MicroAire

Orthopaedic Power Systems

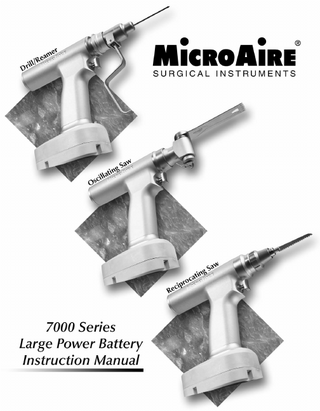

7000 Series Large Power Battery Instrument System Instruction Manual Rev A March 2002

Instruction Manual

24 Pages

Preview

Page 1

- TABLE OF CONTENTS -

Instruction Manual For 7000 Series Large Power Battery Instrument System

7500 Drill/Reamer Handpiece ...1 Drive Couplers...4 7600 Oscillating Saw Handpiece...9 7700 Reciprocating Saw ...15 7500-710 Battery Pack...17 7025 Direct Power Console ...18 Cleaning and Sterilization ...19 Symbol Information ...20 Warranty and Contact Information ...21

- STANDARDS The 7500 Drill/Reamer has been tested to meet the following standards:

5

UL 2601-1

WITH RESPECT TO ELECTRIC SHOCK, FIRE, MECHANICAL HAZARD ONLY IN ACCORDANCE WITH UL 2601-1 AND CAN/CSA C22.2 No. 601.1 EN 60601-1 / IEC 601-1 EN 60601-1-2, DIN EN 60601-1-2, (VDE 0750 part 1-2) EN 55011, Din VDE 0875 part 11 Limiting values of class A, group 1

- ENVIRONMENTAL CONDITIONS Temperature

Operation 32-115°F 0-50°C

Storage and Transportation 0-122°F -20-70°C

Relative Humidity

10-100%

10-75%

Atmospheric Pressure

High Torque Output*:

0-250 rpm, 0-150 in-lb (16.9 Newton Meters)

High Speed Output*:

0-750 rpm, 0-50 in-lb (5.6 Newton Meters)

Cannulation:

.200” (5.0mm)

Weight(not including battery):

2.56 lbs. (1161g)

Battery Weight:

1.59 lbs. (721g)

Battery Power:

14.4 volts

Duty Cycle:

Short time operation only. Two minutes running, allow to cool to room temperature.

*Values are typical. Actual values may vary.

DRILL/REAMER

- TECHNICAL DATA -

1

- INSTRUMENT COMPONENTS -

1 2

4

3 Item Description 1 2 3 4

Coupler Lock Trigger/ Safety Lock Forward / Reverse Control Battery Release Button

MICROAIRE INSTRUCTION MANUAL

- OPERATING CONTROLS -

2

Trigger The Drill/Reamer operates at variable speeds and is controlled by depressing the trigger. The instrument is in the OFF position when the trigger is not depressed. As the trigger is depressed fully the speed increases from 0% to 100%. Forward / Reverse Control The Drill/Reamer will operate in both forward (counterclockwise as viewed from the front end of the instrument), and reverse (clockwise as viewed from the front end of the instrument). The direction is selected with the Forward / Reverse Control switch located on the front base of the instrument. To select the forward direction, move the control switch to the R or ‘F’ position. To select the reverse direction, move the control switch to the F or ‘R’ position. Safety Lock The safety lock is provided to help prevent inadvertent activation Safety OFF of the handpiece when it is not in use and when loading and unloading cutting accessories or drive couplers. To place the safety lock in the ON position, simply rotate the trigger from the vertical position.

Safety ON

Battery Attachment The 7500 Drill/Reamer must have a fully charged 7500-710 battery installed before each use. To attach the battery to the handpiece, place the battery under the base of the instrument with the longer side facing the rear of the instrument. Firmly push the battery into the base of the handpiece until the battery latch clicks into place.

Battery Release Button

Long Side of Battery

Handpiece Base

Drive Coupler Attachment The Drill / Reamer is a two-speed, multi-purpose handpiece with a selection of quick-connect Drive Couplers. The couplers automatically key to the correct drive speed (250rpm or 750rpm). The couplers are designed to accept all standard orthopedic attachments such as Zimmer®, Hudson®, Aesculap®, A.O. Synthes®, Trinkle®, or Jacobs®.

Driver Coupler

DRILL/REAMER

Coupler Lock

3

C Caution • Check Safety Lock and Trigger before operating the handpiece. If the Trigger should stick in the depressed “ON” position, do not use the handpiece. Immediately remove the battery. Return the instrument to the factory for service. Always use the Safety Lock when the instrument is not running. • Check that the Battery is fully seated and locked. • Check Forward / Reverse Control. • Make sure that the Drive Coupler and Attachment are firmly locked in place by testing at low speed. When using a reaming attachment or driving a large pin, keep both hands on the handpiece and advance the trigger slowly to control the reactive torque. • When driving Steinmann pins, use caution to avoid the sharp point that may protrude from the rear cannulation of the instrument.

C Warning • Risk of fire. Replace battery pack only with a MicroAire® 7500-710 Battery Pack. • Explosion hazard. Not suitable for use in the presence of flammable anesthetics or oxygen. • Type BF rating may only be maintained if the instrument is not used to bridge between the patient and ground. • Use care to ensure that there is no electromagnetic interference between this device and other devices in use.

C Note • The 7500 Drill/Reamer, 7600 Oscillating Saw, and 7700 Reciprocating Saw have been designed and tested to also operate with the 7025 Direct Power Console.

MICROAIRE INSTRUCTION MANUAL

- DRIVE COUPLERS FOR 7500 DRILL/REAMER -

4

The 7500 Drill/Reamer has a selection of Drive Couplers that provide a choice of fittings (Hudson®, Zimmer®, Aesculap®, A.O. Synthes®, Trinkle®, and Jacobs®). The drive couplers automatically select the correct speed from the handpiece, 250 or 750 rpm. Connect Drive Couplers To connect a Drive Coupler to the handpiece, pull back the collar on the front of the handpiece, insert the coupler with a twist motion until you feel the coupler lock into position as the collar is released. The drive coupler is not locked until the base of the drive coupler is flush with the released locking collar. Drilling Couplers 7100-003 Jacobs 1/4” (6.35mm) Drill Coupler

750 rpm

7100-002 Trinkle Drive Coupler

750 rpm 7100-006 A.O. Synthes Quick Connect Drill Coupler

750 rpm 7100-004 1/4” (6.35mm) Keyless Drill Coupler

750 rpm 7100-005 1/8” (3.17mm) Keyless Drill Coupler

750 rpm

C Warning Keyless couplers may loosen if used in reverse in high torque applications. 7100-051 Zimmer Coupler

7100-058 Hudson Coupler

750 rpm

DRILL/REAMER

750 rpm

5

Reaming Couplers 7100-001 Zimmer Reamer Coupler

250 rpm 7100-008 Hudson Reamer Coupler

250 rpm 7100-011 Harris/Aesculap Reamer Coupler

250 rpm 7100-111 A.O. Synthes Reaming Coupler

MICROAIRE INSTRUCTION MANUAL

250 rpm

6

7100-112 A.O Synthes Non-reversing Reaming Coupler

250 rpm

- WIRE AND PIN DRIVING To insert a K-wire or Steinmann pin into the drive couplers: 1. 2. 3. 4. 5.

Make sure safety lock is on by turning the trigger to either side. Attach wire or pin coupler to Drill/Reamer. Insert wire or pin into the front or back of the handpiece. Squeeze the wire/pin advance lever to hold wire/pin in place. Depress the trigger while holding advance lever to drive wire/pin.

6. Release advance lever and pull back on handpiece to advance more wire/pin. 7. Use reverse when removing THREADED wire/pin. Hold advance lever and depress trigger while pulling back on the handpiece.

7100-045 Wire Driver Coupler

750 rpm Accepts wires from 1/16” - 7/64” (1.6mm - 2.8mm) 7100-050 Pin Driver Coupler

750 rpm Accepts pins from 1/8” - 5/32” (3.2mm - 4.0mm)

750 rpm High torque for larger pins.

DRILL/REAMER

7100-003 Jacobs 1/4” (6.35mm) Drive Coupler

7

- SCREWDRIVING 7100-002 Trinkle Drive Coupler

750 rpm

- BITS 4100-021 - Screwdriver Bit Holder. 4100-023 - Screwdriver Bit Holder. 4100-024 - Single Slot Screwdriver Bit. 4100-025 - Phillips Screwdriver Bit. 4100-026 - Cruciate Screwdriver Bit. 4100-027 - A.S.I.F. Screwdriver Bit.

C Note 4100-023 Automatic Screwdriver Bit Holder only works with 4100-027 A.S.I.F. Screwdriver Bit.

MICROAIRE INSTRUCTION MANUAL

4100-021 Automatic Screwdriver Bit Holder works with 4100-024 Single Slot Screwdriver Bit, 4100-025 Phillips Screwdriver Bit, and 4100-026 Cruciate Screwdriver Bit.

8

Use either the complete automatic screwdriver assembly or only the bit. Note that the automatic screwdriver assembly provides partial protection from over-torquing the screw. 1. Assemble the bit holder with the proper screwdriver bit only. 2. Unscrew back portion of automatic bit holder and remove. (End opposite white end) 3. Insert the screwdriver bit into the bit holder with the working end of the screwdriver pointing in the direction of the white end of the bit holder. 4. Screw end back on bit holder, over the end of the screwdriver bit. 5. Insert assembled screwdriver assembly into the Trinkle Coupler 7100-002. 6. Push the bit holder over the screw head until the screw is held in place without falling out. 7. Start handpiece slowly to gauge speed. Put in reverse to remove screw if necessary. 8. When bit holder touches the bone, it will snap back. Remove the screwdriver and handtighten.

- STANDARDS The 7600 Oscillating saw has been tested to meet the following standards:

5

UL 2601-1

WITH RESPECT TO ELECTRIC SHOCK, FIRE, MECHANICAL HAZARD ONLY IN ACCORDANCE WITH UL 2601-1 AND CAN/CSA C22.2 No. 601.1 EN 60601-1 / IEC 601-1 EN 60601-1-2, DIN EN 60601-1-2, (VDE 0750 part 1-2) EN 55011, Din VDE 0875 part 11 Limiting values of class A, group 1

- ENVIRONMENTAL CONDITIONS Temperature

Operation 32-115°F 0-50°C

Storage and Transportation 0-122°F -20-70°C

Relative Humidity

10-100%

10-75%

Atmospheric Pressure

Blade Speed:*

0-15,000 cpm

Blade Arc:

4°

Weight (not including battery):

2.76 lbs. (1252g)

Battery Weight:

1.59 lbs. (721g)

Battery Power:

14.4 volts

Duty Cycle:

Short time operation only. Two minutes running, allow to cool to room temperature.

*Values are typical. Actual values may vary.

OSCILLATING SAW

- TECHNICAL DATA -

9

- INSTRUMENT COMPONENTS -

Item Description 1 2 3 4

Blade Mount Load/Unload Latch Trigger/ Safety Lock Battery Release Button

MICROAIRE INSTRUCTION MANUAL

- OPERATING CONTROLS -

10

The 7600 Oscillating Saw is a specially designed instrument primarily for knee replacement surgery. The saw has a rugged high speed oscillating mechanism to drive the extra long and wide saw blades required for total knee osteotomies. The saw can also be used for hip osteotomies and other orthopedic applications. The MicroAire 7600 Oscillating Saw can also be used with revision sternum blades. Trigger The Oscillating Saw operates at variable speeds and is controlled by depressing the trigger. The instrument is in the OFF position when the trigger is not depressed. As the trigger is depressed fully the speed increases from 0% to 100%. Safety Lock The safety lock is provided to help prevent inadvertent activation Safety OFF of the handpiece when it is not in use and when loading and unloading cutting accessories or drive couplers. To place the safety lock in the ON position, simply rotate the trigger from the vertical position.

Safety ON

Battery Attachment The 7600 Oscillating Saw must have a fully charged 7500-710 battery installed before each use. To attach the battery to the handpiece, place the battery under the base of the instrument with the longer side facing the rear of the instrument. Firmly push the battery into the base of the handpiece until the battery latch clicks into place. Please refer to illustration on page 3 of this manual. Saw Blade Load / Unload Mechanism Use only MicroAire® ZO series 7000 Blades. Release the Load / Unload Latch by pulling down and away from cutting head. The Blade Mount will spring open to reveal the pins of the blade mount. Insert the blade flat against the back of the blade hub and over the pins. Push up and back on the latch to lock blade into place. Step 1.

Head Rotation The head of the Oscillating Saw can be rotated side to side in 30° increments. To rotate the head, pull head out directly away from the handpiece, and rotate either direction to desired position.

OSCILLATING SAW

Step 2.

11

C Caution • Check Safety Lock and Trigger before operating the handpiece. If the Trigger should stick in the depressed “ON” position, do not use the handpiece. Immediately remove the battery. Return the instrument to the factory for service. Always use the Safety Lock when the instrument is not running. • Check that the Battery is fully seated and locked. • Be alert to the possibility of overheating at the blade-retaining cap or at the blade teeth.

C Warning • Risk of fire. Replace battery pack only with a MicroAire® 7500-710 Battery Pack. • Explosion hazard. Not suitable for use in the presence of flammable anesthetics or oxygen. • Type BF rating may only be maintained if the instrument is not used to bridge between the patient and ground. • Use care to ensure that there is no electromagnetic interference between this device and other devices in use. Note • The 7500 Drill/Reamer, 7600 Oscillating Saw, and 7700 Reciprocating Saw have been designed and also tested to operate with the 7025 Direct Power Console.

MICROAIRE INSTRUCTION MANUAL

C

12

- STANDARDS The 7700 Reciprocating Saw has been tested to meet the following standards:

5

UL 2601-1

WITH RESPECT TO ELECTRIC SHOCK, FIRE, MECHANICAL HAZARD ONLY IN ACCORDANCE WITH UL 2601-1 AND CAN/CSA C22.2 No. 601.1 EN 60601-1 / IEC 601-1 EN 60601-1-2, DIN EN 60601-1-2, (VDE 0750 part 1-2) EN 55011, Din VDE 0875 part 11 Limiting values of class A, group 1

- ENVIRONMENTAL CONDITIONS Temperature

Operation 32-115°F 0-50°C

Storage and Transportation 0-122°F -20-70°C

Relative Humidity

10-100%

10-75%

Atmospheric Pressure

Blade Speed*:

0-15000 cpm

Blade Stroke:

3.2mm

Weight(not including battery):

2.86 lbs. (1297g)

Battery Weight:

1.59 lbs. (721g)

Duty Cycle:

Short time operation only. Two minutes running, allow to cool to room temperature.

*Values are typical. Actual values may vary.

RECIPROCATING SAW

- TECHNICAL DATA -

13

- INSTRUMENT COMPONENTS -

Item Description 1 2 3 4

Blade Mount Locking Collar Trigger Battery Release Button

- OPERATING CONTROLS -

MICROAIRE INSTRUCTION MANUAL

Trigger The Reciprocating Saw operates at variable speeds and is controlled by depressing the trigger. The instrument is in the OFF position when the trigger is not depressed. As the trigger is depressed fully the speed increases from 0% to 100%.

14

Safety Lock The safety lock is provided to help prevent inadvertent activation Safety OFF of the handpiece when it is not in use and when loading and unloading cutting accessories or drive couplers. To place the safety lock in the ON position, simply rotate the trigger from the vertical position.

Safety ON

Battery Attachment The 7700 Reciprocating Saw must have a fully charged 7500-710 battery installed before each use. To attach the battery to the handpiece, place the battery under the base of the instrument with the longer side facing the rear of the instrument. Firmly push the battery into the base of the handpiece until the battery latch clicks into place. Please refer to illustration on page 3 of this manual.

Saw Blade Load / Unload Mechanism While holding the instrument in front of the body, nose end pointing out, rotate the blade-locking collar to the right, or counterclockwise, to open the blade grippers. Insert the blade inbetween the grippers and all the way back into the blade hub. Rotate the locking collar to the left, or counterclockwise, and turn until the collar is hand tight and will no longer turn. The blade can be oriented and locked into any 360° plane. To remove blade, complete the above steps in reverse. Step 1.

C Caution • Check Safety Lock and Trigger before operating the handpiece. If the Trigger should stick in the depressed “ON” position, do not use the handpiece. Immediately remove the battery. Return the instrument to the factory for service. Always use the Safety Lock when the instrument is not running. • Check that the Battery is fully seated and locked. • Be alert to the possibility of overheating at the blade-retaining cap or at the blade teeth.

RECIPROCATING SAW

Step 2.

15

C Warning • Risk of fire. Replace battery pack only with a MicroAire® 7500-710 Battery Pack. • Explosion hazard. Not suitable for use in the presence of flammable anesthetics or oxygen. • Type BF rating may only be maintained if the instrument is not used to bridge between the patient and ground. • Use care to ensure that there is no electromagnetic interference between this device and other devices in use. Note • The 7500 Drill/Reamer, 7600 Oscillating Saw, and 7700 Reciprocating Saw have been designed and tested to also operate with the 7025 Direct Power Console.

MICROAIRE INSTRUCTION MANUAL

C

16

- BATTERY PACK OPERATION Battery Installation The 7000 Series Battery Large Power System must have a fully charged 7500-710 battery installed before each use. To attach the battery to the handpiece, place the battery under the base of the instrument with the longer side facing the rear of the instrument. Firmly push the battery into the base of the handpiece until the battery latch clicks into place. Please refer to illustration on page 3 of this manual. Battery Charging See the separate operating instructions provided with the MicroAire® 7500-700 or 6640-700 charger you are using. Battery Conditioning In order to ensure the optimal performance of your battery pack, allow the battery to charge for 24 hours prior to first use. This will condition the battery so that it operates at its maximum capacity.

C Caution

BATTERY PACK

The Battery will be drained if left in the instrument when not in use.

17

- 7025 DIRECT POWER CONSOLE (DPC) The direct power console is designed to be used only with MicroAire battery powered instrumentation. The DPC uses the MicroAire 7007-000 connecting cable/receptacle only. All personnel should become familiar with the power equipment prior to set-up for use in any procedure. In-service should include, but not limited to, central processing, members of the surgical team, and bioengineering. To use the DPC with any of the MicroAire battery powered equipment: 1. Turn “ON” the Direct Power Console using the switch on the right hand side of the console. 2. Insert the console connector on the 7007-000 cable into the receptacle on the left side of the console. Be sure to line up the “Red Dots” for proper insertion of the cable. 3. Insert the power receptacle on the 7007-000 into the bottom of handpiece and connect as you would the battery pack. 4. Follow handpiece instructions for use.

MICROAIRE INSTRUCTION MANUAL

Refer to separate detailed 7025 instruction manual for Warnings, Cautions, Cleaning, Troubleshooting, and Warranty information.

18

- CLEANING 1. Scrub the handpiece, couplers, and batteries using warm water, a soft brush, and mild detergent. Scrub the instrument with the brush, paying close attention to the instrument crevices. The cannulated shaft in the Drill/Reamer should be cleaned after each use with a MicroAire 9600-161 or comparable cleaning brush. Take care to keep the instrument as upright as possible to restrict water from flowing into the battery cavity. 2. Rinse all items thoroughly under running water, again paying close attention to the battery cavity by keeping instrument as upright as possible. Dry all instruments and accessories with a lint free towel.

- STERILIZATION MicroAire surgical instruments are normally sterilized using steam autoclaving by either gravity discharge, or pre-vacuum sterilization. DO NOT immerse the instruments in disinfecting fluid or use a chemical sterilizer. The following sterilization processes have been validated based on AAMI protocols. The exposure times and temperatures are the minimum validated requirements to ensure sterility. Complete System (Handpieces & Couplers in Case, wrapped) Gravity Displacement • 55 minutes @ 270°- 279°F (132° - 137°C) 8 minutes drying time (Minimum) Pre-vacuum • 4 minutes @ 270°- 279°F (132° - 137°C) 8 minutes drying time (Minimum) Handpiece Only (unwrapped)

Pre-vacuum • 4 minutes @ 270°- 279°F (132° - 137°C) 8 minutes drying time (Minimum) Battery* Gravity Displacement (unwrapped) • 3 minutes @ 270°- 279°F (132° - 137°C) No drying time Pre-vacuum (wrapped) • 4 minutes @ 270° - 279°F (132° - 137°C) No drying time * Exceeding recommended steam sterilization exposure times or temperatures for the battery may reduce battery life and/or performance.

CLEANING & STERILIZATION

Gravity Displacement • 35 minutes @ 270°- 279°F (132° - 137°C) 8 minutes drying time (Minimum)

19