OLYMPUS

A Cord MAJ-860 Instructions

16 Pages

Preview

Page 1

USA: CAUTION:

INSTRUCTIONS

Federal law restricts this device to sale by or on the order of a physician.

A CORD

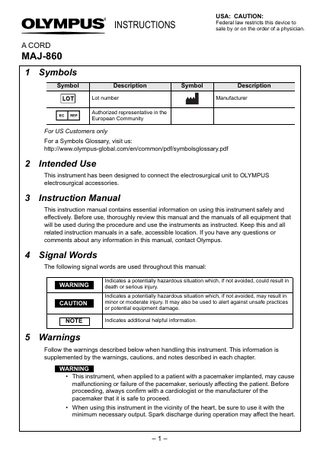

MAJ-860 1 Symbols Symbol

Description

Symbol

Lot number

Description Manufacturer

Authorized representative in the European Community

For US Customers only For a Symbols Glossary, visit us: http://www.olympus-global.com/en/common/pdf/symbolsglossary.pdf

2 Intended Use This instrument has been designed to connect the electrosurgical unit to OLYMPUS electrosurgical accessories.

3 Instruction Manual This instruction manual contains essential information on using this instrument safely and effectively. Before use, thoroughly review this manual and the manuals of all equipment that will be used during the procedure and use the instruments as instructed. Keep this and all related instruction manuals in a safe, accessible location. If you have any questions or comments about any information in this manual, contact Olympus.

4 Signal Words The following signal words are used throughout this manual: WARNING

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury. It may also be used to alert against unsafe practices or potential equipment damage.

NOTE

Indicates additional helpful information.

5 Warnings Follow the warnings described below when handling this instrument. This information is supplemented by the warnings, cautions, and notes described in each chapter. WARNING • This instrument, when applied to a patient with a pacemaker implanted, may cause malfunctioning or failure of the pacemaker, seriously affecting the patient. Before proceeding, always confirm with a cardiologist or the manufacturer of the pacemaker that it is safe to proceed. • When using this instrument in the vicinity of the heart, be sure to use it with the minimum necessary output. Spark discharge during operation may affect the heart.

–1–

WARNING • When using an electrocardiograph or other physiological monitoring equipment simultaneously with this instrument on a patient, any monitoring electrodes should be placed as far away as possible from the electrodes used with the electrosurgical unit. Needle monitoring electrodes should not be used, as they may cause patient burns. Physiological monitoring equipment incorporating high-frequency current limiting devices is recommended. • Do not use this instrument for any purpose other than its intended use. • The electrosurgical unit should not be used adjacent to or stacked with other electrical equipment, except equipment that is intended for this purpose and tested by the manufacturer. • Electromagnetic interference may occur on this instrument near equipment marked with the following symbol or other portable memory and mobile RF (Radio Frequency) communications equipment such as cellular phones. If electromagnetic interference occurs, mitigation measures may be necessary, such as reorienting or relocating this equipment, or shielding the location.

6 Checking the Package Contents A cord (1 pcs) Instruction manual

7 Nomenclature and Functions 1) A cord jack 2) Model reference label 3) Cable 4) A cord plug

Nomenclature 1) A cord jack

Description The A cord jack connects to the plug on the electrosurgical accessory. A green reference label indicates that the instrument is autoclavable.

2) Model reference label

The Model reference label indicates the product number.

3) Cable

The Cable transmits high-frequency current from the electrosurgical unit to the electrosurgical accessory.

4) A cord plug

The A cord plug connects to the A cord plug connector of the electrosurgical unit.

8 Specifications WARNING Use this instrument only in combination with products recommended by Olympus. If combined with products not recommended by Olympus, patient or operator injury malfunction, or equipment damage may result.

–2–

CAUTION • Never use the instrument with an endoscope that is incompatible with high-frequency current. Using an incompatible endoscope may compromise patient or user safety, such as tissue burning or thermal injury, and may result in more severe equipment damage. • Do not use the instrument with activating output over the rated high-frequency voltage in Section 8.1, “Specifications”. This could cause patient, operator, or assistant injury, such as thermal injury. It could also damage the instrument, the endoscope, and electrosurgical accessories.

8.1

Specifications Plug diameter (mm)

ø8

Total length (m) Rated high-frequency voltage

2100 Vp (4200 Vp-p)

Coagulation

3500 Vp (7000 Vp-p)

Compatible OLYMPUS electrosurgical unit

UES-30, ESG-400

Compatible OLYMPUS electrosurgical accessory

CD-series, KD-600 series

EMC

8.2

2 Cut

Applied standards

IEC 60601-1-2: 2001 IEC 60601-2-2: 2006 IEC 60601-1-2: 2007 IEC 60601-2-2: 2009 IEC 60601-1-2: 2014 • This instrument complies with the EMC standard for medical electrical equipment, edition 2 (IEC 60601-1-2: 2001), edition 3 (IEC 60601-1-2: 2007), and edition 4 (IEC 60601-1-2: 2014). However, when connecting to an instrument that complies with the EMC standard for medical electrical equipment, edition 1 (IEC 60601-1-2: 1993), the whole system complies with edition 1. • CISPR 11 of emission: Group 1, Class B (UES-30, standby mode) Group 1, Class A (ESG-400, standby mode)

Ambient temperature

10 – 40C (50 – 104F)

Relative humidity

30 – 85%

Environment Operating environment

Atmospheric pressure 700 – 1060 hPa (0.7 – 1.1 kgf/cm2) (10.2 – 15.4 psia) Transportation and storage environment

Ambient temperature

–40 to +70C (–40 to +158F)

Relative humidity

10 – 95%

Atmospheric pressure 700 – 1060 hPa (0.7 – 1.1 kgf/cm2) (10.2 – 15.4 psia)

–3–

9 Operation WARNING • This instrument, when applied to a patient with a pacemaker implanted, may cause malfunctioning or failure of the pacemaker, seriously affecting the patient. Before proceeding, always confirm with a cardiologist or the manufacturer of the pacemaker that it is safe to proceed. • Before each case, prepare and inspect this instrument as instructed below. Inspect other equipment to be used with this instrument as instructed in their respective instruction manuals. Should any irregularity be observed, do not use the instrument; contact Olympus. Damage or irregularity may compromise patient or user safety, such as infection control risk, tissue irritation, punctures, hemorrhages, mucous membrane damage, tissue burning, or thermal injury burn to the patient, operator, or assistant, and may result in more severe equipment damage. • This instrument was not sterilized before shipment. Before using this instrument for the first time, reprocess it according to the instructions in Chapter 10, “Reprocessing”. Do not use an instrument that has not been cleaned and sterilized. This poses an infection control risk or can cause tissue irritation.

9.1

Preparation

Equipment and personal protective equipment Prepare all equipment and personal protective equipment that will be used with the instrument in accordance with their respective instruction manuals. Appropriate personal protective equipment may include eyewear, a face mask, moisture-resistant clothing, and chemical-resistant gloves.

Spare instrument Always have a spare instrument available.

Reprocessing equipment Prepare reprocessing equipment as described in Section 10.2, “Required reprocessing equipment” for immediate reprocessing after use.

9.2

Inspection Wear the personal protective equipment as specified in equipment needed in Chapter 10, “Reprocessing”. Before each case, always inspect the instrument according to the following procedures. If an irregularity in the instrument is detected, use a spare instrument inspecting it thoroughly before use.

Inspection of the sterile package Inspect the sterile package for tears, inadequate sealing, or water damage. If the sterile package shows any irregularities, the sterile condition of the instrument may have been compromised. Use a spare instead.

Appearance inspection Make sure that there are no scratches or cracks on the instrument.

Making and inspecting the connections CAUTION • Do not connect any equipment or inspect any connections when the electrosurgical unit is ON. This could cause operator or assistant injury, such as thermal injury. • Do not pull the cable to unplug the A cord plug or A cord jack. This could damage the instrument.

–4–

If any of following steps reveals irregularities, do not use the instrument; use a spare instead.

Connecting the instrument to electrosurgical accessories and inspecting the connection

1 Insert the A cord jack into the plug of electrosurgical accessories and confirm that it clicks into place.

2 Remove the A cord jack. Connecting the instrument to an electrosurgical unit and inspecting the connection

1 Insert the A cord plug into the electrosurgical unit’s A cord plug connector and confirm that it clicks into place.

2 Remove the A cord plug. 9.3

Operation The operator of the instrument must be a physician or medical personnel under the supervision of a physician and must have received sufficient training in clinical endoscopic technique. It only describes basic operation and precautions related to the operation of the instrument. WARNING • When using the instrument, always wear appropriate personal protective equipment. Otherwise, blood, mucous, and other potentially infectious material from the patient could pose an infection control risk. Appropriate personal protective equipment may include eyewear, a face mask, moisture-resistant clothing, and chemical-resistant gloves that fit properly and are long enough so that your skin is not exposed. • Do not loop the instrument or bundle it with cables from other medical equipment (electrocardiograph, endoscopic video system, electrosurgical unit, etc.). High-frequency signals and spark discharge noise during cauterization may cause malfunctions in the other medical equipment that could have an adverse effect on the patient. Another possibility is that output from the electrosurgical unit will be abnormal and patient injury, such as punctures, hemorrhages, or mucous membrane damage, could occur. CAUTION • Do not use the instrument with activating output over the rated supply voltage as specified in the tables in Section 8.1, “Specifications”. This could cause patient, operator, or assistant injury, such as thermal injury. It may also damage the endoscope, instrument, and electrosurgical accessories. • Do not connect any equipment when the electrosurgical unit is ON. Doing so may burn the operator or assistant. • Do not activate output if the instrument is wet. This could burn the patient, operator, or assistant. • Do not touch the instrument or allow it to touch anyone when output is activated. This can cause burns to the patient, operator, or assistant. • Do not pull the cable to unplug the A cord plug or A cord jack. This could damage the instrument.

–5–

If output cannot be activated when the instrument is combined with the electrosurgical unit, inspect the electrosurgical unit as described in its instruction manual.

1 Insert the A cord plug into the electrosurgical unit’s A cord plug connector until it clicks. 2 Plug the A cord jack into the plug of electrosurgical accessories until it clicks. 3 After connecting A cord plug and A cord jack to the electrosurgical accessories and electrosurgical unit respectively, turn the electrosurgical unit ON.

4 Switch the electrosurgical unit OFF. 5 Remove the A cord plug from the electrosurgical unit’s A cord plug connector. 6 Remove the A cord jack from the electrosurgical accessories.

10 Reprocessing WARNING This instrument was not sterilized before shipment. Before using this instrument for the first time, reprocess it according to the instructions in this chapter. Do not use an instrument that has not been cleaned and sterilized. This poses an infection control risk or can cause tissue irritation.

10.1 General policy • The medical literature reports incidents of patient cross-contamination resulting from improper cleaning or sterilization. It is strongly recommended that reprocessing personnel have a thorough understanding of and follow all national and local hospital guidelines and policies. A specific individual or individuals in the endoscopy unit should be responsible for reprocessing endoscopic equipment. It is highly desirable that a trained backup should be available when the primary reprocessing individual(s) be absent. • All individuals responsible for reprocessing should thoroughly understand: Your institution’s reprocessing procedures Occupational health and safety regulations National and local hospital guidelines and policies The instructions in this manual The mechanical aspects of endoscopic equipment Pertinent germicide labeling • Olympus EndoTherapy accessories are compatible with 2.0 – 3.2% glutaraldehyde solution. However, routine biological monitoring is not feasible with glutaraldehyde and, therefore, it should not be used to sterilize reusable medical devices that are compatible with other methods of sterilization that can be biologically monitored, such as steam sterilization. WARNING • Failure to properly clean and sterilize the instrument after each examination can compromise patient safety. To minimize the risk of transmitting diseases from one patient to another, after each examination the instrument must undergo thorough cleaning followed by sterilization. • If the instrument is not cleaned meticulously, effective sterilization cannot be obtained. Clean the instrument thoroughly before sterilization to remove microorganisms or organic material, which can limit the effectiveness of the sterilization process.

–6–

WARNING • Patient debris and reprocessing chemicals are hazardous. Wear personal protective equipment to guard against dangerous chemicals and infectious material. During cleaning and sterilization, always wear appropriate personal protective equipment, such as eyewear, a face mask, moisture-resistant clothing, and chemical-resistant gloves that fit properly and are long enough so that your skin is not exposed. Always remove contaminated protective clothing before leaving the reprocessing area. • The reprocessing procedures described in this manual should be completed on the same day the instrument has been used. If reprocessing is delayed, residual organic debris will solidify and it may be difficult to effectively reprocess the instrument.

10.2 Required reprocessing equipment Wear the protective equipment as specified in equipment needed in Chapter 10, “Reprocessing”.

1 Prepare the following equipment. The required amount of detergent solution and other equipment depends on the number of instruments to be reprocessed.

2 Fill an immersion basin with detergent solution at the temperatures and concentrations recommended by the manufacturers. Also, fill the ultrasonic cleaner with a detergent solution appropriate for ultrasonic cleaning.

Equipment needed for reprocessing To perform proper reprocessing, the equipment in the following table is required. For details on preparation and directions for use of the following equipment, refer to the respective instruction manuals or contact the equipment manufacturer. Contact Olympus for the names of specific brands of detergent solutions.

Equipment needed Protective equipment

Appropriate personal protective equipment may include eyewear, face mask, moisture-resistant clothing, and chemical-resistant gloves.

Immersion basin for detergent solution

Use a basin with a depth and diameter large enough to allow complete immersion of the instrument.

Detergent solution for immersion

Use a neutral pH, low-foaming, medical grade detergent solution.

Ultrasonic cleaner

Use a medical grade ultrasonic cleaner with a frequency range of 38 – 47 kHz.

Detergent solution for ultrasonic cleaning

Use a neutral pH, low-foaming, medical grade detergent solution with no abrasive.

Lint-free cloths

Use clean, dry, lint-free cloths.

Packages for steam sterilization

Use packages compatible with steam sterilization (autoclaving).

Sealing device for sterile package

Sealing the packages may require a device such as a heat sealer. Prepare an appropriate sealing device according to the packages to be used.

Autoclave

Use an autoclave that will operate at the conditions specified in Section 10.4, “Sterilization”.

–7–

10.3 Cleaning WARNING When cleaning, avoid exposure to the fluids discharged from reprocessing chemicals. They may pose an infection control risk or cause skin irritation.

Immersion WARNING Immerse the instrument in detergent solution immediately after use. If the instrument is not cleaned immediately, it may be difficult to effectively reprocess and this could result in reduced performance.

1 Immerse the entire instrument in the detergent solution for the time specified in manufacturer’s instructions. If no time is specified, immerse for between 5 minutes and 3 hours.

2 Remove the instrument from the detergent solution.

Ultrasonic cleaning 1 Immerse the entire instrument in the detergent solution. 2 Clean ultrasonically for 30 minutes. For details on operation of the ultrasonic cleaner, refer to the instruction manual for the ultrasonic cleaner.

3 Remove the instrument from the detergent solution.

Rinsing CAUTION • After ultrasonic cleaning, rinse the instrument thoroughly to remove residual detergent. Residual detergent solution could cause tissue irritation in the next patient. • Do not forcefully squeeze, wipe, or scrub the instrument. This could cause damage to the instrument or result in reduced performance.

1 Rinse the instrument under clean running tap water. 2 Confirm that no debris is left on the surfaces of the instrument. 3 Wipe the exterior of the instrument with a clean, dry lint-free cloth. 10.4 Sterilization

Sealing the package 1 Before sterilization, the instrument must be thoroughly cleaned and dried. Residual moisture inhibits sterilization.

2 Place the instrument in a package. 3 Seal the packages. For details on sealing, refer to the instruction manual for the package and the sealing device.

Steam sterilization (autoclaving) WARNING • Use biological indicators as recommended by your hospital’s policy and follow the manufacturer’s instructions, all national and local hospital guidelines and policies. • Always leave space between the packages in the autoclave. If the packages are placed too close together, effective sterilization will not be possible.

–8–

WARNING • Allow the packages to dry within the autoclave using the autoclave’s drying cycle (if applicable) or by opening the door of the autoclave and allowing the packages to air dry. Handling a wet package can compromise its sterility. • The results of sterilization depend on various factors such as how the sterilized instrument was packed or the positioning, method of placing and loading of the instrument in the sterilization device. Verify the sterilization effects by using biological or chemical indicators. Also, follow the guidelines for sterilization issued by medical administrative authorities, public organizations or the infection management sections at each medical facility, as well as the instruction manual for the sterilization device.

1 Place the sealed packages containing the instrument in the autoclave and sterilize in accordance with the conditions listed below. For details on operation of the autoclave, refer to the instruction manual for the autoclave or other manufacturer instructions.

2 After steam sterilization, let the instrument gradually cool down to room temperature. Sudden changes in temperature may damage the instrument. NOTE Autoclavable products have a green reference label. Products that do not have green reference labels are not autoclavable.

Prevacuum

Table 1

Temperature

Exposure time

132 – 134C (270 – 274F)

5 minutes

Recommended steam sterilization (autoclaving) conditions

11 Storage WARNING • Do not store the instrument in a sterile package that is damaged, wet, or improperly sealed. Otherwise, the sterility of the instrument may be compromised and pose an infection control risk or cause tissue irritation. • Do not store the sterile packages containing the instrument in a place where they will be damaged, wet, or improperly sealed. Otherwise, the sterility of the instrument may be compromised and pose an infection control risk or cause tissue irritation.

11.1 Inspection before storage Prior to storage, inspect the sterile packages as follows: Confirm that the sterile packages containing the instrument are free from tears, inadequate sealing, and water damage. If tears, inadequate sealing, or water damage are detected, repackage and sterilize again as described in Section 10.4, “Sterilization”.

11.2 Storage Store the instrument in sterile packages at room temperature in a clean and dry environment. Do not store them in direct sunlight. Ensure that the packages are not crushed by surrounding objects during storage. Follow any additional storage instructions provided by the manufacturer of the sterile package.

–9–

12 EMC information Guidance and manufacturer’s declaration - Electromagnetic emissions This instrument is intended for use by medical personnel in hospitals and for use in the electromagnetic environment specified below. The customer or the user of this instrument should assure that it is used in such an environment. Emissions test

Compliance

Electromagnetic environment - Guidance

RF emissions CISPR 11

Group 1

This instrument uses RF (Radio Frequency) energy only for its internal function. Therefore, its RF emissions are very low and are not likely to cause any interference in nearby electronic equipment.

Radiated emissions CISPR 11

Class A (ESG-400)

This instrument is suitable for use in all establishments other than domestic establishments and those directly connected to a low voltage power supply network that supplies buildings used for domestic purposes.

Class B (UES-30)

This instrument's RF emissions are very low and are not likely to cause any interference in nearby electronic equipment.

Main terminal conducted emissions CISPR 11

Not Apply

This instrument does not have AC power input.

Harmonic emissions IEC 61000-3-2

Same as above

Same as above

Voltage fluctuations/ flicker emissions IEC 61000-3-3

Same as above

Same as above

WARNING The use of accessories that are not approved by the manufacturer may result in an increase of electromagnetic emissions and the compliance with the stipulated limit values are not guaranteed anymore.

– 10 –

Guidance and manufacturer’s declaration - Electromagnetic immunity (IEC 60601-1-2: 2014) This instrument is intended for use by medical personnel in hospitals and for use in the electromagnetic environment specified below. The customer or the user of this instrument should assure that it is used in such an environment. WARNING Portable RF communications equipment (including peripherals such as antenna cables and external antennas) should be used no closer than 30 cm (12 inches) to any part of the video system center, including cables specified by Olympus. Otherwise, degradation of the performance of this equipment could result. Immunity test

IEC 60601 -1-2 (2014) Compliance Electromagnetic environment test level level - Guidance

Electrostatic discharge (ESD) IEC 61000-4-2

Contact: 8 kV Air: 2, 4, 8, 15 kV

Same as left

Floors should be made of wood, concrete, or ceramic tile that hardly produces static. If floors are covered with synthetic material that tends to produce static, the relative humidity should be at least 30%.

Electrical fast transient/burst IEC 61000-4-4

2 kV for power supply lines 1 kV for input/output lines

Not apply

This instrument does not have AC power input.

Surge IEC 61000-4-5

Differential mode: 0.5, 1 kV Common mode: 0.5, 1, 2 kV

Same as above

Same as above

Voltage dips, short interruptions, and voltage variations on power supply input lines IEC 61000-4-11

0% UT(100% dip in UT) for Same as 0.5 cycle/1 cycle above

Same as above

70% UT(30% dip in UT) for 25 cycle (50 Hz)/ 30 cycle (60 Hz) Phase angle causing voltage dips: 0° 0% UT(100% dip in UT) for 250 cycle (50 Hz)/ 300 cycle (60 Hz)

Power frequency (50/60 Hz) magnetic field IEC 61000-4-8

30 A/m (50 Hz or 60 Hz)

Definition

UT is the a.c. mains voltage prior to application of the test level.

Same as left

– 11 –

It is recommended to use this instrument by maintaining enough distance from any equipment that operates with high current.

Immunity test Conducted RF IEC 61000-4-6

IEC 60601 -1-2 (2014) Compliance Electromagnetic environment test level level - Guidance 3V (150 kHz - 80 MHz)

Same as left

Refer to the guidance in the left column.

6V (ISM band of 150 kHz - 80 MHz)

Same as left

Refer to the guidance in the left column.

ISM (industry, science, and medical care) band of 6.765 MHz - 6.795 MHz, 13.553 MHz - 13.567 MHz, 26.957 MHz - 27.283 MHz, and 40.66 MHz - 40.70 MHz between 0.15 MHz and 80 MHz Radiated RF IEC 61000-4-3

3 V/m (80 MHz - 2.7 GHz)

Same as left

Refer to the guidance in the left column.

Proximity magnetic field from RF communication equipment IEC 61000-4-3

Refer to the next table.

Same as left

Refer to the guidance in the left column.

Test frequency [MHz]

Band*1 [MHz]

Modulation*2

Maximum power [W]

Immunity test level [V/m]

385

380 - 390

Pulse modulation*2 18 Hz

1.8

27

450

430 - 470

FM*3 ±5 kHz deviation 1 kHz sine

2

28

704 - 787

Pulse modulation*2 217 Hz

0.2

9

800 - 960

Pulse modulation*2 18 Hz

2

28

1700 - 1990

Pulse modulation*2 217 Hz

2

28

2400 - 2570

Pulse modulation*2 217 Hz

2

28

5100 - 5800

Pulse modulation*2 217 Hz

0.2

9

710 745 780 810 870 930 1720 1845 1970 2450 5240 5500 5785

*1 For some services, only the uplink frequencies are included. *2 The carrier shall be modulated using a 50% duty cycle square wave signal. *3 As an alternative to FM modulation, 50% pulse modulation at 18 Hz may be used because while it does not represent actual modulation, it would be worst case.

– 12 –

Guidance and manufacturer’s declaration - Electromagnetic immunity (IEC 60601-1-2: 2007, 2001) This instrument is intended for use in the electromagnetic environment specified below. The customer or the user of this instrument should assure that it is used in such an environment. Portable and mobile RF communications equipment should be used no closer to any part of this instrument, including cables, than the recommended separation distance calculated from the equation applicable to the frequency of the transmitter.

Immunity test

IEC 60601 -1-2 (2007, 2001) test level

Electrostatic discharge (ESD) IEC 61000-4-2

Contact: 2, 4, 6 kV Air: 2, 4, 8 kV

Same as left

Floors should be made of wood, concrete, or ceramic tile that hardly produces static. If floors are covered with synthetic material that tends to produce static, the relative humidity should be at least 30%.

Electrical fast transient/burst IEC 61000-4-4

2 kV for power supply lines 1 kV for input/output lines

Not apply

This instrument does not have AC power input.

Surge IEC 61000-4-5

Differential mode: 0.5, 1 kV Common mode: 0.5, 1, 2 kV

Same as above

Same as above

Voltage dips, short interruptions, and voltage variations on power supply input lines IEC 61000-4-11

<5% UT (>95% dip in UT) for 0.5 cycle

Same as above

Same as above

Same as left

It is recommended to use this instrument by maintaining enough distance from any equipment that operates with high current.

Compliance Electromagnetic environment level - Guidance

40% UT (60% dip in UT) for 5 cycle 70% UT (30% dip in UT) for 25 cycle <5% UT (>95% dip in UT) for 5 seconds

Power frequency (50/60 Hz) magnetic field IEC 61000-4-8

3 A/m (50 Hz, 60 Hz)

Definition

UT is the a.c. mains voltage prior to application of the test level.

– 13 –

Immunity test

IEC 60601 (2007, 2001) test level

Conducted RF IEC 61000-4-6

3 Vrms (150 kHz – 80 MHz)

Radiated RF IEC 61000-4-3

3 V/m (80 MHz – 2.5 GHz)

Compliance level 3 V (V1)

Electromagnetic environment - Guidance Recommended separation distance

3.5 d = --------V1 3 V/m (E1)

Recommended separation distance

3.5 d = --------E1 7 d = ----E1

Definition

P

P P

80 MHz – 800 MHz

800 MHz – 2.5 GHz

Where “P” is the maximum output power rating of the transmitter in watts (W) according to the transmitter manufacturer and “d” is the recommended separation distance in meters (m).

NOTE • At 80 MHz and 800 MHz, the higher frequency range applies. • These guidelines may not apply in all situations. Electromagnetic propagation is affected by absorption and reflection from structures, objects and people. • Electromagnetic interference may occur in the vicinity of high-frequency electrosurgical equipment and/or other equipment marked with the following symbol:

• Field strength from fixed RF transmitters as determined by an electromagnetic site surveya) should be less than the compliance level in each frequency rangeb). a)

Field strength from fixed transmitters, such as base stations for radio (cellular/cordless) telephones and land mobile radios, amateur radio, AM and FM radio broadcast and TV broadcast cannot be predicted theoretically with accuracy. To assess the electromagnetic environment due to fixed RF transmitters, an electromagnetic site survey should be considered. If the measured field strength in the location in which this instrument is used exceeds the applicable RF compliance level above, this instrument should be observed, additional measures may be necessary, such as re-orienting or relocating this instrument.

b)

Over the frequency range 150 kHz to 80 MHz, field strength should be less than 3 V/m.

– 14 –

Recommended separation distances between portable and mobile RF communications equipment and this instrument (IEC 60601-1-2: 2007, 2001) This instrument is intended for use in an electromagnetic environment in which radiated RF disturbances are controlled. The customer or the user of this instrument can help prevent electromagnetic interference by maintaining a minimum distance between portable and mobile RF communications equipment (transmitters) and this instrument as recommended below, according to the maximum output power of the communications equipment. Rated maximum output power of transmitter P (W)

Others

Separation distance according to frequency of transmitter (m) (Calculated as V1=3 and E1=3) 150 kHz – 80 MHz

80 MHz – 800 MHz

800 MHz – 2.5 GHz

d = 1.2 P

d = 1.2 P

d = 2.3 P

0.01

0.12

0.12

0.23

0.1

0.38

0.38

0.73

1

1.2

1.2

2.3

10

3.8

3.8

7.3

100

12

12

23

For transmitters rated at a maximum output power not listed above, the recommended separation distance “d” in meters (m) can be estimated using the equation applicable to the frequency of the transmitter, where “p” is the maximum output power rating of the transmitter in watts (W) according to the transmitter manufacturer.

NOTE • At 80 MHz and 800 MHz, the separation distance for the higher frequency range applies. • These guidelines may not apply in all situations. Electromagnetic propagation is affected by absorption and reflection from structures, objects and people.

– 15 –

Manufactured by A8F, Ping An International Financial Center, No. 1-3, Xinyuan South Road, Chaoyang District, Beijing, 100027 P.R.C. Fax: (86)10-5976-1299 Telephone: (86)10-5819-9000

2951 Ishikawa-cho, Hachioji-shi, Tokyo 192-8507, Japan Fax: (042)646-2429 Telephone: (042)642-2111

Distributed by

Olympus Tower 9F, 446, Bongeunsa-ro, Gangnam-Gu, Seoul, Korea 135-509 Fax: (02)6255-3494 Telephone: (02)6255-3210

3500 Corporate Parkway, P.O. Box 610, Center Valley, PA 18034-0610, U.S.A. Fax: (484)896-7128 Telephone: (484)896-5000 5301 Blue Lagoon Drive, Suite 290 Miami, FL 33126-2097, U.S.A. Fax: (305)261-4421 Telephone: (305)266-2332

491B, River Valley Road #12-01/04, Valley Point Office Tower, Singapore 248373 Fax: 6834-2438 Telephone: 6834-0010 3 Acacia Place, Notting Hill, VIC 3168, Australia Fax: (03)9543-1350 Telephone: (03)9265-5400

KeyMed House, Stock Road, Southend-on-Sea, Essex SS2 5QH, United Kingdom Fax: (01702)465677 Telephone: (01702)616333

(Premises/Goods delivery) Wendenstrasse 14-18, 20097 Hamburg, Germany (Letters) Postfach 10 49 08, 20034 Hamburg, Germany Fax: (040)23773-4656 Telephone: (040)23773-0

117071, Moscow, Malaya Kaluzhskaya 19, bld. 1, fl.2, Russia Fax: (095)958-2277 Telephone: (095)958-2245

RK0037 05

©2016 OLYMPUS MEDICAL SYSTEMS CORP. All rights reserved. – 16 – Printed in Japan 20200327 *0000