medtronic

POWEREASE Driver Reprocessing Instructions

1 Page

Preview

Page 1

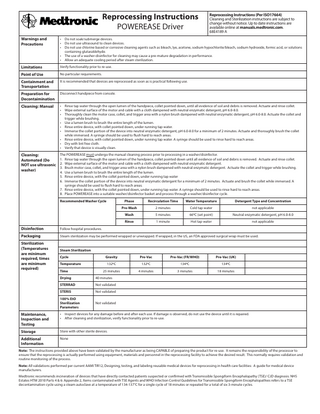

Reprocessing Instructions POWEREASE Driver Warnings and Precautions

• • • • •

Do not soak/submerge devices. Do not use ultrasound to clean devices. Do not use chlorine based or corrosive cleaning agents such as bleach, lye, acetone, sodium hypochlorite/bleach, sodium hydroxide, formic acid, or solutions containing glutaraldehyde. The use of a washer-disinfector for cleaning may cause a pre-mature degradation in performance. Allow an adequate cooling period after steam sterilization.

Limitations

Verify functionality prior to re-use.

Point of Use

No particular requirements.

Containment and Transportation

It is recommended that devices are reprocessed as soon as is practical following use.

Preparation for Decontaimination

Disconnect handpiece from console.

Cleaning: Manual

• • • • • • • • •

Cleaning: Automated (Do NOT use ultrasonic washer)

Reprocessing Instructions (Per ISO17664) Cleaning and Sterilization instructions are subject to change without notice. Up to date instructions are available online at manuals.medtronic.com. 68E4189 A

Rinse tap water through the open lumen of the handpiece, collet pointed down, until all evidence of soil and debris is removed. Actuate and rinse collet. Wipe external surface of the motor and cable with a cloth dampened with neutral enzymatic detergent, pH 6.0-8.0. Thoroughly clean the motor case, collet, and trigger area with a nylon brush dampened with neutral enzymatic detergent, pH 6.0-8.0. Actuate the collet and trigger while brushing. Use a lumen brush to brush the entire length of the lumen. Rinse entire device, with collet pointed down, under running tap water. Immerse the collet portion of the device into neutral enzymatic detergent, pH 6.0-8.0 for a minimum of 2 minutes. Actuate and thoroughly brush the collet while immersed. A syringe should be used to flush hard to reach areas. Rinse entire device, with collet pointed down, under running tap water. A syringe should be used to rinse hard to reach areas. Dry with lint free cloth. Verify that device is visually clean.

The POWEREASE must undergo the manual cleaning process prior to processing in a washer/disinfector. 1. Rinse tap water through the open lumen of the handpiece, collet pointed down until all evidence of soil and debris is removed. Actuate and rinse collet. 2. Wipe external surface of the motor and cable with a cloth dampened with neutral enzymatic detergent. 3. Brush motor case, collet, and trigger area with a nylon brush dampened with neutral enzymatic detergent. Actuate the collet and trigger while brushing. 4. Use a lumen brush to brush the entire length of the lumen. 5. Rinse entire device, with the collet pointed down, under running tap water 6. Immerse the collet portion of the device into neutral enzymatic detergent for a minimum of 2 minutes. Actuate and brush the collet while immersed. A syringe should be used to flush hard to reach areas. 7. Rinse entire device, with the collet pointed down, under running tap water. A syringe should be used to rinse hard to reach areas. 8. Place POWEREASE into a suitable washer/disinfector basket and process through a washer/disinfector cycle. Recommended Washer Cycle

Phase

Recirculation Time

Water Temperature

Detergent Type and Concentration

Pre-Wash

2 minutes

Cold tap water

not applicable

Wash

5 minutes

660C (set point)

Neutral enzymatic detergent, pH 6.0-8.0

Rinse

1 minute

Hot tap water

not applicable

Disinfection

Follow hospital procedures.

Packaging

Steam sterilization may be performed wrapped or unwrapped. If wrapped, in the US, an FDA approved surgical wrap must be used.

Sterilization (Temperatures are minimum required, times are minimum required)

Steam Sterilization Cycle

Gravity

Pre-Vac

Pre-Vac (FR/WHO)

Pre-Vac (UK)

Temperature

1320C

1320C

1340C

1340C

25 minutes

4 minutes

3 minutes

18 minutes

Time Drying

40 minutes

STERRAD

Not validated

STERIS

Not validated

100% EtO Sterilization Parameters

Not validated

Maintenance, Inspection and Testing

• •

Storage

Store with other sterile devices.

Additional Information

None

Inspect devices for any damage before and after each use. If damage is observed, do not use the device until it is repaired. After cleaning and sterilization, verify functionality prior to re-use.

Note: The instructions provided above have been validated by the manufacturer as being CAPABLE of preparing the product for re-use. It remains the responsibility of the processor to ensure that the reprocessing is actually performed using equipment, materials and personnel in the reprocessing facility to achieve the desired result. This normally requires validation and routine monitoring of the process. Note: All validations performed per current AAMI TIR12, Designing, testing, and labeling reusable medical devices for reprocessing in health care facilities: A guide for medical device manufacturers. Medtronic recommends incineration of devices that have directly contacted patients suspected or confirmed with Transmissible Spongiform Encephalopathy (TSE)/ CJD diagnosis. NHS Estates HTM 2010 Parts 4 & 6: Appendix 2, Items contaminated with TSE Agents and WHO Infection Control Guidelines for Transmissible Spongiform Encephalopathies refers to a TSE decontamination cycle using a steam autoclave at a temperature of 134-137°C for a single cycle of 18 minutes or repeated for a total of six 3-minute cycles.