Ohio Medical Corporation

Vacuum Regulator, Intermittent Suction Unit Instructions for Use Rev 6 Feb 2014

Instructions for Use

74 Pages

Preview

Page 1

Table of Contents Safety Instructions... 2 Intended use ... 2 Receiving/Inspection ... 2 User Responsibility ... 2 Definitions/Abbreviations ... 3 Regulator Identification... 4 Operation ... 4 Cleaning ... 9 Troubleshooting ... 9 Warranty ... 10

Safety Instructions This manual provides you with important information about the Intermittent Suction Unit (ISU). To ensure the safe and proper use of this device, READ and UNDERSTAND all of the safety and operating instructions. IF YOU DO NOT UNDERSTAND THESE INSTRUCTIONS, OR HAVE ANY QUESTIONS, CONTACT YOUR SUPERVISOR, DEALER OR THE MANUFACTURER BEFORE ATTEMPTING TO USE THE DEVICE.

Intended Use: The vacuum regulator is intended to be used in the medical facility as a means to evacuate media (i.e. fluids) from the body.

Receiving / Inspection: Remove product from package and inspect for damage. If product is damaged, DO NOT USE and contact your dealer or equipment provider. WARNINGS This device is to be used only by persons who have been adequately instructed in its use.

Do not use this device in the presence of flammable anesthetics. Static charges my not dissipate and a possible explosion hazard exists in the presence of these agents.

User Responsibility This product performs as explained in this manual as long as the assembly, use, repair and maintenance are properly followed according to our instructions. Periodic review of this device is recommended. If any damage or defects are present, the product should not be used. This includes parts that may have been altered, contaminated, worn or missing. If any of the above are noted, immediate repair / replacement is required. In compliance with the Ohio Medical Warranty, repair of this device is not to be performed by anyone other than a qualified professional and

2

6700-0359-000

done in strict accordance to the written instructions provided by Ohio Medical. If this device is subject to improper maintenance, repair, use and/or abuse leading to malfunction of the device, replacement is the sole responsibility of the user. AAA A 12345

This alpha character indicates the year of product manufacture and when the serial number was assigned; “Y” = 1995, “Z” = 1996, “A” = 1997, etc. “I” and “O” are not used.

CAUTIONS

Only competent individuals trained in the repair of this equipment should attempt to service it.

Detailed information for more extensive repairs is included in the service manual solely for convenience of users having proper knowledge, tools and test equipment, and for service representatives trained by Ohio Medical.

Not for field or transport use.* *

The categories of Field and Transport Use are specifically defined in ISO 10079-3, “Field” means accidents or emergencies outside the hospital. “Transport” means use in ambulances, cars and airplanes. These situations may expose the equipment to uneven support, dirt, water, mechanical shock and temperature extremes. Ohio Medical suction equipment has not been tested to comply with the specific requirements of these categories.

Definitions/Abbreviations WARNING

= Possible injury to patient or operator

CAUTION

= Possible damage to equipment

Note

= Provides additional information to clarify a point in the text.

Important

= Similar to a note but of greater emphasis.

= Attention. Alerts you to a warning or caution in the text.

MAX

= maximum

High Flow High Vacuum

= high flow, high vacuum

|O|O| (INTER)

= intermittent; cycles on and off

| (CONT)

= on

O (OFF) mmHg kPa mL mm

= off = Millimeters of Mercury = Kilopascal = Milliliter = Millimeter = Consult Instructions for use = Serial Number = Manufacturer

3

6700-0359-000

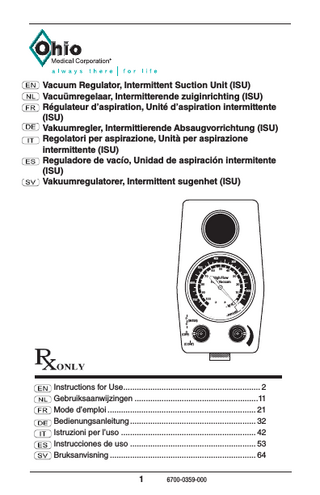

Regulator Identification Intermittent Suction Unit (ISU)

1

Figure 1

Fitting/Patient Port Probe/Adapter Port

Vacuum Gauge Mode Selector Switch Suction Control Knob

400 300 500 60 70 600

700

50

40

80

20

90

10

0

100

100

- kP 0

200

High Flow 30 High Vacuum

a

-mm

Hg

(INTER)

0 (OFF) (CONT)

Operation Equipment Setup Insert the probe into the vacuum wall outlet. If the regulator is mounted elsewhere, connect a vacuum supply hose between the regulator’s probe adapter and the wall outlet. WARNING

Connection to positive pressure sources such as oxygen and medical air, even momentarily, could injure the patient or operator.

CAUTION

Connection to positive pressure sources such as oxygen and medical air, even momentarily, could damage the equipment.

Use hospital-supplied suction tubing between the end piece and the collection container, and between the patient port and the patient (minimum inside diameter is 6 mm [0.25 in.]). An Ohio Medical high flow filter and overflow safety trap should be used between the collection canister or liner and the vacuum regulator to prevent contamination of the regulator, wall outlet and pipeline system. ISO 10079-3 (section 5.1.2) states that “the usable volume of the collection container shall not be less than 500 mL.”

4

6700-0359-000

High Flow Suction Filters Hydrophilic: Nipple 20 Pack 6730-0350-800 200 Pack 6730-0351-800

Hydrophobic: Nipple Threaded 3 Pack 6700-0570-800 6700-0580-800 10 Pack 6700-0571-800 6700-0581-800 50 Pack 6700-0572-800 6700-0582-800

Attaching the Overflow Safety Trap (OST) CAUTION

To help prevent aspirate from entering the regulator, wall outlet and pipeline equipment, a safety trap should be attached prior to its use. Aspirate in the regulator, wall outlet and pipeline equipment may impair its operation. The use of the overflow safety trap and suction filter will help prevent this and extend the life of suction equipment.

Trap fitting

2

Figure 2

1. Raise the sleeve and insert the trap into the regulator fitting. 2. Turn the trap clockwise about one and a half turns to engage the threads. The trap does not need to be screwed tight; an O-ring in the regulator fitting provides a vacuum seal.The trap should rotate freely to allow the desired tubing positioning.

3. Lower sleeve to lock trap in position.

Regulator Sleeve

DISS fitting

3

Figure 3

1. Insert trap into the regulator fitting. Situate the tubing in the desired position. 2. Turn the DISS wing nut clockwise to engage threads and tighten (there is no O-ring, so the vacuum seal depends on a tight connection).

Regulator Wing nut

5

6700-0359-000

Mode Selection

4

Figure 4 Note: In this text, the international graphic symbol:

| O | O |

will be written as |O|O|. |O|O| (INTER) - Suction is intermittent (cycled “on” and “off”) and the suction level can be adjusted with the suction control knob. 0 0

(INTER)

0 (OFF) (CONT)

O (OFF) - No suction is supplied to the patient. 0 0

(INTER)

0 (OFF) (CONT)

| (CONT) - Suction is continuous and can be adjusted with the suction control knob. 0 0

(INTER)

0 (OFF) (CONT)

Setting the suction level

5

Figure 5 Intermittierende Absaugvorrichtung

100

14 12

Fu ll V ac t o 760 0

(INTER)

0 (OFF) (CONT)

6

6700-0359-000

40

20

Pa

26 Fu ll V ac t o 100

0

8

2

24 180

60 10

6 4

22

-k

Hg

Clamp

16 18 20

80

120 140

160

m

1. Clamp the connective tubing to occlude the fitting port

-m

6

Figure 6

2. Turn the mode selector switch to | (CONT). 0 0

(INTER)

0 (OFF) (CONT)

7

Figure 7 0 0

3. Rotate the suction control knob until the vacuum gauge indicates the required setting.

WARNING

(INTER)

0 (OFF) (CONT)

The regulator fitting port or patient connector must be occluded when setting the prescribed suction level so that the patient does not receive higher than required suction.

Pre-Use Checkout Procedure WARNING

The Pre-Use Checkout Procedure must be performed before using the equipment on each patient. If the regulator fails any part of the Pre-Use Checkout Procedure, it must be removed from service and repaired by qualified service personnel.

All tests must be performed with the regulator in its normal (vertical) operating position and with a minimum supply vacuum of 500 mmHg (66.7 kPa). 1.

Turn the mode selector switch to O (OFF).

2.

Rotate the suction control knob one full turn clockwise (increase).

3.

Clamp the connective tubing to occlude the fitting port. The gauge needle should not move.

4.

Unclamp the connective tubing.

5.

Turn the mode selector switch to | (CONT).

6.

Rotate the suction control knob fully counter-clockwise (decrease).

7.

Clamp the connective tubing. The gauge needle should not move.

8.

With the connective tubing clamped, increase the suction to 12.0 kPa (90 mmHg).

9.

Slowly open and close the clamped tubing to create various flow rates through the regulator. Check that the suction level is maintained when the tubing is clamped.

7

6700-0359-000

10. Turn the mode selector knob to |O|O|. 11. Clamp the connective tubing. 12. Ensure that the timing cycles are 15 second “On” and 8 seconds “OFF” both with a tolerance of ± 3 seconds by observing the gauge needle. Note: The ISU starts in the off cycle. 13. Reduce the suction level to zero and turn the mode selector to O (OFF).

Patient Setup 1. Make sure the Pre-Use Checkout Procedure has been performed.

8

Figure 8

2. Turn the mode selector switch to | (CONT) and clamp tubing.

Clamp 400 300 500 60 70 600

50

40

20

90 700

10

0

100

100

- kP 0

200

High Flow 30 High Vacuum

80

a

-mm

Hg

(INTER)

0 (OFF) (CONT)

Underwater Seal Line

2 cm H2O Made in USA

3. Set the prescribed suction level. WARNING

The regulator must be occluded when setting the prescribed suction level so that the patient does not receive higher than required suction.

4. Turn the mode selector switch to O (OFF). 5. Attach the patient tubing to the collection canister or liner’s patient port. 6. Turn the mode selector knob to | (CONT) or |O|O| (INTER).

8

6700-0359-000

Cleaning Routing cleaning of the regulator is recommended as a standard procedure after each use. Wipe all exterior surfaces with a solution of water and mild detergent. Should misuse occur resulting in accidental flooding of the regulator, the regulator may be sterilized using ethylene oxide (ETO). See section 5.2 (Sterilization) of the regulator service manual. After sterilization follow the service checkout procedures in section 8 (Service Checkout Procedure) of the regulator service manual. WARNINGS

Clean and sterilize all suction equipment before shipment to ensure transportation personnel and service personnel are not exposed to any hazardous contamination.

After patient use, regulators may be contaminated. Handle in accordance with your hospital’s infection control policy.

Following sterilization with ethylene oxide, parts should be quarantined in a well ventilated area to allow dissipation of residual ethylene oxide gas absorbed by the material. Aerate parts for 8 hours at 54°C (130°F). Follow your hospital sterilization procedure

Do not steam autoclave or liquid sterilize the regulator. Severe impairment to the operation of the regulator will result. The only acceptable method of sterilization is with gas (ethylene oxide).

CAUTION

Troubleshooting If the regulator does not operate and you have performed the Pre-Use Checkout Procedure, the following procedures may be used to attempt to correct the problem. Problem

Possible Cause

Remedy

No suction

Mode selector is in the O (OFF) position or between positions Leak in system

Switch to I (On) or |O|O| (INTER) position Check lid is secure on the collection container Check tubing connections Rotate the suction control knob in the increase direction (clockwise)

Suction control knob at full decrease No suction

In the off cycle of the |O|O| mode

In the |O|O| mode the regulator starts in the of cycle. Wait at least 20 seconds to determine if regulator is functioning.

Important: If the above actions do not correct the problems or other problems exist, refer to the ISU service manual or refer servicing to qualified service personnel.

9

6700-0359-000

Warranty This Product is sold by Ohio Medical Corporation, a Delaware corporation (the “Company”) under the express terms of the warranty set forth below. For a period of THIRTY SIX (36) MONTHS from the date the Company ships this Product to the customer, but in no event for a period of more than three years from the date of original delivery by the Company to an authorized dealer, this Product, other than its expendable parts (e.g., batteries for Digital Gauge) is warranted to be free from functional defects in materials and workmanship and to conform in all material respects to the description for the Product contained in this operation manual, if this Product is properly operated under conditions of normal use, regular periodic maintenance and service is performed and repairs are made in accordance with this operation manual. The warranty period for all expendable parts of the Product is sixty (60) days from the date the Company ships the Product to the customer. The Company’s sole and exclusive obligation and customer’s sole and exclusive remedy under the above warranty is limited to repair or replacement, at the Company’s option, of the defective Product. The foregoing warranty shall not apply if the Product has been repaired or altered by anyone other than the Company or an authorized dealer; or if the Product has been subjected to abuse, misuse, negligence, or accident. The Company reserves the right to stop manufacturing any product or change materials, designs, or specifications without notice. This warranty is extended to only the initial customer with respect to the purchase of this Product directly from the Company or an authorized dealer as new merchandise. Dealers are not authorized to alter or amend the warranty of any Product described in this agreement. Any statements, whether written or oral, will not be honored or be made part of the agreement of sale. THIS WARRANTY IS EXPRESSLY IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. THE COMPANY SHALL NOT BE LIABLE FOR INCIDENTAL, COLLATERAL, CONSEQUENTIAL, OR SPECIAL DAMAGES INCLUDING, BUT NOT LIMITED TO, LOST PROFITS, OR LOSS OF USE. THE COMPANY’S LIABILITY, IN THE AGGREGATE, SHALL NOT EXCEED THE PURCHASE PRICE OF THE PRODUCT. In order to file a warranty claim, customer is required to return Product prepaid to the Company at 1111 Lakeside Drive, Gurnee IL, 60031 USA. As determined at the sole discretion of the Company, Products which qualify under the warranty will be repaired or replaced, at the Company’s option, and returned to customer via ground delivery at the Company’s expense. All claims for warranty must first be approved by Ohio Medical Corporation Customer Service Department. For International customer returns: intl.customerservice@ ohiomedical.com or 1-800-662-5822 (Option 3). Upon approval the customer service department will issue a Return Goods Authorization (RGA) number. An RGA must be obtained prior to commencement of any warranty claim. Form No. 550023(Rev.1) 2012

10

6700-0359-000

North America United States Customer Service, Distribution Center Technical Support, Sales and Service Equipment Service Center Ohio Medical Corporation 1111 Lakeside Drive Gurnee, IL 60031 USA P: 866 549 6446 P: +1 847 855 0800 F: +1 847 855 6218

Ohio Medical Corporation Authorized Representative

EC REP

OxygenCare Ltd. 2 Holfeld Business Park Kilmacanogue Co Wicklow Ireland Tel: +353 1 2769700 Fax: +353 1 2764970

© 2012 Ohio Medical Corporation. This document contains information that is proprietary and confidential to Ohio Medical Corporation. Use of this information is under license from Ohio Medical Corporation. Any use other than that authorized by Ohio Medical Corporation is prohibited.

Ohio Medical, Ohio Medical Corporation, and the Ohio Medical Corporation Logo are registered trademarks of Ohio Medical Corporation.

6700-0359-000 Rev6 02/2014

74

6700-0359-000