SDI Limited

ultramat 2 INSTRUCTIONS FOR USE

INSTRUCTIONS FOR USE

1 Page

Preview

Page 1

ultramat 2 INSTRUCTIONS FOR USE Thank you for purchasing this dual voltage amalgamator, which has a high precision microprocessor controlled timer providing consistent and accurate trituration, ensuring the optimal handling and clinical characteristics of mixed materials.

E N G L I S H

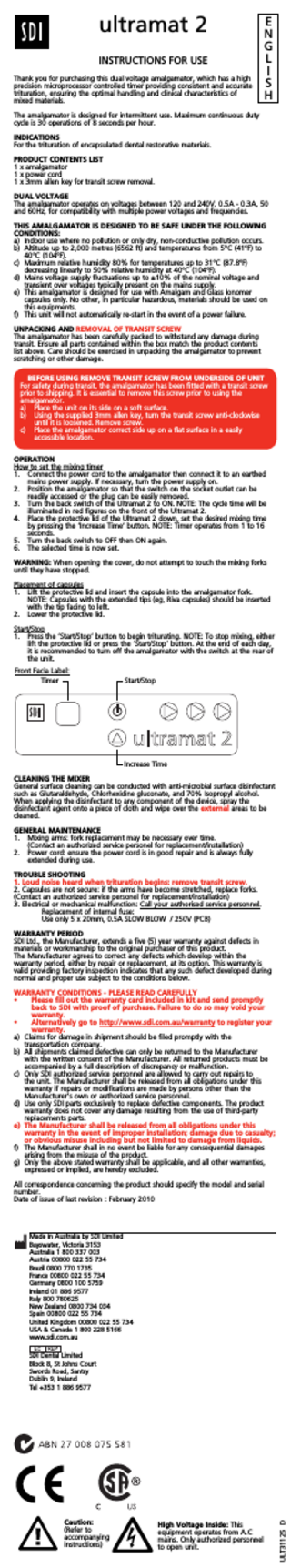

The amalgamator is designed for intermittent use. Maximum continuous duty cycle is 30 operations of 8 seconds per hour. INDICATIONS For the trituration of encapsulated dental restorative materials. PRODUCT CONTENTS LIST 1 x amalgamator 1 x power cord 1 x 3mm allen key for transit screw removal. DUAL VOLTAGE The amalgamator operates on voltages between 120 and 240V, 0.5A - 0.3A, 50 and 60Hz, for compatibility with multiple power voltages and frequencies. THIS AMALGAMATOR IS DESIGNED TO BE SAFE UNDER THE FOLLOWING CONDITIONS: a) Indoor use where no pollution or only dry, non-conductive pollution occurs. b) Altitude up to 2,000 metres (6562 ft) and temperatures from 5°C (41ºF) to 40°C (104ºF). c) Maximum relative humidity 80% for temperatures up to 31°C (87.8ºF) decreasing linearly to 50% relative humidity at 40°C (104ºF). d) Mains voltage supply fluctuations up to ±10% of the nominal voltage and transient over voltages typically present on the mains supply. e) This amalgamator is designed for use with Amalgam and Glass Ionomer capsules only. No other, in particular hazardous, materials should be used on this equipments. f) This unit will not automatically re-start in the event of a power failure. UNPACKING AND REMOVAL OF TRANSIT SCREW The amalgamator has been carefully packed to withstand any damage during transit. Ensure all parts contained within the box match the product contents list above. Care should be exercised in unpacking the amalgamator to prevent scratching or other damage. BEFORE USING REMOVE TRANSIT SCREW FROM UNDERSIDE OF UNIT For safety during transit, the amalgamator has been fitted with a transit screw prior to shipping. It is essential to remove this screw prior to using the amalgamator. a) Place the unit on its side on a soft surface. b) Using the supplied 3mm allen key, turn the transit screw anti-clockwise until it is loosened. Remove screw. c) Place the amalgamator correct side up on a flat surface in a easily accessible location. OPERATION How to set the mixing timer 1. Connect the power cord to the amalgamator then connect it to an earthed mains power supply. If necessary, turn the power supply on. 2. Position the amalgamator so that the switch on the socket outlet can be readily accessed or the plug can be easily removed. 3. Turn the back switch of the Ultramat 2 to ON. NOTE: The cycle time will be illuminated in red figures on the front of the Ultramat 2. 4. Place the protective lid of the Ultramat 2 down, set the desired mixing time by pressing the ‘Increase Time’ button. NOTE: Timer operates from 1 to 16 seconds. 5. Turn the back switch to OFF then ON again. 6. The selected time is now set. WARNING: When opening the cover, do not attempt to touch the mixing forks until they have stopped. Placement of capsules 1. Lift the protective lid and insert the capsule into the amalgamator fork. NOTE: Capsules with the extended tips (eg, Riva capsules) should be inserted with the tip facing to left. 2. Lower the protective lid. Start/Stop 1. Press the ‘Start/Stop’ button to begin triturating. NOTE: To stop mixing, either lift the protective lid or press the ‘Start/Stop’ button. At the end of each day, it is recommended to turn off the amalgamator with the switch at the rear of the unit. Front Facia Label: Timer

Start/Stop

Increase Time CLEANING THE MIXER General surface cleaning can be conducted with anti-microbial surface disinfectant such as Glutaraldehyde, Chlorhexidine gluconate, and 70% Isopropyl alcohol. When applying the disinfectant to any component of the device, spray the disinfectant agent onto a piece of cloth and wipe over the external areas to be cleaned. GENERAL MAINTENANCE 1. Mixing arms: fork replacement may be necessary over time. (Contact an authorized service personel for replacement/installation) 2. Power cord: ensure the power cord is in good repair and is always fully extended during use. TROUBLE SHOOTING 1. Loud noise heard when trituration begins: remove transit screw. 2. Capsules are not secure: if the arms have become stretched, replace forks. (Contact an authorized service personel for replacement/installation) 3. Electrical or mechanical malfunction: Call your authorised service personnel. Replacement of internal fuse: Use only 5 x 20mm, 0.5A SLOW BLOW / 250V (PCB) WARRANTY PERIOD SDI Ltd., the Manufacturer, extends a five (5) year warranty against defects in materials or workmanship to the original purchaser of this product. The Manufacturer agrees to correct any defects which develop within the warranty period, either by repair or replacement, at its option. This warranty is valid providing factory inspection indicates that any such defect developed during normal and proper use subject to the conditions below. WARRANTY CONDITIONS - PLEASE READ CAREFULLY • Please fill out the warranty card included in kit and send promptly back to SDI with proof of purchase. Failure to do so may void your warranty. • Alternatively go to http://www.sdi.com.au/warranty to register your warranty. a) Claims for damage in shipment should be filed promptly with the transportation company. b) All shipments claimed defective can only be returned to the Manufacturer with the written consent of the Manufacturer. All returned products must be accompanied by a full description of discrepancy or malfunction. c) Only SDI authorized service personnel are allowed to carry out repairs to the unit. The Manufacturer shall be released from all obligations under this warranty if repairs or modifications are made by persons other than the Manufacturer’s own or authorized service personnel. d) Use only SDI parts exclusively to replace defective components. The product warranty does not cover any damage resulting from the use of third-party replacements parts. e) The Manufacturer shall be released from all obligations under this warranty in the event of improper installation; damage due to casualty; or obvious misuse including but not limited to damage from liquids. f) The Manufacturer shall in no event be liable for any consequential damages arising from the misuse of the product. g) Only the above stated warranty shall be applicable, and all other warranties, expressed or implied, are hereby excluded. All correspondence concerning the product should specify the model and serial number. Date of issue of last revision : February 2010

Made in Australia by SDI Limited Bayswater, Victoria 3153 Australia 1 800 337 003 Austria 00800 022 55 734 Brazil 0800 770 1735 France 00800 022 55 734 Germany 0800 100 5759 Ireland 01 886 9577 Italy 800 780625 New Zealand 0800 734 034 Spain 00800 022 55 734 United Kingdom 00800 022 55 734 USA & Canada 1 800 228 5166 www.sdi.com.au

Caution: (Refer to accompanying instructions)

High Voltage Inside: This equipment operates from A.C mains. Only authorized personnel to open unit.

ULT31125 D

SDI Dental Limited Block 8, St Johns Court Swords Road, Santry Dublin 9, Ireland Tel +353 1 886 9577