OLYMPUS

CF-HQ190L-I EVIS EXERA III COLONOVIDEOSCOPE Reprocessing Manual Dec 2011

Reprocessing Manual

110 Pages

Preview

Page 1

REPROCESSING MANUAL

INSTRUCTIONS

Chapter 1

General Policy

1

Chapter 2

Function and Inspection of the Accessories for Reprocessing

9

Compatible Reprocessing Methods and Chemical Agents

23

Reprocessing Workflow for Endoscopes and Accessories

31

Reprocessing the Endoscope (and related reprocessing accessories)

39

Chapter 6

Reprocessing the Accessories

85

Chapter 7

Reprocessing Endoscopes and Accessories Using an Automated Endoscope Reprocessor/Washer-Disinfector

97

Storage and Disposal

99

Chapter 3

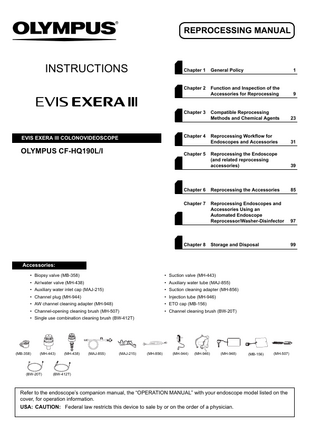

EVIS EXERA lll COLONOVIDEOSCOPE

Chapter 4

OLYMPUS CF-HQ190L/I

Chapter 5

Chapter 8

Accessories: • Biopsy valve (MB-358)

• Suction valve (MH-443)

• Air/water valve (MH-438)

• Auxiliary water tube (MAJ-855)

• Auxiliary water inlet cap (MAJ-215)

• Suction cleaning adapter (MH-856)

• Channel plug (MH-944)

• Injection tube (MH-946)

• AW channel cleaning adapter (MH-948)

• ETO cap (MB-156)

• Channel-opening cleaning brush (MH-507)

• Channel cleaning brush (BW-20T)

• Single use combination cleaning brush (BW-412T)

(MB-358)

(MH-443)

(BW-20T)

(MH-438)

(MAJ-855)

(MAJ-215)

(MH-856)

(MH-944)

(MH-946)

(MH-948)

(MB-156)

(MH-507)

(BW-412T)

Refer to the endoscope’s companion manual, the “OPERATION MANUAL” with your endoscope model listed on the cover, for operation information. USA: CAUTION: Federal law restricts this device to sale by or on the order of a physician.

Contents

Contents Chapter 1 General Policy ... 1 1.1

Instructions ... 1

1.2

Importance of reprocessing ... 2

1.3

Signal words ... 2

1.4

Precautions ... 3

1.5

Reprocessing before the first use ... 7

1.6

Reprocessing and storage after use ... 8

1.7

Reprocessing before patient procedure ... 8

Chapter 2 Function and Inspection of the Accessories for Reprocessing ...9 2.1

ETO cap (MB-156) ... 9

2.2

Channel plug (MH-944) ... 10

2.3

Injection tube (MH-946) ... 11

2.4

Channel cleaning brush (BW-20T) ... 13

2.5

Channel-opening cleaning brush (MH-507) ... 15

2.6

Auxiliary water tube (MAJ-855) ... 16

2.7

Suction cleaning adapter (MH-856) ... 17

2.8

AW channel cleaning adapter (MH-948) ... 18

2.9

Single use combination cleaning brush (BW-412T) ... 19

2.10 Auxiliary water inlet cap (MAJ-215) ... 22

Chapter 3 Compatible Reprocessing Methods and Chemical Agents ...23 3.1

Compatibility summary ... 23

3.2

Water (for reprocessing) ... 26

3.3

Detergent solution ... 26

3.4

Disinfectant solution ... 26

3.5

Rinse water ... 27

3.6

Alcohol ... 27

3.7

Ethylene oxide gas sterilization ... 28

3.8

Steam sterilization (autoclaving) ... 29

CF-HQ190L/I REPROCESSING MANUAL

i

Contents

Chapter 4 Reprocessing Workflow for Endoscopes and Accessories...31 4.1

Summary of reprocessing workflow ... 31

4.2

Workflow for manually cleaning and disinfecting endoscopes and accessories ...32

4.3

Workflow for cleaning and disinfecting endoscopes and accessories using an AER/WD ...34

4.4

Workflow for manually cleaning and sterilizing endoscopes and accessories ...36

Chapter 5 Reprocessing the Endoscope (and related reprocessing accessories) ...39 5.1

Summary of reprocessing the endoscope ... 39

5.2

Preparing the equipment for reprocessing ... 41 Equipment needed ... 41

5.3

Precleaning the endoscope and accessories ... 43 Equipment needed ... 43 Preparation ... 44 Wipe the insertion section ... 44 Aspirate water ... 45 Flush the air/water channel with water and air ... 46 Flush the auxiliary water channel ... 47 Detach the suction tube and the water container’s metal tip from the endoscope ... 49 Detach the endoscope from the light source ... 49

5.4

Leakage testing of the endoscope ... 49 Equipment needed ... 49 Detach the accessories from the endoscope ... 50 Perform the leakage test ... 51

5.5

Manually cleaning the endoscope and accessories ... 53 Equipment needed ... 53 Clean the external surface ... 54 Brush the channels ... 55 Aspirate detergent solution through the instrument channel and the suction channel ... 61 Flush the air/water channel with detergent solution ... 63 Flush the auxiliary water channel with detergent solution ... 66 Immerse the endoscope and accessories in detergent solution ... 67 Remove detergent solution from all channels ... 67 Dry external surfaces ... 69

5.6

Manually disinfecting the endoscope and accessories ... 70 Equipment needed ... 70 Preparation ... 70 Flush all channels with disinfectant solution ... 71 Immerse the endoscope and accessories in disinfectant solution ... 72 Remove the endoscope and accessories from disinfectant solution ... 73

ii

CF-HQ190L/I REPROCESSING MANUAL

Contents

5.7

Rinsing the endoscope and accessories following disinfection ... 74 Equipment needed ... 75 Rinse the endoscope and accessories ... 76 Alcohol flush ... 78

5.8

Sterilizing the endoscope and accessories ... 80 Ethylene oxide gas sterilization of the endoscope and accessories ... 80 Steam sterilization (autoclaving) of the accessories ... 82

5.9

Presoaking the endoscope ... 82 Equipment needed ... 83

Chapter 6 Reprocessing the Accessories ... 85 6.1

Summary of reprocessing the accessories ... 85 Equipment needed ... 86

6.2

Manually cleaning the accessories ... 87

6.3

Manually disinfecting the accessories ... 90

6.4

Rinsing the accessories following disinfection ... 92 Rinse the accessories ... 92 Alcohol flush ... 94

6.5

Sterilizing the accessories ... 95 Ethylene oxide gas sterilization ... 95 Steam sterilization (autoclaving) ... 96

Chapter 7 Reprocessing Endoscopes and Accessories Using an Automated Endoscope Reprocessor/Washer-Disinfector ...97 7.1

Reprocessing endoscopes and accessories using an automated endoscope reprocessor/washer-disinfector... 97

Chapter 8 Storage and Disposal ... 99 8.1

Precaution of storage and disposal ... 99

8.2

Storing the disinfected endoscope and accessories ... 100

8.3

Storing the sterilized endoscope and accessories ... 102

8.4

Disposal ... 102

CF-HQ190L/I REPROCESSING MANUAL

iii

Contents

iv

CF-HQ190L/I REPROCESSING MANUAL

1.1 Instructions

Chapter 1 1.1

General Policy

Ch.1

Instructions • This manual contains the reprocessing methods recommended by Olympus for the endoscopes and accessories listed on the front cover. • This instruction manual contains essential information on reprocessing endoscopes and accessories safely and effectively. • Before reprocessing, thoroughly review this manual and the manuals of the reprocessing equipment and chemicals that will be used for reprocessing. Reprocess all the devices as instructed. • Note that the complete instruction manual set for the endoscope and accessories consists of this manual and the “OPERATION MANUAL” with your endoscope model listed on the cover. Both manuals accompanied the endoscope at shipment. • Keep this manual and all related manuals in a safe and accessible location (e.g., in the reprocessing area). • If you have any questions or comments about any information in this manual, or if a problem that cannot be solved occurs while reprocessing, contact Olympus.

Terms used in this manual AER/WD: AER and WD are abbreviated names for Automated Endoscope Reprocessor and Washer-Disinfector, which are used for reprocessing endoscopes and accessories.

Disinfection: Some countries classify the disinfection level and define “high-level disinfection”, and other countries do not. The term “disinfection” is used, including meaning “high-level disinfection”, in this manual. For disinfectant solution, follow the instructions as described in Chapter 3.4, “Disinfectant solution”.

CF-HQ190L/I REPROCESSING MANUAL

1

1.2 Importance of reprocessing

Ch.1

1.2

Importance of reprocessing

The medical literature reports incidents of cross-contamination resulting from improper reprocessing. It is strongly recommended that all individuals engaged in reprocessing closely observe all instructions given in this manual and the manuals of all ancillary equipment, and have a thorough understanding of the following items: • Professional health and safety policies of your hospital • Instruction manuals for the endoscope, accessories, and all the other reprocessing equipment • Structure and handling of the endoscope and accessories • Handling of pertinent chemicals When selecting appropriate methods and conditions for cleaning and disinfection and sterilization, follow the policies at your institution, applicable national laws and standards, and professional society guidelines and recommended practices, in addition to the instructions given in this manual.

1.3

Signal words

The following signal words are used throughout this manual:

WARNING

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury. It may also be used to alert against unsafe practices or potential equipment damage.

NOTE

2

Indicates additional helpful information.

CF-HQ190L/I REPROCESSING MANUAL

1.4 Precautions

1.4

Ch.1

Precautions WARNING • An insufficiently reprocessed endoscope and/or accessories may pose an infection control risk to the patients and/or operators who contact them. • The endoscope reprocessor, video system center, light source, and/or front panels of equipment may cause an infection control risk. Perform proper cleaning and disinfection as described in their respective instruction manuals. A tap and/or basin that medical personnel come in contact with may cause an infection control risk as well. Perform proper replacement, cleaning, and disinfection. • All disinfection methods (whether performed manually or by an AER/WD), and all sterilization methods (whether performed by ethylene oxide gas or steam) require thorough prior cleaning of the instruments being reprocessed. If the instruments are not adequately cleaned prior to disinfection/sterilization, these processes will be ineffective. Immediately after each patient procedure and before disinfection/sterilization, thoroughly clean the endoscope and the accessories used with the endoscope. • All channels of the endoscope, including the instrument channel and the auxiliary water channel, and all accessories used with the endoscope during the patient procedure, such as all valves and the auxiliary water tube (MAJ-855), must be reprocessed after each patient procedure, even if the channels or accessories were not used during the patient procedure. Insufficient reprocessing of these components may pose an infection control risk to patients and/or operators. • Residual disinfectant solution may cause adverse reactions in patients. Therefore, rinse all external surfaces and channels of the endoscope and accessories thoroughly with water to remove residual disinfectant solution after disinfection. • The results of sterilization depend on various factors. These factors include how the equipment was packaged and the placing and loading of the package in the sterilization device. Verify the sterilization process using biological and/or chemical indicators. Follow the guidelines for sterilization issued by national authorities, professional organizations and infection control professionals, including the frequency of the above verification, as well as the instruction manual for the sterilization device.

CF-HQ190L/I REPROCESSING MANUAL

3

1.4 Precautions

Ch.1

WARNING • Establish an internal system of identifying contaminated versus reprocessed endoscopes and accessories to prevent both mix-ups and cross-contamination. Some national or professional guidelines recommend separating dirty (contaminated) area, clean area, and storage area. Touching a reprocessed endoscope and/or accessories with contaminated gloves or placing them on a contaminated hanger or surface, including letting them touch the floor, will recontaminate them. • Prior to each patient procedure, confirm that the endoscope and accessories have been properly reprocessed and stored. If there are any doubts or questions, reprocess them again before the patient procedure, following the instructions given in this manual. • Perform a leakage test on the endoscope after each precleaning procedure. Do not use the endoscope if a leak is detected. Use of an endoscope with a leak may cause a sudden loss of the endoscopic image, damage to the bending mechanism, or other malfunctions. Use of a leaking endoscope may also pose an infection control risk. Leakage tester

Figure 1.1 • Store alcohol in an airtight container. Alcohol stored in an open container may cause a fire hazard and may result in a loss of efficacy due to evaporation. • Do not use the AW channel cleaning adapter (MH-948) for patient procedures. It will cause continuous insufflation and could result in patient injury.

AW channel cleaning adapter (MH-948)

Figure 1.2

4

CF-HQ190L/I REPROCESSING MANUAL

1.4 Precautions

Ch.1

WARNING • The accessories listed on the front cover of this manual cannot be refurbished or repaired and are intended to be replaced once they show any signs of wear and tear. Should any irregularity be observed, use a replacement accessory instead. Using defective accessories may cause equipment malfunction, reduce the efficacy of reprocessing, present a risk to patients and/or operators, or damage the endoscope and/or accessories. • Single-use brushes, such as the single use combination cleaning brush (BW-412T), are designed for cleaning only one endoscope and its related accessories. Dispose of the single-use brush immediately after use. Using a single-use brush to clean multiple endoscopes and/or accessories may reduce its cleaning efficacy and may damage the brush. A damaged brush may break, which can damage the endoscope or accessories. • Patient debris and used reprocessing chemicals pose infection control risks. To guard against contact with dangerous chemicals and potentially infectious material, wear appropriate personal protective equipment during reprocessing. Such protective equipment should include appropriate eyewear, face mask, cap, moisture-resistant clothing, shoe covers, and chemical-resistant gloves that fit properly and are long enough to prevent skin exposure. • The reprocessing room must be adequately ventilated to minimize the risks from chemical vapors. • Always remove contaminated personal protective equipment before leaving the reprocessing area to prevent contamination from spreading. • Only Olympus-recommended or Olympus-endorsed AERs/WDs have been validated by Olympus. When using an AER/WD that is not recommended by Olympus, the manufacturer of the AER/WD is responsible for validating compatibility of the AER/WD with each Olympus endoscope and accessory. • Before using an AER/WD, confirm that it is capable of reprocessing the endoscope including all channels and accessories. Be sure to attach all required connectors/adapters. Otherwise, insufficient reprocessing may pose an infection control risk. If you are uncertain as to the ability of your AER/WD to reprocess the endoscope including all channels and accessories, contact the manufacturer of the AER/WD for specific instructions and information on compatibility and required connectors/adapters. • Instructions provided in this manual are not valid for Olympus devices repaired by a non-Olympus facility. The Olympus recommended reprocessing procedures have not been validated for reprocessing devices repaired by a non-Olympus facility. In the event that your device has been repaired by a non-Olympus facility, please contact the repair facility for instructions regarding reprocessing.

CF-HQ190L/I REPROCESSING MANUAL

5

1.4 Precautions

Ch.1

WARNING • Prions, which are the pathogenic agents of the Creutzfeldt-Jakob disease (CJD) cannot be destroyed or inactivated by the reprocessing methods stated in this instruction manual. When using the endoscope and accessories on patients with CJD or variant Creutzfeldt-Jakob disease (vCJD), be sure to use them for such patients only, or immediately dispose of them after use in an appropriate manner to prevent the usage of exposed devices on other patients. For methods to handle CJD, please follow the respective guidelines in your country. • The endoscope and accessories may be damaged by published methods for destroying or inactivating prions. For information on the durability of Olympus equipment against a particular reprocessing method, please contact Olympus. In general, Olympus cannot guarantee the effectiveness, safety, and durability of reprocessing methods not described in this reprocessing manual. If you choose to use a reprocessing method not recommended in this manual, the local institution and/or physicians must assume responsibility for its safety and efficacy. Make sure to carefully inspect each piece of endoscopic equipment for irregularities (damage) prior to each patient procedure. Do not use the equipment if any irregularity is found. • Good quality control practices typically require appropriate documentation. Items such as local SOPs (Standard Operating Procedures), confirmation of operator training, routine testing of the disinfectant’s MEC (Minimal Effective Concentration), confirmation of the disinfectant’s use-life, etc. should be documented as performed.

CAUTION • Before immersing the endoscope in reprocessing fluids, confirm that the ETO cap (MB-156) is not attached to the endoscope. If the ETO cap is attached, the reprocessing fluids will be able to penetrate the inside of the endoscope, and it can be damaged. • When aerating or irrigating the endoscope channels, the air or water pressure must not exceed 0.5 MPa (5 kgf/cm2, 71 psig). Higher pressures may cause damage to the endoscope.

6

CF-HQ190L/I REPROCESSING MANUAL

1.5 Reprocessing before the first use

Ch.1

CAUTION • When reprocessing an endoscope that has a flexibility adjustment mechanism, make sure that the insertion tube is set to its most flexible condition (indicated by the “” mark on the flexibility adjustment ring). If the endoscope is reprocessed while the insertion tube is in a rigid condition, the endoscope may be damaged.

“” mark Flexibility adjustment ring

Figure 1.3 • Store spare accessories in their original packaging to prevent damage. • To prevent damage, do not apply excessive force to the endoscope and accessories during reprocessing. • Vapors from disinfectant solution and alcohol may damage electronic devices such as computers. Properly manage the quality and durability of the devices used in reprocessing rooms and the ventilation performance of the rooms.

1.5

Reprocessing before the first use

New endoscopes, repaired endoscopes, accessories, and the carrying case for endoscopes are not reprocessed prior to shipping from Olympus, regardless of whether those instruments are for new purchase, demo or loaner purposes. Reprocess all such endoscopes and accessories received from Olympus according to the instructions given in this manual before storage and before using them in a patient procedure.

CF-HQ190L/I REPROCESSING MANUAL

7

1.6 Reprocessing and storage after use

Ch.1

1.6

Reprocessing and storage after use WARNING • Do not reuse rinse water. • Disinfectant solution is only effective when used according to the disinfectant manufacturer’s instructions. Follow the manufacturer’s instructions regarding activation (if required), concentration, temperature, contact time and use life required to achieve disinfection. • If the disinfectant solution is reused, check its efficacy by proper methods, such as using a test strip, according to the disinfectant manufacturer’s recommendations prior to use. • Do not reuse alcohol. • Alcohol is not a sterilant or high-level disinfectant. • To maintain sterility of equipment following sterilization, use sterile packaging and wraps according to national guidelines.

1.7

Reprocessing before patient procedure WARNING • Improper storage practices, such as not thoroughly drying external and internal surfaces (lumens) prior to storage, will lead to an infection control risk. • Improper handling, such as touching a reprocessed endoscope and/or accessories with contaminated gloves, placing a reprocessed device on a contaminated hanger or surface, allowing devices to touch the floor, etc. will recontaminate the device.

NOTE Some national or professional guidelines recommend reprocessing endoscopes prior to their first use of the day. Confirm that the endoscope and accessories have undergone proper reprocessing following their last use and that they have been stored properly. Check the storage period of reprocessed endoscopes, and check for surface contamination (e.g., dust). Check the expiration date marked on all items and check for tears or breaches in the sterile packaging. If there are any doubts or questions concerning whether a device is contaminated, reprocess it again following the instructions given in this manual.

8

CF-HQ190L/I REPROCESSING MANUAL

2.1 ETO cap (MB-156)

Chapter 2

Function and Inspection of the Accessories for Reprocessing

Ch.2

Certain accessories are required for reprocessing the endoscope. This chapter describes the function of these accessories. It also describes how to inspect these accessories before using them to reprocess the endoscope.

2.1

ETO cap (MB-156)

Connector

Figure 2.1

Function When performing ETO gas sterilization, the ETO cap must be attached to the venting connector on the endoscope connector.

CAUTION If the ETO cap is not attached to the endoscope during ethylene oxide gas sterilization, the air inside the endoscope will expand and could rupture the bending section cover and/or damage the angulation mechanism.

Inspection Confirm that the ETO cap is free from scratches, flaws, and debris.

CF-HQ190L/I REPROCESSING MANUAL

9

2.2 Channel plug (MH-944)

2.2

Channel plug (MH-944)

Ch.2 Biopsy valve cap

Plug frame

Suction plug Air/water plug

Figure 2.2

Function The channel plug is used to plug the openings of the instrument channel port and the suction and air/water cylinders of the endoscope whenever the injection tube (MH-946) is used to flush the suction and air/water channels of the endoscope with reprocessing fluids.

Plug frame

Biopsy valve cap

Instrument channel port

Figure 2.3

NOTE When attached to the endoscope, the channel plug is designed to allow a small amount of fluid to exit from the openings of the endoscope. This enables reprocessing fluids to contact the endoscope openings.

Inspection Confirm that the suction plug, air/water plug, and the biopsy valve cap of the channel plug are free from cracks, scratches, and debris. NOTE The channel plug does not need to be reprocessed prior to its first use.

10

CF-HQ190L/I REPROCESSING MANUAL

2.3 Injection tube (MH-946)

2.3

Injection tube (MH-946) Ch.2 Information card

Suction channel tube Connector plug

Suction channel port

Air pipe port

Air/water channel port

Air/water channel tube Filter tube

Suction port

Filter mesh

Figure 2.4

Function The injection tube is used to inject reprocessing fluids into the instrument channel, suction channel, and air/water channels of the endoscope. It is also used to flush air through these channels to expel fluids. Suction channel tube

Syringe

Suction port

Air/water channel tube

Air pipe port

Basin

Connector plug

Reprocessing fluids

Figure 2.5

CF-HQ190L/I REPROCESSING MANUAL

11

2.3 Injection tube (MH-946)

Inspection 1 Confirm that all components of the injection tube are free from cracks, scratches,

Ch.2

flaws, and debris.

2 Confirm that the filter mesh is in the suction port of the injection tube. 3 Attach a clean 30 ml syringe to the suction channel port of the injection tube. With the suction port of the injection tube immersed in the water as described in Section 3.2, “Water (for reprocessing)”, withdraw the syringe plunger and confirm that the water is drawn into the syringe. Depress the plunger and confirm that the water is emitted from the suction channel tube of the injection tube. Confirm that the water is not emitted from the suction port when removing the suction port from the water. Suction channel port Suction channel tube Syringe Suction port

Figure 2.6

4 Move the syringe to the air/water channel port of the injection tube. With the suction port of the injection tube immersed in the water, withdraw the syringe plunger and confirm that the water is drawn into the syringe. Depress the plunger and confirm that the water is emitted from the air pipe port of the injection tube. Confirm that the water is not emitted from the suction port when removing the suction port from the water. Air/water channel port Suction channel tube Syringe Suction port

Air pipe port

Figure 2.7

12

CF-HQ190L/I REPROCESSING MANUAL

2.4 Channel cleaning brush (BW-20T)

NOTE The injection tube does not need to be reprocessed prior to its first use.

Ch.2

2.4

Channel cleaning brush (BW-20T) Metal tip Shaft

Bristles

Brush head

Figure 2.8

Function The channel cleaning brush is used to brush the inside of the instrument channel and suction channel of the endoscope, and the interior and openings of the suction valve (MH-443), the air/water valve (MH-438), and the biopsy valve (MB-358).

Suction cylinder Instrument channel

Suction channel

Figure 2.9

CF-HQ190L/I REPROCESSING MANUAL

13

2.4 Channel cleaning brush (BW-20T)

Depress

Ch.2

Biopsy valve (MB-358)

Suction valve (MH-443)

Air/water valve (MH-438)

Figure 2.10

Inspection 1 Confirm that the brush head and the metal tip of the distal end are securely attached. Check the brush head for loose or missing bristles.

2 Check the bristles for damage. If the bristles are crushed, gently straighten them with your gloved fingertips.

3 Check for bends, scratches, and other damage to the shaft. 4 Visually check for debris on the shaft and/or the bristles of the brush head. If there is debris on the brush, immerse the brush in the water as described in Section 3.2, “Water (for reprocessing)” and clean the brush until no debris is observed on the brush. NOTE The channel cleaning brush does not need to be reprocessed prior to its first use.

14

CF-HQ190L/I REPROCESSING MANUAL

2.5 Channel-opening cleaning brush (MH-507)

2.5

Channel-opening cleaning brush (MH-507) Ch.2 Bristles

Shaft

Brush head

Brush handle

Figure 2.11

Function The channel-opening cleaning brush is used to brush the suction cylinder and the instrument channel port of the endoscope.

Suction cylinder Instrument channel port

Figure 2.12

Inspection 1 Check the brush head for loose or missing bristles. 2 Check the bristles for any damage. If the bristles are crushed, gently straighten them with your gloved fingertips.

3 Check for bends, scratches, and other damage to the shaft. 4 Visually check for debris on the shaft and/or the bristles of the brush head. If there is debris on the brush, immerse the brush in the water as described in Section 3.2, “Water (for reprocessing)” and clean the brush until no debris is observed on the brush. NOTE The channel-opening cleaning brush does not need to be reprocessed prior to its first use. CF-HQ190L/I REPROCESSING MANUAL

15