Pilling

Model #528300P Lightsource Installation / Service / Operating Manual R02

Installation / Service / Operating Manual

16 Pages

Preview

Page 1

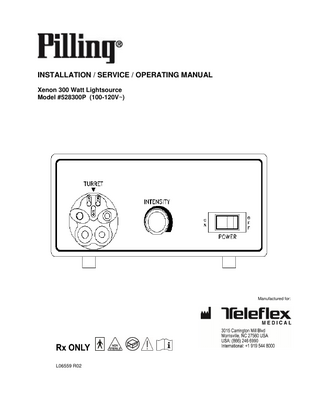

INSTALLATION / SERVICE / OPERATING MANUAL Xenon 300 Watt Lightsource Model #528300P (100-120V~)

Manufactured for:

L06559 R02

TABLE OF CONTENTS To ensure safety, this operating manual should be read and understood in its entirety before operating the 300 Watt Xenon Lightsource. It is essential to follow the instructions contained herein with particular attention given to the warnings and cautions. SPECIFICATIONS Product Classifications ... 1 Technical Specifications ... 2 Allowable Ambient Conditions ... 2 INSPECTION OF UNIT Receiving/Handling ... 3 System Inspection ... 3 SYMBOL EXPLANATION…...…………………………………………………………...4 WARNING / CAUTION . ... 5 EQUIPMENT LAYOUT / FUNCTIONALITY Front Panel ... 6 Back Panel ... 7 360o Rotary Turret Operation ... 8 GENERAL OPERATION Lightsource Operation ... 9 Cleaning ... 9 LAMP REPLACEMENT / SERVICE REPAIR Lamp Replacement ... 10 Troubleshooting ... 11 Replacement Parts/Service ... 11 WARRANTY/NOTATIONS. ... 12 WARNING DIAGRAMS . ... 13 WIRING SCHEMATIC ... 14

Page 1

Specifications PRODUCT CLASSIFICATION: The Xenon lightsource is classified as Medical Equipment, UL60601-1 Continuous Operation, Class I Equipment, Type BF. Not suitable for use near flammable anesthetic mixtures, Ordinary Equipment, without protection against ingress of water. The user must select a suitable fiberoptic connection device to assure proper and safe function. Headlamps must be certified to assure safe and compliant use. Endoscopic applications must include fiberoptic probes that are certified to IEC60601-2-18, which is required for endoscopic equipment. This equipment has been tested and found to comply with the limits for medical devices in IEC-601-1-2: 1994. These limits are designed to provide reasonable protection against harmful interference in a typical medical installation. This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to other devices in the vicinity. However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful interference to other devices, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the following measures:

Reorient or relocate the receiving device. Increase the separation between the equipment.

Connect the Equipment into an outlet on a circuit different from that to which the other device(s) are connected.

Consult the manufacturer or field service technician for help.

Page 2

Specifications TECHNICAL SPECIFICATIONS: Input Specifications Input Line Voltage: Power Consumption:

100-120 V~220-240V~ 50/60Hz 500 Watts Maximum

Physical Specifications: Weight: Dimensions:

14 lbs 5 in. high x 12 in. wide x 12 in. deep

Lightsource Specifications: Lamp Type: Average Lamp Life: Power Output: Illuminating Aperture: Dimming System: Electrical Power Cord/Plug: Leakage Current:

Xenon Ceramic Short Arc 500 Hours 300 Watts Up to 6.0mm Manual Shutter Hospital - Grade < 100 micro Amps (100-120v~) < 300 micro Amps (220-240~)

ALLOWABLE AMBIENT CONDITIONS: Operating Temperature: Storage Temperature: Humidity:

6o C to 40o C -40o C to 70o C 30 to 85% (Relative)

Page 3

Inspection of Unit RECEIVING / HANDLING: The Xenon lightsource is supplied in protective, non-sterile packaging. Avoid placing the unit in a dusty or dirty environment. Dirt entering the air intake may shorten the life of the unit. Inspect shipping container for evidence of shipping damage, preferably in the presence of the carrier. Noted damage should be reported to the carrier's agent. Remove all packaging material from around the unit and carefully inspect for damage.

SYSTEM INSPECTION: The lightsource must be inspected before each use according to the procedure below. Should any irregularity or abnormality be found, do not use the lightsource, contact Teleflex® Medical – AcuLux at (239) 734-3575. 1.

Visually inspect the electrical powercord, receptacle, intensity control, rotary turret to assure that there is no evidence of wear, damage or fraying.

2.

Be sure the fiberoptic cable connector being utilized is clean and dry before plugging it into the rotary indexing turret and select a position accepting your ACMI, Olympus, Pilling, Storz or Wolf type fiberoptic cable.

Page 4

Symbol Explanation Continuous Operation, Class 1 Equipment, Type BF

Attention: Consult instructions for use. Read instruction manual for warnings, precautions and instructions for use. Advises the user of a possibility of damage to the equipment may occur.

Symbol on power switch indicates power is ON when pressed. Alternate indication is a green LED switch light

Symbol on power switch indicates power is OFF when pressed.

Protective Earth Ground Symbol in electrical rating signified AC mains power

Advises the user of a hazard that could result in serious injury

Caution: Federal law restricts this device to sale by or on the order of a physician

Non Sterile Product

Do not use if package is damaged Consult instructions for use

Manufacturer

Page 5

Warning/Caution WARNING: - The lightsource must not be used in the presence of flammable anesthetics or solutions due to the danger of possible explosion. - One must not look directly at the lamp output. The light produces high intensity visible and ultraviolet radiation that may burn the skin or eyes. The lightsource must never be used in procedures requiring direct illumination of the eye, as permanent eye damage may result. - Grounding reliability is achieved only when connected to a "Hospital-Use" or "Hospital-Grade" receptacle. Inspect electrical plug and cord routinely. Do not use if damage is discovered. - Due to the internal voltage of the power supply, a hazard exists for electrical shock. Always disconnect the main power line before attempting any service or replacement of lamps. - Avoid bodily contact with the lamp and socket until they have sufficiently cooled. Portions of the lamp can reach very high temperatures, which could cause serious burns if touched while hot. - The end of the fiberoptic cable can cause burns. Do not place on protective drapes or the patient. - Xenon Lamps are under high pressure. Do not subject lamps to careless handling or high mechanical forces. Lamp fracture may occur resulting in possible personal injury. CAUTION: - Do not block any air vents or louver. Adequate cooling is required for proper operation of the unit. - Do not operate unit if fan is not operating properly. - Fiberoptic cables must be rinsed free of soaking/disinfectant solution and dried before plugging into the rotary indexing turret. - Use only liquid cables or fiberoptic cables constructed with high temperature epoxy.

Page 6

Equipment Layout FRONT PANEL:

1.

POWER ON/OFF CIRCUIT BREAKER SWITCH Turns Power On and Off and provides over current Protection.

2.

MANUAL INTENSITY CONTROL Provides Control of Lamp Intensity

3.

ROTARY TURRET Provides for proper connection of ACMI, Olympus, Pilling, Storz and Wolf type fiberoptic cables to the lightsource (Turret Operation – Page 8)

Page 7

Equipment Layout BACK PANEL:

1.

COOLING EXHAUST WITH FINGER GUARD

2.

CONTACT NAME AND ADDRESS

3.

INPUT POWER INFORMATION Specifies input power required. CAUTION: Always check model number for correct voltage before connection. Damage may occur due to application of incorrect voltage.

4.

MODEL AND SERIAL NUMBER LABEL Identifies specific lightsource. Use this number in all correspondence about this lightsource.

5.

LAMP HOUR INDICATOR Displays Elapsed Hours of Lamp Operation with 1/10 hour resolution.

6.

LAMP HOUR INDICATOR RESET SWITCH Resets Lamp Hour Indicator to 0.0 hours. Should only be used when lamp is installed or replaced.

7.

POWER INPUT RECEPTACLE: Provides connection of powercord to lightsource.

Page 8

Rotary Turret 360o ROTARY TURRET OPERATION: The Xenon lightsource is equipped with a rotary turret allowing the adaptation and use of a wide range of fiberoptic cables such as ACMI, Olympus, Pilling, Storz and Wolf. Color Coded tabs have been built into the turret allowing O.R. Personnel to adapt correct cable into appropriate Turret Ports as follows: Acmi (Blue) / Olympus (Yellow) / Pilling (Lt. Blue) / Storz (Green) / Wolf (Red) To select, simply rotate the turret in either direction until the desired adaptation port lines up with the indicator arrow on the front panel. The last step is to plug in your fiberoptic cable. Special built-in indexing assures proper alignment and maximum illumination.

Pilling Dual Cable Illumination

Pilling Single Cable Illumination

Page 9

General Operation LIGHTSOURCE OPERATION: 1. Verify that the lower air intakes and rear cooling exhaust louver are not blocked. 2. Connect to the proper power source using only "hospital grade" marked powercord and receptacle. CAUTION: The powercord should never be sharply bent, strained or crushed. 3. Insert a compatible, clean, dry, fiberoptic cable into the Selected Turret Port. 4. Rotate the Intensity Control Knob counterclockwise to the OFF Position. 5. Turn Power Switch ON 6. Adjust the intensity knob clockwise for the desired level of light output/illumination. 7. When procedure is completed, turn the intensity control knob counterclockwise to its lowest setting (OFF). 8. Switch the power switch to the O (OFF) position. CAUTION: Allow the lightsource to cool for five (5) minutes before disconnecting the fiberoptic cable.

CLEANING: 1.

Before attempting any maintenance or cleaning of the system, be sure that the system is disconnected from the power source and that the unit is cool.

2.

The lightsource housing must be kept free of dust and any accumulation of dirt around the air intakes and cooling exhaust louver.

3.

The exterior of the unit may be cleaned by wiping it with a dampened (not dripping) cloth and a mild detergent. Use of paper products is not recommended.

Page 10

Lamp Replacement LAMP REPLACEMENT: Teleflex® Medical recommends that you always have a Xenon Lamp/Cartridge in stock and should be replaced when the lamp reaches 500 hours of operation to insure the user maximum reliability. Operation of the lamp beyond 500 hours may result in lamp failure. It is recommended that the lamp be replaced before lightsource has 500 hours. Xenon Lamp Cartridge Replacement #528302P. WARNING: Lamps are under pressure and must be handled with care. Safety glasses or face shield should be worn. 1.

Power lightsource OFF. WARNING: Allow lightsource to cool for a minimum of 10 minutes, if unit has been running.

2.

Disconnect power cord from lightsource.

3.

Open lamp side cover door. WARNING: Allow old lamp cartridge to cool for a minimum of 10 minutes. Remove old lamp cartridge by pulling handle.

4.

Remove new lamp cartridge from packaging. CAUTION: Do not touch the bulb with bare hands. Finger marks can cause early deterioration of material leading to possible failure. If handled, clean with an alcohol swab.

5.

Place new lamp cartridge into lightsource with lamp lens facing front of unit. Hold handle and slide cartridge into lamp holder base.

6.

Press lamp in firmly with the heel of your hand.

7.

Close lamp side cover door. Reconnect power cord into lightsource. Turn on Power.

8.

With unit powered up, depress hour meter reset switch and release. Hour meter should read "0.0". Do not hold switch in for more than one (1) second.

Page 11

Service/Repair TROUBLESHOOTING: SYMPTOM

PROBABLE CAUSE

Fan not Running

Check Main Power Connection Lamp Access Door not properly shut

Lamp Does Not Ignite

Check Main Power Connection Lamp Access Door not properly shut Check Lamp Hour Meter to verify if lamp is near 500 hours Lamp Improperly Installed (Refer to Lamp Replacement Procedure – Page 10)

Unstable Light (Flickers)

Lamp Improperly Installed (Refer to Lamp Replacement Procedure – Page 10) Check Lamp Hour Meter to verify if lamp is near 500 hours

Lamp has Low Output

Check Lamp Hour Meter to verify if lamp is near 500 hours Check Intensity Control Knob for proper functioning Check Fiberoptic Cable for Broken Fibers/Transmission

All other repairs and maintenance not mentioned in this section should be referred directly to Teleflex® Medical – AcuLux (239) 734-3575. When requesting information concerning the systems, always furnish serial and model numbers identified on the back panel of the lightsource.

Replacement Parts Contact Teleflex® Medical for all replacement parts or other fiberoptic accessories at (866) 246-6990. 300 Watt Xenon Lamp/Cartridge... #528302P 300 Watt Xenon Lamp... #528303P

Page 12

Warranty/Notations WARRANTY: Teleflex® Medical warrants the Xenon lightsource when new, to be free of defects in material and workmanship and to perform in accordance with manufacturer’s specifications when subject to normal use and service for a period of three years from date of purchase from Teleflex Medical or an authorized agent. Teleflex® Medical will either repair or replace any components found to be defective or at variance from manufacturer’s specification within this time at no cost to the customer. It shall be the purchaser’s responsibility to return the product to the authorized distributor, agent, or service representative. This warranty does not cover the product of breakage or failure due to tampering, misuse, neglect, accidents, improper installation, modification, shipping, or to improper maintenance, service and cleaning procedures. This warranty is also void if the product is not used in accordance with manufacturer’s recommendations or if required service by other than Teleflex® Medical or an authorized agent. Purchase date determines warranty requirements. No other express or implied warranty is given. DISPOSAL: When life of this product or lamp has ended, dispose of it reliably and properly in a dedicated container and not with general waste. Teleflex Medical cannot advise lamp users as to general or specific disposal regulations for federal, state/provincial, and/or local municipalities. It is the responsibility of the waste generator to ensure proper classification and disposal of waste products. NOTATIONS: The information contained in this manual is subject to change without notice. Teleflex® Medical makes no warranty of any kind with regard to this material, including, but not limited to, the implied warranties or merchantability and fitness for a particular purpose. Teleflex® Medical shall not be liable for errors contained herein or for incidental consequential damages in connection with the furnishing, performance, or use of this material. ACMI, Olympus, Storz and Wolf are trade names for each respective company.