referencing Tray

Page Number 10 7 4 4 9 9 9 9 9 9 4 5 13 13 13 13 13 13 13

Steam Sterilization (Autoclave) ... 12 Standard Protocol for Sterilizable Items ... 12 Items With Special Sterilization Instructions ... 12 Table 2: Items with Special Sterilization Instructions Part Number 9660237 9731672 9731968 9731974 9732133 9732175 9732664 9733769 9733770 9733771 9734442

2 of 13

Description Click and Point Handle Pyrametrix Plus Sterilization Tray Ortho Zimmer Knee Tray Ratcheting T-Handle Ortho EM Screwdriver EM Ortho Tracker Holder Ortho Hip Navigation Tray Cranial Registration Tray Cranial Vertek® Biopsy Tray Cranial Navigation Tray

Page Number 12 13 12 12 12 12 12 13 13

StealthStation® NavLock™ Tray

13 13

9734443

StealthStation® CD Horizon® Legacy™ Taps and Drivers Tray

13

9734444

StealthStation® CD Horizon® Solera™ Taps and Drivers Tray

13

9734445

StealthStation Non-Cannulated Awl-Tip Taps Tray

13

9734446

StealthStation® Universal Drill Guide Tray

13

9734447

StealthStation Tactile Probes Tray

13

9734448

StealthStation Spine Referencing Tray

13

®

® ®

01/2011

9730713, rev. 12

Equipment Cleaning and Sterilization, cont.

Cleaning Sterilizable Items Clean the instruments prior to first use and after each use. Before cleaning, disassemble instruments that were assembled from multiple components.

# Caution: Certain instruments have special cleaning requirements that differ from the standard requirements given below. Refer to "Instruments With Special Cleaning Instructions" on page 4. For instruments that are not listed in "Instruments With Special Cleaning Instructions", use the "Non-Wired Instruments (Passive)" or the "Wired Instruments (Active)" cleaning instructions given below.

Non-Wired Instruments (Passive) Note: Remove and properly dispose of the single-use sterile spheres before cleaning. 1. Rinse the instrument under running tap water to remove any visible soil. A soft-bristled brush or clean cloth may be used to aid in soil removal. 2. Prepare an enzymatic-neutral pH detergent per the detergent manufacturer’s recommendations. 3. Immerse the instrument in the enzymatic detergent solution and let it soak for a minimum of three (3) minutes. 4. Thoroughly clean the instrument using a soft-bristled brush. Pay particular attention to any crevices and other hard-to-clean areas to remove all foreign matter. 5. Flush crevices, lumens, and blind holes in the instrument with fresh detergent solution until the solution runs clear. 6. Thoroughly rinse the instrument in deionized (DI) water for a minimum of one (1) minute to remove any residual detergent. 7. Flush crevices, lumens, and blind holes in the instrument with DI water. 8. Dry the instrument with a clean, soft cloth. 9. Examine the instrument for visible soil. If present, repeat cleaning.

Wired Instruments (Active) # Caution: Do not submerge components that contain LEDs or any other electronics (e.g. Linear Registration Probe, Active Cranial Reference Frame), and do not allow liquid to enter the electrical connections. Electronic components may be permanently damaged as a result of submersion. Allow any submerged component 24 hours of air-dry time before attempting to assess damage. 1. Prepare an enzymatic-neutral pH detergent solution per the detergent manufacturer’s recommendations. 2. Soak a clean cloth in the detergent solution and wipe each portion of the instrument (cable and body) for a minimum of three (3) minutes. 3. Thoroughly clean the instrument using a soft-bristled brush. Pay particular attention to crevices and other hard-to-clean areas to remove all foreign matter. 4. Flush crevices, lumens, and blind holes in the instrument with fresh detergent solution until the solution runs clear. 5. Flush the instrument with deionized (DI) water. 6. Soak a clean cloth in DI water and wipe each portion of the instrument (cable and body) for a minimum of two (2) minutes to remove any residual detergent. 7. Dry the instrument with a clean, soft cloth. 8. Examine the instrument for visible soil. If present, repeat cleaning.

3 of 13

01/2011

9730713, rev. 12

Equipment Cleaning and Sterilization, cont.

Instruments With Special Cleaning Instructions Note: Remove and properly dispose of the single-use sterile spheres before cleaning instruments.

Spine 963-799 APT Driver 9734228, 9734259, 9734315 NavLock™ Trackers Remove the APT Handle, the tracker, and the tip or tap from the APT Driver. Clean the APT Driver and the NavLock™ Tracker after each use according to the following instructions: 1. Rinse the device under running tap water to remove visible soil. Actuate the device and scrub with a soft-bristled brush during the rinse. 2. Prepare an enzymatic-neutral pH detergent (such as Enzol® Enzymatic Detergent) solution per the detergent manufacturer’s recommendations and immerse the device in the detergent solution. 3. Actuate the device and scrub with a soft-bristled brush to remove all visible soil while in the detergent solution and allow to soak for five (5) minutes. 4. Rinse the device with deionized (DI) water for one (1) minute. Actuate and flush the device during the rinse. 5. Prepare a fresh enzymatic detergent solution per the detergent manufacturer’s recommendations and place the solution in an ultrasonic cleaner. 6. Immerse the device in the detergent solution and sonicate for fifteen (15) minutes. 7. Rinse the device with deionized (DI) water for one (1) minute. Actuate and flush the device during the rinse. 8. Prepare a fresh enzymatic detergent solution per the detergent manufacturer’s recommendations and place the solution in an ultrasonic cleaner. 9. Immerse the device in the detergent solution and sonicate for an additional fifteen (15) minutes. 10. Rinse the device with deionized (DI) water for one (1) minute. Actuate and flush the device during the rinse. 11. Dry the device with a clean, soft cloth. 12. Examine the device for visible soil. If present, repeat cleaning.

9731110 Image Guided Unilateral Handle Remove the instrument from the handle and clean the handle after each case according to the following instructions: 1. Rinse the handle under running tap water to remove visible soil. A soft-bristled brush or clean cloth may be used to aid in soil removal. 2. Prepare an enzymatic-neutral pH detergent per the detergent manufacturer’s recommendations. 3. Immerse the handle in the prepared enzymatic detergent and actuate the handle by pressing the button. Allow the handle to soak for a minimum of two (2) minutes. 4. Thoroughly clean the handle with a soft-bristled brush, paying particular attention to cracks and crevices to remove all visible soil. Using fresh detergent, flush blind holes. 5. After brushing, rinse the handle in deionized (DI) water for a minimum of one (1) minute. 6. Flush blind holes with DI water while actuating the button. 7. Prepare fresh enzymatic detergent per the detergent manufacturer’s recommendations. 8. Immerse the handle in the prepared enzymatic detergent in an ultrasonic cleaner and sonicate for a minimum of ten (10) minutes.

4 of 13

01/2011

9730713, rev. 12

Equipment Cleaning and Sterilization, cont. 9. After sonication, rinse with DI water for a minimum of one (1) minute. Flush blind holes with DI water while actuating the button. 10. Dry the handle with a clean, soft cloth. 11. Examine the handle for visible soil. If present, repeat cleaning.

9732484 AXIEM™ APT Handle 9733676 A-Mav Cutting Guide 10 9733677 A-Mav Cutting Guide 12 9734410 Ratcheting Egg Handle Remove the AXIEM™ Tip or Tap from the AXIEM™ APT Handle assembly. Do not unscrew the spring retention screw from the rear of the handle. Remove and properly dispose of the AXIEM™ Stylet. Clean the handle according to the following instructions: 1. Rinse the device under running tap water to remove visible soil. A soft-bristled brush or clean cloth may be used to aid in soil removal. 2. Prepare enzymatic-neutral pH detergent per the detergent manufacturer’s recommendations. 3. Immerse the device in the prepared enzymatic detergent and actuate the device by sliding the chuck mechanism back and forth. Allow the device to soak for a minimum of three (3) minutes. 4. Thoroughly clean the device with a soft-bristled brush paying particular attention to crevices and other hard-to-clean areas to remove all visible soil. 5. Using fresh detergent, flush blind holes and lumens. 6. Rinse the device thoroughly with deionized (DI) water for a minimum of one (1) minute to remove all residual detergent. 7. Flush all blind holes and lumens with DI water. 8. Prepare fresh enzymatic detergent per the detergent manufacturer’s instructions. 9. Immerse the device in the prepared detergent in an ultrasonic cleaner and sonicate for a minimum of ten (10) minutes. 10. After sonication, rinse the device in DI water for a minimum of one (1) minute. 11. Flush blind holes and lumens with DI water while actuating the chuck. 12. Dry the device with a clean, soft cloth. 13. Examine the device for visible soil. If present, repeat cleaning.

9732355 Vertex Max Cannulated Drill Guide 1. Unscrew and remove the trocar (9733139) from the drill tube (9733140), and then unscrew and remove the drill tube from the drill guide. 2. Detach the handle assembly. a. Rotate the handle so that it almost touches one side of the tracker. b. Slide the handle assembly off of the shaft of the drill guide. 3. Remove the adjustable stop (9733332) from the drill bit or tap. 4. After disassembling the device, clean according to the instructions for “Non-Wired Instruments (Passive)” on page 3. 5. After cleaning, reattach the handle assembly to the drill guide shaft. 6. Place the reassembled drill guide, the trocar, the drill tube, and the adjustable stop in their appropriate positions in the sterilization tray, and then sterilize according to the instructions for “Steam Sterilization (Autoclave)” on page 12. 5 of 13

01/2011

9730713, rev. 12

Equipment Cleaning and Sterilization, cont.

Orthopaedics 9731256 Spring Paddle 1. Rinse the instrument base under running tap water to remove visible soil. Do not immerse the active tracker or cable of the instrument. A softbristled brush or clean cloth may be used to aid in soil removal. 2. Prepare an enzymatic-neutral pH detergent per the detergent manufacturer’s instructions. Immerse the Spring Paddle base (up to 25 mm) in the prepared enzymatic detergent and soak for a minimum of three (3) minutes. Do not soak the active tracker or the cable in the enzymatic detergent. 3. Prepare another enzymatic-neutral pH detergent per the detergent manufacturer’s instructions. Soak a clean cloth in the prepared enzymatic detergent and wipe the cable and tracker of the Spring Paddle for a minimum of three (3) minutes. 4. Thoroughly clean the instrument with a soft-bristled brush paying particular attention to crevices and other hard-to-clean areas to remove all visible soil. 5. Repeatedly flush fresh enzymatic detergent into blind holes, cracks, and crevices until the solution runs clear. 6. Thoroughly rinse the base with deionized (DI) water for a minimum of one (1) minute to remove all residual detergent. Do not immerse the tracker portion or cable of the instrument. 7. Soak a clean cloth in DI water and wipe the cable and tracker of the Spring Paddle for a minimum of two (2) minutes to remove all residual detergent. 8. Dry the device with a clean, soft cloth. 9. Examine the instrument for visible soil. If present, repeat cleaning.

9731974 Ratcheting T-Handle Remove the drive key and clean the Ratcheting T-handle after each use according to the instructions given here. Note: Clean the drive key according to the instructions for “Non-Wired Instruments (Passive)” on page 3. 1. Rinse the device under running tap water to remove visible soil. A softbristled brush or clean cloth may be used to aid in soil removal. 2. Prepare an enzymatic-neutral pH detergent per the detergent manufacturer’s instructions. 3. Immerse the device in the prepared enzymatic detergent and actuate the device by sliding the chuck mechanism back and forth. Allow the device to soak for a minimum of three (3) minutes. 4. Thoroughly clean the device with a soft-bristled brush and a pipe cleaner. Pay particular attention to crevices and other hard-to-clean areas to remove all visible soil. 5. Using fresh detergent, flush blind holes and lumens. 6. Rinse the device thoroughly with de-ionized (DI) water for a minimum of one (1) minute to remove all residual detergent. Flush all blind holes and lumens with DI water. 7. Prepare fresh enzymatic detergent per manufacturer’s instructions. Immerse the device in the prepared detergent in an ultrasonic cleaner and sonicate for a minimum of fifteen (15) minutes. 8. After sonication, rinse the device in DI water for a minimum of one (1) minute. Flush blind holes and lumens with DI water while actuating the chuck. 9. Dry the device with a clean, soft cloth. 10. Examine the device for visible soil. If present, repeat cleaning starting at step 2.

6 of 13

01/2011

9730713, rev. 12

Equipment Cleaning and Sterilization, cont.

9732159 Quick Release Reference Frame 1 9732160 Quick Release Reference Frame 2 9732520 Quick Release Frame Base 9732567 Locking Screw 1. Disengage the Frame from the Base, remove the Locking Screw from the Base, and loosen the Indexing Knob. 2. Rinse the device components under running tap water to remove any visible soil. A soft-bristled brush or clean cloth may be used to aid in soil removal. 3. Prepare an enzymatic-neutral pH detergent per the detergent manufacturer’s recommendations. Immerse the device components in the prepared enzymatic detergent solution, actuate the device, and let it soak for a minimum of three (3) minutes. 4. Thoroughly clean the exterior of the device components with a soft-bristled brush. Use a pipe cleaner and syringe to clean the lumens. Pay particular attention to crevices and other hard-to-clean areas to remove all visible soil. 5. Flush crevices, lumens, and blind holes in the device with fresh detergent solution until the solution runs clear. 6. Thoroughly rinse the device components in deionized (DI) water for a minimum of one (1) minute to remove any residual detergent. 7. Flush crevices, lumens, and blind holes in the device components with deionized (DI) water. 8. Prepare fresh enzymatic detergent solution per manufacturer’s recommendations. Immerse the Frame and Base in the prepared detergent solution in an ultrasonic cleaner and sonicate for a minimum of ten (10) minutes. 9. After sonication, rinse the Frame and Base in DI water for a minimum of one (1) minute. Flush blind holes and lumens with DI water. 10. Dry the device components with a clean, soft cloth. 11. Examine the device components for visible soil. If present, repeat cleaning starting at step 3.

Cranial 960-537 Vertek® Articulating Arm 9734252 Vertek® II Articulating Arm After each use, remove all instrumentation from the articulating arm and follow the appropriate instructions below for cleaning and sterilization. • Use the Noncritical Use cleaning instructions if the arm is not to be used in the sterile field and has not come in contact with broken skin or mucous membranes. • Use the Critical Use cleaning and sterilization instructions in all other cases.

w Warning: Do not manually apply lubricant to the articulating arm. Instrument milk may be used in an automatic wash cycle. Noncritical Use Cleaning Instructions After non-critical use and when not intended for future sterile use, wipe the articulating arm thoroughly using an enzymatic neutral pH detergent, rinse-free detergent, or mild disinfectant, per the manufacturer’s recommendations for that agent.

7 of 13

01/2011

9730713, rev. 12

Equipment Cleaning and Sterilization, cont. Critical Use Cleaning Instructions

# Caution: Do not use ultrasonic cleaning; it may impair the performance of the device. Automatic Cleaning 1. Prior to placing the device into the washer, thoroughly rinse the device while actuating all joints under running tap water to remove gross contamination. 2. Run the automatic cleaning cycle. Refer to the following table for cycle parameters. Phase Pre-wash 1 Enzyme wash

Recirculation (min) 02:00 02:00

Water Temperature Cold tap water Hot tap water

Detergent Type and Concentration N/A

Wash 1

02:00

66°C

Rinse 1 PURW rinse

00:15 00:10

Hot tap water 66°C

Renu-Klenz®, 1/4 oz/gallon, or equivalent neutral pH detergent N/A N/A

Enzol®, 1 oz./gallon, or equivalent neutral pH enzymatic detergent

Manual Cleaning 1. Remove visible soil by rinsing the device under running tap water while actuating all joints. You may use a soft-bristled brush or clean cloth to aid in the removal of soil. 2. Prepare neutral pH enzymatic detergent (follow manufacturer's instructions). Immerse the device in the prepared enzymatic detergent, actuate the device and allow it to soak for a minimum of 10 minutes. 3. Thoroughly clean the device exterior with a soft bristle brush. Pay particular attention to crevices and other hard-to-clean areas to remove all visible soil. 4. Using fresh detergent and a syringe, repeatedly flush blind holes and cracks until the solution runs clear. 5. Rinse the device thoroughly with DI water for a minimum of 1 minute to remove all residual detergent. 6. Using a syringe, flush blind holes, cracks, and ball joints with DI water. 7. Dry the device using a clean, soft cloth. 8. Examine the device for visible soil. If soil is observed, repeat cleaning. 9. After cleaning, sterilize the device according to the instructions for “Steam Sterilization (Autoclave)” on page 12.

9732566 Short Bedrail Adapter The Short Bedrail Adapter is ordinarily draped during the procedure. However, if cleaning becomes necessary, disassemble the device first: 1. Remove the three (3) screws used to attach the starburst to the adapter. 2. Remove the screw that holds the handle to the adapter and disassemble the washers, compression spring, clamp screw, and clamp block. 3. After disassembling the device, clean according to the instructions for “Non-Wired Instruments (Passive)” on page 3. 4. After cleaning, sterilize the device according to the instructions for “Steam Sterilization (Autoclave)” on page 12.

8 of 13

01/2011

9730713, rev. 12

Equipment Cleaning and Sterilization, cont.

ENT 960-363 FESS Frame Strap 9731234 eNV® Straight Suction 9731249 eNV® Head Tracker Frame 9731250 eNV® Curved Suction 9732374 eNV® Ostium Seeker 9732501 Silicone Pad 9733445 EM ENT Head Frame EM ENT Instrument Set

9733446 EM ENT Registration Probe 9733447 EM ENT Straight Probe 9733448 EM ENT Ostium Seeker 9733449 EM ENT Straight Suction 9733450 EM ENT 70° Curved Suction 9733451 EM ENT 90° Curved Suction EM ENT Supplemental Instrument Set

9734306 EM ENT 45° Frontal Suction 9734307 EM ENT 90° Frontal Suction 9734308 EM ENT Small Straight Suction 9734309 EM ENT 45° Suction Curette 9734310 EM ENT 90° Suction Curette 9734311 EM ENT Elevator Remove and properly dispose of the single-use sterile spheres and the adhesive pad before cleaning the eNV® Head Tracker. 1. Promptly and thoroughly rinse the device with deionized (DI) water to remove visible soil. A soft-bristled brush or clean cloth may be used to aid in soil removal. 2. Prepare an enzymatic-neutral pH detergent per the detergent manufacturer's recommendations. 3. Immerse the device in the prepared enzymatic detergent and soak for a minimum of two (2) minutes. 4. Thoroughly clean device components with a soft-bristled brush. Pay particular attention to crevices and other hard-toclean areas to remove all visible soil. 5. Repeatedly flush blind holes, lumens, cracks, and crevices with fresh enzymatic detergent solution until the solution runs clear. 6. Thoroughly rinse device components with DI water for a minimum of one (1) minute to remove all residual detergent. 7. Prepare fresh enzymatic detergent per the detergent manufacturer's recommendations. 8. Immerse the device in the prepared enzymatic detergent in an ultrasonic cleaner and sonicate for a minimum of ten (10) minutes. 9. After sonication, rinse the device in DI water for a minimum of one (1) minute. 10. Flush blind holes and lumens with DI water. 11. Dry the device with a clean, soft cloth. 12. Examine device components for visible soil. If present, repeat cleaning.

9 of 13

01/2011

9730713, rev. 12

Equipment Cleaning and Sterilization, cont.

Trays 9733769 Cranial Registration Tray 9733770 Cranial Vertek® Biopsy Tray 9733771 Cranial Navigation Tray 9734442 StealthStation® NavLock™ Tray 9734443 StealthStation® CD Horizon® Legacy™ Taps and Drivers Tray 9734444 StealthStation® CD Horizon® Solera™ Taps and Drivers Tray 9734445 StealthStation® Non-Cannulated Awl-Tip Taps Tray 9734446 StealthStation® Universal Drill Guide Tray 9734447 StealthStation® Tactile Probes Tray 9734448 StealthStation® Spine Referencing Tray To clean the trays: 1. Unlatch and remove the container’s lid. 2. Inspect the gasket inside the lid to make sure that the fit is accurate and the surface is undamaged. Do not remove the gasket to clean the tray. w Warning: Do not use the tray if the gasket is damaged. 3. Remove the tray of instruments and clean them according to the instructions for “Non-Wired Instruments (Passive)” on page 3. 4. Remove the four filter retention plates by turning the handle of each locking mechanism clockwise. 5. Inspect the gaskets in each filter retention plate. w Warning: Do not use the tray if any gasket is damaged. 6. Place the filter retention plates in a basket for cleaning. 7. Discard all single-use, disposable items including filters, chemical indicators, and load cards. 8. Clean the tray and filter retention plates in an automatic washer-decontaminator. Use a pH-neutral detergent and follow the washer manufacturer’s instructions concerning correct use and secure positioning of the items. Try to avoid water collection by washing and drying the tray upside down. # Caution: Do not use alkaline detergents or scratch pads because they will damage the aluminum. Note: If necessary, you may clean the tray and filter retention plates manually with a soft cloth moistened with a pH-neutral detergent. Thoroughly rinse the tray and plates to remove all detergent because detergent residue can adversely affect the container’s appearance. Lubricate the latching mechanism with pH-neutral instrument lubricant. 9. Use a soft cloth to dry the tray and the filter retention plates. To prepare these trays for sterilization: 1. Inspect the following components before each sterilization cycle: a. Make sure that the gaskets in the lid and in the filter retention plates are pliable, do not have cracks or tears, and are properly and firmly affixed. Do not use the tray if any gasket is damaged. b. Make sure that all retention plates are secure. If a plate is loose, adjust the tension by pressing downward along the plate’s perimeter. c. Make sure that the filter retention posts in the lid and label holders on the front of the container are secure. 2. You need two circular filters (Case Medical pn SCF01) for the container's base. Place one filter over each set of perforations in the base and place a filter retention plate over each filter. Note: Filters are single-use only. Discard filters after one use.

10 of 13

01/2011

9730713, rev. 12

Equipment Cleaning and Sterilization, cont. 3. Secure the filter retention plates by pushing downwards at the center and rotating the handle counter-clockwise until you hear it click. 4. Arrange the clean instruments in the baskets. w Warning: The instrument part numbers are printed on each basket. Place only the listed instruments in the tray. Placing additional items in the tray affects sterilization efficacy and dry time. 5. Place the baskets in the base of the container. Make sure that the part number on the basket matches the part number on the base. 6. Place a chemical indicator (Case Medical pn SCI001) in the corner of the instrument basket. 7. You need two circular filters for the container's lid. Place one filter over each set of perforations in the lid and place a filter retention plate over each filter. 8. Secure the filter retention plates by pushing downwards at the center and rotating the handle counterclockwise until you hear it click. 9. Place the lid on the base. 10. On both sides of the container, position the top of the latch over the ridge in the lid and push the bottom section of the latch in toward the container. You will feel a solid click. 11. Place the appropriate metal ID tags in the label holders located on either side of the container latches. Use a load card (Case Medical pn SCL01) in the label holder on the right. 12. Thread the guide on the tamper-evident seal (Case Medical pn SCS01) through the lock holder and secure it. Repeat this process on the other latch. # Caution: Using a non-approved tamper-evident seal could damage the locking clip. 13. Place the container flat on the shelf of the sterilizer cart. If necessary, up to three containers may be stacked and processed in an autoclave. w Warning: Do not wrap the tray. 14. Sterilize the tray according to the “Items With Special Sterilization Instructions” on page 12. When you are ready to use the sterilized tray: 1. Before you open the tray, make sure that: a. The tamper-evident seals are intact. b. The external chemical indicators have changed color to indicate that the tray was steam sterilized. c. You have selected the correct instrument set. 2. Break the tamper-evident seals and discard them. 3. Unlatch the container. 4. Use the rings at the top of the lid to remove the lid. Using the rings avoids contaminating the container’s contents. 5. Check the internal chemical indicator to make sure that it has changed color to indicate that the tray was steam sterilized. 6. Remove the basket of instruments and place it in the sterile field.

11 of 13

01/2011

9730713, rev. 12

Equipment Cleaning and Sterilization, cont.

Steam Sterilization (Autoclave) Standard Protocol for Sterilizable Items Medtronic Navigation instruments are designed to withstand at least 100 steam sterilization cycles when sterilized using recommended parameters.

w Warning: The recommended sterilization parameters are only valid with equipment that is properly maintained and calibrated.

w Warning: Instruments cannot be sterilized to an adequate Sterility Assurance Level (SAL) without prior cleaning and decontamination. # Caution: Sterilize instruments using the following parameters for steam, subject to the exceptions listed in the "Items With Special Sterilization Instructions" section on page 12. Prevacuum cycle (See also Alternative Prevacuum cycle, below)

• Temperature: 270°F (132° C) • Steam time: Five (5) minutes • Minimum dry time: Thirty (30) minutes* • Wrapped or unwrapped (Flash) configuration** Gravity cycle

• Temperature: 270°F (132° C) • Steam time: Fifteen (15) minutes • Minimum dry time: Thirty (30) minutes* • Wrapped or unwrapped (Flash) configuration** Alternative Validated Prevacuum cycle (Required in some countries)

• Temperature: 134°C (273°F) • Steam time: Eighteen (18) minutes • Minimum dry time: Thirty (30) minutes* • Wrapped or unwrapped (Flash) configuration** * Minimum dry time is required with wrapped configurations only. ** Flash sterilization should only be performed following proper cleaning and decontamination. Note: Because of the variability in cleaning efficiencies and sterilizer operating parameters, all given parameters (temperature, time, etc.) should be validated by persons who have training and expertise in sterilization processes. Deviation from the recommended sterilization processes is at the risk of the user facility.

Items With Special Sterilization Instructions 9732664 and 9732540 Ortho Hip Navigation Tray and Instrument Set 9660237 Click and Point Handle 9731974 Ratcheting T-Handle 9732133 Ortho EM Screwdriver 9732175 EM Ortho Tracker Holder These items may be sterilized using a four (4) minute prevacuum cycle. (Use standard temperature and dry time.) 9731968 Ortho Zimmer Knee Tray Sterilize using standard parameters for prevacuum steam sterilization, or use gravity steam sterilization with a cycle time of twenty (20) minutes. (Use standard temperature and dry time.)

12 of 13

01/2011

9730713, rev. 12

Equipment Cleaning and Sterilization, cont. 9733769 Cranial Registration Tray 9733770 Cranial Vertek® Biopsy Tray 9733771 Cranial Navigation Tray Sterilize these cranial trays using standard parameters for prevacuum steam sterilization, or use gravity steam sterilization with a cycle time of thirty (30) minutes. (Use standard temperature and dry time.) These items may be sterilized using a four (4) minute prevacuum cycle. (Use standard temperature and dry time.) 9734442 StealthStation® NavLock™ Tray 9734443 StealthStation® CD Horizon® Legacy™ Taps and Drivers Tray 9734444 StealthStation® CD Horizon® Solera™ Taps and Drivers Tray 9734445 StealthStation® Non-Cannulated Awl-Tip Taps Tray 9734446 StealthStation® Universal Drill Guide Tray 9734447 StealthStation® Tactile Probes Tray 9734448 StealthStation® Spine Referencing Tray Sterilize these spine trays using standard parameters for prevacuum steam sterilization, or use gravity steam sterilization with a cycle time of fifty (50) minutes. (Use standard temperature and dry time.) These items may be sterilized using a four (4) minute prevacuum cycle. (Use standard temperature and dry time.) Pyrametrix Plus Sterilization Tray 9731672 and 9731673 Outer Sterilization Tray and Lid 9731675 and 9731816 Spine Reference Frame and Clamps Tray and Lid 9731815 and 9731814 Percutaneous Reference Pin Sterilization Tray and Lid When sterilizing items in these trays, use a seven (7) minute prevacuum cycle or a thirty (30) minute gravity cycle. (Use standard temperature and dry time.)

13 of 13

01/2011

9730713, rev. 12