Instruction Manual

282 Pages

Preview

Page 1

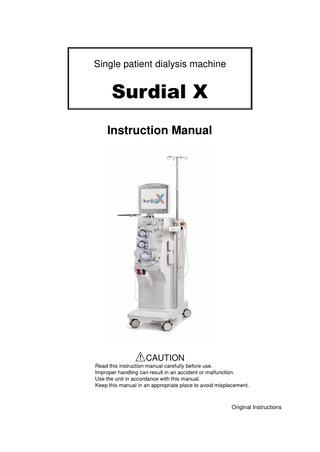

Single patient dialysis machine

Surdial X Instruction Manual

! CAUTION Read this instruction manual carefully before use. Improper handling can result in an accident or malfunction. Use the unit in accordance with this manual. Keep this manual in an appropriate place to avoid misplacement.

Original Instructions

1. Preface Thank you for purchasing NIPRO SINGLE PATIENT DIALYSIS MACHINE Surdial X.

Brief description This is a single patient dialysis machine with a built-in dialysate preparation system and piston pump ultrafiltration control system. Preparation is based on a feedback control method. Any other device or equipment need not to be used in combination with this machine for dialysis treatment. This machine controls and monitors dialysate circuit and extracorporeal blood circuit. The extracorporeal blood circuit control panel is designed to allow easy settings and operations. The blood can be heparinized either continuously or by one single bolus injection using the heparin pump. The Surdial X can be used for either acetate dialysis or bicarbonate dialysis The screen of the operation panel contains a clear 15 inch TFT color liquid crystal display with a touch panel. It allows dialogue-assisted operation and easy management of emergency situation during an alarm. This machine reflects the state-of-art. This machine is classified in class IIb according to MDD and is equipped with all necessary safety device required for the performance and patient safety. Refer to chapter 11 for the applicable standards.

Important notices This instruction manual describes proper and safe operation of the machine. It is not intended for patient management. Before using the machine, the responsible organization or person has to be instructed by the manufacturer how to use the machine and be familiar with the contents of the operating instructions Read this instruction manual (and related instructions) carefully before use. Understand the machine’s features and handling instructions and use it properly. This instruction manual describes operation with standard functions. Copyright of this instruction manual is protected and owned by the manufacturer. Copying, duplicating, translating a part or a complete instruction manual without the manufacturer’s permission is prohibited.

Service life To guarantee the optimal lifetime of the Surdial X it is recommended to respect the regular care, maintenance and technical inspections of the machine.

Preface-1

Intended use of this machine The Surdial-X can be used for patients with acute or chronic renal failure and when hemodialysis is prescribed by a physician. The Surdial-X is intended to be used by trained operators for hospital, health center or limited care. The system is a single patient hemodialysis system, which provides dialysis fluid with a prescribed concentration and temperature to be used for hemodialysis treatment. The system is intended to be used with high and low permeability dializers. The Surdial-X monitors during the dialysis treatment dialysate, blood circuit and machine functions. The system tolerances (e.g. Fluid balance, air infusion) are designed to treat patients with their body weight of 30kg or more. Depending on the model, the following types of therapies can be carried out: Hemodialysis (HD) Isolated ultrafiltration (ISO-UF) Single needle dialysis (SN-DP/SN-CC) Online Hemofiltration (O-HF in pre and post dilution) Online Hemodialfiltration (O-HDF in pre and post dilution) Single needle online Hemofiltration (SN-DP/SN-CC O-HF in pre and post dilution) Single needle online Hemodialfiltration (SN-DP/SN-CC O-HDF in pre and post dilution) All therapies can be carried out with different kind of UF, bicarbonate and sodium profiles.

Intended operators of this machine This machine is intended to be operated by qualified doctors, nurses and clinical engineers with skills specific to dialysis treatment such as introduction of blood to extracorporeal blood circuit, etc. If the operator chooses to link this machine to third party software (applications), the operator bears all responsibility and liability in this respect. The manufacturer does not guarantee the compatibility of this machine with third party software (applications) nor that this machine will function correctly after being connected to third party software (applications), even when subsequently disconnected, and the manufacturer shall bear no responsibility nor liability in this respect. The instruction manual contains any information for the use of this machine. The information must be carefully studied before attempting to operate the machine

Preface-2

Contra-indications This machine is not designed, manufactured, or sold for use other than for hemodialysis for patients with acute or chronic renal failure. Attention should be paid to contra-indications valid for extracorporeal treatment in general. Do not use high potassium percentage hemodialysis concentrates for HYPERKALEMIA. Do not use potassium free hemodialysis concentrates for HYPOKALEMIA uncontrollable coagulation anomalies. A different method of extra-corporal treatment maybe indicated for hemodynamically unstable patients.

RISKS and BENEFITS of hemodialysis Hemodialysis treatment improves uremia, anemia, hypertension, etc.

However, it can also cause

angialgia at puncture site, acceleration of hemorrhage, thrombosis and thrombemboli, infectious diseases, disconnection, air embolism, hypothermia, hypotension during hemodialysis, nausea, vomiting, disequilibrium syndrome, arteriosclerosis, cardiac failures, bone diseases, amyloidosis, arrhythmia, anemia, etc.

Responsibilities The organizer of hemodialysis is considered to work under the correct circumstances by means: - Compliance with national and local safety regulations - The operating instructions must be available at all times - Correct and safe state and placement of the machine.

Daily inspection by operator Check the following items before and after using the equipment on the same day. Ensure normal operation of the equipment. (1)

Look for abnormalities, such as leakage around the equipment. Check for loosening of clamps for the water supply opening and drainage opening hoses.

(2)

There is not residual chemical solution.

(3)

Residual quantities of disinfection or acetic acid solution being enough.

(4)

Consumption of disinfection or acetic acid solution being reasonable.

(5)

The real concentration of dialysate being reasonable.

(6)

There is no abnormal sound, a bad smell, over heat.

(7)

Foreign substance such as disinfectant stain on the equipment exterior.

(8)

Dialysate stain on the equipment. A dialysate stain can cause rust. Wipe it off immediately.

(9)

Abnormality when the start-up test is performed.

(10) If the equipment will be in operation overnight, ensure that the coupler is fit firmly on the coupler holder.

Preface-3

(11) Confirm that dialyzer coupler is properly mounted. (12) Correct syringe must be set.

Service and maintenance by technician Service, maintenance, adjustments, repairs or modifications can only be performed by the manufacturer or technicians authorized by the manufacturer. Detailed information regarding maintenance is described in the service manual. The manual is subject to any change without notice. Any changes will be released as new editions either supplements

Safety The Surdial X complies with the following standards JIS Z 0200 : 2013 JIS Z 0232 : 2004 IEC 60601-1 : 2005 IEC 60601-1-am1 : 2012 IEC 60601-1-2 : 2014 IEC 60601-1-6 : 2010 IEC 60601-1-6-am1 : 2013 IEC 60601-1-8 : 2006 IEC 60601-1-8-am1 : 2012 IEC 60601-1-10 : 2007 IEC 60601-1-10-am1 : 2013 IEC 60601-2-16 : 2012 IEC 80601-2-30 : 2013 IEC 60825-1 : 2014 IEC 62366 : 2007 IEC 62366-am1 : 2014 ISO 10993-1 : 2009

Equipment classification and handling precautions Protections from electric shock for this machine are as follows: Type of protection from electric shock: Class I ME equipment Degree of protection from electric shock: Type B applied part (hydraulic circuit) Type BF applied part (cuff) Ensure the use of a protective earth connection. The power plug is equipped with an earth connection. Incorrect protective earth connection may cause electric shock in the event of malfunction due to electric noise or in the event of failure.

Preface-4

Precaution for fluid penetration Keep the machine out of water. Protection against water and hazardous micro particulate matter infiltration: Drip-proof equipment IPX1

Precaution for flammable atmospheres Do not use this machine in flammable atmospheres.

Laser class and specification (BVM option) Laser Product Class: Class 1 laser product Wavelength: 905 nm

Preface-5

Preface-6

2. Safety Precautions Proper operation and regular maintenance are essential for safe operation. Thoroughly read and understand the safety precautions listed in this instruction manual before use. Operation and safety precautions listed in this manual are specific intended for the use of this unit. If this unit is used for other purposes, which are not listed in this instruction manual, the user will be responsible for the consequential safety issues.

Initial start up Before start up study the technical requirements in chapter 11 to ensure the machine works in the correct conditions. Initial start up can only be performed by a qualified technician with use of the procedures described in the service manual.

Warning symbols (1) Degree of safety hazard, damage and displays (attention-attracting symbols and signaling terms) Degree of safety hazard and damage that result from improper handling is classified into 3 levels. Each level will be indicated by a specific attention-attracting symbol and signaling term.

! DANGER This indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

! WARNING It indicates a potentially hazardous which, if not avoided, could result in death or injury.

! CAUTION This indicates a potentially hazardous, if not avoided, may result in moderate injury or damage in property. (2) Annotation and its display

NOTE Annotation is displayed. Use this as a reference when handling the unit. Because of our ceaseless research and improvement, details of the design of the unit described in this manual may be slightly different from those of the unit you purchased. If you have any question about the unit you purchased or contents of this instruction manual, please contact the nearest branch or agency.

Safety Precautions-1

! DANGER Read this instruction manual before using the unit.

When this machine is operated and maintained in a proper way, a safe and reliable treatment is warranted.

The manufacturer does not warrant the correct functioning of this machine in connection to third party software and/or software applications nor after the machine was connected to such third party software and/or software applications, even when subsequently disconnected. The operator should always verify the correct interaction between this machine and such software and/or software applications.

Before operating the unit, thoroughly read and understand this manual. Improper operation can lead to injury or abnormal operation. This unit should be operated by professionals only.

Learn the methods to immediately stop the treatment.

To avoid serious problems, know how to quickly stop the operation.

Do not allow non-professionals to operate the unit without having proper instructions.

Know how to respond when the unit stops for any reason.

Check the status of the unit and act in accordance with this manual.

During the maintenance, special caution should be exercised for the electronic boards, electric wiring, and terminals.

Do not touch non-isolated electric wiring and terminals.

Do not touch the electronic boards with a wet hand.

Before touching the terminal block, disconnect the power plug from the power supply.

During the connection/disconnection of a patient, special attention should be taken to avoid the following risks that can harm the patient. Avoid air entrance into the patient. Do prime the blood circuit before connecting the patient. Do not connect the patient blood circuit during rinsing/disinfection. Prevent the contact of harmful viruses and chemicals with the patient. Inappropriate connection of the blood circuit is dangerous for the patient. A bad connection can cause extracorporeal leakages. Improper pressure can result in rupture of the circuit. Ensure that the blood circuit is connected properly at all times. Before connecting the patient, ensure that the alarm of the unit is not interrupted. Treatment without using the alarm functions can cause great risks for the patient. Mixing of chlorine and decalcification solutions generates chlorine gases. Inhalation of these toxic gases is very dangerous. Ventilate the room, and be careful not to inhale the generated gases.

! WARNING Connect this unit only to an electric power source with protective earth (commercial use) to avoid the risk of electric shock. Do not use the machine when a defibrillator is used on a patient (disconnect patient from unit) . It`s not allowed by classification, because maybe result of medical intervention is not given/reduced or the machine could be damaged. If the machine was connected when defibrillator was discharged, check all machine functions and perform electrical check.

Safety Precautions-2

Electronic equipment producing radio waves should not be used in the same room or building as where this unit is used refer to chapter 11: Specification. Accessory equipment connected to the analog or digital interfaces must be certified according to the latest IEC standards related to the purpose of the machine. Anyone who connects additional equipment is responsible for ensuring that the system is conform the latest standards of IEC.

Avoid the use of electronic equipment that produces radio waves including cellular phones, transceivers, and radio-controlled toys. Use of this equipment inside of a hospital building can lead to malfunction of the machine. (refer also to chapter 11, specifications)

To prevent a possible accident, inform and instruct people not to carry or use radio-wave producing equipment in the hospital building.

The operator has to verify all the entered parameters in the system are correct. Any deviation between the desired parameters and the displayed parameters must be corrected before using the machine. Venous pressure

Monitoring of the venous Pressure cannot always detect the disconnection of a venous needle from its access site, which may result in extracorporeal blood loss to the environment. When a venous needle disconnects from its access, pressure at the venous monitoring side may only decrease by the pressure maintained within the patient’s access site.

This pressure

drop may be less than the width of the machine’s venous pressure alarm window: in this particular case the disconnection of a venous needle from its access site is not detectable by the machine, even if pressure alarms and alarm windows are properly set.

To reduce the risk of needles disconnection:

Ensure that venous needle and line are firmly secured to the access site area according to your clinic’s protocol.

Ensure that the patient access is visible at all times during the dialysis treatment.

Inspect frequently the patient’s access.

Adjust properly the venous pressure alarm window:

The venous pressure alarm lower limit

should be set as closely as practical to the actual patient’s venous pressure value without generating excessive nuisance alarms Do not change the setting values during treatment if there is no emergency.

Before selecting a function, ensure to understand the function thoroughly.

Provide a drain opening in the floor.

Provide a drain opening near to the unit.

Refer to the “Safety Precautions-16” before servicing the machine.

Maintenance should only be carried out after thoroughly reading and understanding the “Safety Precautions-16”.

Maintenance should be performed in accordance with the directions.

Look for professional help for repair and maintenance actions not listed in the “Safety Precautions-16”.

Do not choose unnecessarily functions during the treatment. Do not tilt the unit more than 5 degrees. It can overturn. Equipment (including software and/or software applications), not permitted to be used together with this machine, may not be connected. The total electric leakage current from the unit and other equipment together can exceed the maximum allowable value.

Safety Precautions-3

The operation and maintenance not specified by the manufacturer and the application of unspecified accessories (including software and/or software applications) may cause death or injury of the patient. The manufacturer is not responsible for the patient safety when the unit is operated, maintained, or calibrated by methods and/or with the use of third party materials (including software and/or software applications) not specified by the manufacturer. Trained and authorized personnel must operate the unit in accordance with the methods established by the manufacturer. Do not modify the unit nor any component thereof. Do not modify the software included in the unit. The manufacturer bears no responsibility nor liability in respect to modifications to the unit or any component thereof (including software and/or software applications) after the unit was connected to third party materials (including software and/or software applications), even when subsequently disconnected. Air bubbles may enter from the connecting point of the extracorporeal blood line at the downstream of the air bubble detector if negative pressure is created at the connecting point. It may occur during the single needle operation and when the central venous catheter is used.

! CAUTION Wear tools for protection when handling chemicals.

Wear protection glasses and rubber gloves when handling chemicals.

Characteristics of all chemicals being used should be realized to be able to treat appropriately when a trouble occurs.

Do not mix sodium hypochlorite with acetic acid, or peracetic acid

If mixed, it may produce chlorine gas harmful to humanbody

Inhalation of the generated chlorine gas will cause serious danger to the human body

Before installing the unit, thoroughly read and understand the installation manual.

Only trained professionals may install the unit.

If the operator chooses to make use of this machine with the help of third party software and/or software applications and/or to link this machine to third party software and/or software applications, the operator bears all responsibility and liability in this respect. The manufacturer does not guarantee the compatibility of this machine with third party software and/or software applications nor that the machine will function correctly after being connected to third party software and/or software applications and the manufacturer shall bear no responsibility nor liability in this respect.

Install the unit in accordance with the installation manual.

The connection of optional parts and the connection with an external unit should be performed after reading and thoroughly understanding the corresponding manuals.

Only trained professionals are allowed to do the connections.

Check the dialysate parameters with external testing equipment before starting any treatment.

Verify the actual dialysate concentration by an osmometer, conductivity meter, flame photometer, etc.

Check if the displayed concentration level is accurate.

Verify, at the end of the cleaning, that there is no residual chemical or acid present.

Safety Precautions-4

Verify, at the end of the disinfection the presence of chemicals (sodium hypochlorite, peracetic acid, or other chemicals) using a test paper or reagent.

Do not use any force on the display monitor and touch panel.

Avoid using force on the display monitor during surface cleaning.

Do not use hard or sharp objects to operate the touch panel. The touch panel can be damaged with operating malfunctions as a result.

Ensure that setting values are not abnormal during treatment.

Clean (disinfect and rinse) the unit thoroughly before use.

Disinfection and rinse are necessary when the machine has been out of use for a long term.

Disinfection and rinse are necessary when the machine has been out of use for a long term to flush the waste water.

Chemical or heat disinfection is needed after each manipulation on the hydraulic circuit (repair, maintenance, …)

Keep the machine always clean.

Use aseptic technique for all blood-side connections

Wipe off blood, dialysate, cleaning solutions carefully.

Clean (disinfect and rinse) regularly.

Note that some cleaning solutions such as “Irgasan” ruin the surface of the BP cover, etc.

Some button operation cannot be accepted on some screens or during some processes. Use only dialysate concentrate containers with an appropriate label mentioning the composition of the concentrate. Respect the color code during the connection of the concentrates (red for A concentrate, blue for B concentrate). Technicians should use not contaminated tools and work under clean conditions When using Central venous catheters the following instructions must be followed. No other additional ME devices must be connected if these conditions are not fulfilled.

Connect the dialysis system to a potential equalization conductor connection terminal of the Surdial X must be connected to the potential equalization of the electrical facility bus bar in order to avoid micro-shocks.

If additional ME equipment is used, ensure that all leakage currents are below the limit as for CF applied parts.( below 10μA Max in normal conditions and below 50μA in single fault conditions.) This also applies for defibrillators. Which have no applied part type CF.

Integrate all additional equipment to the potential equalization of the dialysis system

This rule applies to all other electric ME equipment and non electric ME equipment (ex patient bed) which are used in the reachable area of the patient.

Use disposable products with the CE marking only.

Handle used disposables carefully to prevent infecting yourselves and other persons. Used disposables might be contaminated with viruses (hepatitis, aids, HIV, MRSA, …)

To ensure the performance and safety of this unit, use water, dialysate concentrate, and fluid replacement with appropriate quality.

The Blood Volume Measurement is a Class 1 laser product pursuant to IEC 60825-1: 2014. Read the instruction manual thoroughly before using the product.

Operation and adjustment procedures which are not described in the instruction manual may lead to dangerous exposure to laser radiation.

Disassembling the BVM module may result in exposure to Class 3B invisible laser radiation.

Safety Precautions-5

Do not use broken or damaged BVM module.

Do not stare at the invisible laser aperture through a mirror. It may hurt your skin or cornea.

Physiological parameters which are measured by the BVM module are not intended for patient treatment or monitoring.

As tests for the determination of the laser classification are limited to tests during normal operation, it may be the case for embedded laser products, that laser radiation above the AEL of the class of the product can become accessible during maintenance or service when the product is disassembled (see IEC60825-1 6.2.1).

Precautions The following precautions should be noted when using this unit: 1. This unit should be operated by skilled personnel only. 2. Important notes concerning the installation of the machine: (1) Keep the unit out of water. (2) Only use the machine in normal conditions. Normal air pressure, temperature, humidity, wind, sunlight. No air containing dust, salt, sulfur… (3) Stability in terms of tilt, vibration, or impact (including those during delivery) should be taken care of. (4) Do not install the unit where chemicals are stored or gasses are generated. (5) Take care about the frequency, voltage, and allowed current /power consumption of the power source. (6) Connect the earth protection properly. (7) Confirm the default value of the treatment data and set intended parameter as necessary. 3. Important notes concerning the use of the machine: (1) Inspect touch panel sensitivity, polarity, dial settings, and meters. Verify that the machine operates properly. (2) Ensure that the earth protection is fully connected. (3) Verify that all cable connections are intact. (4) Exercise caution for concomitant use of equipment (including software and/or software applications), since it can result in false diagnosis or danger. (5) Re-examine the external circuit that will be connected directly to the patient. 4. Important notes concerning the operation of the machine: (1) Monitor the unit and patient for any abnormality at all times. (2) When an abnormality is discovered in the unit or patient, act appropriately (e.g., stop the operation after confirming the safety of the patient). (3) Do not allow the patient to touch the unit. 5. Important notes concerning the end of the treatment: (1) Turn the power off after returning operation buttons, dials, etc., to the original positions by the indicated processes. (2) Unplug the unit as necessary to remove from the power source. (3) When removing cables, do not apply inappropriate force such as pulling them by holding the cables. (4) Take care about the storage conditions: 1) Keep the unit out of water. 2) Store the unit in normal conditions. Normal air pressure, temperature, humidity, wind, sunlight. No air containing dust, salt, sulfur… 3) Stability in terms of tilt, vibration, or impact (including those during delivery) should be taken care of. 4) Do not store the unit where chemicals are stored or gasses are generated.

Safety Precautions-6

5) Clean accessories, cables, etc., and keep them in an organized way. 6) Ensure to keep the unit clean to be ready for the next use. 6. When the unit fails, do not attempt to fix it. Note the failure description on the machine and look for professional help. 7. Do not modify the unit nor any component thereof. Do not modify the software included in the unit. The manufacturer bears no responsibility nor liability in respect to modifications to the unit or any component thereof (including software and/or software applications) after the unit was connected to third party materials (including software and/or software applications), even when subsequently disconnected. 8. Maintenance (See on and after "Safety Precautions-16".) (1) Ensure to maintain the unit and its parts. (2) Ensure that the machine operates normally and safely after a long period out of use. 9. Check other handling precautions listed on the instruction manual of the unit.

Emergency Stop ! WARNING Before stopping the system emergently, ensure that it will not interfere with the treatment. If interference is a concern, stop the system after taking the necessary measures. Monitor the patient at all times even if treatment is complete.

Emergency stop using the I/O power key In all processes, if abnormalities are found in the unit and if continued use of the unit would interfere with the treatment, press the I/O power key to turn off the system. (In such cases as the liquid crystal display is suddenly turned off, or the touch panel button does not work.)

! WARNING All movements in the liquid crystal display, dialysate circuit, blood pump, and heparin pump stop.

! CAUTION After recovering the system using the I/O power key, if abnormalities are found in the unit movements or it is impossible to continue using the unit, turn off the I/O power key and the power breaker to stop the unit. Contact the nearest branch or agency.

NOTE To operate the I/O power key, press it for more than 3.0 sec.

Safety Precautions-7

Emergency stop using the power breaker When the I/O power key is turned on but the power breaker is turned off, the dialysis function stops and the power failure screen appears in the liquid crystal display. The power failure backup operation takes place thereafter.

! CAUTION When the I/O power key is turned on and the power breaker is turned off, the liquid crystal display, the touch panel, the blood pump, the single needle pump (option), the bubble detector, the heparin pump, the venous clamp and the arterial clamp operate in the power failure backup fashion. Turn off the Blood pump I/O button and Heparin pump I/O button when necessary. Additionally, the alarm buzzer goes off. Press the Mute key to mute.

Transporting the Unit and Prohibited Actions ! CAUTION Keep the transfer position when the unit is tilted more than 5 degrees. It can overturn. Hold the frame when the unit is lifted. Holding the cover may damage it and the unit may fall. (1)

Release 2 locks at the right front and the left front of the caster.

(2)

Transport the unit in the stand up position (vertical to the floor).

(3)

Always push the back of the unit when transporting.

(4)

Four or more people should attend when the unit needs to be lifted. (Three people should lift it by holding the frame leg and the other person should support the head of the unit.)

NOTE Do not transport on a rugged road. If a bump of 1 cm or more is present, spread a flat board or iron plate that can support the weight of the unit on top of it before transporting or slowly jiggle the unit to go through the level difference. If a gap of 1 cm or more is present, spread a flat board or iron plate that can support the weight of the unit on top of it before transporting. All 4 casters should be in contact with the road when transporting. Support the front of the unit, because the center of mass is toward the back. When transporting on a slope, be sure to face the front of the unit on the mountain side. Ensure that no objects are in the way while transporting. When transporting by a track, do not lay the unit on its side.

Safety Precautions-8

Transfer position Keep the transfer position described below for safety purposes when transporting the unit from room to room: (1)

Close all the covers.

(2)

Stop water supply and central supply of dialysate to the machine from the facility.

(3)

Open the System-Maintain-Flowchart screen and turn the “Forced Out” ON.

(4)

Turn V46, V45, V43, V44, V53 and V35 ON, and turn these solenoid valves OFF several seconds later.

(5)

Turn V48, V47, V29, V51, V53 and V35 ON, and turn these solenoid valves OFF several seconds later.

(6)

Turn V55, V1, V10, V4 and V35 ON and confirm the pressure is released with the PD display value.

(7)

Turn the Forced Out OFF.

(8)

Turn off the I/O power key and the power breaker and disconnect the power plug from the power supply.

(9)

Disconnect the LAN cable.

(10) Remove the supply/drainage line and the central hoses. (11) Remove the blood circuit and the dialyzer. (12) Put down the concentrate tank or unhang the concentrate bag (13) Put down the chemical bottle. (14) Remove all items on the tray and move the tray to the top of the unit. (15) Unhang all items from the hanger.

Disposals Disposal of the unit The following are the precautions to be exercised when disposing the unit: (a)

Dispose resins (including the electric circuit board), rubbers, and electric wires as industrial wastes or in accordance with the rules practiced in your community.

(b)

To distinguish iron from stainless steel, bring a magnet close to them: if attracted to the magnet, it is iron; if not, it is stainless steel. The surface of iron is painted or plated for anticorrosion.

Safety Precautions-9

Disposal of the Lead Acid battery for power failure backup ! DANGER The lead acid battery installed for power failure backup is specifically made for this unit. Connecting this battery in other equipment can cause it to leak, release heat, or burst.

Handling precautions The lead acid battery can leak, release heat, or burst if the following precautions are not exercised. Be sure to take precautions. -Do not throw it into fire or apply heat. -Do not connect the positive and negative sides with metals, such as wire. -Do not remove or scratch the external tube. -Do not apply strong shock or throw it against an object. -Do not disassemble or modify.

NOTE The lead acid battery is a consumable. It deteriorates in long-term use. The battery deteriorates even if the power failure backup operation is not performed.

! DANGER If fluid inside of the lead acid battery and lithium battery contacts eyes, it can result in blindness. Do not rub. Wash the eyes immediately with water. Receive treatment from a physician without delay. If fluid inside of the lead acid battery contacts skin or clothes, it can damage the skin. Wash it off with clean water without delay.

Safety Precautions-10

Upon disposing the product Used lead acid battery is a valuable resource. Stick a tape on the terminal or connecting cord and bring it to the recycle shop that accepts lead acid batteries.

Symbols

Follow instruction manual

Degree of protection against electric shock: Type B

Degree of protection against electric shock: Type BF

Connector for nurse call button

Central alarm output

Power switch – ON

Power switch – OFF

Stand-by or preparatory state for a part of device

Alternating current

Protective earth terminal

Potential equalization conductor connection terminal

Safety Precautions-11

Keep transport position when moving the device on more than 5-degree slope .

Alarm sounds mute switch

Blood pump switch Green – ON Red – OFF

Bubble detector

Blood sensor

Clamp

Warning label: Hazard symbol for hazardous Laser Radiation (IEC60825-1:2014)

LASER BVM module is a Laser Product Class 1 1 (IEC60825-1:2014)

This document is usable with the software version “1.506”. Check the list below for compliance with the software version and this document before use.

The software version can be checked on the

startup screen. Document ID Number (as described on the rear cover)

Software Version

DN1138-2004

1.506

Safety Precautions-12

Precautions to be taken before handling ! CAUTION Do not connect the equipment to a patient during maintenance.

Service technician Only Service technician who received a technical training of dialysis machines from Nipro, are allowed to maintain the machine. Otherwise, a person who is being supervised by a trained technician, is allowed to maintain the equipment.

Well-planned maintenance Use of the equipment without planning maintenance, can decrease work efficiency and cause injury, accident, and errors. It can also interfere with the original purpose, maintenance. Schedule the time to maintain the equipment, and prepare necessary tools, parts, testing equipment, and documents in advance.

Clothes Try to minimize injury and accident by wearing appropriate clothes to work on the equipment. Select clothes that do not attract a lot of electrostatics. Avoid exposing skin even if the surrounding temperature is high.

Handling the equipment Work in accordance with the instructions. Read the attached Instruction Manual carefully. Transport and handle the equipment in accordance with the Manual. Be sure to check the electric power line, water supply/drainage line, and other connection lines before working on the equipment.

Replacement parts Use the parts specified by the manufacturer.

Liability for readjustment and repair A person who readjusted or repaired unit or any component thereof (including software and/or software applications) is liable for consequential events. This includes modifications to the unit or any component thereof (including software and/or software applications) resulting from the connection to third party materials (including software and/or software applications), even when subsequently disconnected.

Safety Precautions-13