OLYMPUS

OLYMPUS Mobile Workstations, Trolleys and Support Arms

MAJ-2147 LCD Monitor Arm Instructions Issue 2 Sept 2017

Instructions

36 Pages

Preview

Page 1

INSTRUCTIONS COMPACT LCD MONITOR ARM

MAJ-2147 1 Intended Use The MAJ-2147 LCD Compact Monitor Arm has been designed to mount up to 26" VESA standard flat screen monitors (3.9 to 8.5 kg) on a compatible Olympus trolley.

2 Instructions for use These instructions for use contains essential information on using this equipment safely and effectively. Before use, thoroughly review these instructions for use and the instructions for use of all other equipment which will be used. If you have any questions or comments about any information in these instructions for use, contact Olympus. Retain these instructions for use with the trolley instructions for use for future reference. Installation of this device should be performed by suitably qualified service personnel in accordance with these instructions for use.

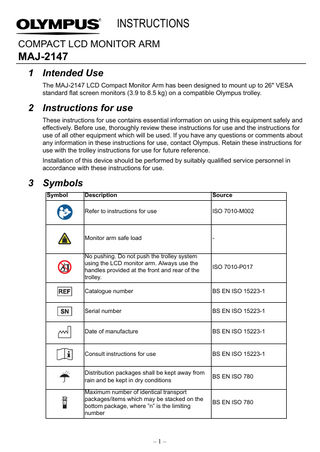

3 Symbols Symbol

Description

Source

Refer to instructions for use

ISO 7010-M002

Monitor arm safe load

-

No pushing. Do not push the trolley system using the LCD monitor arm. Always use the handles provided at the front and rear of the trolley.

ISO 7010-P017

Catalogue number

BS EN ISO 15223-1

Serial number

BS EN ISO 15223-1

Date of manufacture

BS EN ISO 15223-1

Consult instructions for use

BS EN ISO 15223-1

Distribution packages shall be kept away from rain and be kept in dry conditions

BS EN ISO 780

Maximum number of identical transport packages/items which may be stacked on the bottom package, where ”n” is the limiting number

BS EN ISO 780

–1–

Contents of the distribution packages are fragile, BS EN ISO 780 therefore handle with care This is the correct upright position of the distribution packages for transport and/or storage

BS EN ISO 780

Unit complies with relevant European directives

Medical Device Directive 93/42/EEC

Distribution packages shall be stored, transported and handled within temperature limits

BS EN ISO 780

Humidity limitation

BS EN ISO 15223-1

Atmospheric pressure limitation

BS EN ISO 15223-1

Manufacturer

BS EN ISO 15223-1

4 Signal Words WARNING

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury. CAUTION

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury. NOTE

Indicates additional helpful information.

–2–

5 Compatibility The MAJ-2147 LCD Compact Monitor Arm is compatible with the following Olympus trolleys: TC-C4 Compact Trolley

6 Checking the Package Contents • Remove all items from the packaging and confirm the following components are present. • Contact your Olympus service centre if any parts are damaged or missing. Item 1

2 3 4 5 6

Description LCD Compact Monitor Arm: 2x Cable clips 1x Cable swivel guide 1x Upper cable guide M12 nyloc nut Instruction manual Cable tie 6 mm A/F Allen wrench Spanner

Qty. 1

1 1 6 1 1

7 Warnings and Cautions WARNING

• Use only the fixing supplied to mount the MAJ-2147 to the trolley, otherwise damage • • • •

• • • •

to equipment or personal injury may result. Secure the LCD monitor to the VESA mount using only the fixing screws supplied with the LCD monitor. Do not modify this equipment without authorisation of the manufacturer. Do not put excessive downward force on the LCD monitor arm when it is extended. Otherwise the workstation may lose stability and topple causing equipment damage and/or personal injury. Always place the LCD monitor arm in its highest position before removing the monitor, otherwise the gas strut will force the arm to extend rapidly upwards when the last screw is removed which may cause personal injury and/or equipment damage. Do not install or use LCD monitor arms and monitors on an empty trolley. Install LCD monitor arms and monitors after all other equipment has been installed in an appropriate place on the trolley. Only fit monitors as specified in chapter 16, as overloading may cause structural impairment of the LCD monitor arm. The LCD monitor arm is only compatible with the TC-C4 trolley. Do not attempt to fit the LCD monitor arm to any other trolley, as its safe use may be compromised.

CAUTION

• The LCD monitor arm is shipped in the fully extended position. Do not attempt to close the arm without a monitor installed, otherwise personal injury may result.

• Take care not to pinch fingers between moving joints on the LCD monitor arm. • Do not hang any items from the LCD monitor arm other than the LCD monitor and cables. Otherwise, additional items will affect the performance of the LCD monitor arm and may cause it to fail unexpectedly.

–3–

• Take care that cables do not become taut and are free to move around joints when rotating the LCD monitor arm. • Do not leave the monitor in a position where you may hit your head. • Only extend the LCD monitor arm when the trolley is on a flat level surface with both castor brakes applied. • Be careful when using the LCD monitor arm, as it can protrude outside of the compact trolley when in use.

8 Assembling the LCD Monitor Arm NOTE

• Only one person is needed to install the compact LCD monitor arm. 1. Position the workstation on a level surface. 2. Apply all brakes.

3. Remove the blanking plug from the top tray.

–4–

4. Place the LCD monitor arm in the fixing hole of the top tray ensuring the alignment pins locate in the holes in the top tray.

5. Secure the fixed monitor mount using the M12 nyloc nut. CAUTION

• Keep hold of the LCD monitor arm until the M12 nyloc nut is fitted, otherwise the LCD monitor arm may fall and cause equipment damage or personal injury. 6. Tighten the M12 nyloc nut using spanner provided.

–5–

9 Attaching the LCD Monitor The LCD monitor arm is pre-tensioned to counterbalance an LCD monitor weighing approximately 7.8 kg. • If installing a monitor of different weight, install as described in this section, then refer to chapter 14 and adjust the LCD monitor arm tension. CAUTION

• Secure the LCD monitor to the VESA mount using only the fixing screws supplied with the LCD monitor. 1. Insert two monitor fixing screws into the top two monitor fixing holes on the back of the LCD monitor. Leave a gap the thickness of the VESA mount.

2. Lift the LCD monitor onto the VESA mount. 3. Lightly fasten the two screws.

4. Insert the remaining two monitor fixing screws into the two lower fixing holes. 5. Completely fasten all four screws.

–6–

10 Connecting the LCD Monitor 1. To remove the upper cable guide from the LCD monitor arm, firmly pinch the base of the upper guide as shown. Cable tie fixing positions Cable tie fixing positions (to secure cables on the outside of the upper cable cover, if required)

Upper cable guide

2. Pull down and lift away the upper cable guide. 3. Use a flat bladed screwdriver to open the cable swivel guide.

Cable swivel guide

4. Remove the cable swivel guide from the LCD monitor arm. 5. Refer to the LCD monitor instruction manual and connect the power and signal cables to the monitor. 6. Route the power and the monitor signal cables along the LCD monitor arm, down the monitor stand and through the cable openings at the rear of the trolley top tray as shown. –7–

Fit cable tie

1

Fit cable tie

Fit cable tie

2

Re-fit the upper cable guide.

3

Figure 10a

–8–

4

Rotate the LCD monitor arm left and right and adjust cable length.

Fit cable tie

5

6 Re-fit cable swivel guide

Figure 10b –9–

7. Route the power and the signal cables within the cable management features at the rear of the trolley. 8. Connect to the equipment as instructed by the equipment instruction manuals. NOTE

If the LCD Monitor is supplied with an external power supply, it is recommended that the power supply be positioned on the upper surface of the installed endoscopic video system at the rear of the trolley. 9. Fasten the monitor cables to the monitor stand using the two pre-fitted cable guides. CAUTION

• Make sure that cables do not become taut and are free to move around joints when rotating the LCD monitor arm.

11 Removing the LCD Monitor WARNING

• Before removing the monitor, place the LCD monitor arm in its highest position. Otherwise the gas strut will force the arm to extend rapidly upwards when the last screw is removed which may cause personal injury and equipment damage. 1. Disconnect all cables from LCD monitor. 2. Place the LCD monitor arm in its highest position. 3. Remove the two lower fixing screws. 4. Hold the LCD monitor and slightly loosen the upper two fixing screws. 5. Lift the LCD monitor and remove it from the VESA mount.

12 Transport • To ensure best stability and visibility during trolley transport, position the LCD monitor over the trolley and rotate it to provide the most favorable view in the direction of travel.

– 10 –

13 Operating Instructions CAUTION

• Take care not to pinch fingers between moving joints on the LCD monitor arm. • Do not leave the monitor in a position where you may hit your head. • Do not hang any items from the LCD monitor arm other than the LCD monitor and cables. Otherwise, additional items will affect the performance of the LCD monitor arm and may cause it to fail unexpectedly. • Make sure that cables do not become taut and are free to move when rotating the LCD monitor arm. 1. Position the workstation in the operating location. 2. Apply all brakes. 3. Hold the LCD monitor and move it carefully to the required position. 4. Tilt it as required and let go of the LCD monitor, it will remain in this position until moved again. NOTE

If raising or lowering the LCD monitor arm against an end stop, momentarily hold the arm against the stop to reduce the potential for the arm to bounce away from the stop.

– 11 –

14 Adjusting the LCD Monitor Arm The LCD monitor arm is pre-tensioned to counterbalance an LCD monitor weighing approximately 7.8 kg. If installing a monitor of different weight, adjust the tension as described below. 1. Install the LCD monitor as described in chapter 9. 2. Using a 6 mm Allen wrench, turn the adjustment screw in the direction of ‘+’ for a heavier monitor and ‘-’ for a lighter monitor. Initially it is recommended that the screw is adjusted by a full turn. 3. After each adjustment, carefully move the LCD monitor arm from stop to stop, momentarily holding it at each stop, letting go and then observing any movement away from the stop. Adjustment is correct when the monitor remains in position ±10 mm. If the monitor rises noticeably from the lower stop, more adjustment towards ‘-’ is required. If the monitor falls noticeably from the upper stop, more adjustment towards ‘+’ is required. For fine adjustment, it is recommended that the screw is moved ¼ turn at a time, but note that several full screw turns may be necessary before fine adjustment is made. Adjustment screw

Figure 11

– 12 –

15 Reprocessing, Inspection and Maintenance 15.1 Reprocessing General information for reprocessing Reprocess the product according to the instructions in this chapter.

Instructions for using reprocessing agents - The reprocessing agent must be approved by the manufacturer for cleaning and disinfection of medical devices and for the material to be reprocessed. - Refer to national and local guidelines regarding the approval of using alcohol as cleaning and disinfecting agent. - Select contact times and concentrations of the solution in accordance with the instructions given by the manufacturer of the cleaning and disinfecting agent. - The reprocessing agent must be approved and validated by the FDA, EPA or a comparable institution for its efficiency. - Reprocessing may lead to an increased wear of the product. Inspect the products thoroughly before use for traces of wear. WARNING

• Should the equipment become soiled with blood or other potentially infectious materials, reprocess the product according to the instructions in this chapter otherwise the potentially infectious material from the patient could pose an infection risk. • The use of Chlorine releasing agent above 1000 ppm and/or non-aqueous neutral detergent may cause corrosion to the compact trolley paint work, causing paint to lift and surface rust to form.

– 13 –

WARNING

• The LCD monitor arm has been chemically verified to withstand the following cleaning agents, i.e. the agent does not negatively affect materials or functional performance of the product: - 2% Aqueous Neutral Detergent - 70% Ethyl alcohol - 70% Isopropyl alcohol - Sodium Hypochlorite NaCIO (see dilution table below) Dilution Factor

Sodium Hypochlorite NaCIO (CAS#7681-52-9) Active Ingredient

# Parts Water

# Parts NaCIO

5.25%

9

1

6.15%

10

1

8.25%

14

1

Use of cleaning chemicals not listed above should be checked with your Olympus service center prior to use. CAUTION

• Do not allow any fluids into contact with electrical equipment. • Do not use harsh or abrasive cleaning materials on the LCD monitor arm. • Ensure all surfaces are thoroughly dried before reusing the LCD monitor arm.

Cleaning

Cleaning procedure Perform the following cleaning procedure immediately after use. If cleaning is delayed, organic debris will dry and it can be difficult to effectively clean the surfaces. 1. Thoroughly wipe the surfaces of the LCD monitor arm until visibly clean using a soft, lintfree wipe that is soaked with a suitable reprocessing agent. 2. In case of heavy soiling use additional clean wipes. 3. Let the surfaces dry before disinfection or wipe them dry using a lint-free cloth.

Inspection prior to disinfection • Visually inspect the product thoroughly after cleaning. The product must be visually clean.

• If there are any signs of debris, repeat the cleaning process. CAUTION

• Use personal protective equipment to guard against dangerous chemicals and potentially infectious material, otherwise, blood, mucus and other potentially infectious material from the patient could pose an infection risk.

• During cleaning, ensure worn protective equipment, such as eye wear, face mask, moisture-resistant clothing and chemical-resistant gloves fit properly and are long enough so that your skin is not exposed.

– 14 –

Disinfection

Disinfection procedure 1. Thoroughly wet the surfaces of the LCD monitor arm with a lint-free cloth that is soaked with a suitable disinfectant. 2. The surfaces must remain visibly wet for the period specified by the disinfectant’s manufacturer. If necessary, use additional wipes to assure the designated continuous wet contact time. 3. Wipe the surfaces dry using a lint-free cloth after the contact time has elapsed.

Suitable reprocessing agents for disinfection • Low-level disinfection efficacy has been validated by wiping with 70% Isopropyl alcohol and then wiping dry using a lint-free cloth.

15.2 Inspection and Maintenance 1. Annually check the security of the fixings, tighten the fixings if necessary. WARNING

• The MAJ-2147 LCD monitor arm incorporates a gas strut containing gas and oil under high pressure. Do not disassemble the LCD monitor arm. CAUTION

• Regular maintenance is required to prevent risk to the user.

– 15 –

16 Specifications Product name Weight Monitor compatibility Load capacity

MAJ-2147 Compact LCD Monitor Arm 4.6 kg Up to 26" VESA standard flat screen monitor 75 x 75 mm/100 x 100 mm VESA pitch 3.9 to 8.5 kg

17 Customer Spare Parts NOTE

• In order to maintain standards compliance, it is important that replacement components should have the same specification as those fitted originally. This can best be guaranteed by using only those spare parts and components listed in this instruction manual.

• Only fit those spare parts listed below. All other repair parts must be fitted by service staff using the instructions provided within the Olympus service manual. Item Cable clip Cable swivel guide Upper cable guide Fitting kit Instruction manual

Part No K10029956 K10021468 K10021469 K10029955 K10029957

Replacing the Cable Clip 1. Pull the damaged cable clip off of the LCD monitor arm and discard. 2. Position the replacement cable clip over the LCD monitor arm and snap into place. 3. Make sure that the cables are retained by the cable clip and that the cable clip is fully seated before use.

Replacing the Cable Swivel Guide 1. Use a flat bladed screwdriver to lever open the cable swivel guide and remove it from the LCD monitor arm. 2. Place the cables in the replacement cable swivel guide. 3. Place the cable swivel guide around the LCD monitor arm. 4. Close the cable swivel guide ensuring that the cables are retained. 5. Ensure that the cable swivel guide is free to rotate about the arm and that it is fully seated prior to use.

– 16 –

Replacing the Upper Cable Guide 1. Firmly pinch the base of the upper cable guide and pull down and lift away. 2. Place the cables in the replacement upper cable guide. 3. Position the upper cable guide in the slots on the top of the LCD monitor arm. 4. Slide the upper cable guide up until it clips into position, ensuring that it is fully seated prior to use.

18 End of Life The MAJ-2147 LCD monitor arm should not be disassembled at the end of its life as it contains components under pressure which may harm the user. • Dispose of the LCD monitor arm in accordance with local guidelines.

– 17 –

OLYMPUS MEDICAL SYSTEMS CORP. 2951 Ishikawa-cho, Hachioji-shi, Tokyo 192-8507, Japan Fax: (042) 646-2429 Telephone: (042) 642-2111

OLYMPUS EUROPA SE & CO. KG (Premises/Goods delivery) Wendenstrasse 14-18, 20097 Hamburg, Germany (Letters) Postfach 10 49 08, 20034 Hamburg, Germany Fax: (040)23773-4656 Telephone: (040)23773-0

OLYMPUS AMERICA INC. 3500 Corporate Parkway, P.O. Box 610, Center Valley, PA 18034-0610, U.S.A. Fax: (484) 896-7128 Telephone: (484) 896-5000

KEYMED (MEDICAL AND INDUSTRIAL EQUIPMENT) LTD. KeyMed House, Stock Road, Southend-on-Sea, Essex SS2 5QH, United Kingdom Fax: (01702) 465677 Telephone: (01702) 616333

OLYMPUS SINGAPORE PTE LTD. 491B, River Valley Road #12-01/04, Valley Point Office Tower, Singapore 248373 Fax: 6834-2438 Telephone: 6834-0010

OLYMPUS (BEIJING) SALES & SERVICE CO,. LTD. A8F, Ping An International Financial Center, No. 1-3, Xinyuan South Road, Chaoyang District, Beijing, 100027 P.R.C. Fax: (86)10-5976-1299 Telephone: (86)10-5819-9000

OLYMPUS MOSCOW LIMITED LIABILITY COMPANY 117071, Moscow, Malaya Kaluzhskaya 19, bld. 1, fl.2, Russia Fax: (095) 958-2277 Telephone: (095) 958-2245

OLYMPUS AUSTRALIA PTY. LTD. 3 Acacia Place, Notting Hill, VIC 3168, Australia Fax: (03)9543-1350 Telephone: (03)9265-5400

OLYMPUS LATIN AMERICA INC. 5301 Blue Lagoon Drive, Suite 290 Miami, FL 33126-2097, U.S.A. Fax: (305)261-4421 Telephone: (305)266-2332

OLYMPUS KOREA CO,. LTD. Olympus Tower 9F, 446, Bongeunsa-ro, Gangnam-gu, Seoul, Korea 135-509 Fax: (02)6255-3494 Telephone: (02)6255-3210

Issue 2 September 2017

©KeyMed 2017 Printed in UK K10029928