MINDRAY

A Series Disassembly of Breathing System for Cleaning Disinfection Autoclaving Guide Rev A Feb 2020

Guide

3 Pages

Preview

Page 1

Disassembly of A-Series Breathing System for Cleaning, Disinfection and Autoclaving

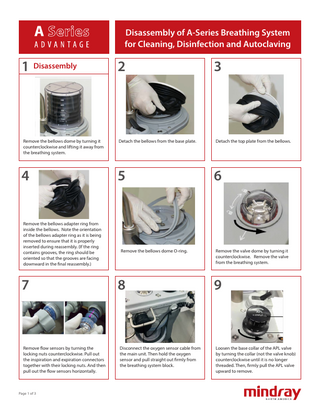

1 Disassembly

2

3

Remove the bellows dome by turning it counterclockwise and lifting it away from the breathing system.

Detach the bellows from the base plate.

Detach the top plate from the bellows.

4

5

6

Remove the bellows dome O-ring.

Remove the valve dome by turning it counterclockwise. Remove the valve from the breathing system.

7

8

9

Remove flow sensors by turning the locking nuts counterclockwise. Pull out the inspiration and expiration connectors together with their locking nuts. And then pull out the flow sensors horizontally.

Disconnect the oxygen sensor cable from the main unit. Then hold the oxygen sensor and pull straight out firmly from the breathing system block.

Loosen the base collar of the APL valve by turning the collar (not the valve knob) counterclockwise until it is no longer threaded. Then, firmly pull the APL valve upward to remove.

Remove the bellows adapter ring from inside the bellows. Note the orientation of the bellows adapter ring as it is being removed to ensure that it is properly inserted during reassembly. (If the ring contains grooves, the ring should be oriented so that the grooves are facing downward in the final reassembly.)

Page 1 of 3

Disassembly of A-Series Breathing System for Cleaning, Disinfection and Autoclaving

10/11

12

13

Press and hold the buckle on the bypass assembly to take out the bypass assembly downward.

To remove the PAW gauge simply hold it and lift it straight up from the breathing system block.

Rotate the locking mechanism handle clockwise into the unlocked position. Remove the absorber canister. Then remove the Pre-Pak or loose fill absorbent from the canisters. Dispose of the absorbent as per the local regulations.

14

15

16 Cleaning

At the base of the bag arm, locate the retaining ring. Turn the ring counterclockwise until it is no longer threaded. Lift the bag arm from the breathing system block.

To prevent damage, wash each component gently using a recommended cleaning agent (see TABLE on Page 3). Ensure that all surfaces are cleaned. Rinse with clean, hot water, and allow to dry.

Pull out the canister bottom plate upward.

While holding the sides of the breathing system block, firmly separate and slide it away from its mounting arm.

17 Disinfection

18

Use an approved disinfecting agent (see TABLE on Page 3) for all components while adhering to facility policies and procedures.

Connect all components to the breathing system by reassembling all components in the reverse order. Prior to use after cleaning or disinfecting, power up the system and follow the onscreen prompts to perform the leak test and the compliance test.

After all components are completely dry, inspect them for damage before disinfection or re-assembly and functional testing. If disinfecting the components, continue with step 17, otherwise skip to step 18.

All breathing system components (including the absorber canister components) are autoclavable except the PAW gauge, flow sensor, O2 sensor, and bellows. The components can be autoclaved up to a maximum temperature of 134 ºC (273 ºF) for 20 minutes. Please refer to full Operating Instructions Manual for additional details on Autoclaving, Cleaning and Disinfection

Page 2 of 3

Disassembly of A-Series Breathing System for Cleaning, Disinfection and Autoclaving

A-Series Cleaning and Disinfection Quick Reference Card The anesthesia system should be cleaned and disinfected before its first use, then in compliance with facility procedures. For step by step instructions, please refer to the Cleaning and Disinfection section of the operator’s manual. Table below lists the allowable cleaning agents, allowable disinfecting agents and provides the autoclaving process for the anesthesia system.

Agent

Classification

*Water

Cleaning agent

*Green soap tincture

Cleaning agent

*Sodium hypochlorite solution, 0.5% available chorine

Disinfecting agent

*Isopropyl alcohol (70%)

Disinfecting agent

*PDI Super Sani-Cloth® Germicidal Disposable Wipe

Disinfecting agent

*Cidex ® OPA (Only for bellows, Inspiratory Pressure Gauge and Ins/Exp Flow sensors)

Disinfecting agent

*ALPET® D2 Surface sanitizer wipes

Disinfecting agent

Metrex Cavi Wipe

Disinfecting agent

PDI Sani-Cloth® HB Germicidal Disposable Wipe

Disinfecting agent

PDI Sani-Cloth® Plus Germicidal Disposable Cloth

Disinfecting agent

**Autoclaving process

Autoclaving

TM

* For equipment with the symbol

, all the listed disinfecting agents are available for use. For equipment without the symbol , only the disinfecting agents marked with “*” are available for use. ** All breathing system components are autoclavable except the PAW gauge, flow sensors, O2 sensor, and bellows. Remove those components prior to beginning the autoclave process. Autoclavable components can accommodate a maximum temperature of 134 ºC (273 ºF).

Mindray DS USA, Inc. 800 MacArthur Blvd. Mahwah, NJ 07430 Tel: 1.800.288.2121 Tel: 1.201.995.8000 Fax: 1.800.926.4275 www.na.mindray.com

046 - 009638 - 00 ( 2 . 0 )

Page 3 of 3 Mindray North America 800 MacArthur Blvd., Mahwah, NJ 07430 Tel: 800.288.2121 Tel: 201.995.8000 Fax: 800.926.4275 www.mindray.com ©2020 Mindray DS USA, Inc. Mindray® is a registered trademark of Shenzhen Mindray Bio-Medical Electronics Co., Ltd. All rights reserved. 03/20 P/N: 0002-08-1655 Rev A