RUDOLF Medical GmbH

LAP Needle Holder , Light Model Instructions for Use

5 Pages

Preview

Page 1

INSTRUCTIONS FOR USE (EN) D0780 / Rev.B / DCR00787

LAP Needle holder; light model

LAP Needle holder, light model

Article number LP352-021

LP352-022

LP352-023

LP353-033

LP353-045

LP353-133

LP353-145

LP353-233

LP353-245

LP353-330

LP353-345

LP354-033

LP354-045

LP354-133

LP354-145

LP354-233

LP354-245

LP354-330

LP354-345 Intended Use A needle holder, also called needle driver, is a surgical instrument, similar to a hemostat, used by doctors and surgeons to hold a suturing needle for closing wounds during suturing and surgical procedures. The parts of a simple needle holder are the jaws, the joint and the handles. Most needle holders also have a clamp mechanism that locks the needle in place, allowing the user to maneuver the needle through various tissues. To maintain a firm grip on the needle, the jaws are often textured and short compared to the shank (increasing the applied force following the principle of a lever).

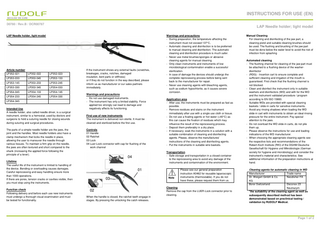

If the instrument shows any external faults (scratches, breakages, cracks, notches, damaged insulation, bent parts or stiffness) or if they do not function in the way described, please inform us as manufacturer or our sales partners immediately. Warnings and precautions - Do not use damaged instruments. - The instrument has only a limited stability. Force applied too strongly can lead to damage and negatively affects its functioning. First use of new instruments The instrument is delivered non-sterile. It must be cleaned and sterilized before the first use. Controls 01 Handle 02 Ratchet 03 Lock 04 Luer-Lock connector with cap for flushing of the work channel

Function check Following delivery and before each use new instruments must undergo a thorough visual examination and must be tested for functionality.

Application area - After use, the instruments must be prepared as fast as possible. - Remove residues and stains on the instrument immediately after use with a single use cloth or tissue. - Do not use a fixating agents or hot water (>40°C) as this can cause the fixation of residues which may influence the result of the reprocessing process. - Deposit them preferably in a dry place. - If necessary; soak the instruments in a solution with a suitable combination of cleaning and disinfecting agents. Please, observe the manufactures’ instructions of the cleaning and disinfecting agents. - Put the instruments in suitable wire baskets. Transportation - Safe storage and transportation in a closed container to the reprocessing area to avoid any damage of the instruments and contamination of the environment.

04

Lifetime The useful life of the instrument is limited to handling of the device. Bending or overloading causes damages. Careful reprocessing and easy handling ensure more than 1000 operations. If there are pores, tension cracks or cavities visible, then you must stop using the instruments.

Warnings and precautions - During preparation, the temperature affecting the instrument must not exceed 137°C, - Automatic cleaning and disinfection is to be preferred to manual cleaning and disinfection. The automatic cleaning and disinfection procedure is much safer. - Never use metal brushes/sponges or abrasive cleaning agents for manual cleaning. - Only clean instruments and instruments of low microbiological contamination enable a successful sterilization. - In case of damage the devices should undergo the complete reprocessing process before being sent back to the manufacturer for repair. - Never use cleaning agents with bleaching agents, such as sodium hypochlorite, as it causes severe corrosion.

01 03 02 When the handle is closed, the ratchet teeth engage in stages. By pressing the unlocking the catch releases.

Note

Please see our general preparation instruction A0462 for reusable laparoscopic instruments (thermostable). If you do not have these, please request them from us.

Cleaning Remove the cap from the LUER-Lock connector prior to cleaning.

Manual Cleaning For cleaning and disinfecting of the jaw part, a cleaning pistol and suitable cleaning brushes should be used. The flushing and brushing of the jaw part must be done below the water level to avoid the risk of infection from splashing Automated cleaning - The flushing channel for cleaning of the jaw part must be attached to a flushing device of the washerdisinfector - (RDG) - Insertion cart to ensure complete and sufficient cleaning and irrigation of the mouth is guaranteed. First check that the flushing channel is not blocked. - Clean and disinfect the instrument only in suitable washers and disinfectors (WD) and with for the WD and the instrument validated procedure / program according to EN ISO 15883. - Suitable WDs are provided with special cleaning baskets / slide-in carts for sensitive instruments. - Avoid any rinsing shadows when loading the WD slide-in cart with instruments to obtain an ideal rinsing pressure for the entire instrument. Pay special attention to the jaws. - Do not overload the WD slide-in carts, do not pile them up. - Please observe the instructions for use and loading indications of the WD manufacturer. - When choosing the appropriate cleaning agents see the respective lists and recommendations of the Robert-Koch Institute (RKI) of the DGHM Deutsche Gesellschaft für Hygiene und Mikrobiologie (German society for hygiene and microbiology) and consider the instrument’s material and characteristics. See additional information of the preparation instructions at hand. Cleaning agents for automatic cleaning in WD Manufacturer Trade name Dr. Weigert GmbH & Co. Neodisher FA KG Borer Switzerland Deconex 23 Neutrazym *the suitability of the cleaning agent as well as subsequently described method has been demonstrated based on preclinical testing / validation by RUDOLF Medical.

Page 1 of 2

INSTRUCTIONS FOR USE (EN) D0780 / Rev.B / DCR00787

A - Cleaning program (Miele G 7735) - 1 min. pre-cleaning with cold water - Draining - 3 min. pre-cleaning with cold water - Draining - 5 min cleaning at 55°C with 0,5 % alcaline detergent - or 5 min cleaning at 45°C with 0,5 % enzymatic detergent - Draining - 3 min. neutralization with warm water (>40°C) and neutralizer - Draining - 2 min. rinse with warm tap water (>40°C) - Draining Maintenance, Control and Inspection - After the cleaning and disinfection, the instruments must be inspected visually for cleanness. They must be macroscopically clean (no visible residues/soiling). Pay special attention to grooves, ratchets, closures and other difficult accessible areas. - Should there still be any visible residues or liquids repeat the cleaning and disinfecting procedure. - Prior to any sterilization the instruments must be assembled and inspected for function, wear and tear and for damages, and if necessary it has to be exchanged. After the inspection, dismantle the instrument if necessary for sterilization. Packaging - Appropriate packaging for sterilization according ISO 11607 and EN 868. - General adjust the sterilizing accessories and the sterile packing to the content of the packing instrument and the sterilization procedure. - Please, observe the manufactures’ instructions of the sterilizer. Sterilization - Sterilization is to be carried out using a steam sterilization procedure validated by DIN EN ISO 13060 / ISO 17665 (fractionated vacuum procedure) in a sterilizer in accordance with EN 285, DIN 58946. - 3 pre-vacuum phases with at least 60 mbar pressure - 134°C - 5 min or 132°C - 4min. - Drying time: minimum 10 min. - Please, observe the manufactures’ instructions of the sterilizer.

LAP Needle holder; light model - Redo the cap onto the LUER-Lock connector immediately after sterilization. Storage - The reprocessed instruments must be stored in suitable and reusable sterilization containers in accordance with DIN EN 868-1 and DIN EN 868-8 and should be stored until use in accordance with DIN 58953-9. - The sterilizing container should be designed in such a way that the instrument is safely fixed and protected from damage. - Storage of sterilized instruments in a dry, dark, low microbiologically contaminated clean and dust free environment at moderate temperatures of 5°C to 40°C. - The storage area should be free of temperature fluctuations. Additional Instructions - If the described chemistry and machines are not available, it is the duty of the user to validate his process.

Symbols and explanations Please read these instructions carefully before using the product for the first time. Always follow the instructions in this manual. Keep these instructions for use in a safe place. Batch code

Article number

Non sterile Indicates a possible danger to persons or property CE marking

Symbol for manufacturer - It is the duty of the user to ensure that the reprocessing processes including resources, materials and personnel are capable to reach the required results. State of the art and often national law requiring these processes and included resources to be validated and maintained properly. Likewise, any modification by the reprocessor from the instructions provided must be properly evaluated for effectiveness and potential adverse consequences. Repairs - Even when used as intended surgical instruments are subject to more or less severe wear, depending on how intensely they are used. This wear cannot be avoided due to technical reasons. - Please do not carry out any repairs yourself. Servicing and repairs may only be carried out by ourselves - the manufacturer - or by other persons we authorized. - Surgical instruments that are to be sent back for repair must be cleaned, disinfected and sterilized.

Caution! Failure to observe the warnings and precautions can lead to death or serious injuries.

RUDOLF Medical GmbH + Co. KG Zollerstr. 1, 78567 Fridingen, Germany Tel. +49 7463 9956-0 Fax +49 7463 9956-56 [email protected] www.rudolf-med.com

Page 2 of 2

WARNINGS AND PRECAUTIONS -

INSTRUCTIONS FOR USE (EN) LAPAROSCOPY NEEDLE HOLDER − DISMOUNTABLE

-

The flushing channel is intended only for the cleaning and reprocessing of the lumen of the handle. Handle the instrument with great care. Do not exert too much pressure on the instruments. Insert the instrument carefully into the trocar to avoid potential damage to the instrument.

PRIOR TO EACH USE: VISUAL AND FUNCTIONAL INSPECTION Check for: - External damage (e.g., deformed shaft, dents, burrs, cracks or sharp edges) - Correct functioning - Detergent or disinfectant residues - Free passage through the working channels

ASSEMBLY / DISASSEMBLY Operating elements

RUDOLF Medical GmbH + Co. KG Zollerstrasse 1, 78567 Fridingen an der Donau, Germany Tel. +49 7463 9956-0 Fax +49 7463 9956-56 [email protected] www.RUDOLF-med.com D1162 / Rev D / ACR00401 / 2022-12-14

PLEASE READ BEFORE REPROCESSING AND KEEP IT IN A SAFE PLACE The following instructions refer to the disassembly of the instrument after surgery and assembly after the cleaning and disinfection process. Detailed instructions for reprocessing can be found in the IFU D0462:

RUDOLF Medical instruments are delivered non-sterile and must be cleaned, disinfected, and sterilized before first use and immediately after each use. Protective caps and transport packaging must be removed beforehand. We recommend treating the mechanical parts of the instrument with a lubricant before sterilization.

D1162

(1) Handle (2) Ratchet (3) Lock (4) Luer-Lock connector with cap (5) Union nut

Page 1 of 3

For the reprocessing, the cap is removed from the Luer-Lock connector and is reattached after the sterilization, but only immediately before use.

ASSEMBLY

When the handle is closed the ratchet teeth gradually engages. When pressing the lock, the ratchet releases

Preparation before reprocessing For reprocessing, the instrument needs to be disassembled and the cap removed from the LuerLock of the flushing connection (4). The Luer-Lock flushing channel is intended only for the cleaning and reprocessing of the handle.

DISASSEMBLY 1. 2. 3. 4.

Remove the cap from the Luer-Lock flushing channel. Unscrew the union nut from the handle. Remove the insert including the tube from the handle adaptor groove. Remove the insert from the tube by rotating it counterclockwise.

1. Screw the insert (1) into the tube (2) clockwise and tighten the insert manually. 2. Position the insert with the jaws closed into the handle adaptor groove. Press the handle (3) slightly so that the insert is positioned against the handle groove. Note: The jaws must open upwards. For orientation, use the mark “TOP” at the working end.

Needle holder elements: (1) Instrument insert (2) Tube with union nut (3) Handle with cap for Luer-Lock flushing channel

D1162

Page 2 of 3

3. Tighten the union nut manually.

SYMBOLS

Note: Make a functional test by opening and closing the jaws using the handle and ratchet.

Consult instructions for use. Batch code Article no.

QTY

No. per package Non-sterile

4. Attach the cap to the Luer-Lock flushing channel.

Caution Manufacturer Date of manufacture CE marking according to Medical Device Regulation (EU) 2017/745 (MDR) Lubricate with silicon-free, biocompatible white medical oil approved for steam sterilization.

Medical Device

D1162

Page 3 of 3