OLYMPUS

OLYMPUS Mobile Workstations, Trolleys and Support Arms

MAJ-1643 Drawer Unit Instructions Issue 4 Jan 2012

Instructions

24 Pages

Preview

Page 1

INSTRUCTIONS DRAWER UNIT

MAJ-1643

1 Intended Use The MAJ-1643 drawer unit is designed to provide secure storage of ancillary items on the WM-NP2 mobile workstation. The MAJ-1643 can be stacked up to a maximum of three units high.

2 Instruction Manual This instruction manual contains essential information on using this equipment safely and effectively. Before use, thoroughly review this manual and the manuals of all other equipment which will be used. If you have any questions or comments about any information in this manual, please contact Olympus. Retain this instruction manual with the workstation instruction manual for future reference.

3 Signal Words CAUTION

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury. It may also be used to alert against unsafe practices or potential equipment damage. NOTE

Indicates additional helpful information.

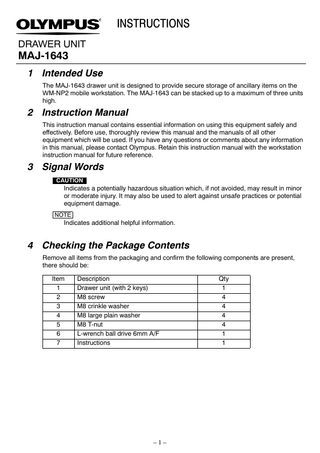

4 Checking the Package Contents Remove all items from the packaging and confirm the following components are present, there should be: Item 1 2 3 4 5 6 7

Description Drawer unit (with 2 keys) M8 screw M8 crinkle washer M8 large plain washer M8 T-nut L-wrench ball drive 6mm A/F Instructions

–1–

Qty 1 4 4 4 4 1 1

5 Assembly NOTE

• The MAJ-1643 may be fitted as a single unit or in multiples up to a maximum of three units high, see section 6. • Depending on the combination of drawers being fitted, you may need to reposition a shelf (see section 7). 1. Position the workstation on a flat surface and apply both castor brakes. 2. Remove the rear door, turn the latch to release the top then lift from the two studs (Figure 1).

Latch

Figure 1 3. Referring to the cross-section view in Figure 2 and the steps below, fit the two M8 T-nuts. (1) Insert one corner of the T-nut into the slot inside of the workstation. (2) Push the T-nut in so that its ball goes inside the slot. (3) Push the other corner of the T-nut into the slot using the supplied L-wrench ball drive or similar. (4) Position one T-nut about 50mm below the shelf upon which the drawer unit will be fitted and the other T-nut another 50mm lower.

–2–

Top view - inserting T-nut

1

2

3

50mm

50mm M8 T-nut

Figure 2 4. Referring to Figure 3, check the positions of the six tabs, four slots and one spring plunger and then unlock the drawer unit using the supplied key. Unlock before assembly

Folded tabs

Fixing slots

Spring plunger

Figure 3

–3–

5. Hold the drawer unit with both hands as shown in Figure 4a and push it up against the shelf so that all the six tabs enter their cutouts. At this stage, the drawer unit is correctly positioned if it protrudes beyond the shelf by about 2cm. Check that there is no gap between the drawer unit and the shelf, and then slide the drawer unit back into the shelf while pressing down from above, as shown in Figure 4b, until the fixing slots (see Figure 3) are aligned with the slots in which the T-nuts are inserted. If the drawer unit is difficult to slide, press it down by gently tapping on it with the palm of your hand.

a

b Figure 4 6. From the rear of the workstation, fit the fixing slots gently over the T-nuts using two M8 screws, M8 crinkle washers and M8 plain washers, as shown in Figure 5. If the screw positions of the fixing slots and the T-nuts are not aligned, insert the supplied L-wrench ball drive through the fixing slot and lever the drawer until they are aligned. When all four screws have been fitted, tighten firmly with the L-wrench ball drive.

–4–

Drawer unit

M8 screw M8 crinkle washer M8 plain washer

Figure 5 7. Refer to the steps described in Figure 6 when removing the drawer from the housing. (1) Pull the drawer out as far as possible. (2) Press the release levers on each side of the drawer in the direction of the arrows. (3) Open the drawer again and remove from the housing. Housing

Drawer Release lever

Figure 6 CAUTION

• The maximum storage load of each drawer is 5kg, otherwise stability may be compromised and this equipment may be damaged. • Ensure each drawer is locked when moving the workstation.

–5–

6 Multiple drawer unit assembly 1. Change the height of the shelves to suit the number of drawer units being installed and the devices mounted on the shelves. (See section 7 Moving a shelf) 2. Fit a single drawer unit on a shelf using the steps described in section 5 Assembly. 3. A second and third drawer unit can be fitted by repeating steps 5 and 6 of section 5 Assembly. Figure 7 shows the third drawer unit fitted on the second shelf from the bottom.

Figure 7

7 Moving a shelf Use the following steps to reposition the intermediate shelves. CAUTION

Before commencing shelf adjustment, ensure equipment is disconnected and removed from the shelf. 1. Remove any equipment that is on the shelf. 2. Position the workstation on a flat surface and apply the brakes on two diagonally opposite castors. 3. Remove the two cable ducts that are fitted on the rear of the intermediate shelf and the cable tie that is fitted at the same height as the shelf. You can remove the cable tie by inserting a flat bladed screwdriver behind the pin in the middle of the cable tie and pulling it towards you, as shown in Figure 8.

–6–

Cable duct

Stud

Cable tie

Figure 8 4. Check that nothing has been placed on the shelf and, referring to Figure 9, loosen the two M8 screws that are securing the shelf about half a turn using the supplied 6mm L-wrench ball drive – do not remove.

M8 screw

Spring plunger

Figure 9 5. Take a firm hold of the shelf and, referring to Figure 10, unlock the two spring plungers fitted on each side. Pull the spring plunger head towards you, twist 90° and release. The spring plunger remains extended and is unlocked. NOTE

The spring plungers cannot be removed from the shelves. 6. Take a firm hold of the shelf, check where you will move it after removal, and remove the two M8 screws that were loosened in step 4.

–7–

7. Move the shelf to the required height and lock the spring plungers. While still pulling the spring plunger head, twist 90° and release. The spring plunger head tries to spring back to its original position. The spring plunger head will lock back into its original position after you reposition the shelf so that the spring plungers are aligned with the column holes. CAUTION

After moving the shelf, check that the four spring plunger heads are not protruding. If any spring plunger head is protruding, the shelf may tilt and get damaged due to insufficient engagement with the shelf holes. 8. Check that the shelf is not tilting and firmly tighten the two M8 screws with the L-wrench ball drive. 9. Fit the cable tie and cable ducts that were removed in step 3. Position the cable duct against the shelf, align the cable tie (with pin removed) with the shelf hole, and press the pin all the way through the cable tie into the hole to secure the cable duct.

Figure 10

–8–

8 Removing the drawer unit 1. Position the workstation on a flat surface, apply both castor brakes. 2. Empty the contents of the drawer. 3. From the rear of the workstation, remove the four M8 screws, M8 crinkle washers and M8 plain washers securing the drawer (see Figure 5). 4. Unlock the drawer. From the front of the workstation, take a firm hold of the drawer unit (see Figure 4) and pull forwards, one side of the drawer unit will disengage. CAUTION

Take care not to trap fingers when removing the drawer unit. 5. Referring to Figure 11, locate the spring plunger on the rear of the drawer unit, pull down and twist 90° to lock “open”. CAUTION

Please take care not to slide the drawer unit forwards with the spring plunger unlocked, as it will fall off the shelf. NOTE

The spring plungers cannot be removed from the shelves.

Figure 11 6. From the front of the workstation, take a firm hold of the drawer unit and prepare to support its weight (6kg), pull the drawer unit forwards where it will completely disengage and be free of the shelf.

–9–

9 Cleaning and Maintenance 1. Periodically check the security of the fixing screws, tightening as necessary. CAUTION

Regular maintenance is recommended to prevent risk to the user. 2. The drawer unit should be cleaned if it becomes contaminated by wiping with a soft gauze cloth using Aqueous Neutral Detergent or 70% alcohol. CAUTION

Use personal protective equipment to guard against dangerous chemicals and potentially infectious material, otherwise, blood, mucus and other potentially infectious material from the patient could pose an infection risk. During cleaning, wear appropriate protective equipment, such as eye wear, face mask, moistureresistant clothing and chemical-resistant gloves that fit properly and are long enough so that your skin is not exposed. 3. When removing the drawer from the housing for cleaning, refer to step 7 described in section 5 Assembly.

10 Specifications Product name Dimensions (mm)

Weight Load capacity Drawer stacking

MAJ-1643 Drawer unit Height Depth Width Overall: 115 480 487 Drawer: 115 336 475 6kg unladen 5kg each drawer 3 units maximum

11 Spare parts Item Drawer keys (2)

Part No K10021523

– 10 –

OLYMPUS MEDICAL SYSTEMS CORP. 2951 Ishikawa-cho, Hachioji-shi, Tokyo 192-8507, Japan Fax: (042) 646-2429 Telephone: (042) 642-2111

OLYMPUS EUROPA HOLDING GMBH (Premises/Goods delivery) Wendenstrasse 14-18, 20097 Hamburg, Germany (Letters) Postfach 10 49 08, 20034 Hamburg, Germany Fax: (040)23773-4656 Telephone: (040)23773-0

OLYMPUS AMERICA INC. 3500 Corporate Parkway, P.O. Box 610, Center Valley, PA 18034-0610, U.S.A. Fax: (484) 896-7128 Telephone: (484) 896-5000

KEYMED LTD. KeyMed House, Stock Road, Southend-on-Sea, Essex SS2 5QH, United Kingdom Fax: (01702) 465677 Telephone: (01702) 616333

OLYMPUS SINGAPORE PTE LTD. 491B, River Valley Road #12-01/04, Valley Point Office Tower, Singapore 248373 Fax: 6834-2438 Telephone: 6834-0010

OLYMPUS (BEIJING) SALES & SERVICE CO,. LTD. A8F, Ping An International Financial Center, No. 1-3, Xinyuan South Road, Chaoyang District, Beijing, 100027 P.R.C. Fax: (86)10-5976-1299 Telephone: (86)10-5819-9000

OLYMPUS MOSCOW LIMITED LIABILITY COMPANY 117071, Moscow, Malaya Kaluzhskaya 19, bld. 1, fl.2, Russia Fax: (095) 958-2277 Telephone: (095) 958-2245

OLYMPUS AUSTRALIA PTY. LTD. 31 Gilby Road, Mount Waverley, VIC., 3149, Australia Fax: (03)9543-1350 Telephone: (03)9265-5400

OLYMPUS LATIN AMERICA INC. 5301 Blue Lagoon Drive, Suite 290 Miami, FL 33126-2097, U.S.A. Fax: (305)261-4421 Telephone: (305)266-2332

OLYMPUS KOREA CO,. LTD. Olympus-Tower, 114-9 Samseong-Dong, Gangnam-Gu, Seoul 135-090 Korea Fax: (02)6255-3494 Telephone: (02)6255-3210

Issue 4 January 2012

© KeyMed 2012 Printed in UK K10020652